Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

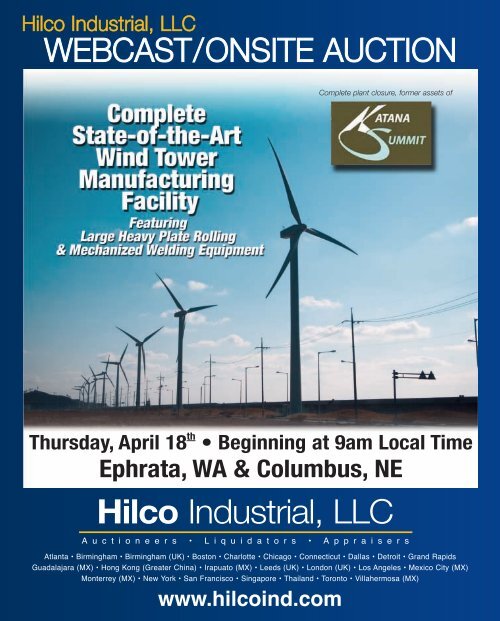

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

WEBCAST/ONSITE AUCTION<br />

Complete plant closure, former assets of<br />

Thursday, April 18 th • Beginning at 9am Local Time<br />

Ephrata, WA & Columbus, NE<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids<br />

Guadalajara (MX) • Hong Kong (Greater China) • Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX)<br />

Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<br />

www.hilcoind.com

HILCO INDUSTRIAL, LLC WEBCAST/ONSITE AUCTION<br />

Complete plant closure, former assets of<br />

Auction DAte<br />

thursDAy, April 18 th<br />

Beginning At 9Am locAl time<br />

preview DAte<br />

weDnesDAy, April 17 th<br />

9Am to 4pm locAl & morning of sAle<br />

For earlier inspection, please contact Mark<br />

reynolds at 205-595-5999 or eMail<br />

Mreynolds@hilcoind.coM<br />

Auction locAtion<br />

& preview locAtion #1<br />

(assets listed on pages 2-6)<br />

1980 fAirchilD Avenue<br />

ephrAtA, wA 98823<br />

preview locAtion #2<br />

(assets listed on page 7)<br />

1600 eAst 29th Avenue<br />

columBus, ne 68601<br />

preview at this location is by appointMent only.<br />

please contact Mark reynolds at 205-595-5999 or<br />

eMail Mreynolds@hilcoind.coM<br />

Directions to Auction & preview locAtion #1<br />

from grAnt county internAtionAl Airport: eXit Airport to wA-17 n,<br />

continue to wA-282 w. eXit At nAt wAshington wAy AnD turn right.<br />

tAKe the 2nD right onto 5th Ave se, then tAKe the seconD left onto<br />

enterprise st.<br />

Directions to preview locAtion #2<br />

from columBus municipAl Airport: eXit Airport to Bill BABKA Drive<br />

AnD turn right. turn left onto 18th Ave AnD tAKe the thirD left onto<br />

us-30 e / 23rD st, turn right onto e 29th Ave. DestinAtion will Be on the<br />

right.<br />

further informAtion<br />

• An 18% Buyer's premium will Be chArgeD on All Assets. the Buyer’s<br />

premium will Be reDuceD to 15% for pAyments mADe By cAsh, compAny<br />

checK or wire trAnsfer. Auction will Be conDucteD in english,<br />

Accepting u.s. currency only.<br />

• removAl DeADline is friDAy, mAy 10 with hours of removAl Between 8Am to<br />

4pm monDAy thru friDAy. Buyers with items left on site After DeADline Are<br />

suBject to fines of $500 per DAy.<br />

• for further informAtion on mAchinery & eQuipment, pleAse contAct<br />

mArK reynolDs At 205-595-5999 or emAil mreynolDs@hilcoinD.com<br />

• for pAyments pleAse contAct lesiA joseph At 616-732-1800 X19 or emAil<br />

ljoseph@hilcoinD.com or hilco Accounts receivABle At<br />

hin_Ar@hilcoinD.com<br />

• for customer service, pleAse contAct sAnDi neely At 248-254-9999 X16<br />

or emAil sneely@hilcoinD.com<br />

information contained herein deemed to be accurate at time of printing and subject to change.<br />

For updated information, please visit our website at www.hilcoind.com for any<br />

date, sale process, terms and conditions and list of available assets.<br />

Ephrata, Washington Location Available<br />

as a Complete Turnkey Facility<br />

Favorable Lease Assumptions Available, Contact Mark Reynolds<br />

at 205-595-5999 Or Email mreynolds@hilcoind.com for details.<br />

Assets will also be offered piecemeal<br />

CNC PLATE BENDING ROLL SYSTEM<br />

1 – DAVI MODEL MCB3060WT 10' x 2-3/4" 4-ROLL DOUBLE<br />

PINCH CNC PLATE ROLL SYSTEM, S/N 20540151<br />

(2005), Siemens Simatic Multi Panel CNC Operator<br />

Terminal, Overhead Support, Front & Rear Tip-Up Roller<br />

Support Tables, 120-HP, 460 Volt, 60 Hz, With Power<br />

Infeed Table, (16) 6-1/2" Diameter Rolls – (12) Powered /<br />

(4) Idler On 32" Centers, 100" Roll Width, Overall Table<br />

Size 9-1/2' Wide x 34' Length, Hydraulic Elevation<br />

See page 7 for additional Davi CNC Plate Bending Roll<br />

System available.<br />

2005<br />

CNC PLASMA CUTTING SYSTEM<br />

1 – MESSER MODEL TMC 4514 TRAVELLING GANTRY CNC<br />

PLASMA PLATE CUTTING SYSTEM, S/N TMC4514LP-08-5187<br />

(2008), Global 5-Axis CNC Control, 146" Wide x 90' Long<br />

Down Draft Cutting Table (In 5' Sections), 14' x 100' Cutting<br />

Travels, 100' Long Rail x 17' CC Distance On Rail, A & C Axis<br />

Model Skew Rotator Infinity CNC Controlled Plasma Bevel<br />

Head, Hypertherm HPR260 HyPerformance Plasma Cutting<br />

Power Source, S/N 260-005157, Overhead Power Track, With<br />

Torit Model DF03-18 Dust Collector, S/N 2320326-1, 15-HP<br />

LARGE QUANTITY OF Messer Spare Parts And Consumables<br />

2008<br />

2<br />

To schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Location #1: Ephrata, WA<br />

