Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

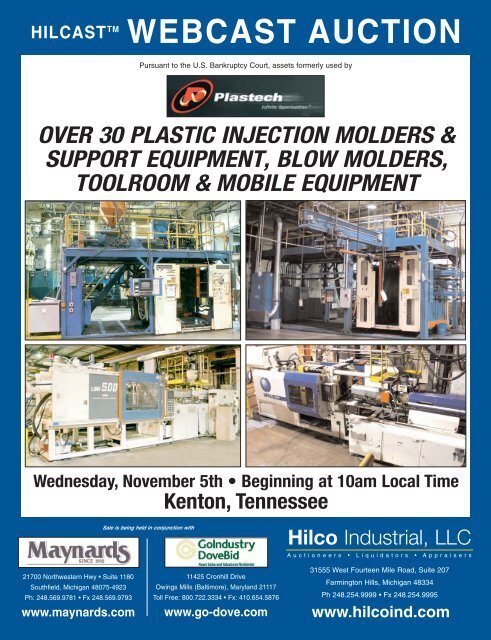

HILCAST TM<br />

WEBCAST AUCTION<br />

Pursuant to the U.S. Bankruptcy Court, assets formerly used by<br />

OVER 30 PLASTIC INJECTION MOLDERS &<br />

SUPPORT EQUIPMENT, BLOW MOLDERS,<br />

TOOLROOM & MOBILE EQUIPMENT<br />

Wednesday, November 5th • Beginning at 10am Local Time<br />

Kenton, Tennessee<br />

Sale is being held in conjunction with<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph: 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

11425 Cronhill Drive<br />

Owings Mills (Baltimore), Maryland 21117<br />

Toll Free: 800.722.3334 • Fx: 410.654.5876<br />

www.go-dove.com<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com

HILCAST TM WEBCAST AUCTION<br />

Pursuant to the U.S. Bankruptcy Court,<br />

assets formerly used by<br />

THIS EQUIPMENT IS LOCATED AT 515 POPLAR STREET • KENTON, TN 38233<br />

(22) PLASTIC INJECTION MOLDING MACHINES<br />

WEDNESDAY, NOVEMBER 5TH<br />

Beginning at 10am Local Time<br />

Auction Location<br />

515 Poplar St. • Kenton, TN 38233<br />

(All equipment will be sold from this location)<br />

2-Day Preview<br />

Monday & Tuesday, November 3rd & 4th<br />

9am to 4pm Local Time or Earlier By<br />

Appointment. Please contact Mark<br />

Reynolds at 205.595.5999 or Email<br />

mreynolds@hilcoind.com<br />

Preview Locations<br />

515 Poplar St. • Kenton, TN 38233<br />

396 State Hwy. • Winnsboro, SC<br />

539 N. Belevedere Rd • Gallatin, TN 37066<br />

Directions<br />

To Kenton, TN Location:<br />

From Nashville International Airport:<br />

Exit the airport and take the ramp to I-40 W. Keep right at the fork to continue<br />

toward I-40 W. Keep right at the fork to continue toward I-40 W and merge onto<br />

I-40 W. Go 134 miles and take exit 82B for US-45 N toward Milan. Turn right at N<br />

Highland Ave/TN-5/US-45. Continue to follow N Highland Ave/TN-5. Take the<br />

ramp onto TN-186/TN-5/US-45 Continue to follow TN-5. Continue on TN-366/US-<br />

45/US-45W. Go 3.4 miles and turn right at N Central Ave/TN-5/US-45W. Continue<br />

to follow TN-5/US-45W. Go 7.2 miles and make a slight right toward TN-5/TN-<br />

54/US-45/US-45W. Make another slight right at TN-5/TN-54/US-45/US-45W.<br />

Continue to follow TN-5/US-45W. Go 20.2 miles and turn right at Williams St.<br />

To Winnsboro, SC Location:<br />

From Charlotte Douglas International Airport:<br />

Head east on Airport Loop/Josh Birmingham Pkwy. Take the ramp onto Billy<br />

Graham Pkwy. Proceed 4 miles continue on W Woodlawn Rd (signs for Rock<br />

Hill). Slight right to merge onto I-77 S Entering South Carolina. Go 56 miles and<br />

take exit 41 toward Winnsboro/Rd 41. Turn right at Old River Rd. Make a slight<br />

left at SC-200. Turn left at 321/N Congress St. Continue to follow 321. Turn right<br />

at 9th St/Ninth St. Turn left at Hunstanton Dr. Turn left to stay on Hunstanton Dr.<br />

To Gallatin, TN Location:<br />

From Nashville International Airport:<br />

Proceed south on Terminal Drive to Donelson Pike. Turn left to take the Donelson<br />

Pike North ramp toward I–40. Merge onto Donelson Pike/TN–255 North. Merge<br />

onto I–40 W via the ramp on the left toward Knoxville. Proceed 1.4 miles on I–40<br />

to Briley Pkwy./TN–155 N. Merge onto Briley Pkwy./TN–155 N via Exit 215B and<br />

proceed 8.7 miles to I–65 N. Take the I–65 N exit, Exit 15 16, toward<br />

Louisvlle/Ellington Pky./Briarville Rd./US–31E S. Merge onto I–65 N via Exit 16A<br />

on the left toward Louisville. Proceed 5.5 miles on I–65 N. Keep right to take<br />

Vietnam Veterans Blvd./TN–386 N via Exit 95 toward Hendersonville/ Gallatin.<br />

Proceed 15 miles on Vietnam Veterans Blvd./TN–386 N. Vietnam Veterans<br />

Blvd./TN–386 N becomes Long Hollow Pike/ TN–174. Proceed .7 miles to<br />

Belvedere Dr N. Turn right onto Belvedere Dr N and proceed .1 mile to the preview<br />

site, 539 N Belvedere Dr., Gallatin, TN 37066.<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . . . . . . 800.435.9792<br />

Further Information<br />

• A buyer’s premium will be in effect. The auction will be<br />

conducted in English, accepting U.S. Currency only.<br />

• Removal Deadline is Friday, November 21st, 2008<br />

with Hours of Removal between 8am to 4pm Monday<br />

thru Friday. After November 21st at 4pm buyer will<br />

incur a cost of $500 daily for entry into the facility.<br />

• For further information please contact<br />

Mark Reynolds at 205.595.5999<br />

or Email mreynolds@hilcoind.com<br />

• For Payment & Customer Service please contact<br />

Sandi Neely at 248.254.9999 x16 or Email<br />

sneely@hilcoind.com<br />

VAN DORN DEMAG<br />

MODEL700H-RS-125F-LP<br />

700-TON X 125 OZ.<br />

PLASTIC INJECTION<br />

MOLDING MACHINE<br />

FARRELL 1000-TON<br />

PLASTIC INJECTION<br />

MOLDING MACHINE<br />

(1 OF 2) FARREL<br />

700-TON PLASTIC INJECTION<br />

MOLDING MACHINES<br />

THE FOLLOWING EQUIPMENT IS LOCATED AT 515 POPLAR STREET • KENTON, TN 38233<br />

(22) PLASTIC INJECTION MOLDING MACHINES<br />

1 – VAN DORN MODEL 1000H-RS-165LP 1000-TON X 165 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 143, Hydraulic<br />

