WEBCAST AUCTION - Hilco Industrial

WEBCAST AUCTION - Hilco Industrial

WEBCAST AUCTION - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

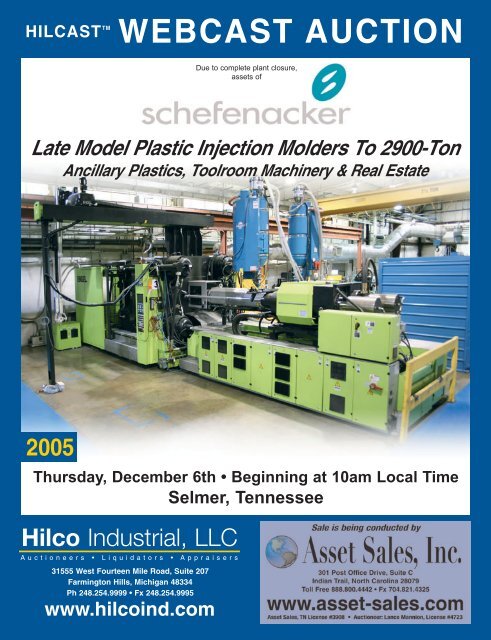

HILCAST TM<br />

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

Due to complete plant closure,<br />

assets of<br />

Late Model Plastic Injection Molders To 2900-Ton<br />

Ancillary Plastics, Toolroom Machinery & Real Estate<br />

2005<br />

Thursday, December 6th • Beginning at 10am Local Time<br />

Selmer, Tennessee<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com

HILCAST TM <strong>WEBCAST</strong> <strong>AUCTION</strong><br />

Due to complete plant closure, assets of<br />

(24) PLASTIC INJECTION MOLDING MACHINES<br />

2005<br />

THURSDAY, DECEMBER 6TH<br />

Beginning at 10am Local Time<br />

Preview Date<br />

Wednesday, December 5th<br />

9am to 4pm Local Time<br />

Auction Location<br />

640 Mulberry Ave • Selmer, TN 38375<br />

Directions to Sale<br />

Selmer, TN is approximately 75 Miles East of<br />

Memphis, TN or 35 Miles South of Jackson, TN.<br />

Located on US Hwy. 45 1/4 Mile South of the<br />

Interchange of US Hwy’s. 45 & 64.<br />

From Memphis International Airport:<br />

Go south on Winchester Road. Turn slight left toward<br />

FAA Vehicles. Turn slight left then turn left. Take the<br />

ramp toward I-240 / Downtown / Rental Car Return.<br />

Merge onto Plough Blvd. and go 1.3 miles and merge<br />

onto I-240 E toward Nashville. Travel 5.8 miles and<br />

merge onto Bill Morris Pkwy / TN-385 E via Exit 16.<br />

Proceed for 14.6 miles then take the US-72 W / US-72<br />

E Exit toward Collierville. Keep right at the fork to go on<br />

US-72 E (Crossing into Mississippi). Go 65.1 miles then<br />

merge onto US-45 N via the ramp on the left (Crossing<br />

into Tennessee). Go 16.5 miles and end at 640<br />

Mulberry Ave. Watch for Auction Signs & Parking.<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . . . . . . 800.435.9792<br />

Hotels:<br />

Hampton Inn . . . . . . . . . . . . . . . . . 662.286.5949<br />

Holiday Inn Express . . . . . . . . . . . . 662.287.1407<br />

Further Information<br />

• A buyer’s premium will be in effect.<br />

The auction will be conducted in English,<br />

accepting U.S. Currency only.<br />

• Removal Deadline is December 21, 2007<br />

with Hours of Removal between<br />

8am to 4pm Monday thru Friday.<br />

After December 21st at 4pm buyer<br />

will incur a cost of $500 daily for entry<br />

into the facility.<br />

• For further information please contact<br />

Mark Reynolds at 205.595.5999 or<br />

E-mail mreynolds@hilcoind.com<br />

• For Payment & Customer Service<br />

please contact:<br />

Sandi Neely at 248.254.9999 x16<br />

or Email sneely@hilcoind.com<br />

1000-TON ENGEL DUO 7050/1000 WP,<br />

135 OZ. WIDE PLATEN HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINE<br />

TO 1998<br />

A Buyer’s Premium of 12.5% for All On-Site Sales<br />

and 15% for All Webcast Sales Will Be In Effect.<br />

For Complete Terms & Conditions Please Visit<br />

www.hilcoind.com<br />

750-TON<br />

DEMAG<br />

MODEL D750-6110,<br />

HORIZONTAL<br />

PLASTIC INJECTION<br />

MOLDING MACHINE<br />

(1 OF 4)<br />

600-TON<br />

CINCINNATI<br />

MODEL MH600,<br />

(2) 76-OZ. & (2) 60-OZ.<br />

HORIZONTAL<br />

PLASTIC<br />

INJECTION<br />

MOLDING MACHINES<br />

2<br />

For more information, visit us on the web @ www.hilcoind.com

(24) PLASTIC INJECTION MOLDING MACHINES<br />

2001 2001<br />

300-TON ARBURG ALLROUNDER MODEL SELECTA 630S-2500-1300<br />

HORIZONTAL PLASTIC INJECTION MOLDING MACHINE<br />

300-TON ARBURG ALLROUNDER MODEL SELECTRA 630S-2500-875<br />

HORIZONTAL PLASTIC INJECTION MOLDING MACHINE<br />

300-TON CINCINNATI MILACRON MODEL VH300-21<br />

HORIZONTAL PLASTIC INJECTION MOLDING MACHINE<br />

1998<br />

250-TON CINCINNATI MILACRON MODEL MH250-29<br />

HORIZONTAL PLASTIC INJECTION MOLDING MACHINE<br />

(24) PLASTIC INJECTION MOLDING MACHINES<br />

1 – 1000-TON ENGEL DUO 7050/1000 WP, 135 Oz. WIDE PLATEN HORIZONTAL PLASTIC<br />

INJECTION MOLDING MACHINE, S/N 52509 (2005), 1000-Ton Clamping Force, Opening Stroke<br />

78.7”, Mold Height 23.6” Min. – 53.5” Max., Maximum Daylight 102.4”, Platen Size 78.7”H x 72”V,<br />

Tie Bar Spacing 55.9”H x 46.1”V, Tie Bar Diameter 8”, Maximum Mold Weight 46,300-Lbs., Ejector<br />

Stroke 11.8”, Ejector Force 24-Tons, Screw Diameter 4.1”, Screw Stroke 18.9”, Injection Capacity<br />

254 Cubic Inch, L/D Ratio 20:1, Nozzle Stroke 27.6”, CC100 Controls Core Pull, Power Centering<br />

Pin, Automatic Mold Clamping, Power Adjustable Mold Height, with Engel Model ERC 83/1-E<br />

3-Axis Servo Drive Gantry Type Robot, S/N 154749 (2005) (#3) (The Engel Robot has 3 Servo<br />

Controlled Axis', But Does Have Pneumatic Wrist Action)<br />

1 – 750-TON DEMAG MODEL D750-6110 HORIZONTAL PLASTIC INJECTION MOLDING<br />

MACHINE, S/N 824-0099,Toggle Clamp, Platen Size 55-1/2” x 55-1/2”, Tie Bar Spacing 38” x 38”,<br />

Demag Ergotech Microprocessor Controls (#10)<br />

1 – 750-TON DEMAG MODEL D750-NCIII (7500 – 6110) HORIZONTAL PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 824-0113, Toggle Clamp, Platen Size 57” x 57”, Tie Bar Spacing 38” x<br />

38”, Demag Ergotech Microprocessor Controls (#11)<br />

2 – 600-TON CINCINNATI MODEL MH600-76 HORIZONTAL PLASTIC INJECTION MOLDING<br />

MACHINES, S/Ns H06A4098015, H06A4098016 (Both 1998), Hydraulic Clamp, 76 oz. Shot<br />

Capacity, Platen Size 49” x 49”, Tie Bar Spacing 34” x 34”, Clamp Stroke 44.9”, Maximum Daylight<br />

66”, Hydraulic Ejectors, Camac 486 Microprocessor Controls, Vacuum Receiver (#7, 5)<br />

2 – 600-TON CINCINNATI MILACRON MODEL MH600-60 HORIZONTAL PLASTIC INJECTION<br />

MOLDING MACHINES, S/Ns H06A4098009 (1998), H06A0496014 (1996), Hydraulic Clamp, 60<br />

oz. Shot Capacity, Platen Size 49” x 49”, Tie Bar Spacing 34” x 34”, Clamp Stroke 44.9”, Maximum<br />

Daylight 66”, Hydraulic Ejectors, Camac 486 Microprocessor Controls, Vacuum Receiver (#6, 4)<br />

1 – 300-TON ARBURG ALLROUNDER MODEL SELECTA 630S-2500-1300 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINE, S/N 186798 (2001), Hydraulic Clamp, 29 oz. Shot<br />

Capacity, Platen Size 35.43” x 35.43”, Tie Bar Spacing 24.8” x 24.8”, Opening Stroke 23.62”, Mold<br />

Height 11.81”, Maximum Daylight 35.43” – 51.18”, Selogica Microprocessor Controls, Air Blow-Off,<br />

Core Pull, Robot Interface, (6) Additional Heat Zones Vacuum Receiver (#18)<br />

1 – 300-TON ARBURG ALLROUNDER MODEL SELECTRA 630S-2500-875 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINE, S/N 186797 (2001), Hydraulic Clamp, 11.4 oz. Shot<br />

Capacity, Platen Size 35.43” x 35.43”, Tie Bar Spacing 24.8” x 24.8”, Opening Stroke 23.62”, Mold<br />

Height 11.81”, Maximum Daylight 35.43” – 51.18”, Selogica Microprocessor Controls, Air Blow-Off,<br />

Core Pull, Robot Interface, (6) Additional Heat Zones (#20)<br />

1 – 300-TON CINCINNATI MILACRON MODEL VH300-21 HORIZONTAL PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 3903A21/91-23, Hydraulic Clamp, 21 oz. Shot Capacity, Platen Size<br />