CNC PLASMA CUTTING • CNC PLATE BENDER • TURNING ROLLS<br />

WELDING SYSTEMS • ABRASIVE BLAST BOOTH SYSTEMS<br />

WELDING MANIPULATOR SYSTEMS<br />

4 – ROMAR / OGDEN MODEL RM7060VHDS-TCM-EA-G2500 ROMAR COLUMN<br />

& BOOM WELDING MANIPULATORS WITH ODGEN WELDING SYSTEMS,<br />

(2006), Dual Weld System, Horizontal Outreach 6000mm (19' 6"), Under Boom<br />

Height 7000mm (22' 9"), Lifting Speed 1060 mm/min @ 60 Hz, Boom Speed<br />

150-1500 mm/min @ 5-60 Hz, Travelling Speed 250-2500 mm/min @ 5-60 Hz,<br />

Slewing Manual +/- 180°, Power Rotation, Rail Gauge G-G 2500mm, Odgen<br />

Welding System With (2) Lincoln DC1000 Welding Power Supplies With Wire<br />

Feed Welding Heads, (1) Lincoln Power Wave System Interface, (1) Weld<br />

Engineering Mighty-Mac Heavy Duty Flux Supply & Recovery System, Main<br />

Control Panel With Allen Bradley Compact Logix L32E PLC, (3) Power Flex 40<br />

Programmable Drives, (3) Sola SLR Series Line Reactors, (2) Allen Bradley<br />

Panel View Plus 1500 Touch Screen Operator Interface Terminals, With 15' High<br />

Free Standing Operator Platform; #'s Odgen 1/ MN04, Odgen 2/ MN03, Ogden<br />

3/ MN01, Odgen 4/ MN02; *Note – Odgen 1/MN04 Equipped With Rotating Head<br />

1 – RANSOME MODEL 18x18 WELDING MANIPULATOR, S/N 6218221,<br />

Travels – 18' Horizontal / 18' Vertical, Model 84" Gauge Power Travelling<br />

Carriage Base, S/N 7629615, (2) 15' Floor Mounted Track Sections, With<br />

ESAB Model LAF 1250 DC Welding Power Supply, A2-A6 Process Controller,<br />

Wire Feed Head, Sub-Arc Flux System<br />

1 – RANSOME MODEL XHD WELDING MANIPULATOR, S/N 6322520, 12'<br />

Horizontal Travel, 16' Vertical Travel, Power Travelling Carriage Base, With<br />

ESAB Model LAF 1250 DC Welding Power Supply, A2-A6 Process Controller,<br />

Wire Feed Head, Sub-Arc Flux System<br />

1 – PANDJIRIS MODEL 14x14 WELDING MANIPULATOR, S/N 800-5778-3,<br />

Travels – 14' Horizontal / 14' Vertical, Stationary Base, With ESAB Model LAF<br />

1250 DC Welding Power Supply, A2-A6 Process Controller, Lincoln Power<br />

Wave System Interface, Wire Feed Head, Sub-Arc Flux System<br />

1 – PORTABLE MINI-MANIPULATOR, S/N NA, Estimated 6' x 6' Travels<br />

TURNING ROLLS AND FIT-UP ROLLS<br />

1 – ROMAR BLAST BOOTH TURNING ROLLS, Roll Size 13" Face x 20"<br />

Diameter, Track Mounted Rolling Frame; (3) AC Powered Rolls, (3) Idler Rolls<br />

1 – GROOVED STEEL PAINT TURNING ROLLS, Roll Size 8" Face x 20"<br />

Diameter w/ 3-3/8" Wide Grooves, Track Mounted Rolling Frame; (6) AC<br />

Powered Rolls (6) Idler Rolls<br />

LARGE QUANTITY TURNING ROLLS, (As New As 2008), Including Romar &<br />

Ransome, Single Dual & Three Wheel Self-Adjusting, Turning Capacity From 15<br />

To 135-Tons, Rolling & Stationary Frames, Including; (26) TR Series AC Powered<br />

Turning Rolls, (18) IR Series Idler Rolls, (5) Ogden FR Series Fit-Up Rolls With<br />

Hydraulic Power Units, (4) SR Series Hydraulic Lift Rolls<br />

2006<br />

New as 2008<br />

2006<br />

WORK ROLLS<br />

3 – WORK ROLL STANDS, 10', Roll Spacing Adjustable From 2'-7', AC Powered<br />

1 – WORK ROLL STAND, 8-1/2" Diameter Rolls On 48" Centers, 24' Length, AC Powered, Stationary<br />

WIND TOWER FLANGE RINGS<br />

LARGE QUANTITY OF Wind Tower Flange Rings, Used For Handling Tower Sections in<br />

Fabrication, Blast, Prime and Paint Process, All 2” Thick, Various OD’s From 8’ To 15’<br />

PLATE BEVELERS<br />

2 – PULLMAX MODEL X97 PLATE BEVELERS, S/Ns X-97-76001-94 & X-97-76002045, Up To<br />

2” Thick Plate, 1” Maximum Bevel Width, 25° – 55° Angle<br />

PORTABLE MILLING MACHINE<br />

1 – CLIMAX MODEL CM6000/6066-F1 PORTABLE CIRCULAR FLANGE MILLING MACHINE,<br />

S/N 1010358, (2007), ID Mounting Range 78.5" – 178.5", Milling Diameter Range 78.5" – 197",<br />

Flatness Tolerance .0004 Inches/Foot, 1.5 kW Servo Feed Motor, .0005 – 0.85 RPM Table<br />

Speed Range, 25 HP Hydraulic Power Unit, 15 HP Effective at Spindle, #50 Taper NMTB Tool<br />

Holder, 24” Radial Travel Per Set Up, 8” (Stroke Z-Axis) Spindle Travel, Turning Arm Swing<br />

Diameter, Min. 135”- Max. 208” S/N 1015445, (2009), Set-Up Accessories, Gang Box<br />

ABRASIVE BLAST BOOTH SYSTEMS<br />

1 – THRU-FEED STEEL SHOT ABRASIVE BLAST BOOTH, (2006), 20' Width x 128' Length,<br />

