Pharmacy Guidance Document - himss

Pharmacy Guidance Document - himss

Pharmacy Guidance Document - himss

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

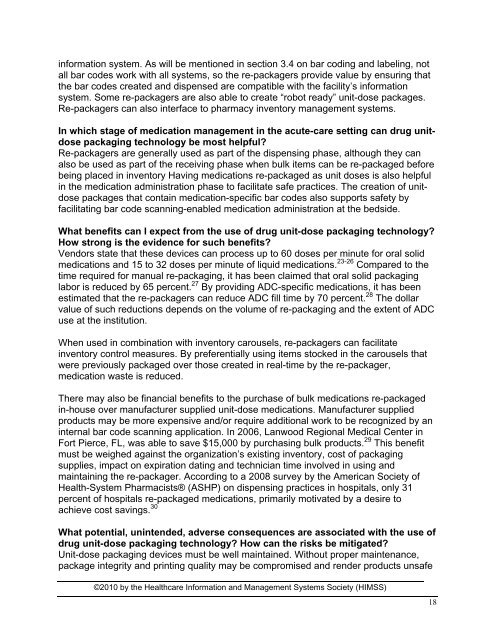

information system. As will be mentioned in section 3.4 on bar coding and labeling, not<br />

all bar codes work with all systems, so the re-packagers provide value by ensuring that<br />

the bar codes created and dispensed are compatible with the facility’s information<br />

system. Some re-packagers are also able to create “robot ready” unit-dose packages.<br />

Re-packagers can also interface to pharmacy inventory management systems.<br />

In which stage of medication management in the acute-care setting can drug unitdose<br />

packaging technology be most helpful?<br />

Re-packagers are generally used as part of the dispensing phase, although they can<br />

also be used as part of the receiving phase when bulk items can be re-packaged before<br />

being placed in inventory Having medications re-packaged as unit doses is also helpful<br />

in the medication administration phase to facilitate safe practices. The creation of unitdose<br />

packages that contain medication-specific bar codes also supports safety by<br />

facilitating bar code scanning-enabled medication administration at the bedside.<br />

What benefits can I expect from the use of drug unit-dose packaging technology?<br />

How strong is the evidence for such benefits?<br />

Vendors state that these devices can process up to 60 doses per minute for oral solid<br />

medications and 15 to 32 doses per minute of liquid medications. 23-26 Compared to the<br />

time required for manual re-packaging, it has been claimed that oral solid packaging<br />

labor is reduced by 65 percent. 27 By providing ADC-specific medications, it has been<br />

estimated that the re-packagers can reduce ADC fill time by 70 percent. 28 The dollar<br />

value of such reductions depends on the volume of re-packaging and the extent of ADC<br />

use at the institution.<br />

When used in combination with inventory carousels, re-packagers can facilitate<br />

inventory control measures. By preferentially using items stocked in the carousels that<br />

were previously packaged over those created in real-time by the re-packager,<br />

medication waste is reduced.<br />

There may also be financial benefits to the purchase of bulk medications re-packaged<br />

in-house over manufacturer supplied unit-dose medications. Manufacturer supplied<br />

products may be more expensive and/or require additional work to be recognized by an<br />

internal bar code scanning application. In 2006, Lanwood Regional Medical Center in<br />

Fort Pierce, FL, was able to save $15,000 by purchasing bulk products. 29 This benefit<br />

must be weighed against the organization’s existing inventory, cost of packaging<br />

supplies, impact on expiration dating and technician time involved in using and<br />

maintaining the re-packager. According to a 2008 survey by the American Society of<br />

Health-System Pharmacists® (ASHP) on dispensing practices in hospitals, only 31<br />

percent of hospitals re-packaged medications, primarily motivated by a desire to<br />

achieve cost savings. 30<br />

What potential, unintended, adverse consequences are associated with the use of<br />

drug unit-dose packaging technology? How can the risks be mitigated?<br />

Unit-dose packaging devices must be well maintained. Without proper maintenance,<br />

package integrity and printing quality may be compromised and render products unsafe<br />

©2010 by the Healthcare Information and Management Systems Society (HIMSS)<br />

18