39.37” x 39.37”, Tie Bar Spacing 27.17” x 27.17”, Camac VLC Microprocessor Control, Vacuum<br />

Receiver (#29)<br />

1 – 300-TON CINCINNATI MILACRON MODEL VT-300-21 HORIZONTAL PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 4038A61/90-15, Toggle Clamp, 21 oz. Shot Capacity, Platen Size<br />

36.25” x 36.25”, Tie Bar Spacing 26” x 25”, Camac VEL Microprocessor Controls, Vacuum<br />

Receiver (#19)<br />

1 – 250-TON CINCINNATI MILACRON MODEL MH250-29 HORIZONTAL PLASTIC<br />

INJECTION MOLDING MACHINE, S/N H02A0498007 (1998), Hydraulic Clamp, 29 oz.<br />

Shot Capacity, Platen Size 30.5” x 30.5”, Tie Bar Spacing 22” x 22”, Nozzle Stroke 11”,<br />

Camac 486 Microprocessor Controls, Vacuum Receiver (#22)<br />

1 – 250-TON CINCINNATI MILACRON MODEL MH250-29 HORIZONTAL PLASTIC<br />

INJECTION MOLDING MACHINE, S/N H02A0498004 (1998), Hydraulic Clamp, 29 oz.<br />

Shot Capacity, Platen Size 30.5” x 30.5”, Tie Bar Spacing 22” x 22”, Nozzle Stroke 11”,<br />

Camac 486 Microprocessor Controls, Vacuum Receiver (#23)<br />

1 – 242-TON ARBURG ALLROUNDER MODEL CENTEX 570C-2200-675 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINE, S/N 184000 (2001), Hydraulic Clamping,<br />

10.5 oz. Shot Capacity, Platen Size 31.3” x 31.3”, Tie Bar Spacing 22.44” x 22.44”, Opening<br />

Stroke 25.59”, Mold Height 11.81”, Maximum Daylight 37.4”, Selogica Microprocessor<br />

Controls, Air Blow-Off, Core Pull, Robot Interface, (6) Additional Heat Zones (#12)<br />

1 – 150-TON CINCINNATI MILACRON MODEL ACT-150B-226 HORIZONTAL PLASTIC<br />

INJECTION MOLDING MACHINE, S/N 4043A01/87-26, Toggle Clamp, Platen Size 26” x<br />

26”, Tie Bar Spacing 18” x 18”, Fanuc Controls, Vacuum Receiver (#26)<br />

2 – 150-TON CINCINNATI MODEL ACT-150C-226 TOGGLE CLAMP PLASTIC INJECTION<br />

MOLDING MACHINES, S/Ns 4043A01/8807, NA, 26” x 26” Platen, 18” x 18” Tie Bar<br />

Clearance, Fanuc Controls (Not In Service) (#24, 25)<br />

2 – 143-TON ARBURG ALLROUNDER MODEL CENTEX 470C-1300-350 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINES, S/Ns 186795 & 186796 (BOTH 2001),<br />

Hydraulic Clamp, 4.5 oz. Shot Capacity, Platen Size 25.59” x 25.9”, Tie Bar Spacing 18.5”<br />

x 18.5”, Opening Stroke 19.69”, Mold Height 9.84”, Maximum Daylight 29.53”, Selogica<br />

Microprocessor Controls, Air Blow-Off, Core Pull, Robot Interface, (6) Additional Heat<br />

Zones (#21 & 15)<br />

1 – 110-TON ARBURG ALLROUNDER MODEL CENTEX 420C-1000-350 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINE, S/N 186464 (2001), Hydraulic Clamping, 4.5<br />

oz. Shot Capacity, Platen Size 25.59” x 25.59”, Tie Bar Spacing 16.54” x 16.54”, Opening<br />

Stroke 19.69”, Mold Height 9.84, Maximum Daylight 29.53”, Selogica Microprocessor<br />

Controls, Air Blow-Off, Core Pull, Robot Interface, (6) Additional Heat Zones, Vacuum<br />

Receiver (#14)<br />

2 – 88-TON ARBURG ALLROUNDER MODEL CENTEX 420C-800-250 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINES, S/Ns 183900 (2001) & 183494 (2000),<br />

Hydraulic Clamp, 3.1 oz. Shot Capacity, laten Size 23.82” x 23.82”, Tie Bar Spacing 16.54”<br />

x 16.54” Opening Stroke 19.69”, Mold Height 9.84”, Maximum Daylight 29.53”, Selogica<br />

Microprocessor Controls, Air Blow-Off, Core Pull, Robot Interface, (6) Additional Heat Zones<br />

(#17 & 28)<br />

2 – 85-TON CINCINNATI MILACRON MODEL VISTA SENTRY VSX85-9.59 HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINES, S/Ns S85A0498027 & S85A0498011<br />

(BOTH 1998), Toggle Clamp, 9.6 oz. Shot Capacity, Platen Size 24”H x 22”V, Tie Bar Spacing<br />

16”Hx 14”V, Camac VSX Microprocessor Controls, Vacuum Receiver (#13 & 16)<br />

To schedule an auction, please contact us at 248.254.9999 3

MULTI-COLOR INJECTION MOLDING MACHINES<br />

1998<br />

1998<br />

1800-TON KRAUSS-MAFFEI MODEL KM 1800-1650-1200-620-620-R4<br />

MULTI-COLOR 4-BARREL PLASTIC INJECTION MOLDING MACHINE<br />

1998<br />

1800-TON KRAUSS-MAFFEI MODEL KM 1800-1650-1200-620-R3<br />

MULTI-COLOR 4-BARREL PLASTIC INJECTION MOLDING MACHINE<br />

1998<br />

1200-TON KRAUSS-MAFFEI MODEL KM 1200F – KM 1200-620-620-620-1650<br />

MULTI-COLOR 4-BARREL PLASTIC INJECTION MOLDING MACHINE<br />

500-TON KRAUSS-MAFFEI MULTINJECT<br />

KM500-700-520CZ, MULTI-COLOR 2-BARREL<br />

HORIZONTAL PLASTIC INJECTION MOLDING MACHINE<br />

2005<br />

GREEN VALLEY MODEL TITAN SEMI-AUTOMATIC<br />

MOLD CHANGING SYSTEM<br />

Real Estate is being<br />

offered at auction.<br />

Please see page 11 of this brochure.<br />

MULTI-COLOR INJECTION MOLDING MACHINES<br />

1 – 1800-TON KRAUSS-MAFFEI MODEL KM 1800-1650-1200-620-620-R4 MULTI-COLOR 4-BARREL PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 4843 (1998), Vertical Hydraulic Clamp, (4) Mobile Base Horizontal Hydraulic Injection Barrels<br />

each, with Self-Contained Hydraulics, 4-Post Vertical Tie Bar Construction, Stationary Lower Bed Size 96” x 76”, Working<br />

Space Between Tie Bars 72”LR x 48”FB, 72” Diameter Rotary Upper Platen, (1) Type SPr 1650F Barrel,<br />

(2) Type SPr 620F Barrels, (1) Type SPr 1200F Barrel, (5) Krauss-Maffei Micro Control MC3 CNC Control Terminals,<br />

Mezzanine Mounted 90 Kw Main Press Hydraulic Unit, with Reservoir & Main Electrical Control Cabinet (#8)<br />

1 – 1800-TON KRAUSS-MAFFEI MODEL KM 1800-1650-1200-620-R3 MULTI-COLOR 4-BARREL PLASTIC INJECTION<br />

MOLDING MACHINE, S/N 4844 (1998), Vertical Hydraulic Clamp, (4) Mobile Base Horizontal Hydraulic Barrels Each with<br />

Self-Contained Hydraulics, 4-Post Vertical Tie Bar Construction, Stationary Lower Bed Size 96” x 76” Working Space Between<br />

Tie Bars 72”LR x 48”FB, 72” Diameter Rotary Upper Platen, (1) Type SP1650F Barrel, (1) Type SP620F Barrel,<br />

(1) Type SP1200F Barrel, (1) Type SP1650 Barrel, S/N 4794 (1989), (5) Krauss-Maffei Micro Control MC3 CNC Control<br />

Terminals, Mezzanine Mounted 90 Kw Main Press Hydraulic Unit, with Reservoir & Main Electrical Control Cabinet (#9)<br />

1 – 1200-TON KRAUSS-MAFFEI MODEL KM 1200F – KM 1200-620-620-620-1650 MULTI-COLOR 4-BARREL PLASTIC<br />

INJECTION MOLDING MACHINE, S/N 4795 (1991), Vertical Hydraulic Clamp, 1200-Ton Clamping Force, (4) Mobile Base<br />

Horizontal Hydraulic Injection Barrels Each with Self-Contained Hydraulics, 4-Post Vertical Tie Bar Construction, Stationary<br />

Lower Bed Size 66”LR x 62”FB, Working Space Between Tie Bars 40” x 40”, 48” Diameter Rotary Upper Platen, (1) Type<br />

SP1650F Barrel, with Vacuum Receiver, (3) Type SP620F Barrels, with Vacuum Receivers, (5) Krauss-Maffei Micro Control<br />

MC3 CNC Control Terminals, 65 Kw Main Press Hydraulic Unit, Main Electrical Control Cabinet (#1)<br />

1 – 500-TON KRAUSS-MAFFEI MULTINJECT MODEL KM 500-700-520CZ MULTI-COLOR 2-BARREL HORIZONTAL<br />

PLASTIC INJECTION MOLDING MACHINE, S/N 504032 (1998), With Rotary Table, Hydraulic Clamp, Top/Bottom Barrel<br />

Configuration, Distance Between Tie Bars 32” x 32”, Stationary Platen Size 60”H x 57”V, 43” Diameter Rotary Moveable<br />

Platen, Krauss Maffei Microprocessor Controls, Allen Bradley Power Flex 700 Inverter Drive Control, Hydraulic Accumulator,<br />

(2) Vacuum Receivers (#27)<br />

MOLD CHANGING SYSTEM<br />

1 – GREEN VALLEY MODEL TITAN SEMI-AUTOMATIC MOLD CHANGING SYSTEM, S/N 2147 (2005), 2-Station, Capacity<br />