Door Opening 18' 6" Wide x 18' Height, Double End Swing Doors, Full Length In-Floor Shot<br />

Recovery System With Bucket Elevator, (2) Hand Application Blast Pot Systems, (1) NST<br />

Model BA100 Compressed Air Purifier Breathing Air Panel, Floor Standing Bolted Panel<br />

Construction<br />

1 – FARR MODEL 50L DUST COLLECTOR, S/N 94DC22323, 40-HP, Pneumatic Pulse Jet,<br />

Used With Thru-Feed Blast Booth<br />

1 – PANGBORN MODEL ROTOBLAST THRU-FEED ABRASIVE PLATE BLAST SYSTEM, S/N<br />

ES-1838-8-S971004, 14' High x 9' Wide, Blast Chamber Size Estimated 12' Wide x 20' Length,<br />

(8) 50-HP Shot Wheels (4 Per Side), In-Floor Shot Recovery System With R & L Side Bucket<br />

Elevators & Shot Feed Systems, 16' Entry / Exit Sections, Estimated 54' Overall Length,<br />

Control Panel, In-Floor Link Chain Drag Transfer Conveyor With (3) Vertical Plate Transfer Cars<br />

1 – BLAST BOOTH DUST COLLECTION SYSTEM, Mfg'r NA, Estimated 50-HP, Pneumatic<br />

Pulse Jet, Screw Auger Hopper Bottom, Used With Pangborn Rotoblast<br />

INFEED CONVEYORS<br />

2 – POWER ROLLER INFEED CONVEYORS, 10' Overall Width, 8' Roller Width, 10" Diameter<br />

Rollers On 32" Centers, 50' Length, – Indoor Section<br />

For more information, please visit us on the web at www.hilcoind.com 3

Location #1: Ephrata, WA<br />

PAINT SHOP EQUIPMENT • THERMAL SPRAY SYSTEM<br />

COMPRESSORS • WIND TOWER HANDLERS • FORKLIFTS<br />

2006<br />

PORTABLE SCREENING PLANT<br />

1 – EXTEC MODEL S5 CRAWLER MOUNTED PORTABLE SCREENING<br />

PLANT, S/N 10477 (2006), Estimated 1000 Hours<br />

1 – WILDCAT MODEL 626 COUGAR PORTABLE TROMMEL SCREEN,<br />

S/N 1W9SS53246F351502 (2006), Estimated Less Than 1000 Hours<br />

FORKLIFTS AND WIND TOWER HANDLER TRUCKS<br />

2 – SVE TRUCK MODEL TMF 25-18 WIND TOWER HANDLER TRUCKS,<br />

(LOG STACKER / HANDLER TRUCKS), S/Ns 1051484, 4122036, Nominal<br />

Capacity 25/18-Ton For Log Stacking With Grapple Hook, Max. 9500mm,<br />

Cummins Diesel, Enclosed Cab, Pneumatic Tires, In 2007 Upgraded And<br />

Rebuilt By SVE Denmark Dealer (NP Trucks) To Accommodate Wind Tower<br />

Application To Handle 45 Metric Tons (45,000 Kg.)<br />

4 – HYSTER MODEL H360HD 36,000-LB. MAXIMUM CAPACITY FORKLIFTS,<br />

S/Ns F019E01803C, F019E01802C, F019E01561B, F019E02116D,<br />

Capacity Ratings: 212.6" Lift @ 24" Load Center, Perkins Diesel, Powershift<br />

Automatic, 12.00x20 Wide-Wall Hauler Pneumatic Tires – Dual FR / Single<br />

RR, 212.6" Lift Height, 2-Stage Mast, 176" Mast Height, 2500mm (98.4")<br />

SSFP Carriage, Side Shift, 96" Forks With Independent Power Fork<br />

Positioning, Enclosed Cab<br />

1 – HYSTER MODEL H50XM 4,750-LB. FORKLIFT, S/N D177B44179V, Load<br />

Capacity Rating: 4750-Lbs. @ 171.3" Lift @ 24" Load Center / 4600-Lbs. @<br />

189" Lift @ 24" Load Center, LPG, Solid Cushion Tires – Dual 7.00x12/5.00<br />

FR / 6.00x9/4.00 RR, 189" Lift, 3-Stage Mast, Side Shift, 42" Forks<br />

1 – ARROW MODEL 90CE60 TELESCOPIC JIB BOOM FORKLIFT ATTACHMENT,<br />

S/N EB-5440/W, Capacity 6,000-Lbs. @ 83" Load Center, Weight 410-Lbs.<br />

1 – WORK BASKET FORKLIFT ATTACHMENT<br />

2006<br />

PAINT / CURE BOOTH<br />

1 – SPRAY SYSTEMS PAINT / CURE BOOTH, (2006), 20' Width x 126' Length, 18' Inside Height,<br />

Double End Power Roll-Up Doors, Outdoor Weather-Rite LP Gas Fired Air Make-Up Unit, Floor<br />

Standing Bolted Steel Panel, With 15' x 10' Side Attached Paint Mixing Kitchen<br />

PAINT SHOP EQUIPMENT<br />

2 – BESSAMAIRE AIR MAKE-UP UNITS, MUAJHF3-40TMP-631, S/N 06-000400 (2006),<br />

MUAJHVF3-40TMA-631, S/N 05-003023 (2005), Propane Gas Fired, Input BTU 115,200 Min –<br />

3,456,000 Max, Ambient Temperature 70°F, 40,000 SCFM Air Flow, 40-HP, Maximum Discharge<br />

Temperature 140°F<br />

2 – GRACO MODEL X-TREME 2-COMPONENT PAINT MIX STATIONS, Each With (2) Xtreme 56:1<br />

Paint Pumps, Resin & Catalyst Heat Tanks & Lines, Hose Heat, Explosion-Proof Electric Enclosures<br />

QUANTITY OF PAINT SHOP SUPPORT EQUIPMENT Including Paint Mix Tanks, Graco Paint<br />

Mix / Pump Stations, Graco Model X-Treme X60 Paint Pumps, Series 107A, Uni Ram Model<br />

