Introduction to rubber processing and safety issues - HSE

Introduction to rubber processing and safety issues - HSE

Introduction to rubber processing and safety issues - HSE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Calendering<br />

<strong>Introduction</strong><br />

A calender is a machine with a number of horizontal rolls (sometimes called bowls), heated or unheated, through<br />

which material <strong>and</strong>/or <strong>rubber</strong> is passed under pressure. They can create either a <strong>rubber</strong> sheet of a required<br />

thickness, or apply a thin layer of <strong>rubber</strong> on<strong>to</strong> a cloth liner. This is known as frictioning or combining.<br />

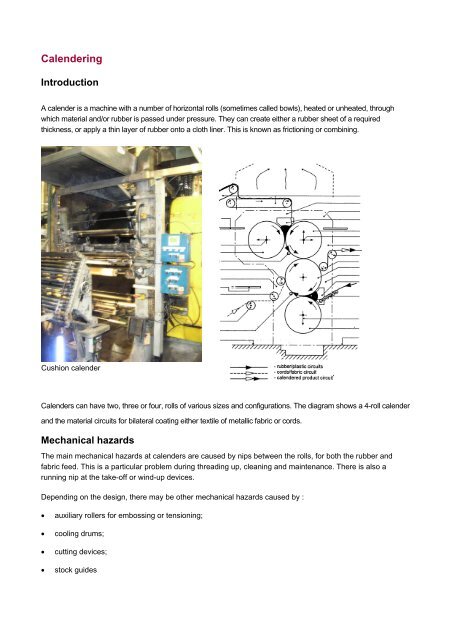

Cushion calender<br />

Calenders can have two, three or four, rolls of various sizes <strong>and</strong> configurations. The diagram shows a 4-roll calender<br />

<strong>and</strong> the material circuits for bilateral coating either textile of metallic fabric or cords.<br />

Mechanical hazards<br />

The main mechanical hazards at calenders are caused by nips between the rolls, for both the <strong>rubber</strong> <strong>and</strong><br />

fabric feed. This is a particular problem during threading up, cleaning <strong>and</strong> maintenance. There is also a<br />

running nip at the take-off or wind-up devices.<br />

Depending on the design, there may be other mechanical hazards caused by :<br />

<br />

<br />

<br />

<br />

auxiliary rollers for embossing or tensioning;<br />

cooling drums;<br />

cutting devices;<br />

s<strong>to</strong>ck guides