3 x 30,000-Lb., 30,000-Lb. Capacity Power Upender, Allen Bradley Micro Logix 1200 PLC Controls, (Machine #3)<br />

4 For more information, visit us on the web @ www.hilcoind.com

THE EQUIPMENT LISTED BELOW IS LOCATED OFF-SITE<br />

Please Contact Brent Bonham at 616.233.0702 or Email bbonham@hilcoind.com<br />

to Schedule a Preview Appointment.<br />

1997<br />

HUSKY MODEL D2650RS/200/200 2,900-TON X 885-OZ. 2-PLATEN<br />

PLASTIC INJECTION MOLDING MACHINE<br />

CINCINNATI MILACRON MAXIMA MODEL ML1760-232 1,760-TON X 232-OZ.<br />

2-PLATEN PLASTIC INJECTION MOLDING MACHINE<br />

2000<br />

HUSKY MODEL EW1350RS 135/115 1,500-TON X 211-OZ. 2-PLATEN<br />

PLASTIC INJECTION MOLDING MACHINE<br />

1998<br />

PLASTIC INJECTION MOLDING MACHINES & ROBOTS<br />

1 – HUSKY MODEL D2650RS/200/200 2,900-TON X 885-OZ. 2-PLATEN PLASTIC INJECTION MOLDING MACHINE, S/N 13173<br />

(1997), Hydraulic Clamp, Platen Size 120” H x 102” V, Distance Between Tie Bars 84.6” x 66.9”, Mold Shut Height 43.3” x 74.8”,<br />

Maximum Daylight 169”, Clamp Stroke 94.5”, Screw Diameter 7.87”, Screw Stroke 33.46”, Screw L/D Ratio 25:1, Hydraulic Ejector<br />

Stroke 13.78” Maximum, Injection Pressure 21,219 Maximum, Injection Capacity 1051.3 Cu. In., Husky/Siemens Simatic S5 CNC<br />

Controls, Nitrogen Charged Hydraulic Accumulator, 450-HP (#19)<br />

1 – HUSKY MTE50 CNC ROBOT, S/N 14033, 4-Axis Servo Drive, Husky/GE Fanuc Power Motion CNC Hand<br />

1 – CINCINNATI MILACRON MAXIMA MODEL ML1760-232 1,760-TON X 232-OZ. 2-PLATEN PLASTIC INJECTION MOLDING<br />

MACHINE, S/N H35A0196001 (1996, Installed New 1998), Hydraulic Clamp, Platen Size 97.6” H x 82.7”V, Distance Between Tie Bars<br />

72.0” x 55”, Die Size 26.8” Min. – 63.0” Max., Maximum Daylight 120.0”, Clamp Stroke 98.4”, Screw Diameter 4.92”, Hydraulic Ejectors,<br />

CAMAC 486 Programmable Controls, 185-HP (#12)<br />

1 – HUSKY MODEL EW1350RS 135/115 1,500-TON X 211-OZ. 2-PLATEN PLASTIC INJECTION MOLDING MACHINE, S/N 200068<br />

(2000), Hydraulic Clamp, Platen Size 92.9” H x 79.1” V, Distance Between Tie Bars 66.9” x 53.1”, Mold Stroke Maximum 90.5”, Mold<br />

Shut Height 31.5” – 55.1”, Maximum Daylight 122”, Hyrdaulic Ejector Stroke 11.8”, Screw Diameter 4.528”, Screw Stroke 23.672”,<br />

Screw L/D Ratio 25:1, Maximum Screw Speed 100 RPM, Injection Pressure Maximum 31,981 PSI, Injection Capacity 380.3 Cu. In.,<br />

Husky/Fanuc CNC Controls,Siemens Simatic S5 Drive Controls, 300-HP, Nitrogen Gas Charged Hydraulic Accumulator (#16)<br />

1 – HUSKY MTE15 CNC ROBOT, S/N 179237 (2000), Pneumatic A-Axis, 33.1-Lb. Capacity, Husky/GE Fanuc Power Motion, Hand<br />

Pendant Control (#16)<br />

1 – HUSKY MODEL H1000 RS 135/115 1,100-TON X 211-OZ. 2-PLATEN PLASTIC INJECTION MOLDING MACHINE, S/N 200105<br />

(2001), Hydraulic Clamp, Platen Size 86.6” H x 73.2” V, Distance Between Tie Bars 61.0” x 51.9”, Mold Space 23.6” – 51.2”, Maximum<br />

Daylight 102.2”, Screw Stroke 23.6”, Screw Diameter 4.92”, Screw Speed 100 RPM, Screw L/D Ratio 25:1, Injection Capacity 2,453.5<br />

Cu. In., Injection Pressure 2210 Bar, Husky/Beckhoff C6140 CNC Controls, 200-HP (#18)<br />

1 – HUSKY MTE35 4-AXIS CNC ROBOT, S/N NA (2001), Servo Drive, 77.2-Lb. Capacity (#18)<br />

1 – CINCINNATI MILACRON MODEL VL1000-179WP 1,000-TON X 179-OZ. WIDE PLATEN PLASTIC INJECTION MOLDING MACHINE,<br />

S/N H21A0498004 (1998), Hydraulic Clamp, Platen Size 79” H x 63” V, Distance Between Tie Bars 60” H x 44” V, Die Size 14” Min. 44”<br />

Max., Maximum Daylight 77.0”, Clamp Stroke 48.0”, Screw Diameter 4.3”, Hydraulic Ejectors, CAMAC 486C Programmable Controls,<br />

175-HP (#15)<br />

1 – CINCINNATI MILACRON OPTIMUM AZ-1000 3-AXIS CNC ROBOT, S/N C-98025, 80-Lb. Capacity, Cutler Hammer Panel Mate<br />

Power Pro Pendant Control (#15)<br />

1 – HPM MODEL 650 1X-60 650-TON X 60-OZ. PLASTIC INJECTION MOLDING MACHINE, S/N 65-646 (Controls & Electrics Updated<br />

1994), Hydraulic Clamp, Platen Size 48” x 48”, Distance Between Tie Bars 30” x 30”, Die Size 12.0” Min. – 30.0” Max., Maximum Daylight<br />

45.0”, Clamp Stroke 35.0”, Screw Diameter 3.5”, Hydraulic Ejectors on Press #’s 3 & 4, Modicon Panel Mate Plus Programmable Control,<br />

Digital Technologies Power Miser Programmable Clamp Control, 70-HP (# 5)<br />

DRYERS/HOPPERS<br />

3 – THORESON MCCOSH T-D SERIES TD480 PORTABLE DEHUMIDIFYING DRYER, S/Ns 200-607-10 (2000), 200-608-10 (2000), 201-605-05<br />

3 – THORESON MCCOSH DRYER HOPPERS<br />

MISCELLANEOUS DRYERS, HOPPERS, & CONVEYORS<br />

CINCINNATI MILACRON MODEL VL1000-179WP 1,000-TON X 179-OZ.<br />

WIDE PLATEN PLASTIC INJECTION MOLDING MACHINE<br />

To schedule an auction, please contact us at 248.254.9999 5

(18) DRYERS • (12) DRYER/HOPPERS • (16) ROBOTS<br />

CINCINNATI MILACRON 4-STATION<br />

DRYING HOPPER STAND<br />

(3 OF 8) AEC WHITLOCK WD25MR & WD50MR<br />

MINI-DRYER PORTABLE DEHUMIDIFYING DRYERS<br />

2003 1999<br />

CONAIR CAROUSEL MODEL DM 200<br />

DEHUMIDIFYING DRYER<br />

2001<br />

(1 OF 5) RANGER MODEL RT500S3,<br />

3-AXIS GANTRY TYPE SERVO DRIVE<br />

PARTS ROBOTS<br />

(1 OF 2) RANGER MODEL RT200S3,<br />

3-AXIS GANTRY TYPE SERVO DRIVE<br />

PARTS ROBOTS<br />

(18) DRYERS<br />

1 – CINCINNATI MILACRON MATERIAL DRYING STATION, With (1) Model Dd700 Desiccant Dryer, S/N 3933A02-99-20<br />

(1999), 15 Kw Regen Heater, Dual Desiccant Canisters, Canister Filter, Programmable Controls<br />

1 – CINCINNATI MILACRON 4-STATION DRYING HOPPER STAND, (2) Approximately 800-Lb. Hoppers, (2) Approximately<br />

600-Lb. Hoppers, (4) Vacuum Receivers, (1) Programmable Hopper Control Panel, SN/FS Hopper Heaters,<br />

S/N 3933A02-99-21-03 (1999), Heater Kw: (1) @ 14.9, (3) @ 7.5<br />

1 – CINCINNATI MILACRON MODEL DD750 DESICCANT DRYER, S/N 3933A02-98-17 (1998), 15 Kw Regen Heater,<br />

Dual Desiccant Canisters, Canister Filter, Programmable Controls<br />

1 – CINCINNATI MILACRON 4-HOPPER MATERIAL DRYING STATION, INCLUDING: (1) Model FN Heater Control,<br />

S/N 3933A02-98-17 (1998) Heater Kw: Process – 1ea. 19.8, 3ea. 7.5 Programmable Controls, Canister Filter Dial<br />

Desiccant Canisters, (1) Drying Stand, with (4) Drying Hoppers,(3) Approximately 400-Lb., (1) Approximately 200-Lb. Each,<br />

with Vacuum Receiver<br />

1 – CONAIR CAROUSEL MODEL DM 200 DEHUMIDIFYING DRYER, S/N 168084, Revision TEKC/0602, with CM-200<br />

Programmable Controls<br />

1 – CONAIR MODEL CH33 DRYING HOPPER, S/N 166440, Approximately 1000-Lb., Steel Stand Mounted, with Vacuum Loader<br />

4 – AEC WHITLOCK MODEL WD50MR MINI-DRYER PORTABLE DEHUMIDIFYING DRYERS, S/Ns 31E0334, 31E0336,<br />

31E0337, 31E0335, 50 CFM, Process Heater 5 Kw, Regen Heater 2.5 Kw, Model SRC04 Vacuum Hopper, with Vacuum<br />