Urs2000 Solvent Recycler, Cascade Automatic Spray Gun Cleaning System<br />

THERMAL SPRAY SYSTEM<br />

1 – METALLISATION MODEL S-350 TWIN WIRE ARC SPRAY SYSTEM, S/N 5350-050,<br />

Energizer Model 2227, Rated Current 20, Arcspray 140 Pistol, Sub Model CG23 S/N 75950,<br />

Voltage 23V, Current 350A, Material Type 02E – Diameter 2.3mm,<br />

Transport Cart<br />

AIR COMPRESSORS & DRYERS<br />

3 – KAESER MODEL DSD200 200-HP ROTARY SCREW AIR COMPRESSORS,<br />

S/Ns 1101, 1100, 1098 (2007), 865 CFM, 145 PSIG, Air Cooled, Kaeser<br />

Sigma Microprocessor Control<br />

1 – KAESER MODEL CSD-100ST 100-HP ROTARY SCREW AIR<br />

COMPRESSOR, S/N 1033 (2008), 417 CFM, 125 PSIG, Air Cooled,<br />

Kaeser Sigma Microprocessor Control, New; Disconnected From Power<br />

1 – AIR TEK MODEL ES1000 ELITE SERIES REFRIGERATED COMPRESSED<br />

AIR DRYER, S/N 05H-D02302, Capacity 1050 SCFM @ 100 PSI @ 100°F,<br />

Max. W.P. 200 PSIG<br />

2 – ZEKS MODEL HEAT SINK REFRIGERATED COMPRESSED AIR DRYERS,<br />

S/Ns 152963, 120455<br />

1 – CHAMPION MODEL HB10-8 10-HP TWO-STAGE HORIZONTAL TANK<br />

MOUNTED AIR COMPRESSOR, S/N R30-18314<br />

1 – INGERSOLL RAND MODEL SSR-EP50 50-HP ROTARY SCREW AIR<br />

COMPRESSOR, S/N D2692-U85-C, 205 CFM, 125 PSIG, Not In Service<br />

3 – VERTICAL COMPRESSED AIR RECEIVER TANKS, 500 to 3800-<br />

Gallon, M.A.W.P. To 165 PSIG @ 400°-450°F<br />

New as 2008<br />

2006<br />

4<br />

To schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Location #1: Ephrata, WA<br />

TELEHANDLER • AERIAL LIFTS • WELDING EQUIPMENT<br />

BRIDGE & GANTRY CRANES • CRANE ATTACHMENTS<br />

TELEHANDLER<br />

1 – CARE LIFT MODEL ZOOM BOOM 10044-44 TELESCOPIC BOOM<br />

ROUGH TERRAIN FORKLIFT, S/N B1004406479E, Maximum Capacity<br />

10,000-Lbs., Maximum Lift Height 44', Lifting Capacity: 10,000-Lbs. @ 24"<br />

L.C. to 35' / 8,000-Lbs. @ 24" L.C. to 44', 4WD, 4WS, Cummins B3.9C 110-<br />

HP / 82 KW Diesel, Front Outriggers, 14.00-24 Pneumatic Tires, 60" Wide<br />

Carriage, 48" Forks<br />

AERIAL LIFTS<br />

1 – SNORKEL MODEL TB-A42RFO TELESCOPIC BOOMLIFT, S/N 971211<br />

(1997), Maximum Platform Height 42', Maximum Platform Reach 33', 500-Lb.<br />

Capacity, 2WD, Gasoline, Foam Filled Tires, 30"x60" Platform<br />

1 – SNORKEL 60' TELESCOPIC BOOMLIFT, S/N NA, Not In Service<br />

2 – SKY JACK ELECTRIC SCISSORS LIFTS, SJIII-4830, S/N 86644, 30'<br />

Maximum Platform Height, 700-Lb. Capacity; M3015, S/N 16831, 15'<br />

Maximum Platform Height, 500-Lb. Capacity<br />

BRIDGE CRANES<br />

4 – CANADIAN OVERHEAD HANDLING 100-TON CAPACITY HOT METAL<br />

BRIDGE CRANES, S/Ns 2804, 2805, 2806, 2807, (New 2004 – Never Used),<br />

Crane Capacity 100-Ton, Hot Metal Hoist 30T / Ea, Two Hoist 60T / Ea;<br />

Note – These Cranes Are Disassembled And Stored On The Ground<br />

1 – MUNCK 70-TON CAPACITY TOP RIDING DOUBLE GIRDER BRIDGE<br />

CRANE, S/N 2728, Derated From 70-Ton to 40 Ton, Due To Crane Rail<br />

Capacity (Hoist Drum Needs To Be Re-Wrapped To Accommodate 70 Ton),<br />

70' Span, Estimated 30' Lift, .5 / 8 FPM Hoist Speed, 65 FPM Trolley Speed,<br />

Radio Controls<br />

1 – KRANCO 40-TON CAPACITY TOP RIDING DOUBLE GIRDER BRIDGE<br />

CRANE, S/N 12919, 70' Span, 30' Lift, 17.5 max. FPM Hoist Speed, 100<br />

max. FPM Trolley Speed, 150 max. FPM Bridge Speed, 5 Step Variable All<br />

Motions, Radio Controls<br />

1 – CAPCO 25-TON CAPACITY TOP RIDING DOUBLE GIRDER BRIDGE<br />

CRANE, S/N CP144623 (2001), Shaw Box 25-Ton Top Riding Hoist S/N<br />

40509 With 25-Ton Rotating Block, 70' Span, 18’6” Under Hook, 3/14 FPM<br />

Hoist, 12-120 FPM Bridge, 18/65 FPM Trolley, Radio Controls, (Crane<br />

De-Rated For Use In Current Building)<br />

1 – P & H MODEL PACESETTER DUAL TROLLEY 15 / 15-TON CAPACITY<br />

TOP RIDING DOUBLE GIRDER BRIDGE CRANE, S/ CP-30347, Dual<br />

Trolley 15-Ton Top Riding Hoists, 70' Span, Estimated 30' Lift, Radio Controls<br />