Clamp, Platen Size 64” x 64”, Tie Bar Spacing 52” x 44”, Finley Tech Touch Screen Control (#5)<br />

1 – FARRELL 1000-TON PLASTIC INJECTION MOLDING MACHINE, S/N 80WH1323-2, Hydraulic Clamp, Platen Size 70” x 63”, Tie<br />

Bar Spacing 52” x 44”, Finley Tech Touch Screen Control (#4)<br />

1 – VAN DORN DEMAG MODEL 700H-RS-125F-LP 700-TON X 125 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 659 (1994),<br />

Hydraulic Clamp, Platen Size 62” x 53”, Tie Bar Spacing 45” x 36”, Path Finder Microprocessor Controls (#93)<br />

1 – VAN DORN DEMAG MODEL 700H-RS-125F-LP 700-TON X 125 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 660 (1994),<br />

Hydraulic Clamp, Platen Size 62” x 53”, Tie Bar Spacing 45” x 36”, Path Finder Microprocessor Controls (#11)<br />

1 – FARREL 700-TON PLASTIC INJECTION MOLDING MACHINE, S/N 80WH1322-2, Hydraulic Clamp, Platen Size 60” x 51”, Tie Bar<br />

Spacing 44” x 35”, Finley Tech Microprocessor Controls (#3)<br />

1 – FARREL 700-TON PLASTIC INJECTION MOLDING MACHINE, S/N 80WH1-322, Hydraulic Clamp, Platen Size 60” x 51”, Tie Bar<br />

Spacing 44” x 35”, Allen Bradley Panel View Plus 1000 Microprocessor Controls (#2)<br />

1 – UBE MODEL UM 500-T 500-TON PLASTIC INJECTION MOLDING MACHINE, S/N 83956 (1999), Toggle Clamp, Platen Size 46” x<br />

46”, Tie Bar Spacing 32” x 32”, Xycom Microprocessor Controls (#23)<br />

1 – UBE MODEL PZ 500 UST-SA 500-TON PLASTIC INJECTION MOLDING MACHINE, S/N 24699 (1992), Toggle Clamp, Platen Size<br />

46” x 46”, Tie Bar Spacing 32” x 32”, Humma UBE Injection Control System (#10)<br />

1 – UBE MODEL PZ 500 UST-SA 500-TON PLASTIC INJECTION MOLDING MACHINE, S/N 24698 (1992), Toggle Clamp, Platen Size<br />

46” x 46”, Tie Bar Spacing 32” x 32”, Humma UBE Injection Control System<br />

1 – VAN DORN DEMAG MODEL 500H-RS-60F 500-TON X 60 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 719 (1994),<br />

Hydraulic Clamp, Platen Size 47” x 47”, Tie Bar Spacing 32” x 32”, Path Finder Microprocessor Controls (#91)<br />

1 – VAN DORN DEMAG MODEL 500H-RS-60F 500-TON X 60 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 718 (1994),<br />

Hydraulic Clamp, Platen Size 47” x 47”, Tie Bar Spacing 32” x 32”, Microprocessor Controls (#90)<br />

1 – HPM MODEL H400-32, 400-TON X 32 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 94245 (1996), Hydraulic Clamp, Platen<br />

Size 43” x 43”, Tie Bar Spacing 30” x 30”, Command 9000 Microprocessor Controls (#12)<br />

1 – HPM MODEL H300-ED-32, 300-TON X 32 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 96345 (1996), Hydraulic Clamp,<br />

Platen Size 42” x 42”, Tie Bar Spacing 30” x 30”, CPI Microprocessor Controls (#13)<br />

1 – VAN DORN MODEL 300-RS-30F 300-TON X 30 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 1472, Toggle Clamp, Platen<br />

Size 36” x 40”, Tie Bar Spacing 24” x 24”, Relay Electrics (#6)<br />

1 – NIIGATA MODEL NN275H 275-TON PLASTIC INJECTION MOLDING MACHINE, S/N 35756H (2000), Toggle Clamp, Platen Size<br />

35” x 35”, Tie Bar Spacing 24” x 24”, Microprocessor Controls (#22)<br />

1 – CINCINNATI MILACRON MODEL VT-220-20, 220-TON X 20 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N T37A0193024,<br />

Toggle Clamp, Platen Size 30” x 30”, Tie Bar Spacing 21” x 19”, Camac VEL Microprocessor Controls (#24)<br />

1 – VAN DORN MODEL 200-RS-14F 200-TON X 14 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 2384, Toggle Clamp, Platen<br />

Size 30” x 32”, Tie Bar Spacing 21” x 18”, Relay Electrics (#10)<br />

1 – TOSHIBA MODEL ISG 90V21-2, 90-TON PLASTIC INJECTION MOLDING MACHINE, S/N 392201 (2003), Hydraulic Clamp, Platen<br />

Size 21” x 21”, Tie Bar Spacing 14” x 14”, Injectvisor V21 Microprocessor Controls, Techomagnete Electromatic Mold Chuck<br />

1 – VAN DORN HT SERIES MODEL 85-RS-5F-HT 85-TON X 5 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 493 (1993),<br />

Toggle Clamp, Platen Size 23” x 24”, Tie Bar Spacing 13” x 13”, CRT Path Finder Microprocessor Controls (#33)<br />

1 – VAN DORN HT SERIES MODEL 85-RS-5F-HT 85-TON X 5 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 210 (1990),<br />

Toggle Clamp, Platen Size 23” x 24”, Tie Bar Spacing 13” x 13”, CRT Path Finder Microprocessor Controls (#32)<br />

1 – VAN DORN HT SERIES MODEL 85-RS-5F-HT 85-TON X 5 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 209 (1990),<br />

Toggle Clamp, Platen Size 23” x 24”, Tie Bar Spacing 13” x 13”, CRT Path Finder Microprocessor Controls (#31)<br />

1 – VAN DORN HT SERIES MODEL 85-RS-5F-HT 85-TON X 5 OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 520 (1994),<br />

Toggle Clamp, Platen Size 23” x 24”, Tie Bar Spacing 13” x 13”, CRT Path Finder Microprocessor Controls (#30)<br />

Additional Plastic Injection Molders Available at the Winnsboro, SC Location (See Page 5)<br />