Receiver, S/Ns 31E0317, 31E0318, 31E0320, 31E0316, Allen Bradley Micro Logix 1000 PLC Control<br />

4 – AEC WHITLOCK MODEL WD25MR, MINI DRYER PORTABLE DEHUMIDIFYING DRYERS, S/Ns 31E0333, 31E0330,<br />

31E0331, 31E0332, 25 CFM, Process Heater 2.5 Kw, Regen Heater 1.5 Kw, Model SRC04 Vacuum Hopper, with Vacuum<br />

Receiver, S/Ns 31E0319, 31E0313, 31E0321, 31E0315, Allen Bradley Micro Logix PLC Controls<br />

4 – AEC WHITLOCK MODEL WD10MR, PORTABLE MINI-DRYERS, S/Ns 31E0326, 31E0328, 31E0327, 31E0329, 10 CFM,<br />

1 Kw Process Heater, 1 Kw Regen Heater, Model SRC02 Vacuum Hopper, with Receiver, S/N 31E0323, 31E0325, Allen<br />

Bradley Micro Logix 1000 PLC Control<br />

1 – NOVATECH MODEL MPC-100, MICROPROCESSOR CONTROLLED DRYER, S/N 3-4029-0330, 17.3 KVA, MCD-100<br />

Programmable Controls<br />

(12) DRYER/HOPPERS<br />

2 – NOVATECH NOVADRIER MODEL M50, DRYERS, S/Ns 3A3837-1190 & 3A3450-1081 (2005), 150-Lb. Hopper,<br />

S/N 3A3837-6638 (2005), Vacuum Receiver, Bunting Magnetic Separator (Mach. #3)<br />

10 – NOVATECH NOVADRIER MODEL N-7 DRYERS/HOPPERS, S/Ns (4) NA,10A3373-1161, 3A3716-1354, 3A3716-1353,<br />

10A3319-1205, 3A3647-1235, 3A3716-1352, 20-Lb. Capacity Hopper, S/Ns 10A3207-6410, 10A3207-1097,<br />

10A3207-6411, 10A3375-6836, 3A3716-9858, 3A3716-9857, 10A3319-6685, 3A3647-9707, 3A3716-9856, (TO 2006),<br />

Vacuum Receiver, Bunting Magnetic Separator (Mach. #9, 12, 15, 17, 20, 21, 28)<br />

WITTMAN MODEL W433, 3-AXIS SERVO<br />

DRIVE GANTRY TYPE PARTS ROBOT<br />

2000<br />

MOTOMAN MODEL SUPER SV3X,<br />

6-AXIS CNC ROBOT TYPE YR-SV3-J12<br />

(16) ROBOTS<br />

5 – RANGER MODEL RT500S3, 3-AXIS GANTRY TYPE SERVO<br />

DRIVE PARTS ROBOTS, with Hand Pendant Controller,<br />

S/Ns R-11412 (2001) (Mach. #10), R-11409 (2001) (Mach. #11),<br />

R-11694 (2003) (Mach. #7), R-11413 (2001) (Mach. #5),<br />

R-11695 (2003) (Mach. #4)<br />

2 – RANGER MODEL RT200S3, 3-AXIS GANTRY TYPE SERVO<br />

DRIVE PARTS ROBOTS, with Hand Pendant Controller,<br />

S/Ns R-11693 (2003) (Mach. #12), R-11474 (2001) (Mach. #20)<br />

1 – RANGER MODEL RT100S3, 3-AXIS GANTRY TYPE SERVO<br />

DRIVE PARTS ROBOT, with Hand Pendant Controller,<br />

S/N R-11466 (2001) (Mach. #14)<br />

1 – WITTMAN MODEL W433, 3-AXIS SERVO DRIVE GANTRY<br />

TYPE PARTS ROBOT, S/N 5143 (1999) (Mach. #6), Travels:<br />

X – 500mm, Y – 1400mm, Z – 2500mm<br />

2 – RANGER MODEL SPR80, SPRUE-PICKER TYPE ROBOTS,<br />

S/Ns R-11493 (2002), R-11881 (2004), with Mitsubishi MEL SEC<br />

– FX2N-48MR PLC Control<br />

2 – RANGER MODEL SPR60, SPRUE-PICKER TYPE ROBOTS,<br />

S/Ns 11478 (2002) (Mach. #13), 11476 (2002) (Mach. #16)<br />

1 – STABULI UNIMATION TYPE RX130BL, 5-AXIS CNC ROBOT,<br />

S/N F03/5X5ZA1/A/01 (2003), 6 Kg Capacity, Pedestal Mounted<br />

on Steel Skid Base, StaBuli Type CS8 Controls<br />

1 – MOTOMAN MODEL SUPER SV3X, 6-AXIS CNC ROBOT<br />

TYPE YR-SV3-J12, S/N S9M649-1-2-1 (2000), 3 Kg Payload<br />

Capacity, with Yasnac XRC Type ECR-SV3-1300 Controller<br />

(Mounted Inside Automation Tool Co. Special Built Assembly<br />

Cell)<br />

1 – MOTOMAN MODEL SK16X, TYPE YR-SK1G-J02 6-AXIS CNC<br />

ROBOT, S/N RH9220-9088-8 (2000), 16 Kg Payload Capacity,<br />

with Yasnac XRC-SK16X Controller (M Automation Tool Co.<br />

Special Assembly Fixture Cell)<br />

6 For more information, visit us on the web @ www.hilcoind.com

BLENDERS • (51) TEMPERATURE CONTROLLERS • (13) HOT RUNNERS<br />

(1 OF 2) NOVATECH<br />

NOVADRIER M50 DRYERS<br />

2005 2006<br />

(1 OF 10) NOVATECH NOVADRIER<br />

N-7 DRYERS/HOPPERS<br />

(3 OF 5) AEC MODEL OS-007-4,<br />

OPTIMUM SERIES BLENDERS<br />

(1 OF 2) AEC NELMOR SX913,<br />

9” X 13” 3-HP GRANULATORS<br />

VIEW OF CINCINNATI MILACRON MFCL-75, TEMPERATURE CONTROLLERS<br />

VIEW OF HOT RUNNER TEMPERATURE CONTROLLERS<br />

(5) MATERIAL BLENDERS<br />

1 – AEC MODEL OS-007-4, OPTIMUM SERIES BLENDER, S/N 34G0855,<br />

Maximum Blending Capacity 450-Lbs./Hr., 4-Compartment Hopper, Load Cell<br />

Mounted Weigh Hoppers, Automatic Slide Gates, (1) Model SLC08 Autoloader<br />

Vacuum Loader, S/N 34G0856, (1) Model SLC02 Autoloader Vacuum Loader,<br />

S/N 34G0857 AEC Whitlock Series One Autoloader Controls, Portable Stand<br />

Mounted Allen Bradley Micro Logix 1500 PLC Control, with Panel View 550<br />

Touch Screen<br />

1 – AEC MODEL OS-007-4, OPTIMUM SERIES BLENDER, S/N 35F0955,<br />

Maximum Blending Capacity 450-Lbs./Hr., 2-Compartment Hopper, (1) Model<br />

SRC08 Vacuum Receiver, S/N 35G0577, (1) Model SR004 Vacuum Receiver,<br />

S/N 35G0579, Load Cell Mounted Weight Hopper, Automatic Slide Gates,<br />

Bunting Magnetic Separator, Allen Bradley Micro Logix 1500 PLC Controls, with<br />

Panel View 550 Touch Screen, Stationary Stand Mounted<br />

1 – AEC MODEL OS-007-4, OPTIMUM SERIES BLENDER, S/N 35F0954,<br />

Maximum Blending Capacity 450-Lbs./Hr., 2-Compartment Hopper, (1) Model<br />

SRC08 Vacuum Receiver, S/N 35G0575, (1) Model SRC004 Vacuum Receiver,<br />

S/N 35G0579, Load Cell Mounted Weigh Hoper, Automatic Slide Gates, Bunting<br />

Magnetic Separator, Allen Bradley Micro Logix 1500 PLC Control, with Panel<br />

View 550 Touch Screen, Stand Mounted<br />

1 – AEC MODEL OS-007-4, OPTIMUM SERIES BLENDER, S/N 34D0485,<br />

Maximum Blending Capacity 350-Lbs./Hr., 4-Compartment Hopper, Load Cell<br />

Mounted Weigh Hopper, Automatic Slide Gates, (1) Model SRC008 Vacuum<br />

Receiver, S/N 35G057, (1) Model SRC004 Vacuum Receiver, S/N 35G0581,<br />

Bunting Magnetic Separator, Allen Bradley Micro Logix 1500 PLC Controls, with<br />

Panel View 550 Touch Screen, Stand Mounted<br />

1 – AEC MODEL OS-007-4, OPTIMUM SERIES BLENDER, S/N 34D0486,<br />

Maximum Blending Capacity 350-Lbs./Hr., 4-Compartment Hopper, Load Cell<br />

Mounted Weigh Hopper, Automatic Slide Gates, (1) Model SLC04 Autoloader<br />

Vacuum Loader, S/N 34D0488, (1) Model SRC02 Vacuum Receiver,<br />

S/N 31E0324, Bunting Magnetic Separator, Allen Bradley Micro Logix 1500 PLC<br />

Controls, with Panel View 550 Touch Screen, Portable Stand Mounted<br />

PLASTIC GRANULATORS<br />

2 – AEC NELMOR MODEL SX913, 9” X 13” 3-HP GRANULATORS,<br />

S/N E2-913-01002, E2-913-01003<br />

(51) TEMPERATURE CONTROLLERS<br />

1 – TEMPTEK MODEL VTO-2100C, HOT OIL TEMPERATURE CONTROLLER, S/N 96027 (2006),<br />

Oil Media, Digital Readout<br />

1 – ADVANTAGE REGAL MODEL RK-1230HC-41D3, HOT OIL TEMPERATURE CONTROLLER,<br />

S/N 91101 (2006), Oil Media Programmable Controls<br />

9 – ADVANTAGE SENTRA “LE” SERIES MODEL SK-1080ZLE-41D1, TEMPERATURE CONTROLLERS,<br />

S/Ns 92451, 92445, 92449, 92447, 92450, 92448, 924443, 924452, 92440 (ALL 2005), Water Media<br />