2 – SHAW BOX 15-TON CAPACITY TOP RIDING SINGLE GIRDER BRIDGE<br />

CRANES, (2007 – New, Never Used), 67'-6" Span, 18’6” Lift, 9’ Wheel<br />

Base, 19,990 Lbs. Wheel Loading, Shaw Box Model WD 3M-25 Hoists,<br />

S/Ns 07G30F95, 07G30F96, Capacity 33069-Lbs., Duty Rating 2M, Voltage<br />

460-3-60, Hoist Speed 18 / 4.5 FPM, Hoist Motor 20 / 5-HP, Trolley Speed<br />

50 / 16.6 FPM, Trolley Motor 1 / .33-HP; Bridge Speeds Variable 100 FPM,<br />

Note – These Cranes Are Disassembled And Stored On The Ground<br />

2 – PROGRESSIVE 15-TON CAPACITY TOP RIDING DOUBLE GIRDER<br />

BRIDGE CRANES, 70' Span, Estimated 30' Lift, Radio Controls<br />

1 – CONCO TELLUS 10-TON CAPACITY TOP RIDING DOUBLE GIRDER<br />

BRIDGE CRANE, S/N F1946B, Estimated 70' Span, Estimated 30' Lift,<br />

6-Way Hand-Held Pendant Control<br />

ESTIMATED 190' CRANE SUPPORT RUNWAY, W24 x 55 Runway Beam, C12<br />

x 20.7 Cap Channel, 40 LB/YD ASCE Rail, Disassembled, Stored On Ground<br />

New 2004<br />

Never Used<br />

GANTRY CRANES<br />

2 – 10-TON CAPACITY TRAVELLING GANTRY CRANES, Munck 10-Ton Bottom Running<br />

Electric Cable Hoist, Estimated 48' Span, Estimated 25' Under Hook Height, AC Powered<br />

Travel, Floor Mounted Track Rails, Hand-Held Pendant Control<br />

1 – 10-TON CAPACITY TRAVELLING GANTRY CRANE, Munck 10-Ton Bottom Running Electric<br />

Cable Hoist, Estimated 45' Span, Estimated 18' Under Hook Height, AC Powered Travel, Floor<br />

Mounted Track Rails, Hand-Held Pendant Control<br />

1 – 10-TON CAPACITY TRAVELLING GANTRY CRANE, 10-Ton Top Riding Electric Cable Hoist,<br />

Estimated 42' Span, Estimated 17' Under Hook Height, Hand Held Pendant Control; Stored –<br />

Not In Use<br />

1 – 7-TON CAPACITY TRAVELLING GANTRY CRANE, Munck 7-Ton Bottom Running Electric<br />

Cable Hoist, Estimated 45' Span, Estimated 15' Under Hook Height, AC Powered Travel<br />

1 – 2-TON CAPACITY TRAVELLING HALF-GANTRY CRANE, S/N 09096, Bottom Riding Shaw<br />

Box 2-Ton Electric Cable Hoist, Floor Rail Riding AC Powered End Frame, Building Rail Riding<br />

Upper End Truck, Estimated 30' Span, Estimated 18' Under Hook Height, Hand-Held Power<br />

Pendant Control<br />

3 – FLOOR MOUNTED TRACK RAILS, Estimated 75'-100'<br />

CRANE ATTACHMENTS<br />

2 – CALDWELL MODEL UNIVAC 1500 VACUUM TYPE PLATE LIFTING ATTACHMENTS,<br />

S/Ns 07-82318-2, 07-82318-1, 24,000-Lb. Capacity, (8) 27" Diameter Adjustable Vacuum<br />

Pads, Pad Capacity 3000-Lbs., 34' Overall Length, Unit Weight 4870-Lbs.<br />

1 – ANVER VAC-U-LIFT MODEL 15000-26-5-6-15-B16-N30 VACUUM TYPE PLATE LIFTING<br />

ATTACHMENT, S/N 11-9432-1, 15,000-Lb. Capacity, (15) 18" Diameter Adjustable Vacuum<br />

Pads, Pad Capacity 1105-Lbs., 26' Overall Length, Unit Weight 4580-Lbs.<br />

QUANTITY OF Spreader Bars, C-Hooks, 'P' Hooks, Handling Attachments, Shackles, Rigging<br />

Chains & Cables<br />

WELDERS & RELATED<br />

1 – ESAB MODEL PLASMARC ESP-150 PORTABLE PLASMA CUTTING SYSTEM, S/N NA<br />

3 – MILLER MODEL MARK VIII-2 ‘EIGHT-PACK’ MULTIPLE OPERATOR CONSTANT CURRENT<br />

DC WELDING POWER SUPPLIES, S/Ns JD683754, JC630046, HE730716, Input: 230/460<br />

Volts, 170/85 Amperes, 48 KW, Three Phase, 60 Hz; Output: Single Module – 40 Volts, 200<br />

Amperes, 60% Duty Cycle, 80 Max OCV / Total – 800 Amps @ 100% Duty Cycle, 1600 Amps<br />

@ 25% Duty Cycle<br />

2 – LINCOLN MODEL DC-600 WELDING POWER SUPPLIES, S/Ns U1080900762 &<br />

U1080902301, With Multi-Process Switch, Common Steel Skid Frame With Bernard<br />

Tele-A-Boom Welding Boom<br />

4 – LINCOLN MODEL DC-600 WELDING POWER SUPPLIES, S/Ns NA, Each With Multi-<br />

Process Switch, Miller X-Treme 12VS Wire Feeder<br />

1 – DOOR WELD-UP RAISED MEZZANINE PLATFORM, DUAL LANES<br />

2 – HENKEL FLUX BAKE OVENS, KHTF-600 S/N 1208022, 2640 Watts, KF300 S/N 10601,<br />

1000 Watts<br />

QUANTITY OF Welding Power Supplies, Including Miller, Lincoln, Esab, Sub-Arc Set-Up Welding<br />

Table, Wire Feeders, Welding Wire, Welding Leads, Mig Guns, Ground Clamps, Etc.<br />

For more information, please visit us on the web at www.hilcoind.com 5

Location #1: Ephrata, WA<br />

FIELD SERVICE • WIND TOWER FIXTURES<br />

SHOP EQUIPMENT • VEHICLES<br />

FIELD SERVICE EQUIPMENT<br />

2 – SPOKANE DIESEL MODEL SD200 200 KW DIESEL AC GENERATORS, S/Ns NA,<br />

Detroit Diesel Series 40 Diesel, Skid Base, Weather Enclosure<br />

1 – MQ POWER MODEL DCA-25SSIU WHISPERWATT 25KW DIESEL POWERED<br />

PORTABLE AC POWER GENERATOR, S/N 7106405, AC Generator Model<br />

DF-0270I, Three Phase – 60 Hz, 25 KW, 240-480 Volt, 60.1-30.1 Amp, / Single<br />