2<br />

For more information, visit us on the web @ www.hilcoind.com

THIS EQUIPMENT IS LOCATED AT 515 POPLAR STREET • KENTON, TN 38233<br />

PLASTIC INJECTION MOLDERS • ROBOTS • DRYERS • TEMP. CONTROLLERS<br />

VAN DORN DEMAG MODEL 500H-RS-60F 500-TON X 60 OZ.<br />

PLASTIC INJECTION MOLDING MACHINE<br />

HPM MODEL H400-32, 400-TON X 32 OZ.<br />

PLASTIC INJECTION MOLDING MACHINE<br />

STAR AUTOMATION<br />

TW-1500 FM-3, 3-AXIS<br />

CNC SERVO ROBOTS<br />

UBE MODEL UM 500-T 500-TON<br />

PLASTIC INJECTION MOLDING MACHINE<br />

CINCINNATI MILACRON VT-220-20, 220-TON X<br />

20 OZ. PLASTIC INJECTION MOLDING MACHINE<br />

VAN DORN HT SERIES 85-RS-5F-HT 85-TON X<br />

5 OZ. PLASTIC INJECTION MOLDING MACHINE<br />

CONAIR & UNA-DYN CENTRAL<br />

DEHUMIDIFYING DRYERS<br />

STAND MOUNTED SURGE BINS<br />

VIEW OF CONAIR MICROPROCESSOR CONTROLLED<br />

TEMPERATURE CONTROLLERS<br />

MATERIAL DRYERS<br />

1 – CONAIR CENTRAL DEHUMIDIFYING DRYER, MODEL & S/N NA, With Drying Hopper<br />

1 – UNA-DYN MODEL DHD-11 CENTRAL DEHUMIDIFYING DRYER, S/N DHD-1181158,<br />

With Drying Hopper<br />

1 – CONAIR MODEL CS100 DEHUMIDIFYING CAROUSEL DRYER, S/N 123922,<br />

Microprocessor Controls, With Model CH24-15 Hopper, S/N 109749, and Dust Beater<br />

Vacuum Loader<br />

1 – CONAIR MODEL CS100 DEHUMIDIFYING CAROUSEL DRYER, S/N 130057,<br />

Microprocessor Controls, With Model CH24-15 Hopper, S/N 123852, and Dust Beater<br />

Vacuum Loader<br />

1 – ZURN MODEL R-140A REFRIGERATED COMPRESSED AIR DRYER, S/N R-19823,<br />

700 SCFM Capacity<br />

BULK MATERIAL STORAGE EQUIPMENT<br />

2 – KIRK & BLUM STAINLESS STEEL BULK STORAGE SILOS, 12' Diameter x<br />

Approximately 30' High, Cone Bottom, Stand Mounted (Metal Could Possibly be<br />

Aluminum)<br />

1 – PEABODY TEC TANK SILO, S/N 90614, Nominal Capacity 5060 cu.ft., 12'D x 53'H,<br />

Polystyrene Beds, Compacted Density 45 PCF, Funnel Flow Loads<br />

5 – STAND MOUNTED SURGE BINS, Size 54” x 54” x Approximately 10' High, With Vacuum<br />

Receivers<br />

VACUUM DELIVERY EQUIPMENT<br />

1 – CONAIR 10-HP CENTRAL VACUUM PUMP DELIVERY SYSTEM, MODEL & S/N NA,<br />

With Filter (#3)<br />

1 – CONAIR MODEL PD10, 10-HP CENTRAL VACUUM PUMP DELIVERY SYSTEM,<br />

S/N 54265, With Filter<br />

1 – CONAIR MODEL 70002408, 20-HP CENTRAL VACUUM PUMP DELIVERY SYSTEM,<br />

S/N 1B1951, With Filter<br />

1 – CONAIR MODEL 10032706, 25-HP CENTRAL VACUUM PUMP DELIVERY SYSTEM,<br />

S/N 0-1444, With Filter<br />

1 – CONAIR FRANKLIN CENTRAL VACUUM DELIVERY PUMP SYSTEM, MODEL &<br />

S/N NA, 7-1/2-HP, With Canister Filter<br />

(55) TEMPERATURE CONTROLLERS<br />

22 – CONAIR THERMOLATER MODEL TW-1 MICROPROCESSOR CONTROLLED TEMPERATURE<br />

CONTROLLERS, S/Ns 176024, 176023, 175772, 175773, 175767, 145706, 176027, 176020, 175771, 176028,<br />

155052, 176019, 145705, 176025, 176026, 176022, 175774, 175770, 202870, 175766, 202877, 175769<br />

13 – CONAIR THERMOLATER MODEL MX1-DI MICROPROCESSOR TEMPERATURE CONTROLLERS,<br />

S/Ns 56623, 64329, 56616, 63230, 56618, 56621, 83888, 63231, 56622, 64327, 63229, 83889, 63228<br />

10 – CONAIR TEMPRO THERMOLATOR MODEL TC1-DI TEMPERATURE CONTROLLERS, S/Ns 91J060,<br />

96K087, 91J067, 96J129, XX026, NA, 96K089, 96K088, 93A106, 91J061<br />

10 – CONAIR & STERLCO TEMPERATURE CONTROLLERS, MODELS & S/Ns NA<br />

ROBOTS<br />

2 – WITTMANN 3-AXIS CNC SERVO ROBOTS, MODEL & S/N NA, Hand-Held Pendant Control (#23, # NA)<br />

2 – STAR AUTOMATION MODEL TW-1500 FM-3, 3-AXIS CNC SERVO ROBOTS, S/Ns NA, STEC-411<br />

Console Control (#18 & 1-Spare)<br />

5 – STAR AUTOMATION MODEL TW-1800 FM-3, 3-AXIS CNC SERVO ROBOTS, S/N NA, STEC-411 CNC<br />

Console Control (#19, #4 & 3-Spares)<br />

1 – STAR AUTOMATION MODEL TW-1700BM 3-AXIS CNC SERVO ROBOT, S/N NA, STEC-400M CNC<br />

Console Control (#6)<br />

BLENDERS/HOPPERS<br />

2 – CONAIR 2 COMPARTMENT AUTO WEIGH BLENDERS, MODEL & S/N NA, (#23 & Toshiba #NA)<br />

2 – CONAIR MODEL WSH-MB 4 COMPARTMENT BLENDERS, S/N NA, With WSB Series Weigh Scale<br />

Blender Control (#24 & #22)<br />

5 – CONAIR AUTO WEIGH GRAVIMETRIC BLENDERS, MODEL & S/N NA (#4, #10, #11, #12, #3)<br />

5 – CONAIR AUTO WEIGH MODEL GB22X MATERIAL WEIGH SCALE HOPPERS/BLENDERS,<br />

S/Ns 74994, 53741, 53740, MM-96908, 53739, (2) Vacuum Receivers, GB Series Gravimetric Batch<br />

Blender Control<br />

1 – CONAIR AUTO WEIGH MODEL GB200-22X MATERIAL WEIGH SCALE HOPPER/BLENDER,<br />

S/N MM-103831, (2) Vacuum Receivers, GB Series Gravimetric Batch Blender Control<br />

1 – CONAIR MODEL GB131 MATERIAL BLENDER, S/N 18315, WSB Weigh Scale Blender Control<br />

1 – CONAIR WEIGH SCALE BLENDER, MODEL & S/N NA<br />

2 – CONAIR MODEL WSB-MB MICRO BLENDERS, S/N MM106031, 93634 -Not Complete<br />

To schedule an auction, please contact us at 248.254.9999 3

THIS EQUIPMENT IS LOCATED AT 515 POPLAR STREET • KENTON, TN 38233<br />

CONVEYORS • GRANULATORS • FORKLIFTS • AIR COMPRESSORS<br />

VIEW OF PORTABLE BELT CONVEYORS<br />

VIEW OF AEC NELMOR MARATHON<br />

MV1016 GRANULATORS<br />

JLG MODEL 35 ELECTRIC ARTICULATED BOOM<br />

ELECTRIC MANLIFT<br />

VIEW OF NISSAN, TOYOTA & CATERPILLAR FORKLIFTS TO 9,000-LBS.<br />

JOHN DEERE MODEL 650 DIESEL<br />

UTILITY TRACTOR<br />

QUINCY OMANACA31C ROTARY<br />

SCREW AIR COMPRESSOR<br />

BELT CONVEYORS<br />

1 – LAROS MODEL E-510-30-96, 30” X 96” PORTABLE<br />

POWER BELT CONVEYOR, S/N E5102628-035383<br />

1 – EMI MODEL RM-36-13-20, 36” X 13' PORTABLE POWER<br />

BELT CONVEYOR, S/N M-135XX<br />

2 – EMI MODEL RM-36-12-20, 36” X 12' PORTABLE POWER<br />

BELT CONVEYORS, S/Ns 13561, M-13560<br />

1 – EMI MODEL RM-36-16-20, 36” X 16' PORTABLE POWER<br />

BELT CONVEYOR, S/N M-13562<br />

1 – IMS MODEL 131485, 30” X 8' PORTABLE POWER BELT<br />

CONVEYOR<br />

2 – LAROS MODEL A-525-24-54-42-A 24” X 54” PORTABLE<br />

INCLINED POWER BELT CONVEYORS, S/Ns A5251764-<br />

076086, A5251761-076086<br />

7 – LAROS MODEL E-510-36-96, 36” X 96” PORTABLE<br />

POWER BELT CONVEYORS, Variable speed,<br />

S/Ns E5103375-075982, E5102620-03583, E102264-03583,<br />

E102261-035383, E5102626-035383, E5102623-035383,<br />

E5102625-035383<br />

GRANULATORS<br />

1 – GRANUTEC MODEL TFG2030-100, 100-HP GRANULATOR,<br />

S/N 1296-2934, 20” x 30” Opening, 5-HP Discharge Blower,<br />

With Receiver Cyclone<br />

2 – MPG MODEL GP-1220HB PLASTIC GRANULATORS,<br />

S/Ns F-702 (1999), F-719, 20-HP, Opening Size 12” x 20”,<br />

Rear Feed Chute<br />

1 – CONAIR MODEL 72000601 PLASTIC GRANULATOR,<br />

S/N 0-0033, 20-HP, 18” x 14” Opening<br />

1 – BALL & JEWELL MODEL BP27 PLASTICS GRANULATOR,<br />

S/N 99B02483, 15” x 15” Opening<br />

1 – RAPID MODEL 1224-K GRANULATOR, S/N 60 1823,<br />

12” x 24” Opening, 25-HP, Sound Enclosure Panels<br />

1 – POLYMER SYSTEMS 15-HP GRANULATOR, S/N 1116SIL-<br />

2755-90, 16” x 12” Opening, Insulated Sound Enclosure<br />

1 – AEC NELMOR MODEL G1215P1 GRANULATOR,<br />

S/N 98-01905 (1998), 12” x 15” Opening, 10-HP<br />

11 – AEC NELMOR MARATHON MV1016 GRANULATORS,<br />

S/Ns 00B03641 (2000), 00H04099 (2000), 99L3111 (1999),<br />

00803642 (2000), NA (#G3), 99L03396 (1999), 99L03394<br />

(1999), NA (#G2), 99L03395 (1999), 99L03413 (1999),<br />

00B06340 (2000), 10” x 16” Opening, 15-HP<br />

1 – BALL & JEWELL MODEL CG 1620-SCS GRANULATOR,<br />

S/N 33449, 16” x 20” Opening (Missing Motor)<br />

PROCESS COOLING WATER SYSTEM<br />

1 – PROCESS COOLING WATER SYSTEM, With (2) Indoor<br />

Holding & Recirculation Tanks, (2) Thermal Care Outdoor<br />

Stand Mounted Cooling Towers, (1) Marley Outdoor Stand<br />

Mounted Cooling Tower<br />

MANLIFT<br />

1 – JLG MODEL 35 ELECTRIC ARTICULATED BOOM ELEC-<br />

TRIC MANLIFT, S/N 047406-0300030880 (1997), 35'<br />

Maximum Platform Height, 20.5' Maximum Horizontal Reach,<br />

500-LB. Capacity, Solid Tires<br />

FORKLIFTS<br />

1 – NISSAN MODEL YGF03A40TV 9,000-LB. CAPACITY<br />

FORKLIFT, S/N YGF03-001568, Diesel, Dual<br />

Pneumatic Front Tires, 146” Lift, 2-Stage Mast, 42”<br />

Forks<br />

4 – TOYOTA MODEL 42-5FG15, 2750-LB. CAPACITY<br />

FORKLIFTS, S/Ns 405FGU18-75371, NA, 405FG018-<br />

76392, 405FGU18-76403, LPG, Solid Tires, 3-Stage<br />

Mast (Not In Service)<br />

1 – DREXEL SWING MAST SIT-DOWN RIDER TYPE<br />

ELECTRIC FORKLIFT, MODEL & S/N NA, 3-Stage Mast<br />

1 – AUTOMATIC 2200 FORKLIFT BATTERY CHARGER,<br />

S/N NA, 36 Volt<br />

3 – CATERPILLAR MODEL GP18, 3500-LB. CAPACITY<br />

FORKLIFT, S/Ns 3AM02114, 3AM02112 (Not In<br />

Service), 3AM02210 (Not In Service), LPG, Solid Tires,<br />

190” Lift, 3-Stage Mast, Side Shift, 42” Forks<br />

OUTDOOR MAINTENANCE EQUIPMENT<br />

1 – JOHN DEERE MODEL 650 DIESEL UTILITY<br />

TRACTOR, S/N NA, 2 WD, Turf Tires, 3 Pt. Hitch, With<br />

Howse Implement Co. 48” Brush Hog Mower<br />

Attachment<br />

1 – CRAFTSMAN MODEL LT2000 42” RIDING LAWN<br />

MOWER, S/N NA<br />

1 – WEED EATER 22” 5-HP WALK-BEHIND LAWN<br />

MOWER, S/N NA<br />

1 – PARKER GAS POWERED WALK-BEHIND VACUUM, S/N NA<br />

AIR COMPRESSORS & ACCESSORIES<br />

1 – SULLAIR MODEL LS-16 75L, 75-HP ROTARY<br />

SCREW AIR COMPRESSOR, S/N 003-104392 (1996),<br />

Open Skid Base<br />

1 – QUINCY MODEL OMANACA31C ROTARY SCREW<br />

AIR COMPRESSOR, S/N 72889, Approximately 100-HP<br />

1 – GARDNER DENVER MODEL EOHOJD ROTARY<br />

SCREW AIR COMPRESSOR, S/N M06541 (Not In<br />

Service)<br />

1 – ZEKS NC SERIES MODEL 800NCDA400 REFRIGERATED<br />

COMPRESSED AIR DRYER, S/N 130249-1-M398<br />

1 – VERTICAL AIR RECEIVER TANK 36” X 84”<br />

1 – LEROI MODEL W40SSA 40-HP ROTARY SCREW AIR<br />

COMPRESSOR, S/N 4166X2130, Open Skid Base<br />

LAYOUT MACHINE<br />

1 – SHEFFIELD MODEL 16E HORIZONTAL ARM LAY-<br />

OUT MACHINE, S/N 16790, 100” X 70” Steel Grid<br />

Table, 72” Maximum Height Under Arm, Sheffield Model<br />

MP30 4-Axis Measurement Processor, Programmable<br />

Control<br />

FLOOR SCRUBBER<br />

1 – TENNANT MODEL 480 BATTERY POWERED WALK-<br />

BEHIND FLOOR SCRUBBER, S/N NA, With Charger<br />

CHEVROLET SILVERADO 1500 EXTENDED CAB<br />

PICK UP TRUCK<br />

MAINTENANCE SHOP EQUIPMENT<br />

1 – POWERMATIC MODEL 143, 14” VERTICAL BANDSAW,<br />

S/N 5-1842-3<br />

1 – DAYTON MODEL 3Z989, 9” X 16” HORIZONTAL BANDSAW,<br />

S/N 97202<br />

1 – PARMA WORK-A-MATIC VERTICAL BANDSAW, S/N 109281<br />

1 – ROCKWELL MODEL 20, 20” VERTICAL BANDSAW,<br />

S/N 1799918, Series 28-3X0<br />

1 – SOUTH BEND MODEL A 9” X 24” BENCH LATHE,<br />

S/N 12512NAR8, Threading<br />

1 – SUMMIT MODEL 11” X 32” ENGINE LATHE, S/N 554, 84 – 1400<br />

RPM, Threading<br />

SHOP & FACTORY SUPPORT EQUIPMENT<br />

1 – GAFFY 30-TON BRIDGE CRANE<br />

1 – UNITED SILICONE UNI-PRINTER MODEL UP-450 PAD<br />

PRINTER, S/N N PCB-0300-298<br />

1 – GENERAL HYDRAULICS MODEL 315-60R-16 VERTICAL<br />

HYDRAULIC BALER, S/N 6927, 60” x 30” Chamber, Top Mounted<br />

Hydraulics<br />

1 – GRIEVE-HENDRY 2-DOOR ELECTRIC OVEN, S/N NA, 36” X 20”<br />

X 24”<br />

1 – GATES POWER CRIMP 3000 B HYDRAULIC HOSE CRIMPING<br />

PRESS<br />

1 – GREENLEE 882 SERIES HYDRAULIC BENDER, 1-1/4”, 1-1/2”, &<br />

2” Conduit<br />

1 – LANDA MODEL VFP3-70021D HOT WATER PRESSURE<br />

WASHER, S/N P0302-14616, 700 PSI, 2.3 GPM, LPG Burner<br />

1 – BARON MODEL BA-LV-300P OIL FILTRATION SYSTEM,<br />

S/N 89011217, With Holding Tanks, Pumps, etc.<br />

Miscellaneous Maintenance Shop Equipment<br />

VEHICLES<br />

1 – CHEVROLET SILVERADO 1500 EXTENDED CAB PICK UP<br />

TRUCK, VIN: 2GCEC19R9V1211682, Vortec V-8, 2WD, Short Box<br />

(154,000 Miles)<br />

1 – FORD TAURUS SE 4-DOOR SEDAN<br />

1 – SATURN 4-DOOR SEDAN, VIN: 1G8ZK5274TZ1360<br />

4 For more information, visit us on the web @ www.hilcoind.com

THIS EQUIPMENT IS LOCATED AT 396 STATE HIGHWAY • WINNSBORO, SC<br />

PLASTIC INJECTION MOLDERS • VERTICAL CLAMP MOLDERS • ROBOTS<br />

VAN DORN DEMAG 2000 HP-RS-260 FLP 2000-TON X 260 OZ.<br />

PLASTIC INJECTION MOLDING MACHINE<br />

HPM 1500-TON PLASTIC INJECTION MOLDING MACHINE<br />

YUSHIN ABSOLINER VA-2500S<br />

3-AXIS PARTS ROBOT<br />

ENGEL ES600/150, 150-TON<br />

VERTICAL CLAMP PLASTIC<br />

INJECTION MOLDING MACHINE<br />

NEWBURY V9-150-ARS 150-TON<br />

VERTICAL CLAMP PLASTIC<br />

INJECTION MOLDING MACHINE<br />

(1 OF 2) BLUE GIANT MODEL TT1002<br />

SIT-DOWN RIDER TYPE<br />

ELECTRIC TOW TRACTORS<br />

HARRIS/SELCO MODEL V5-HD<br />

VERTICAL HYDRAULIC BALER<br />

THE FOLLOWING EQUIPMENT IS LOCATED AT<br />

396 STATE HIGHWAY • WINNSBORO, SC<br />

PLASTIC INJECTION MOLDING MACHINES<br />

1 – VAN DORN DEMAG MODEL 2000 HP-RS-260 FLP 2000-TON X 260 OZ. PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 0124 (1994), Hydraulic Clamp, Platen Size 96” x 66”, Tie Bar Spacing 72”<br />

x 52”, Quick Mold Change Over System, Siemens Simatic S5, PLC, With Van Dorn Pathfinder<br />

Microprocessor Control (W11M-06)<br />

1 – HPM 1500-TON PLASTIC INJECTION MOLDING MACHINE, S/N 89663, Hydraulic Clamp, Platen<br />

Size 96”H x 60”V, Tie Bar Spacing 72”H x 52”V, Quick Mold Change Over System, HPM Command<br />

90 Microprocessor Control, 60” Maximum Clamp Stroke, 20” Minimum Shut Height, 15.38” Injection<br />

Stroke, 3” Screw Diameter (W11M-07)<br />

1 – HPM 1500-TON PLASTIC INJECTION MOLDING MACHINE, S/N 89388, Hydraulic Clamp, Platen<br />

Size 96”H x 60”V, Tie Bar Spacing 72”H x 52”V, Quick Mold Change Over System, 60” Maximum<br />

Clamp Stroke, 20” Minimum Shut Height, Command 90 Microprocessor Control (W11M-03)<br />

1 – REED 1200-TON PLASTIC INJECTION MOLDING MACHINE, MODEL & S/N NA, Platen Size 88”H<br />

x 44”V, Tie Bar Spacing 44” x 44”, Toggle Clamp, Quick Mold Change-Over System, Total Control<br />

Quick-Panel II Microprocessor Control (W11M-02)<br />

1 – VAN DORN MODEL 500HT-30F 500-TON X 30 OZ. PLASTIC INJECTION MOLDING MACHINE,<br />

S/N 166 (1990), Toggle Clamp, Platen Size 48” x 48”, Tie Bar Spacing 32-1/2” x 32-1/2”, Pathfinder<br />

5000 Microprocessor Controls (W11M-01)<br />

2 – REED 1,000-TON PLASTIC INJECTION MOLDING MACHINES, MODEL & S/N NA, Platen Size 64”<br />

x 64”, Tie Bar Spacing 44” x 44”, Toggle Clamp, Self-Contained Mold Change-Over System, ISB Light<br />

Curtain, Reed Cycle Master II Microprocessor Controls (W11M-11, W11M-12)<br />

1 – VAN DORN MODEL 120-RS-6F-HT 120-TON X 6 OZ. PLASTIC INJECTION MOLDING MACHINE,<br />

S/N 248 (1990), Toggle Clamp, Platen Size 25”H x 27”V, Tie Bar Spacing 17” x 17”, Pathfinder<br />

Microprocessor Controls (W11M-26)<br />

VERTICAL CLAMP INJECTION MOLDING MACHINES<br />

1 – ENGEL MODEL ES600/150, 150-TON VERTICAL CLAMP PLASTIC INJECTION MOLDING<br />

MACHINE, S/N 8186-150-97 (1997), Horizontal Injection Barrel, 46” Diameter Indexing Table, Engle<br />

Microprocessor Controls, Light Curtain<br />

2 – NEWBURY MODEL V9-150-ARS 150-TON VERTICAL CLAMP PLASTIC INJECTION MOLDING<br />

MACHINES, S/Ns 127081150AS84, 127080150A384, Tie Bar Spacing 16” x 16”, Horizontal Injection<br />

Screw, 13” x 70” Shuttle Table, Pneumatic Door Closure<br />

PARTS ROBOTS<br />

2 – YUSHIN ABSOLINER VA-2500S 3-AXIS PARTS ROBOTS, S/N NA, Hand Pendant Control<br />

(W11M-07 & W11M-06)<br />

4 – CONAIR SEPRO MODEL SR4010A3, 3-AXIS ROBOTS, S/Ns P11653, P11654, P11655, & P11656<br />

BUYER’S NOTE:<br />

ALL EQUIPMENT WILL BE SOLD FROM THE 515 POPLAR ST. • KENTON, TN 38233 FACILITY<br />

CONTINUOUS THRU-FEED ABRASIVE BLAST<br />

CLEANING SYSTEM<br />

MOLD TRANSPORT & TRANSFER EQUIPMENT<br />

2 – BLUE GIANT MODEL TT1002 SIT-DOWN RIDER TYPE<br />

ELECTRIC TOW TRACTORS, S/Ns 9010003, 9500002, 1600-LB.<br />

Maximum Drawbar Pull, 36 Volt<br />

2 – INCOE TOWABLE MOLD TRANSFER CARTS, MODEL &<br />

S/N NA, Electric Powered Mold Transfer<br />

BLAST CLEANING SYSTEM<br />

1 – CONTINUOUS THRU-FEED ABRASIVE BLAST CLEANING<br />

SYSTEM, With (2) Zero Aerolyte Model 3048, (2) Inex 48” x 30”<br />

Abrasive Blast Cabinets, S/Ns 46646, 46650, (1) 12” Wide x 18’<br />

Long Wire Mesh Belt Conveyor, (2) Zero Products Model LPH-2L<br />

Dust Collectors, S/N 47134, NA, 900 CFM, (1) Abrasive Media<br />

Chamber<br />

BALER<br />

1 – HARRIS/SELCO MODEL V5-HD VERTICAL HYDRAULIC<br />

BALER, S/N 029562344, 30” x 60” Chamber, Top-Mounted<br />

Hydraulics, Floor Standing<br />

Bid Live in Person Onsite<br />

or Bid By Phone Via Webcast at<br />

www.hilcoind.com<br />

To schedule an auction, please contact us at 248.254.9999 5

THIS EQUIPMENT IS LOCATED AT 396 STATE HIGHWAY • WINNSBORO, SC<br />

TOOLROOM • FORKLIFTS • AERIAL WORK PLATFORM • MISC. EQUIPMENT<br />

TONG IL MODEL T1PL 4, 400 (15.75”) X 1060<br />

(41.73”) ENGINE LATHE<br />

HARIG 6” X 12” HAND-FEED<br />

SURFACE GRINDER<br />

BRIDGEPORT SERIES I 2-HP<br />

VARIABLE SPEED VERTICAL<br />

MILLING MACHINE<br />

DOALL MODEL 2013-20,<br />

20” VERTICAL BANDSAW<br />

KOMATSU MODEL FG25ST-16,<br />

4650-LB. CAPACITY FORKLIFT<br />

SIMON-EAGLE MODEL 32/21 ARTICULATED BOOM<br />

AERIAL WORK PLATFORM<br />

SPANCO 1/2-TON CAPACITY PORTABLE<br />

A FRAME GANTRY<br />

TOOLROOM EQUIPMENT<br />

1 – HYD-MECH MODEL S-20 SERIES II 18” X 12” CAPACITY HORIZONTAL METAL CUTTING<br />

BANDSAW, S/N 00297764<br />

1 – TONG IL MODEL T1PL 4, 400 (15.75”) X 1060 (41.73”) ENGINE LATHE, S/N 005-4287, (8) Spindle<br />

Speeds 60 – 1500 RPM, Quick Change Threading, Taper Attachment, 2-1/4” Hole-Thru Spindle<br />

Acu-Rite III Readout, 6-Jaw Chuck<br />

1 – HARIG 6” X 12” HAND-FEED SURFACE GRINDER, S/N 10764, Permanent Magnetic Chuck<br />

1 – BRIDGEPORT SERIES I 2-HP VARIABLE SPEED VERTICAL MILLING MACHINE,<br />

S/N 12BR200249, 48” Table, With Servo 150 Power Feed, 2-Axis Readout<br />

1 – BRIDGEPORT 2-HP VARIABLE SPEED VERTICAL MILLING MACHINE, S/N 12BR203408,<br />

48” Table, With Servo 150 Power Feed<br />

1 – ESAB MIGMASTER 250 WIRE FEED WELDER, S/N MAGI943080<br />

1 – WILTON TYPE 24714, 24” DRILL PRESS, S/N 91U57, 1.8/2.2KW, (8) Spindle Speeds 90 -3610 RPM,<br />

Power Down Feed<br />

1 – POWERMATIC MODEL 1200, 20” VARIABLE SPEED DRILL PRESS, S/N 8320V161<br />

1 – DOALL MODEL 2013-20, 20” VERTICAL BANDSAW, S/N 377-861267, Blade Speeds 0 – 5200 FPM,<br />

Blade Welder/Grinder<br />

1 – CLAUSING COLCHESTER 15” X 48” ENGINE LATHE, S/N 6/0015/18440 (Not In Service)<br />

PROCESS WATER COOLING SYSTEM<br />

1 – PROCESS COOLING WATER SYSTEM, With (2) Chiller Units, (2) Holding & Recirculation Units,<br />

(2) Outdoor Cooling Towers (Not In Service)<br />

FORKLIFTS<br />

1 – KOMATSU MODEL FG25ST-16, 4650-LB. CAPACITY FORKLIFT, S/N 205378A (2006), LPG,<br />

Solid Tires, 188” Lift, 3-Stage Mast, Side Shift, 48” Forks<br />

1 – KOMATSU MODEL FG25ST-16, 4650-LB. CAPACITY FORKLIFT, S/N 2053817 (2006), LPG,<br />

Solid Tires, 188” Lift, 3-Stage Mast, Side Shift, 48” Forks<br />

1 – BULLDOG 36 VOLT & GNB SCR CHARGER FLX 36 VOLT INDUSTRIAL FORKLIFT BATTERY<br />

CHARGERS<br />

1 – YALE 36 VOLT & GNB SCR CHARGER FLX 36 VOLT INDUSTRIAL FORKLIFT BATTERY<br />

CHARGERS<br />

AERIAL WORK PLATFORM<br />

1 – SIMON-EAGLE MODEL 32/21 ARTICULATED BOOM AERIAL WORK PLATFORM, S/N V3341,<br />

Maximum Work Height 39’, 500-LB. Capacity, Electric 7.00-15 Pneumatic Tires<br />

SCISSORS LIFT<br />

1 – STRATO-LIFT ELECTRIC SCISSORS LIFT PLATFORM, S/N NA (Not In Service)<br />

FLOOR SCRUBBER<br />

1 – TENNANT MODEL 510E SIT-DOWN RIDER BATTERY<br />

POWERED FLOOR SCRUBBER, S/N NA<br />

MISCELLANEOUS EQUIPMENT<br />

1 – WISCONSIN MODEL SB-432 ELECTRIC OVEN,<br />

S/N 063419912, 650 Degree Fahrenheit Maximum Temperature,<br />

Single Door, ID Size 50” x 36” x 24”, Honeywell Digital<br />

Temperature Control<br />

7 – TRION MODEL M26V PORTABLE MEDIA AIR CLEANERS,<br />

S/Ns M26XXV-01-00016, M26XXV-02-00010, M26XXV-99-<br />

00050, M26XXV-99-00049, M26XXV-96-00007, M26XXV-01-<br />

00014, NA<br />

1 – JONES & LAMSON EPIC 30, 30” OPTICAL COMPARATOR,<br />

S/N NA<br />

4 – MOVIN COOL PORTABLE COOLING UNITS<br />

1 – THURMAN MODEL 2400, 5000-LB. CAPACITY X 48” X 48”<br />

ELECTRONIC PLATFORM SCALE, S/N 44512-1, GSE 455<br />

Programmable Readout<br />

1 – CONAIR MODEL 4-26, 4” X 26” IN-LINE PULLER, S/N 169876<br />

(2004), Conair Uni-Drive Control, With Vector Puller Control<br />

1 – CONAIR MODEL SC-5 ROTARY IN-LINE CUTTER,<br />

S/N 170065, CSC Programmable Cutter Control<br />

3 – TECNOMAGNETE 25” X 25” ELECTROMAGNETIC<br />

MAGNETIC CHUCKS<br />

1 – GMF ROBOTICS MODEL P-100 6-AXIS PAINT APPLICATOR<br />

ROBOT, S/N NA (Not Under Power)<br />

1 – ENSIGN MODEL 35-5200 HYDRAULIC TUB DUMPER,<br />

S/N 4060<br />

Miscellaneous Belt Conveyors, Assorted Shipping Dunnage, Large<br />

Quantity Corrugated Cardboard, Containers – Assorted Size,<br />

Oil Totes, Pallet Racking, (3) Pallet Jacks<br />

SPECIAL ASSEMBLY MACHINES<br />

1 – SERIES 500 PALLET SHRINK WRAP MACHINE, S/N NA,<br />

72” Vertical, 48” Diameter Table<br />

1 – MULLER MODEL HP800 PALLET SHRINK WRAP MACHINE,<br />

S/N 69230689, 72” Vertical, 52” x 52” Table<br />

1 – SPANCO 1/2-TON CAPACITY PORTABLE A FRAME<br />

GANTRY, With Acco Wright Way Electric Chain Hoist<br />

6 For more information, visit us on the web @ www.hilcoind.com

THIS EQUIPMENT IS LOCATED AT 539 N. BELEVEDERE RD. • GALLATIN, TN 37066<br />

PLASTIC INJECTION MOLDER • BLOW MOLDERS<br />

DAVIS STANDARD STERLING SE–615–D 15–LB. DUAL<br />

ACCUMULATOR HEAD BLOW MOLDING MACHINE<br />

CINCINNATI MILACRON MODEL VH850–179CE 850–TON X 179–OZ.<br />

PLASTIC INJECTION MOLDING MACHINE<br />

DAVIS STANDARD STERLING DUAL 6–LB.<br />

ACCUMULATOR HEAD BLOW MOLDING MACHINE<br />

DAVIS STANDARD STERLING SE–34–D DUAL 4–LB.<br />

ACCUMULATOR HEAD BLOW MOLDING MACHINE<br />

APV/STERLING 3–LB. DUAL ACCUMULATOR<br />

HEAD BLOW MOLDING MACHINE<br />

THE FOLLOWING EQUIPMENT IS LOCATED AT 539 N. BELEVEDERE RD. • GALLATIN, TN 37066<br />

PLASTIC INJECTION MOLDING MACHINE<br />

1 – CINCINNATI MILACRON MODEL VH850–179CE 850–TON X 179–OZ. PLASTIC INJECTION MOLDING<br />

MACHINE, S/N 3908A21/92–20, Hydraulic Clamp, Platen Size 66” H x 56” V, Tie Bar Spacing 48” H x 36” V,<br />

CAMAC XTL Microprocessor Controls, Vacuum Loader & Hopper<br />

BLOW MOLDING MACHINES<br />

1 – DAVIS STANDARD STERLING MODEL SE–615–D 15–LB. DUAL ACCUMULATOR HEAD BLOW MOLDING<br />

MACHINE, S/N 63577 (1999), 6” Single 300–HP Extruder, 180–Ton Clamp Tonnage, Platen Size 96” x 60”,<br />

Traveling Platen Carriage, Part Take–Out Unit, AC Extruder Motor, Barber Colman MACO 6500 System Status<br />

Computer Control, Pendant Style CNC Operators Control (#17)<br />

1 – DAVIS STANDARD STERLING MODEL SE–35–D 5–LB. DUAL ACCUMULATOR HEAD BLOW MOLDING<br />

MACHINE, S/Ns 09738 (Sustained Minor Heat Damage But Appears Functional) (1994), Single 100–HP Extruder,<br />

65–Ton Clamp, Platen Size 48” x 36”, Barber Colman MACO 8000 Microprocessor Controls, Vacuum Loader, Feed<br />

Hopper (#7)<br />

1 – DAVIS STANDARD STERLING MODEL SE–38–D 8–LB. DUAL ACCUMULATOR HEAD BLOW MOLDING<br />

MACHINE, S/Ns 07827 (1993), Single 100–HP 3–1/2” Extruder, Platen Size 48” x 36”, 65–Ton Clamp, Barber<br />

Colman MACO 8000 Microprocessor Controls, Vacuum Loader, Feed Hopper (#1)<br />

1 – DAVIS STANDARD STERLING MODEL SE–35–D 5–LB. DUAL ACCUMULATOR HEAD BLOW MOLDING<br />

MACHINE, S/Ns 09738 (Sustained Minor Heat Damage But Appears Functional) (1994), Single 100–HP Extruder,<br />

65–Ton Clamp, Platen Size 48” x 36”, Barber Colman MACO 8000 Microprocessor Controls, Vacuum Loader, Feed<br />

Hopper (#6)<br />

1 – DAVIS STANDARD STERLING DUAL 6–LB. ACCUMULATOR HEAD BLOW MOLDING MACHINE, S/N 09737<br />

(1994), Single 75–HP 3–1/2” Extruder, Platen Size 64” x 33”, Barber Colman MACO 8000 Microprocessor Controls<br />

(#11)<br />

1 – IMPCO MODEL B–30–S 5–LB. SINGLE ACCUMULATOR HEAD BLOW MOLDING MACHINE, S/N L–162,<br />

Single 75–HP Extruder, Platen Size 30” x 24” (#10)<br />

1 – APV/STERLING 3–LB. DUAL ACCUMULATOR HEAD BLOW MOLDING MACHINE, S/N 91182, Single 75–HP<br />

Extruder, Platen Size 44” x 20”, Barber Colman MACO 8000 Microprocessor Controls (#16)<br />

BULK MATERIAL HANDLING EQUIPMENT<br />

2 – BULK MATERIAL STORAGE SILOS, Bolted Galvanized Steel Panels, 12' Diameter x Approximately 30' High<br />

FORKLIFT<br />

1 – NISSAN KCUGH02F35PV 6950–LB. CAPACITY LPG FORKLIFT, S/N KCUGH02P901019, Solid Tires, 175” Lift,<br />

3–Stage Mast, Side Shift, 42” Forks<br />

NISSAN MODEL KCUGH02F35PV<br />

6950–LB. CAPACITY LPG FORKLIFT<br />

BUYER’S NOTE:<br />

ALL EQUIPMENT WILL BE SOLD FROM THE<br />

515 POPLAR ST. • KENTON, TN 38233 FACILITY<br />

Bid Live in Person Onsite<br />

or Bid By Phone Via Webcast at<br />

www.hilcoind.com<br />

To schedule an auction, please contact us at 248.254.9999 7

Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Southampton (UK) • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

HILCAST TM<br />

WEBCAST AUCTION<br />

Pursuant to the U.S. Bankruptcy Court, assets formerly used by<br />

OVER 30 PLASTIC INJECTION MOLDERS &<br />

SUPPORT EQUIPMENT, BLOW MOLDERS,<br />

TOOLROOM & MOBILE EQUIPMENT<br />

Wednesday, November 5th • Beginning at 10am Local Time<br />

Kenton, Tennessee<br />

Terms of Sale<br />

A buyer’s premium of 13.5% for onsite sales & 16%<br />

for webcast sales is in effect. Everything will be sold<br />

to the highest bidder for cash, in accordance with<br />

the Auctioneer’s customary “Terms of Sale”, copies<br />

of which will be posted on the premises of the sale<br />

and subject to additional terms announced the day<br />

of sale. All items will be sold “as is, where-is” without<br />

any warranties, express or implied. Although<br />

obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the<br />

items on which they intend to bid prior to sale.<br />

Absolutely no items will be removed until the day<br />

after the conclusion of the sale and payment is made<br />

in full. Subject to additions, deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN<br />

FULL ON THE DAY OF THE AUCTION. If you intend<br />

to pay by wire transfer, we will accept payment the<br />

day after the sale ONLY IF a deposit of 25% of total<br />

purchases is made on the day of the sale. Contact<br />

our office for wire transfer instructions. Only cash,<br />

wire transfer or certified check, payable to <strong>Hilco</strong><br />

<strong>Industrial</strong>, LLC will be accepted. Company checks<br />

payable to <strong>Hilco</strong> <strong>Industrial</strong> LLC will be accepted only<br />

if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales<br />

tax. Purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the Auctioneer of<br />

their entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees payment<br />

to <strong>Hilco</strong> <strong>Industrial</strong>, LLC from (Company Name).<br />

This guarantee will be valid for purchases made at<br />

the Auction of Plastech on November 5th.<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062<br />

All rights reserved • Printed in USA • PLAS3348 • IL License #444000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.