Programmable Controls<br />

9 – ADVANTAGE SENTRA “LE” SERIES MODEL SK-1075LEZ-41D1, TEMPERATURE CONTROLLERS,<br />

S/Ns 91349 (2004), 92464, 92458, 92461, 92459, 92463, 9246, 92460, 92457 (ALL 2005)<br />

2 – ADVANTAGE SENTRA “LE” SERIES MODEL SK-2490LE-11D1, TEMPERATURE CONTROLLERS,<br />

S/Ns 91858, 91857 (BOTH 2005) Water Media<br />

27 – CINCINNATI MILACRON MODEL MFCL-75, TEMPERATURE CONTROLLERS, S/Ns 3931A04-98-9,<br />

3931A04-98-77, 3931A04-98-97, 3931A04-98-92, 3931A04-98-99, 3931A04-98-116, 3931A04-98-112,<br />

3931A04-98-105, 3931A04-98-106, 3931A04-98-117, 3931A04-98-98, 3931A04-98-96, 3931A04-98-104,<br />

3931A04-98-113, 3931A04-98-95, 3931A04-98-80 3931A04-98-89, 3931A04-98-76, 3931A04-98-110,<br />

3931A04-98-85, 3931A04-98-103, 3931A04-98-88, 3931A04-98-114, 3931A04-98-91, 3931A04-98-107<br />

(ALL 1998), 3931A04-02-51 & 3931A04-02-52 (BOTH 2002), Programmable Controls, Water Media,<br />

Temperature Range 30 – 250 Degree Fahrenheit, 10 Kw Heater<br />

2 – AEC MODEL TCU300, TEMPERATURE CONTROLLERS, S/Ns 31D5596, 31B5579<br />

(13) HOT RUNNER TEMPERATURE CONTROLLERS<br />

5 – MOLDFLOW ALTANIUM C-SERIES MICROPROCESSOR CONTROLLED HOT-RUNNER<br />

TEMPERATURE CONTROLLERS, (3) Model CX24, 15 KVA, S/Ns 260360, 260359, 260361, (1) Model<br />

CX35, 35 KVA, S/N 260363, (1) Model CX36, 35 KVA, S/N 260362<br />

2 – 6-ZONE ELECTRIC HOT RUNNER TEMPERATURE CONTROLLERS, with Allen Bradley 1606-XL Power<br />

Supply (Mach. #10 & 11 Fixed)<br />

4 – PORTABLE 6-ZONE ELECTRIC HOT RUNNER TEMPERATURE CONTROLLERS, with 3 KVA<br />

Transformer (Mach. #03, 06, 02, NA)<br />

1 – PORTABLE 6-ZONE ELECTRIC HOT RUNNER TEMPERATURE CONTROLLER, with 3 KVA Transformer<br />

(Mach. #06)<br />

1 – PORTABLE 8-ZONE ELECTRIC HOT RUNNER TEMPERATURE CONTROLLER, with 7.5 KVA<br />

Transformer (Mach. #NA)<br />

1 – AQUA DYNAMICS PORTABLE 2-ZONE ELECTRIC HOT RUNNER TEMPERATURE CONTROLLER,<br />

S/N 0B407, with 3 KVA Transformer (Mach. #07)<br />

Real Estate is being offered at auction. Please see page 11 of this brochure.<br />

To schedule an auction, please contact us at 248.254.9999 7

HOT PLATE & VIBRATION WELDING MACHINES • METALIZERS • OVENS<br />

(2 OF 3) BRANSON MODEL HH24A,<br />

4-POST HOT PLATE WELDING PRESSES<br />

BRANSON VW90-6STD,<br />

2-POST VERTICAL VIBRATION<br />

WELDING PRESS<br />

CASSO-SOLAR HD4E-913-9IDIIG,<br />

DOUBLE DOOR DRIVE-IN<br />

ELECTRIC TEMPERING OVEN<br />

2002 1998<br />

CASSO-SOLAR MODEL EC-606-6,<br />

2-DOOR ELECTRIC TEMPERING OVEN<br />

(1 OF 2) GALILEO VERTICAL ALUMINUM VACUUM METALIZER<br />

ULTRASONIC PLASTIC WELDERS<br />

1 – BRANSON 900 SERIES MODEL 920iw & ULTRASONIC WELDER, S/N NA, Programmable Controls<br />

1 – BRANSON MODEL 8400, ULTRASONIC WELDER, S/N WT80016<br />

2 & 4 POST PLASTIC HOT PLATE & VIBRATION<br />

WELDING ASSEMBLY MACHINES<br />

3 – BRANSON MODEL HH24A, 4-POST HOT PLATE WELDING PRESSES, S/Ns 98R339380-3,<br />

98R339380-1, 98R339380-2, 46”LR x 25”FB Working Bed Size, Allen Bradley SLC5/03 PLC, with<br />

Quick Panel Jr Touch Screen, STi Micro Safe Light Curtain 19” x 20” Hydraulic Advance Rear Platen,<br />

1 – BRANSON MODEL VW90-6STD, 2-POST VERTICAL VIBRATION WELDING PRESS,<br />

S/N 96DVW6-133060, Allen Bradley SLC 500 PLC, with Comm Programming Pad Commander CDE<br />

Inverter Power Supply<br />

1 – BRANSON MODEL VW-6NH, 2-POST VIBRATION PLASTICS WELDING MACHINE,<br />

S/N 00R412529, Branson Programmable Controls, Light Curtain<br />

1 – BRANSON HY-LINE VIBRATION WELDER, S/N NA, Xycom Programmable Controls<br />

1 – FORWARD TECHNOLOGY SPECIAL 2-POST VIBRATION PLASTICS WELDING MACHINE,<br />

Xycom PLC Controls, Sti Mini Safe Light Curtain<br />

2 – BRANSON MODEL S-O TAIL LAMP SPECIAL PLASTIC WELDING MACHINES, S/N SS-339381,<br />

SS-439381, with (3) (Total) Model 921, Ultrasonic Welding Heads, (6) Model 900M Controllers<br />

(Partial – Not Complete)<br />

PLASTIC MATERIAL CONVEYING EQUIPMENT<br />

1 – SOGEVAC MODEL SV300-95031, 10-HP VACUUM CONVEYING SYSTEM VACUUM PUMP,<br />

S/N 300001926502 (2005)<br />

5 – CINCINNATI MILACRON MODEL CML-VLS-500, 5-HP VACUUM CONVEYING PUMPS,<br />

S/N 3934A01-99-60, 3934A01-99-62, 3934A01-99-59, 3934A01-99-61 (ALL 1999), 3934A01-98-26<br />

(1998), with Canister Filter<br />

1 – AEC WHITLOCK MODEL VTTV-3.5, 3.5-HP VACUUM CONVEYING SYSTEM POWER UNIT, S/N 31E0312<br />

1 – CINCINNATI MILACRON VACUUM CONVEYING SYSTEM CANISTER FILTER, S/N NA, 20”<br />

Diameter x 28” High<br />

4 – CINCINNATI MILACRON 24-STATION PROGRAMMABLE VACUUM CONVEYING SYSTEM<br />

CONTROL PANELS, (3) Pump Capacity<br />

1 – AEC WHITLOCK MODEL VTC18L3, 18-STATION PROGRAMMABLE VACUUM CONVEYING VT<br />

CONTROL PANEL, S/N 31E0311, GE Fanuc Series 90 – 30 PLC Control<br />

1 – ASSORTMENT OF 2” ALUMINUM CONVEYING DELIVERY PIPE<br />

BELT CONVEYORS<br />

1 – ROACH 18” X 17’ PORTABLE POWER BELT CONVEYOR, Variable Speed Motor Drive<br />

1 – MFG’R NA 20” X 15’ PORTABLE POWER BELT CONVEYOR, with Variable Speed Motor Drive<br />

1 – MFG’R NA 20” X 15’ PORTABLE POWER BELT CONVEYOR, with 12” x 80” Upper Belt Conveyor<br />

1 – ROACH 24” X 8” PORTABLE POWER BELT CONVEYOR, S/N 325843<br />

1 – PLASTIC PROCESS EQUIPMENT MODEL PC247USMS, 24” X 7’ PORTABLE POWER BELT<br />

CONVEYOR, Variable Speed Control<br />

1 – 36” X 7-1/2’ PORTABLE POWER BELT CONVEYOR<br />

1 – ROACH 24” X 16’ STATIONARY POWER BELT CONVEYOR, 8’ High Stand, with Inclined Down<br />

Discharge (Press #10)<br />

2 – ROACH 12” X 10’ PORTABLE POWER BELT CONVEYORS (Press #11)<br />

STOKES AUTOMAT-D HORIZONTAL ALUMINUM VACUUM METALIZER<br />

PROCESS WATER COOLING EQUIPMENT<br />

2 – CINCINNATI MILACRON MODEL CMPTS-1250-3P-FF, PROCESS WATER COOL-<br />

ING SYSTEMS, S/Ns 3932A03-98-5A & 3932A03-98-4A (BOTH 1998), 72” x 60” x<br />

72” Open Top Holding Tank, (2) 30-HP & (1) 10-HP Process Pumps, Canister Type<br />

Filtration Unit, Water Softening System Cincinnati Milacron PTS Pump Tank Station<br />

Programmable Controls (Cooling Tower #2, 3)<br />

1 – CINCINNATI MILACRON MODEL PTS-800-2P-FF-SP, PROCESS WATER COOL-<br />

ING & RECIRCULATION UNIT, S/N 3941A01-91-2 (1991), 40” x 72” x 72” High<br />

Holding Tank, (2) 30-HP & (1) 10-HP Process Pumps, PEP Flow-Max Cartridge Filter,<br />

Water Softening System, PTS Programmable Controls (Cooling Tower #1)<br />

2 – MARLEY AQUA TOWER WATER COOLING TOWERS, S/N NA,<br />

Stand Mounted, Outside (Cooling Tower #1, 2, 3)<br />

VACUUM METALIZERS<br />

1 – GALILEO VERTICAL ALUMINUM VACUUM METALIZER, S/N NA, 48” Diameter x 48” High<br />

Chamber, Dual Loading Chamber Configuration, Including: (1) Dehumidifying System (Roof<br />

Mounted), (1) Polycold Model P-550-HC Cryogenic Refrigeration Unit, S/N 55974 (1998), (1)<br />

Edwards Model E2M40, 2-Stage High Vacuum Pump, S/N 8521F, (1) Varian Diffusion Pump,<br />

(1) Aerzan Type AMUSA-GMA-13.F7-V-00 15-HP Vacuum Pump, S/N 829941 (2005), with<br />

Allen Bradley Power Flex Drive, (1) Kinney Model KT 300 High Vacuum Pump, S/N<br />

119580604, 15-HP, (1) Automated Vacuum System Control Console, with Allen Bradley SLC<br />

5/03 PLC & Panel View Plus 1000 Touch Screen Controls, (1) IMS True Ton Model 300 AC<br />

Water Chiller, S/N 5385 (Metalizer #1)<br />

1 – GALILEO VERTICAL ALUMINUM VACUUM METALIZER, S/N NA, 48” Diameter x 48” High<br />

Chamber, Dual Loading Chamber Configuration, Including: (1) Dehumidifying System (Roof<br />

Mounted), (1) Polycold Model P-550-HC Cryogenic Refrigeration Unit, S/N 551179 (1999),<br />

(1) Edwards Model E2M40, 2-Stage High Vacuum Pump, S/N 8194, (1) Varian Diffusion<br />

Pump, (1) Kinney KT-300C Triplex 15-HP Vacuum Pump, (1) Automated Vacuum System<br />

Control Console, with Allen Bradley SLC 5/03 PLC & Panel View Plus 1000 Touch Screen<br />

Controls, (1) AEC Model TDWF-7M09S4, Water Chiller, S/N 95C5409 (Metalizer #2)<br />

(Metalizer’s Number 1 & 2 commonly housed in Approximately 27’ x 60’ Modular Building<br />

Structure, Set-Up as R & L Side Mirror Image, Center Roller Conveyor System, with Parts<br />

Exit/Entrance Windows)<br />

1 – STOKES AUTOMAT-D HORIZONTAL ALUMINUM VACUUM METALIZER, S/N NA,<br />

Chamber Size 72” Diameter x 72”, Including: (1) Automated Vacuum Systems Control<br />

Console, with Inficon XTC/2 Programmable Controller & Allen Bradley Panel View 900 PLC<br />

Touch Screen, (2) Stokes 20-HP Vacuum Pumps, (1) Edwards Model E2M40, 2-Stage High<br />

Vacuum Pump, S/N 8159, (1) Polycold Model PFC-1100ST Cryogenic Refrigeration Unit, S/N<br />

96535 (1995), Temperature Range – 100 to – 140 Degree C, (1) Varian Diffusion Pump, (1)<br />

IMS True Ton Model 300AC Water Chiller, S/N 96535 (1995), (1) Milacron Model MCW-5<br />

Glycol-Water Chiller, S/N 3932A01-01-01-8 (2001), (1) Bry-Air Model VFB-18-G <strong>Industrial</strong><br />

Dehumidifying System, S/N 2004G7553, (2) 60” Diameter x 72” Workpiece Rotary Carriers,<br />

(1) Gorbel 1/2-Ton Overhead Hoist Loading System, (1) Modular Structure Enclosure<br />

(Metalizer #3)<br />

TEMPERING OVENS<br />

1 – CASSO-SOLAR MODEL HD4E-913-9IDIIG, DOUBLE DOOR DRIVE-IN ELECTRIC TEMPER-<br />

ING OVEN, S/N 14708 (2002), Double End Doors, Interior Dimensions 110” Wide x 150” Deep x<br />

108” High, Overall Dimensions 126” Wide x 14’ Deep x 10-1/2’ High Plus Approximately 4’<br />

Recirculating Blower Fan Housing Honeywell Digital Temperature Controls<br />

1 – CASSO-SOLAR MODEL EC-606-6, 2-DOOR ELECTRIC TEMPERING OVEN, S/N 12372<br />

(1998), Interior Dimensions 78” Wide x 70” Deep x 69” High, Cart Track Wells, Honeywell<br />

Digital Temperature Controls<br />

8 – (5) TIER METAL PARTS CARTS<br />

8 For more information, visit us on the web @ www.hilcoind.com

MILLS • LATHES • GRINDERS • EDM • AIR COMPRESSORS<br />

2001<br />

2001<br />

REPUBLIC-LAGUN LAGUNMATIC 320<br />

CNC VERTICAL MILLING MACHINE<br />

BRIDGEPORT 1-1/2-HP<br />

VARIABLE SPEED VERTICAL<br />

MILLING MACHINE<br />

ALZMETAL MODEL AB457S,<br />

24” GEARED HEAD DRILL<br />

OKAMOTO MODEL LINEAR<br />

L-6.12B 6” X 12” HAND FEED<br />

SURFACE GRINDER<br />

ELOX MODEL ROYALE, RAM TYPE<br />

ELECTRICAL DISCHARGE MACHINE<br />

2001<br />

CLAUSING-METOSA MODEL C1745SS,<br />

GEARED HEAD ENGINE LATHE<br />

VIEW OF KAESER CSD75, 75-HP & BS61,<br />

50-HP ROTARY SCREW AIR COMPRESSORS<br />

CHEVALIER MODEL FSG-1632AD, 16” X 32”<br />

AUTOMATIC HYDRAULIC SURFACE GRINDER<br />

TO 2004<br />

2002<br />

INGERSOLL RAND TMS-0950,<br />

REFRIGERATED<br />

COMPRESSED AIR DRYER<br />

CNC MILLING MACHINES<br />

1 – REPUBLIC-LAGUN LAGUNMATIC 320 CNC VERTICAL MILLING MACHINE, S/N 26619 (1991), 11” x 58” Table, Delta<br />

Dynapath 20 CNC Controls, Renishaw M15 Machine Interface<br />

1 – DECKEL MODEL FP4NC, UNIVERSAL VERTICAL CNC MILLING MACHINE, S/N 2810-3275, (21) Spindle Speeds<br />

31.5 – 3150 RPM, Travels: X – 22”, Y – 18”, Z – 18”, 17” x 27” T-Slotted Universal Table, 3” Quill Stroke, ST40 Spindle<br />

Taper, Power Drawbar, Deckel Dialogsteverung, (2) 4-Axis CNC Controls<br />

VERTICAL MILLING MACHINES<br />

1 – BRIDGEPORT 1-1/2-HP VARIABLE SPEED VERTICAL MILLING MACHINE, S/N 12BR-152131, Spindle Speeds<br />

60 – 4200 RPM, Table Size 9” x 48”, Servo Type 150 Power Table Feed, Newall Topaz 2-Axis Readout<br />

1 – BRIDGEPORT 1-1/2-HP VARIABLE SPEED VERTICAL MILLING MACHINE, S/N 12BR-168914, Spindle Speeds<br />

60 – 4200 RPM, Table Size 9” x 42”, Dynamic Research 2-Axis Readout<br />

TOOLROOM LATHES<br />

1 – CLAUSING-METOSA MODEL C1745SS, GEARED HEAD ENGINE LATHE, S/N 40325 (2001), (12) Spindle Speeds<br />

40 – 2200 RPM, Quick Change Threading, 2” Hole-Thru-Spindle, Newall Topaz 2-Axis Readout, Coolant, 10” 3-Jaw<br />

Chuck, Follow Rest<br />

1 – TURNMASTER MODEL 17.5, 17” X 60” GEARED HEAD ENGINE LATHE, S/N 1991032, (16) Spindle Speeds<br />

35 – 2000 RPM, Quick Change Threading, Taper Attachment, Acu-Rite III Readout, 3-Jaw Chuck, 5-C Collet Drawbar<br />

1 – ROCKWELL 10” X 36” ENGINE LATHE, S/N NA, Quick Change Threading, 6” 3-Jaw & 8” 4-Jaw Chucks, 7” Faceplate,<br />

5-C Collet Drawbar, Cabinet Base<br />

SURFACE GRINDERS<br />

1 – CHEVALIER MODEL FSG-1632AD, 16” X 32” AUTOMATIC HYDRAULIC<br />

SURFACE GRINDER, S/N G3798003 (1994), 16” x 32” Electromagnetic Chuck,<br />

Auto-Cycle Controls, Incremental Feeds, Overhead Dresser, External Coolant<br />

Unit, Sokki 2-Axis Readout<br />

1 – OKAMOTO MODEL LINEAR L-6.12B 6” X 12” HAND FEED SURFACE<br />

GRINDER, S/N 62159 (2001),Electromagnetic Chuck, with Walker Variable<br />

Control, Acu-Rite 2-Axis Readout<br />

1 – BOYAR SCHULTZ MODEL H612, CHALLENGER 6” X 12” HAND FEED<br />

SURFACE GRINDER, S/N 23954, Electromagnetic Chuck<br />

DRILLS<br />

1 – ALZMETAL MODEL AB457S, 24” GEARED HEAD DRILL, S/N 1889, (1991),<br />

(8) Spindle Speeds 35 – 920 RPM, 8” Column, 22” x 18” Adjustable Table<br />

1 – CINCINNATI BICKFORD 5’ ARM X 9” COLUMN RADIAL DRILL, S/N 1R5613,<br />

(9) Spindle Speeds 100 – 2000 RPM<br />

1 – POWERMATIC MODEL 1200, 20” VARIABLE SPEED DRILL PRESS, S/N NA<br />

SAWS<br />

1 – POWERMATIC MODEL 87, 18” VERTICAL BANDSAW, S/N 987612, Blade<br />

Speeds 37 – 4500 FPM, Blade Welder/Grinder<br />

1 – KYSOR-JOHNSON MODEL J, 10” HORIZONTAL METAL CUTTING<br />

BANDSAW, S/N J-147786<br />

ELECTRICAL DISCHARGE MACHINE<br />

1 – ELOX MODEL ROYALE, RAM TYPE ELECTRICAL DISCHARGE MACHINE,<br />

S/N 063505 (2001), Table Size 20” x 12”, Work Tank Size 32” x 28” x 14”, Xermac<br />

FX-100 Power Supply, System 3R Rotary Work Head, Fagor3-Axis<br />

Programmable Readout, Self-Contained Dielectric Fluid System<br />

LAB & QUALITY CONTROL EQUIPMENT<br />

1 – TINIUS OLSEN MODEL MP987, EXTRUSION PLASTO-METER<br />

(MELT INDEXER), S/N 167500<br />

1 – OMNI MARK MARK-2 HIGH PERFORMANCE DIGITAL PROGRAMMABLE<br />

MOISTURE ANALYZER, S/N NA<br />

1 – SORENSON MODEL DCR40-35A, DC POWER SUPPLY<br />

1 – CRS TOOL MARK-10 PULL TEST FIXTURE, with EG Digital Indicator<br />

1 – WAAGE ELECTRIC MODEL WP4A, 600-WATT ELECTRIC SEAL-PEEL<br />

MELTING POT<br />

1 – OAKTON STABLE TEMP BENCH TOP ELECTRIC LAB OVEN, S/N NA,<br />

12” x 10” x 10”<br />

1 – MITUTOYO NO. 192-672, 0 – 24” DIGITAL HEIGHT GAUGE<br />

1 – BK PRECISION 1760 TRIPLE OUTPUT AC POWER SUPPLY<br />

1 – QUALITY FIRST SYSTEMS MODEL C12001, CALIBRATION BOX<br />

1 – WILSON MODEL 4 OUS, ROCKWELL HARDNESSTESTER, S/N 399<br />

1 – 24” X 36” X 6” BLACK GRANITE SURFACE PLATE<br />

1 – SORENSON DCR 40-40B2, DC POWER SUPPLY<br />

Calipers, Micrometers, Digital Indicators, Dial Indicator Clamps, Force Gages, Dial<br />

Torque Wrenches, Micrometer Torque Wrenches, (3) Ames Hand-Held Hardness<br />

Testers, Height Gauges, Dial Indicators, Pin Gages, Starrett Bench Micrometer,<br />

Scales<br />

AIR COMPRESSORS & DRYERS<br />

1 – KAESER MODEL CSD75, 75-HP ROTARY SCREW AIR COMPRESSOR,<br />

S/N 1036 (2004), 361 CFM, 125 PSIG, Air Cooled, Sound Enclosure Panels,<br />

Programmable Controls<br />

2 – KAESER MODEL BS61, 50-HP ROTARY SCREW AIR COMPRESSORS,<br />

S/Ns 1001 & 5103477 (BOTH 1998), 225 CFM, 125 PSIG, Air Cooled,<br />

Programmable Controls, Sound Enclosure Panels<br />

1 – 10-HP HORIZONTAL TANK TWO-STAGE AIR COMPRESSOR, Speedaire<br />

Compressor Head, Western Tank & Steel Tank<br />

1 – INGERSOLL RAND MODEL TMS-0950, REFRIGERATED COMPRESSED AIR<br />

DRYER, S/N TMS0950-02-08-04 (2002)<br />

1 – KAESER MODEL DRD250, REFRIGERATED COMPRESSED AIR DRYER,<br />

S/N PR250A-2A-9802-26K (1998)<br />

2 – VERTICAL COMPRESSED AIR RECEIVER TANKS, 36” Diameterx 7’ High<br />

To schedule an auction, please contact us at 248.254.9999 9

DIE HANDLER • FORKLIFTS • MISC. SHOP, FACTORY & OFFICE<br />

BRIDGE CRANE<br />

1 – MID-SOUTH CRANE 7-1/2-TON X 40’ SPAN TOP RIDING DOUBLE<br />

GIRDER BRIDGE CRANE, Shaw Box 7-1/2-Ton Top Riding Cable Hoist,<br />

2-Speed Controls, 6-Way Radio Controls, with 140’ Free-Standing Support<br />

Runway<br />

DIE HANDLER<br />

1 – RICO MODEL PLRDHFP800E, 80,000-LB. CAPACITY DIE HANDLER,<br />

S/N R11130 (1997), 457-Hrs. with Battery & Charger<br />

FORKLIFTS<br />

1 – HYSTER MODEL S155XLZ, 15,000-LB CAPACITY FORKLIFT,<br />

S/N B024D05711V (1998), LPG, Solid Tires, 131.5” Lift, 2-Stage Mast,<br />

106” Mast Height, 2-Speed Automatic, Side Shift 60” Forks, 2,300-Hrs.<br />

1 – HYSTER MODEL S50XM, 4,950-LB CAPACITY FORKLIFT,<br />

S/N D187V15062W (2000), LPG, Solid Tires, 189” Lift, 3-Stage Mast, Side<br />

Shift 42” Forks<br />

1 – HYSTER MODEL S50XM, 4,950-LB CAPACITY FORKLIFT,<br />

S/N D187V15013W (2000), SPG, Solid Tires, 189” Lift, Side Shift,<br />

(Not In Service)<br />

FLOOR SCRUBBER<br />

1 – TENNANT MODEL 5700, BATTERY POWERED WALK BEHIND FLOOR<br />

SCRUBBER, S/N NA, with Charger<br />

MATERIAL HANDLING &<br />

WAREHOUSE EQUIPMENT<br />

1 – INFRA PAK MODEL SPRITE, SEMI-AUTOMATIC PALLET SHRINK<br />

WRAP MACHINE, S/N 791003, 60” Vertical<br />

1 – WEIGH-TRONIX MODEL DSL-4848-05, 5000-LB X 48” X 48”<br />

ELECTRONIC PLATFORM SCALE, S/N 25886<br />

1 – TOLEDO MODEL 2191, 2600-LB CAPACITY MECHANICAL PLATFORM<br />

SCALE, S/N 593863, Dial Face, In-Ground Platform, 48” x 48” Platform<br />

2 – TERAOKO PORTABLE ELECTRONIC SCALE SET-UPS, with<br />

(2) S-X 50-Lb., Capacity 11” x 16” Digital Weighing Platforms,<br />

S/Ns 00214402, 00222144, 01225815, 01223955, (1) Model DC-190<br />

Programmable Readout, Cart Mounted<br />

1 – PLASTIC PROCESS EQUIPMENT PNEUMATIC POWERED GAYLORD<br />

CARTON TIPPER, S/N NA<br />

1 – PRESTO MODEL C-74, 1000-LB CAPACITY HYDRAULIC LIFT CART,<br />

S/N XP00278-1, 84” Lift, 12-Volt, 24” Forks<br />

164 – SECTIONS INTERACK, USP, OTHERS ADJUSTABLE PALLET<br />

RACKING, from 9’ Wide x 42” Deep – 16’ to 20’ High, 3 & 4 Tier, Wire Mesh<br />

Shelf Decks<br />

23 – SECTIONS INTERACK, USP, OTHERS ADJUSTABLE PALLET<br />

RACKING, from 9’ Wide x 42” Deep – 24’ High<br />

5 – 24”W X 48” X 65” HIGH PORTABLE FLOW-RACK CARTS,<br />

Aluminum, 2 & 3 Tier<br />

14 – HYDRAULIC PALLET JACKS<br />

6 – RUBBERMAID 1 CUBIC YARD POLY PORTABLE TRASH HOPPERS<br />

18 – EUROKRAFT 30” X 60” 4-WHEEL SHOP TRUCKS, with Wood Deck<br />

& Removable Sides/Handles, Plus (5-Brand New In Box)<br />

9 – EUROKRAFT 24” X 48” 4-WHEEL SHOP TRUCKS, with Wood Deck<br />

& Removable Sides/Handles<br />

10 – RUBBERMAID 2/3 LEVEL PLASTIC SHOP CARTS<br />

APPROX. 896 – PLUS STACKABLE PLASTIC PARTS TOTE PANS,<br />

22” x 22” x 10”<br />

APPROX. 1,640 – PLUS STACKABLE PLASTIC PARTS TOTE PANS,<br />

22” X 22” X 8”<br />

APPROXIMATELY 276 – PLUS STACKABLE PLASTIC PARTS TOTE PANS<br />

QUANTITY ASSORTED SIZE LAMINATE CARDBOARD TOTE BOXES<br />

APPROXIMATELY 125 - 32” X 32” X 30” COLLAPSIBLE SIDE STACKABLE<br />

COMPOSITE PLASTIC SKID BOXES<br />

MISCELLANEOUS DUNNAGE INCLUDING: Plastic Shipping Pallets, Plastic<br />

Tote Pans, Styrofoam Packing Forms, Laminated Cardboard Containers, etc.<br />

2 Wheel Hand Carts, 2 Wheel Barrel Carts, Adjustable Racking, Metal Shelving,<br />

Parts Shelving, Nut & Bolt Cabinets, Fastener Cabinets, with Drawers,<br />

(4) 2-Door Flammables Storage Cabinets<br />

ASSEMBLY MACHINERY<br />

5 – NORDSON MODEL 506, BULK MELTER APPLICATORS,<br />

S/N AN96L22075 (#1), AN99M31308 (#3), AN00J00021 (#5),<br />

AN97D21871 (#4), AN99C32390 (#6)<br />

1 – SPECIAL BUILT 2-STATION TAIL LIGHT ASSEMBLY MACHINE,<br />

Allen Bradley SLC 5/04 PLC, with Panel View 600 Programming Screen,<br />

(2) Sti Light Curtains<br />

1 – SPECIAL BUILT 2-STATION TAIL LAMP HEAT STAKE & ASSEMBLY<br />

PATH CUT MACHINE, Allen Bradley SLC 5/04 PLC, with Panel View 600<br />

Programming Screen, (2) Guard Star B Series Light Curtains, Special Tail<br />

Lamp Stud Installer<br />

1 – HACKETT PRECISION SPECIAL BUILT S5S AUTOMATIC TAIL LAMP<br />

ASSEMBLY LINE, Allen Bradley PLC Controls, with Panel View 900<br />

Programming Screen<br />

QUANTITY OF SPECIAL & CUSTOM BUILT TAIL LAMP ASSEMBLY<br />

MACHINES, INCLUDING: Screw Applicators, Gluing/Sealing Machines,<br />

Riveting Stations, Assembly Machines, etc.<br />

RICO MODEL PLRDHFP800E,<br />

80,000-LB. CAPACITY DIE HANDLER<br />

1997<br />

VIEW OF SECTIONS INTERACK, USP, & OTHERS<br />

ADJUSTABLE PALLET RACKING<br />

1998<br />

HYSTER MODEL S155XLZ,<br />

15,000-LB CAPACITY FORKLIFT<br />

VIEW OF HYDRAULIC PALLET JACKS<br />

MISCELLANEOUS MACHINES SHOP & FACTORY<br />

1 – DECKEL MODEL SOE, SINGLE LIP TOOL GRINDER, S/N 90-7450<br />

1 – TENNSMITH MODEL U4816, 48” X 16 GAUGE MANUAL FINGER-TYPE BENDING BRAKE, S/N 15056<br />

1 – MOTION INDUSTRIES 10-HP PORTABLE HYDRAULIC POWER SUPPLY, S/N 4193, 3000 PSI, 4 GPM, 10<br />

Gallon, with Control Valve & Coupler Hose<br />

1 – MILLER MILLERMATIC 250 DC WIRE FEED WELDER, S/N LA135095<br />

1 – MILLER MODEL 330A/BPLA, AC-DC GAS TUNGSTEN – ARC WELDING MACHINE, S/N HJ198984, Water<br />

Cooler, Foot Pedal, Tig Leads<br />

1 – BOYAR SCHULTZ CABINET TYPE DUST COLLECTOR, S/N FR-5953-H<br />

1 – CUSTOM H-FRAME HYDRAULIC SHOP PRESS, Hand Pump<br />

1 – DEWALT MODEL DW874, 12” ABRASIVE CUT-OFF SAW, S/N NA<br />

8 – BALDOR NO. 332B, 3/4-HP DOUBLE END BUFFERS, Pedestal Base<br />

1 – MILACRON MODEL MCW-5 PORTABLE WATER CHILLER, S/N 3932A01-01-7 (2001)<br />

1 – INDUSTRIAL EQUIPMENT PORTABLE OIL PUMP/CARTRIDGE FILTRATION UNIT, S/N NA<br />

1 – BRUTE PORTABLE PRESSURE WASHER, S/N NA, Cold Water, 2500 PSI, 2.0 GPM, Briggs & Stratton 6.5-HP<br />

Gas Engine<br />

1 – LISTA 20” WIDE X 36” HIGH 6-DRAWER PORTABLE TOOL CABINET<br />

1 – JOBOX MODEL 671990R2, 60” X 30” X 36” 2-DOOR PORTABLE TOOL LOCKER<br />

1 – JOBOX MODEL 690990R1, 60” X 24” X 60” 2-DOOR PORTABLE TOOL LOCKER<br />

1 – ROUSSEAU 48” WIDE X 60” HIGH 10-DRAWER TOOL CABINET<br />

1 – 32” WIDE X 32” HIGH 6-DRAWER TOOL CABINET, with 72” Hardwood Workbench Top<br />

1 – 72” HARDWOOD WORK BENCH TOP, with (2) Sliding Door Storage Units<br />

2 – LISTA 72” HARDWOOD TOP BENCH, with 22” 5-Drawer Cabinet & 2-Drawer Plus Locker Cabinet<br />

Graco Pneumatic Grease Pump, Milwaukee Mag-Drill, Drill Indexes, Shop Vac’s, Double End Grinders, Manual &<br />

Hydraulic Adjustable Portable Die Lift Tables, Pedestal Shop Fans, Chain Slings, Eyebolts, Swivel Eyebolts, Rotary<br />

Table, Machine Vises, Bench Vises, Lathe & Mill Tool Accessories, Large Quantity Stockroom/Crib Supplies, with<br />

Machine Repair Parts, Electrical, Hydraulics & Pneumatics, Fasteners, Fittings, Plumbing, etc.<br />

LUNCHROOM FURNISHINGS<br />

31 – 24” X 48” LUNCHROOM TABLES, with (2) Bench Seats<br />

17 – 18-COMPARTMENT LOCKERS, Compartment Size 10” x 10” x 10”<br />

1 – HOSHIZAKI MODEL DM-180A, COMMERCIAL ICE DISPENSER, S/N R02045C<br />

OFFICES<br />

1 – LOT – QUANTITY OF OFFICE FURNISHINGS INCLUDING: Office Cubicle Workstations, Office Sets, Chairs,<br />

Conference Tables, File Cabinets, Desks, Folding Leg Tables, Folding Metal Chairs, etc.<br />

A Buyer’s Premium of 12.5% for All On-Site Sales<br />

and 15% for All Webcast Sales Will Be In Effect.<br />

For Complete Terms & Conditions Please Visit<br />

www.hilcoind.com<br />

10 For more information, visit us on the web @ www.hilcoind.com

REAL ESTATE TO BE OFFERED AT <strong>AUCTION</strong><br />

BIDDING WILL BEGIN AT 1PM LOCAL TIME THE DAY OF THE SALE<br />

ADDRESS:<br />

640 Mulberry Avenue • Selmer, TN 38375<br />

SIZE:<br />

Approximately 118,500 Square Feet on 15 Acres<br />

DIMENSIONS:<br />

Approximately 609’ x 252’ (irregular)<br />

NUMBER OF BUILDINGS:<br />

One (1) Main Building and<br />

One (1) Small Storage Structure<br />

CONSTRUCTION DATE(S):<br />

Original Structure Constructed in 1959.<br />

The Facility Has Been Expanded Three (3) Times,<br />

in 1970, 1991, and 2001. The Final Expansion Added<br />

60,000 Sq. Ft. to the Building.<br />

COMPOSITION:<br />

Walls: Metal Panel with Masonry and Brick<br />

Floors: 9” Reinforced Concrete Floors<br />

CLEAR HEIGHTS:<br />

24-30’ Clearance in Manufacturing Spaces with<br />

8-10’ Clearance in Maintenance and Office Areas.<br />

TRUCK LOADING:<br />

The Facility Has Five (5) Dock Doors and<br />

Three (3) Drive-In Doors<br />

UTILITIES:<br />

3 Phase Electrical Power with 12,470 Volt<br />

Natural Gas, Sewer and Water<br />

OFFICES:<br />

Approximately 23,000 Sq. Ft. of Demised Office<br />

Area Exists in the Original Portion of the Building<br />

TRANSFORMERS & BRIDGE CRANE (STAY WITH THE BUILDING)<br />

1 – COOPER 3 TRANSFORMER 3000 KVA, S/N 986000689, Cat. No. 0063WA69W18A, HV: 12470GY/7200X24940GY/14400, LV: 480Y/277<br />

1 – HOWARD INDUSTRIES 500KVA NON – PCB TRANSFORMER, S/N 1262860991, Single Phase Transformer, HV: 14400/24940Y, LV: 277/480Y<br />

1 – 10-TON OVERHEAD BRIDGE CRANE<br />

All information is from the Seller and/or other resources deemed reliable and has not been independently verified. No representation, warranty or guarantee, expressed or implied<br />

or by operation of law, is made as to the accuracy, reliability, or completeness of this information. The material is provided subject to errors, omissions, changes, prior sales or<br />

withdrawals, without notice. Buyers and their advisors should conduct careful, independent investigation of the property to determine it’s suitability as to Buyer’s use and needs.<br />

For More Information Regarding the Real Estate, Please Contact<br />

Matt Darin at 847.504.2456 or Email mdarin@hilcorealestate.com<br />

To schedule an auction, please contact us at 248.254.9999 11

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Amsterdam • Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Flagstaff<br />

Grand Rapids • Leeds • London • Los Angeles • New York • Orlando • San Francisco • Toronto<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

HILCAST TM<br />

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

Due to complete plant closure,<br />

assets of<br />

Late Model Plastic Injection Molders To 2900-Ton<br />

Ancillary Plastics, Toolroom Machinery & Real Estate<br />

2005<br />

Thursday, December 6th • Beginning at 10am Local Time<br />

Selmer, Tennessee<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062<br />

All rights reserved • Printed in USA • RIET3268 • Auctioneer: Lance Mannion, License #4723, Asset Sales, TN License #3908, IL License #044000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A buyer’s premium of 12.5% for onsite sales & 15% for<br />

webcast sales is in effect. Everything will be sold to the<br />

highest bidder for cash, in accordance with the Auctioneer’s<br />

customary “Terms of Sale”, copies of which will be posted<br />

on the premises of the sale and subject to additional terms<br />

announced the day of sale. All items will be sold “as is,<br />

where-is” without any warranties, express or implied.<br />

Although obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the accuracy<br />

of the information herein contained. Bidders are encouraged<br />

to thoroughly inspect the items on which they intend to bid<br />

prior to sale. Absolutely no items will be removed until the<br />

day after the conclusion of the sale and payment is made in<br />

full. Subject to additions, deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN FULL<br />

ON THE DAY OF THE <strong>AUCTION</strong>. If you intend to pay by wire<br />

transfer, we will accept payment the day after the sale ONLY<br />

IF a deposit of 25% of total purchases is made on the day of<br />

the sale. Contact our office for wire transfer instructions.<br />

Only cash, wire transfer or certified check, payable to <strong>Hilco</strong><br />

<strong>Industrial</strong>, LLC will be accepted. Company checks payable<br />

to <strong>Hilco</strong> <strong>Industrial</strong> LLC will be accepted only if accompanied<br />

by a bank letter of guarantee, (see sample letter below).<br />

All sales are subject to sales tax. Purchasers claiming<br />

exemptions from taxes must provide proof satisfactory to<br />

the Auctioneer of their entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees payment<br />

to <strong>Hilco</strong> <strong>Industrial</strong>, LLC from (Company Name).<br />

This guarantee will be valid for purchases made<br />

at the Auction of Rietter & Schefenacker on<br />

December 6th.