Phase – 60 Hz, 14.4 KW, 240-120 Volt, 60.1 Amp, Isuzu QD-60 (C240) Diesel,<br />

Trailer Mounted<br />

1 – SULLAIR MODEL 185DPQJD DIESEL POWERED PORTABLE AIR COMPRESSOR,<br />

S/N 004-125839, 185 CFM, John Deere Diesel<br />

1 – SULLAIR MODEL 185DPQPERK DIESEL POWERED AIR COMPRESSOR, S/N<br />

004-141891, 185 CFM, Perkins Diesel, Mounted On Steel Work Frame With Bolt<br />

Holding Bins & Bolts<br />

1 – LINCOLN MODEL CLASSIC II SA250-F3L1011 DIESEL POWERED WELDER /<br />

GENERATOR, S/N U1940515375, Deutz Diesel<br />

1 – LINCOLN MODEL SA250-D3-152 DIESEL POWERED WELDER / GENERATOR,<br />

S/N A1045521, Deutz Diesel<br />

1 – MILLER MODEL LEGEND CONSTANT CURRENT AC/DC WELDER / GENERATOR,<br />

S/N KB153334, Onan Performer 18XSL Gas Engine<br />

1 – POWER WASHER TRAILER, With Model PT100-S Single Axle Trailer Frame,<br />

Estimated 1000-Gallon Water Tank, Shark Model SGP-3530E Steam Cleaner, S/N<br />

S0406-12770, 3000 PSI, 3.5 GPM, Honda GX340 11.0-HP Gas Engine, Fuel Oil<br />

Burner<br />

1 – INGERSOLL RAND MODEL SS-3 CONTRACTOR'S SERIES PORTABLE AIR<br />

COMPRESSOR, S/N A040557, Honda GX160 5.5-HP Gas Engine<br />

1 – HONDA MODEL EG5000 PORTABLE AC GENERATOR<br />

WIND TOWER FIT-UP & FIXTURES<br />

1 – UPRIGHT FLANGE FITTING TABLE<br />

QUANTITY OF Assorted Welded Steel Ring Fixtures, Assorted Flat Steel Rings, Custom<br />

Tandem Axle Transport Dollies<br />

MAINTENANCE SHOP EQUIPMENT / SHOP & FACTORY<br />

1 – UNI-HYDRO MODEL 66-24 HYDRAULIC IRONWORKER, S/N 3P66477X, 80-Ton<br />

Punch Capacity<br />

1 – WELLSAW MODEL 1316 SWIVEL HORIZONTAL METAL CUTTING BANDSAW,<br />

S/N 6364<br />

1 – CLUB CAR ELECTRIC GOLF CART, S/N AG0232-179864, 2-Passenger<br />

2 – CARDINAL 5,000-LB. CAPACITY ELECTRONIC PLATFORM SCALES, With<br />

Model 204 Programmable Readout<br />

14 – INDUSTRIAL COMMERCIAL EQUIPMENT MODEL OHV-500 “FROST-FIGHTER”<br />

PORTABLE FUEL OIL HEATERS, 428,000 BTU/Hr<br />

1 – 100-TON DUAL RAM PORT-A-POWER SET, With Electric Power Unit, (2) Ram<br />

Heads, Gang Box<br />

QUANTITY OF Over (12) Jesco & Other Self-Dumping Hoppers, 1/2 Cu Yd To 1-3/4 Cu<br />

Yd, Assorted Rail Mounted Transfer Cars, PLUS A LARGE QUANTITY OF Shop &<br />

Factory Accessories, Including Maintenance Garage Equipment, Welding & Fab<br />

Shop Accessories, Power & Hand Tools, Rigging & Maintenance Equipment, Paint Shop<br />

Accessories, Crib Supplies, Spare Parts, Service & Maintenance Parts, etc.<br />

TRUCKS / TRAILER / SHIPPING CONTAINERS<br />

1 – INTERNATIONAL MODEL 9200 EAGLE SERIES TANDEM AXLE CONVENTIONAL<br />

DAY CAB TRUCK TRACTOR, VIN: 2HSFMAHR8TC048311, (1996), Cummins<br />

M11-330E Diesel, Eaton-Fuller 9-Speed, 52000-Lb. GVWR – 12F/40R, Air Ride,<br />

187" WB, Engine Brake, Cruise, A/C, Pro-Tech Aluminum Headache Rack<br />

1 – FREIGHTLINER TANDEM AXLE CABOVER FLATBED STRAIGHT TRUCK, VIN:<br />

1FUYARYB2KP363297, (1989), CAT Diesel, Eaton Fuller 9-Speed, Air Ride, 20'<br />

Custom Steel Deck Flatbed, Rear Mounted Low-Profile 5th Wheel<br />

1 – VOLVO MODEL FE-614T SINGLE AXLE CABOVER TRUCK TRACTOR, VIN:<br />

YB3U6A3A8JB421215, (1988), Volvo Diesel, 6-Speed<br />

1 – 45' TANDEM AXLE FLATBED TRAILER, Mfg'r NA, Fixed Spring Ride, Wood Deck<br />

10 – 20' & 40' STORAGE CONTAINERS<br />

PICKUP TRUCKS / VANS<br />

1 – CHEVROLET MODEL ASTRO VAN MINI VAN, VIN: 1GNEL19W5SB272410, AWD,<br />

(2) Bench Seats<br />

1 – FORD MODEL F150 CUSTOM 4x4 PICKUP TRUCK, VIN: 2FTEF14Y2MCB04188,<br />

(1991), 4.9L I-6 Gas, 5-Speed, Standard Cab, 8' Box<br />

1 – CHEVROLET MODEL CHEVY VAN 30 1-TON CUBE VAN, VIN:<br />

2GCHG31K8J4146926, (1988), V-8, Automatic, Dual Rear Wheels, 14' Aluminum<br />

Cube Van Body<br />

1 – GMC MODEL SIERRA CLASSIC 35 ‘CAMPER SPECIAL’ 1-TON DUALLY PICKUP<br />

TRUCK, VIN: TCW34AB511851, (1980), 454 V-8, Automatic, Dual Rear Wheels,<br />

Standard Cab, 8' Box<br />

1 – GMC MODEL 3500 SERVICE TRUCK, VIN: TCL338Z520461, (1980), 350 V-8, 4-Speed,<br />

Dual Rear Wheels, 11' Service Body<br />

LARGE QUANTITY OF SCRAP AVAILABLE<br />

Visit our website www.hilcoind.com for info<br />

6<br />

To schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Location #2: Columbus, NE<br />

CNC PLATE BENDING ROLL • WELDING MANIPULATOR<br />

FLANGE MILLING MACHINE • TANK ROLLS • SUPPORT<br />

Partial Listing Only. Visit our website for lot catalog<br />

www.hilcoind.com<br />

CNC PLATE BENDING ROLL SYSTEM<br />

1 – DAVI MODEL MCB3070WT 4-ROLL DOUBLE PINCH CNC PLATE BENDING ROLL SYSTEM,<br />

S/N 20740184 (2007), Leonai O CNC Controls, 3.5" x 10' Max. Rated Bending Capacity, 2.75"<br />

Max. Rated Pre-Bend Capacity, 27.55" Top Roll Diameter, 25.19" Bottom Roll Diameter, 215-HP<br />

Main Drive Motor, Overhead Plate Support System, With Power Infeed Table, (16) 6-1/2"<br />

Diameter Rolls – (12) Powered / (4) Idler On 32" Centers, 100" Roll Width, Overall Table Size 9-<br />

1/2' Wide x 34' Length, Hydraulic Elevation, Rear-Side Hydraulic Plate Support System<br />

WELDING MANIPULATOR<br />

1 – ESAB MODEL CAB 460M 6x6 MTR COLUMN AND BOOM WELDING MANIPULATOR, S/N<br />

A101264 (2006), 236.2" (6M) Vertical Boom Stroke, 236.2" (6M) Horizontal Boom Stroke, 74.8<br />

IPM Vertical Boom Travel Speed, 59-78 IPM Variable Boom Stroke And Carriage Speed, 360°<br />

Rotating Column, Remote Video Monitoring System, ESAB A2-A6 Weld Process Controller<br />

SELF ADJUSTING TANK TURNING ROLLS<br />

2 SETS – ESAB MODEL 70 TAWEX SELF ADJUSTING TANK TURNING ROLLS, Each Set With<br />

(1) Power & (1) Idler Roll Stand, Set # C004703 – S/N C11007 (Power) / C10788 (Idler) (2006),<br />

Set # C004704 – S/Ns NA, (2006), 35-Ton Max. Load Per Unit, 105-Ton Turning Capacity,<br />

Remote Pendant Control, Motor Driven End Trucks<br />

3 – 4-WHEEL SELF ADJUSTING TANK TURNING ROLLS, Independent End Hydraulic Scissors<br />

Lift, Rubber Roll Size 6-1/2" Face x 20" Diameter, Hydraulic Power Unit, Hand-Held Pendant<br />

Control, Track Riding Manual End Trucks<br />

GROOVED STEEL WHEEL TANK ROLLS<br />

9 – GROOVED STEEL WHEEL PNEUMATIC DRIVEN TANK TURNING ROLLS, 50-Ton Capacity,<br />

With Quantig 3.74:1 Air Motor, 272 In-Lb. Output Torque, Roll Size 8" Face x 20" Diameter,<br />

Groove Size 3-1/4" Wide x 2" Deep, Track Riding Manual End Trucks<br />

9 – GROOVED STEEL WHEEL IDLER TANK TURNING ROLLS, 50-Ton Capacity, Single Steel Roll<br />

Each Side, Roll Size 8" Face x 20" Diameter, Groove Size 3-1/4" Wide x 2" Deep, Track Riding<br />

Manual End Trucks<br />

WIND TOWER FLANGE RINGS<br />

LARGE QUANTITY OF WIND TOWER FLANGE RINGS, Estimated Count (95), Used For Handling<br />

Tower Sections In Fabrication, Blast, Prime, And Paint Process, 2" Thick, Various OD's From 8' To 15'<br />

PORTABLE CIRCULAR FLANGE MILLING MACHINE<br />

1 – CLIMAX MODEL CM6000/6355-S1 PORTABLE CIRCULAR FLANGE MILLING MACHINE,<br />

S/N 1015445, (2009), ID Mounting Range 78.5" - 178.5", Milling Diameter Range 78.5" – 197",<br />

Flatness Tolerance .0004 Inches/Foot, 1.5 kW Servo Feed Motor, .0005 – 0.85 rpm Table Speed<br />

Range, 25 HP Hydraulic Power Unit, 15 HP Effective at Spindle, #50 Taper NMTB Tool Holder,<br />

24” Radial Travel per Set Up, 8” (Stroke Z-Axis) Spindle Travel, Turning Arm Swing Diameter,<br />

Min. 135”- Max. 208” S/N 1015445, Set-Up Accessories, Gang Box<br />

PORTABLE GANTRY MULTI-AXIS WIND TOWER<br />

DOOR CUTTING MACHINE<br />

1 – ADM CNC DOOR CUTTER, Approx. 77" x 156" Cutting Area, Allen Bradley Versa View 1500P<br />

Operator's Terminal, CAND CNC ESP II Enhanced Smart Power Servo Drive Control, 3-Axis<br />

Servo Driven Motors, Plasma Or Flame-Cut Capable<br />

WELDING POSITIONER<br />

1 – RANSOME MODEL 120PA 12,000-LB. CAPACITY POWER WELDING POSITIONER, S/N<br />

2122362, Rotation Torque 144,000-Lbs., Tilt Torque 267,000-Lbs., Variable Speed, Power Rotate<br />

& Tilt, 4' x4' T-Slotted Table, Pendant Control, Adjustable Base<br />

PAINT MIXING & PUMPING EQUIPMENT<br />

2 – COMPLETE PAINT MIXING KITCHENS, Equipment Including: (4) Graco Mixing & Pumping<br />

Stations, (18) Graco Air Powered Paint Pumps, (2) Graco Portable Solvent Pumps, (3) Graco<br />

Portable Air Powered Pumps, Cascade Automatic Spray Gun Cleaning System, Uni-Ram<br />

Solvent Recycler<br />

MATERIAL HANDLING & SUPPORT EQUIPMENT<br />

12 – CUSTOM CARBON BLOCK GROUNDING FRAMES, (3) Pneumatic Cylinder Adjustable<br />

Pad Holders<br />

1 – ATLAS COPCO MODEL KT75TV8034 7.5-HP TWO-STAGE VERTICAL TANK MOUNTED AIR COM-<br />

PRESSOR, S/N HOP34149<br />

1 – RED-D-ARC POWERMATE MODEL DP225 AC POWER DISTRIBUTION PANEL, S/N 1079A-<br />

6, (8) Interrupting Outlets, Stainless Steel Enclosure<br />

1 – AIRCRAFT PUSHER TRACTOR, Detroit Diesel, 4WD, 4WS, 12.00R24 Pneumatic Tires<br />

3 – CUSTOM BUILT PUSH-BACK BARS<br />

2 – CALDWELL MODEL UNIVAC 1500 VACUUM TYPE PLATE LIFTING SPREADER BAR<br />

ATTACHMENTS, S/N 08-92742-1, 08-92742-2, 28,000-Lb. Capacity<br />

2 SKIDS – CUSTOM CARBON BLOCK GROUNDING COMPONENTS, Including Frames, Arms, & Cylinders<br />

LARGE QUANTITY OF Flange Tables, Seam Weld Roll Tables, Track Riding Tower Section Transfer<br />

Cars, Transport Dollies, Scissors Lift Cart, Walk-Behind Electric Scissors Lift Cart, Spreader Bars,<br />

Hairpin C-Hooks, Electromagnetic Lifting Magnets, J-Hook Attachments, Rolling Scaffold & Work<br />

Platforms, Stationary Work Platforms, Assorted Sections Floor Rail Track, Walkways, Platforms,<br />

Risers, Etc.<br />

2009<br />

2007<br />

2006<br />

For more information, please visit us on the web at www.hilcoind.com 7

Ephrata, Washington Location Available as a Complete Turnkey Facility<br />

100,000 Sq. Ft. Modern Heavy Crane Serviced <strong>Industrial</strong> Buildings Built 2008<br />

Real Estate Also Available Separately<br />

Purchase long term ground lease with buildings and improvements, or lease one or both buildings on a year-to-year<br />

per-square-ft. basis. Discount available to the right tenant, subject to the approval of the port and present tenant.<br />

BUILDING #1 – 45,500 SQ. FT., 130' X 360' LONG,<br />

EAVE HEIGHT 32'8"<br />

• (2) Bays: first Bay 80' wide X 350' long, equipped with crane<br />

rails and uprights capable of up to 15-ton capacity overhead<br />

Bridge cranes, crane rail height 21'6"<br />

• (1) Bay 50' wide X 350' wide without Bridge crane rails<br />

• power - 2500 amps, 600 vAc, 3 phase<br />

HILCO WEBCAST/ONSITE AUCTION<br />

Complete plant closure, former assets of<br />

Complete State-of-the-Art Wind Tower Manufacturing Facility<br />

Featuring Large Heavy Plate Rolling & Mechanized Welding Equipment<br />

Large Quantity of Tank Turning Rolls, Work Rolls, Fit-Up Rolls & Grooved Steel Wheel Tank Rolls Available<br />

Thursday, April 18 th • Beginning at 9am Local Time<br />

Ephrata, WA & Columbus, NE<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, LLC • Headquarters 5 Revere Drive, Ste. 206 • Northbrook, IL 60062 • All rights reserved<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC Washington Auctioneer & License: Tim Pfister License #2923 • WA License #2382 • IL License #444.000215<br />

Printed in USA • KAT0267 • Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

BUILDING #2 – 56,000 SQ. FT., 160' X 350', EAVE HEIGHT 41'11"<br />

• (2) crane Bays: 80' wide each X 350' long, equipped with<br />

crane rails and uprights<br />

• (1) Bay capable of handling up to 15-ton capacity overhead<br />

Bridge cranes, crane rail height 32'10"<br />

• (1) Bay capable of handling up to 40-ton capacity overhead<br />

Bridge cranes, crane rail height 29'6"<br />

• power - 2500 amps, 600 vAc, 3 phase<br />

land Area 1225'X300', Approx. 367,500.00 sq. ft., Approx. 9 Acres.<br />

Additional land leases Available for Additional land or expansion. near to rail, siding on the Airport of ephrata<br />

Favorable Lease Assumptions Available, Contact Mark Reynolds at 205-595-5999 Or Email mreynolds@hilcoind.com for details.<br />

Terms of Sale<br />

An 18% buyer's premium will be charged on all assets. the<br />

buyer’s premium will be reduced to 15% for payments<br />

made by cash, company check or wire transfer. everything<br />

will be sold to the highest bidder for cash, in accordance<br />

with the Auctioneer’s customary “terms of sale”, copies of<br />

which will be posted on the premises of the sale and subject<br />

to additional terms announced the day of sale. All items<br />

will be sold “as is, where-is” without any warranties,<br />

expressed or implied. Although obtained from sources<br />

deemed reliable, the Auctioneer makes no warranty or<br />

guarantee to the accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the<br />

items on which they intend to bid prior to sale. Absolutely<br />

no items will be removed until the day after the conclusion<br />

of the sale and payment is made in full. subject to<br />

additions, deletions and prior sale. for updated information,<br />

please visit our website at www.hilcoind.com for any<br />

date, sale process, terms and conditions and list of<br />

available assets.<br />

Payment: All purchAses must Be pAiD in full on<br />

the DAy of the Auction. if you intend to pay by wire<br />

transfer, we will accept payment the day after the sale<br />

only if a deposit of 25% of total purchases is made on<br />

the day of the sale. contact our office for wire transfer<br />

instructions. only cash, wire transfer or certified check,<br />

payable to hilco industrial, llc will be accepted. company<br />

checks payable to hilco industrial, llc will be accepted<br />

only if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales tax.<br />

purchasers claiming exemptions from taxes must provide<br />

proof satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(Bank name) unconditionally guarantees payment to<br />

hilco industrial, llc from (company name). this<br />

guarantee will be valid for purchases made at the<br />

Auction of Katana summit on April 18, 2013.<br />

Follow<br />

Us on: