for TRACTORS - HydraForce

for TRACTORS - HydraForce

for TRACTORS - HydraForce

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

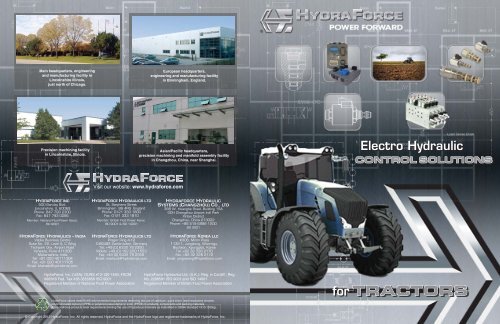

Main headquarters, engineering<br />

and manufacturing facility in<br />

Lincolnshire Illinois,<br />

just north of Chicago.<br />

European headquarters,<br />

engineering and manufacturing facility<br />

in Birmingham, England.<br />

Precision machining facility<br />

in Lincolnshire, Illinois.<br />

Asian/Pacific headquarters,<br />

precision machining and manifold assembly facility<br />

in Changzhou, China, near Shanghai.<br />

Electro Hydraulic<br />

CONTROL SOLUTIONS<br />

Visit our website: www.hydra<strong>for</strong>ce.com<br />

HYDRAFORCE INC<br />

500 Barclay Blvd.<br />

Lincolnshire, IL 60069<br />

Phone: 847 793 2300<br />

Fax: 847 793 0086<br />

Member: National Fluid Power Assoc.<br />

ISO 9001<br />

HYDRAFORCE HYDRAULICS – INDIA<br />

Vatika Business Centre<br />

Suite No. 22, Level 5, C Wing<br />

Techpark One, Airport Road<br />

Yerwada, Pune 411006<br />

Maharashtra, India<br />

Tel: +91 020 40111304<br />

Fax: +91 020 40111105<br />

Email: bharatb@hydra<strong>for</strong>ce.com<br />

HYDRAFORCE HYDRAULICS LTD<br />

St. Stephens Street<br />

Birmingham B6 4RG England<br />

Phone: 0121 333 1800<br />

Fax: 0121 333 1810<br />

Member: British Fluid Power Assoc.<br />

ISO 9001 & ISO 14001<br />

HYDRAFORCE HYDRAULICS LTD<br />

Prager Ring 4-12<br />

D-66482 Zweibrücken, Germany<br />

Tel: +49 (0) 6332 79 2350<br />

Mobile: +49 (0) 162 200 1553<br />

Fax: +49 (0) 6332 79 2359<br />

Email: markusb@hydra<strong>for</strong>ce.com<br />

HYDRAFORCE HYDRAULIC<br />

SYSTEMS (CHANGZHOU) CO., LTD<br />

388 W. Huanghe Road, Building 15A<br />

GDH Changzhou Airport Indl Park<br />

Xinbei District<br />

Changzhou, China 213022<br />

Phone: +86 519 6988 1200<br />

ISO 9001<br />

HYDRAFORCE KOREA LLC<br />

#306, Mirim Plaza<br />

1132-1, Jungdong, Wonmigu,<br />

Bucheon, Kyunggido, Korea<br />

Tel: +82 32 328 2170<br />

Fax: +82 32 328 2172<br />

Email: jong-seongl@hydra<strong>for</strong>ce.com<br />

<strong>HydraForce</strong>, Inc. (USA): DUNS #13-120-1493; FSCM<br />

#005K6 Fed. Tax #36-3555856 ISO 9001<br />

Registered Member of National Fluid Power Association<br />

<strong>HydraForce</strong> Hydraulics Ltd. (U.K.): Reg. in Cardiff.; Reg.<br />

No. 2286591 ISO 9001 and ISO 14001<br />

Registered Member of British Fluid Power Association<br />

<strong>HydraForce</strong> valves meet RoHS environmental requirements restricting the use of cadmium, quick silver, lead hexavalent chrome,<br />

polybrominated biphenyl (PPB) or polybrominated diphenyl ester (PPDE) in products, components and packing materials.<br />

All <strong>HydraForce</strong> products meet requirements limiting the use of hazardous materials as indentified in OSHA Standard 1910.1200(g).<br />

<strong>for</strong> <strong>TRACTORS</strong><br />

© Copyright 2012 <strong>HydraForce</strong>, Inc. All rights reserved. <strong>HydraForce</strong> and the <strong>HydraForce</strong> logo are registered trademarks of <strong>HydraForce</strong>, Inc.

TABLE OF CONTENTS<br />

<strong>HydraForce</strong> hydraulic controls can enhance the capability of any tractor – from<br />

the most basic, value models to the top-of-the-line models equipped with the latest<br />

& most sophisticated options.<br />

Auxiliary Functions -<br />

Hitch Release with Power Lift,<br />

Hydraulic Power Take-Off with<br />

Flow Sharing, Load Sense<br />

EH-Boost..............Pages 10-11<br />

• Increased functionality<br />

• Wide range of adaptable<br />

solutions <strong>for</strong> precise control<br />

• Low leakage load-holding<br />

• Stand-alone or custom<br />

manifold designs<br />

• Flow capabilities up to<br />

380 lpm/100 gpm<br />

With our comprehensive line of cartridge valves, manifolds, and high per<strong>for</strong>mance<br />

electronic controls, <strong>HydraForce</strong> can provide numerous custom control<br />

solutions <strong>for</strong> tractors. This brochure shows some easy ways to apply electrohydraulics<br />

on tractors to improve per<strong>for</strong>mance, increase efficiency, reduce fuel<br />

consumption, reduce operator fatigue, minimize vibration and ensure machine<br />

safety.<br />

Powertrain - Transmission, Lube Control,<br />

PTO Control, Cooling, Clutch........Pages 4-5<br />

• Precise Control<br />

• Rugged & Reliable<br />

• 10,000,000 cycle life testing<br />

• 1,000 hours salt spray rating<br />

• IP69K waterproof coil<br />

The <strong>HydraForce</strong><br />

Difference...........Page 12<br />

Primary Functions -<br />

Brakes, Hitch Control, Accumulator<br />

Charging, Steering........Pages 8-9<br />

• Reliablility & safety<br />

• Power & fuel ecconomy<br />

• Flow capabilities up to 530 lpm/140 gpm<br />

• Dynamic braking solutions<br />

• Pressure Equipment Directive (PED) rated<br />

Electronic Controls.........Page 13<br />

• Rugged & reliable<br />

• Hardware & software<br />

• CoDeSys programming<br />

• Flexible configurations<br />

Suspension Systems -<br />

Front Axle, Cab,<br />

Seat,..........Pages 6-7<br />

• Com<strong>for</strong>t<br />

• Fixed or adaptable<br />

• Improved safety<br />

• Highest quality guaranteed<br />

• Speed to market<br />

• Flexible and responsive<br />

• Over 600 combined years of<br />

cartridge development<br />

experience<br />

• Leading edge technology<br />

2 3

POWERTRAIN<br />

Transmission<br />

Lube Control<br />

PTO Control<br />

Cooling<br />

Clutch<br />

Transmission and PTO Solutions<br />

The circuit shown has a nominal flow<br />

rate of 114 lpm/30 gpm with a main<br />

system relief valve.<br />

Torque Converter<br />

SV98-T39<br />

TS98-T34<br />

Lubrication<br />

TS98-T34<br />

EP12-S35<br />

EP12-S35<br />

Optimize tractor powertrain systems with<br />

hydraulic cartridge valves and manifolds with<br />

programmable controllers.<br />

Synchronize control of transmission clutch, PTO, and fan<br />

with the <strong>HydraForce</strong> CoreTek controller. Its programming<br />

software is available as a free download from the<br />

<strong>HydraForce</strong> web site. The CoreTek controller (circuit<br />

at right) can synchronize proportional valves, such as<br />

the TS98-T34, to regulate <strong>for</strong>ward, reverse and multiple<br />

clutch actuation with smooth and accurate control<br />

of pressure. Clutch fill characteristics can be customprogrammed.<br />

PTO control can be accomplished with the<br />

EHPR98-T38 proportional valve, and fan control with the<br />

TS10-27 pressure regulator valve.<br />

Clutch Engagement Per<strong>for</strong>mance (TS98-T34)<br />

Cooler<br />

SV98-T39<br />

Park Brake<br />

Diff Lock<br />

SV98-T39<br />

4WD<br />

TS98-T34<br />

Fwd Clutch<br />

Rev Clutch<br />

TS98-T34 TS98-T34 EHPR98-T38<br />

1st Clutch<br />

2nd Clutch<br />

3rd Clutch<br />

PTO Clutch<br />

T<br />

Use a Priority Flow Control circuit to give priority to<br />

steering and brakes then allow hydraulic flow <strong>for</strong> other<br />

tractor functions, such as plowing, planting, harvesting,<br />

loading, or suspension control.<br />

EHPR98-T38 Valve<br />

<strong>for</strong> PTO Control<br />

• Clutch engage / disengage, Power Shift<br />

• Accurate clutch pressure control<br />

• Lubrication pressure control<br />

• Main system pressure regulation<br />

• Diff. Lock engage / disengage<br />

• PTO control<br />

Fan Drive Solutions<br />

TSXX-20<br />

CV10-20<br />

SV10-40<br />

A<br />

Fan<br />

Quiet down that fan . . .<br />

Fan drives controlled by hydraulic cartridge valves are<br />

quieter and run on less horsepower than mechanical fan<br />

drives, providing greater fuel economy <strong>for</strong> tractors.<br />

Control valves with multiple temperature inputs can be<br />

used to provide variable fan speed control depending on<br />

air temperature, load, and cooling requirements. If the<br />

radiator gets clogged, two-position, four-way solenoid<br />

valves can automatically reverse fan direction.<br />

Electronic control of the hydraulic cooling system can be<br />

achieved using either an EFDR1 programmable valve<br />

driver or a CoreTek controller (ECU).<br />

Fan Output Per<strong>for</strong>mance<br />

TO<br />

ECM<br />

CoreTek<br />

Model<br />

ECU-0710<br />

CAN HI<br />

CAN LOW<br />

Plug-In<br />

Mount<br />

on<br />

Forward<br />

Valve<br />

Operator Input<br />

4<br />

3<br />

2<br />

1<br />

TS98-T34<br />

Valves <strong>for</strong><br />

Clutch<br />

Control<br />

Reverse<br />

Forward<br />

B<br />

4<br />

3<br />

TS10-27 Valve<br />

<strong>for</strong> Fan Control<br />

2<br />

1<br />

• Flow rates up to 190 lpm (50 gpm)<br />

• Fail safe high or low<br />

• Preconfigured controls available<br />

• Reduce horsepower consumption by up to 30%<br />

4 5

SUSPENSION SYSTEMS<br />

Cab Suspension<br />

Seat Suspension<br />

Axle Suspension<br />

Health and safety consciousness is driving the need <strong>for</strong><br />

better suspensions in tractors. International standards,<br />

such as Vibration Directive 2002/44/EC have heightened<br />

awareness of the impact that vibration, stress and shock<br />

can have on the driver. Tractor manufacturers are seeking<br />

ways to improve seat, cabin, and front axle suspensions<br />

– many of these improvements can be made with<br />

the use of hydraulic cartridge valves and manifolds.<br />

Front Axle Suspensions in Tractors<br />

Increased tractor speeds, greater differences and wider<br />

ranges of load distribution and terrain have created a<br />

resurgence in the use of the suspended front axle to the<br />

tractor market.<br />

A hydro-pneumatic suspension system is an effective<br />

way to reduce vibration on a suspended front axle. A<br />

cartridge manifold is used with an accumulator to keep<br />

the cylinder in its nominal position. The accumulator<br />

functions as a spring by restricting the oil flow and<br />

damping the vibration. With the cylinder in its nominal<br />

position, it can extend completely, to its full stroke.<br />

Hydro-pneumatic suspension systems can be further<br />

enhanced with the addition of a level control manifold<br />

coupled with a position sensor and Electronic Control<br />

Unit (ECU). With an enhanced, “intelligent” system, the<br />

cylinder can fully complete each stroke, regardless of<br />

the load on the axle.<br />

Basic Suspension Solution<br />

This basic hydro-pneumatic suspension system is idea <strong>for</strong><br />

cabin or seat suspension or <strong>for</strong> tractors with a small axle load<br />

range.<br />

• Single or double acting cylinder<br />

• Accumulator<br />

• Level control manifold<br />

• Cartridge valves<br />

• Pressure ratio 1:3 between empty and max loaded axle<br />

RV08-20<br />

RV1<br />

SV08-20<br />

SV1<br />

CYL1<br />

T<br />

ACC1<br />

CK<br />

LS<br />

P<br />

SVCL08-30<br />

SVCL1<br />

Advanced Suspension Solution<br />

Travelling over rough or uneven ground is typical <strong>for</strong> tractors.<br />

When there is a high variance between minimum and<br />

maximum axle load, a more sophisticated axle suspension<br />

system is required, with a spring rate that adjusts continuously<br />

to driving speed, acceleration, or terrain.<br />

• Double-acting system<br />

• Independent accumulators <strong>for</strong> cylinder piston and rod<br />

side<br />

• Constant or variable pressure on rod side<br />

• Integral sensors<br />

• Software developement<br />

• Pressure ratio of more than 1:20 between empty and<br />

max loaded axle<br />

Suspension Options – Damping and Lockout<br />

Front axle suspensions can be designed with special options<br />

<strong>for</strong> damping and lockout using cartridge valves and<br />

manifolds.<br />

Lockout – Sometimes it is desirable to lock out the<br />

suspension. This can be accomplished with a lock-out<br />

manifold that can be used to over-damp the suspension<br />

or completely lock the connection between the hydraulic<br />

cylinder and accumulator.<br />

ACC1<br />

CYL1<br />

Damping – With an intelligent control algorithm in combination<br />

with a proportional valve which acts as a variable<br />

orifice to restrict oil flow between the cylinder and<br />

accumulator, a semi-active suspension system can be<br />

created.<br />

CYL1<br />

ACC2<br />

PC2<br />

SV2<br />

P<br />

CR<br />

ACC2<br />

CV1<br />

LS<br />

ACC1<br />

CP<br />

PC1<br />

SV1<br />

RV1<br />

T<br />

ACC1<br />

How It Works:<br />

Hydro-pneumatic Suspension Diagram<br />

In a hydro-pneumatic suspension system,<br />

a cylinder and accumulator replace the<br />

torsion or leaf spring. The accumulator<br />

acts as the spring and, with restrictions <strong>for</strong><br />

oil flow, damping can be accomplished.<br />

ORF1<br />

CV1<br />

SP1<br />

SV1<br />

6 7

PRIMARY FUNCTIONS<br />

Hitch<br />

Brakes<br />

Accumulator Charging<br />

Steering<br />

<strong>HydraForce</strong> offers valves that are well suited<br />

to the unique needs of Dynamic<br />

Accumulator Charging Circuits which are<br />

commonly used in conjunction with steering<br />

and braking units. Hydraulic braking systems<br />

are common on tractors and towable<br />

implements. These circuits require a delicate<br />

balance between the priority flow steering<br />

and braking sections of the application, while<br />

simultaneously allowing excess flow to be<br />

diverted to tank or various auxiliary functions.<br />

A typical circuit provides priority flow <strong>for</strong><br />

the steering orbital while maintaining a<br />

predetermined range of pressure in the<br />

accumulator(s), to ensure adequate supply of<br />

oil <strong>for</strong> up to 7 brake depressions in the case<br />

of power loss. If one accumulator fails, the<br />

LS10-41 will shift over to protect the operational<br />

one. The ECxx- 42 provides priority<br />

flow in required amount while allowing excess<br />

flow to be used <strong>for</strong> auxiliary functions.<br />

Primary Functions<br />

Primary Functions are the basic / standard control circuits, such<br />

as Steering, Braking, and Hitch (Lift) Control.<br />

Steering / Braking<br />

These functions have priority over all other hydraulic demands.<br />

<strong>HydraForce</strong> manufacture a range of priority on demand pressure<br />

compensators with dynamic load sensing <strong>for</strong> fast response. With<br />

7 different models of priority on demand pressure compensator<br />

valves (ECxx-43), the rated flow capacities range from 34 lpm to<br />

530 lpm (9 gpm to 140 gpm).<br />

Dual Accumulator Charging<br />

<strong>HydraForce</strong> Inverted Shuttle Valve LS10-41 provides<br />

additional safety when using dual accumulators. In the event of<br />

one accumulator failing (eg a ruptured bladder, etc.), the failed<br />

accumulator is isolated from the rest of the circuit, allowing the<br />

second accumulator to supply steering / braking.<br />

Primary Steering and Brake Solution<br />

BRAKES<br />

PRE-CHARGE<br />

BRAKES<br />

DYNAMIC<br />

STEERING<br />

RVD50-20P, PED rated product <strong>for</strong> accumulator charging circuits<br />

The RVD50-20P is a direct-acting, poppet type, hydraulic safety relief valve. The<br />

RVD50-20P is suitable <strong>for</strong> use as a safety accessory in Category IV, Group 2<br />

applications according to the pressure equipment directive (PED) 97/23/EC, which is<br />

primarily concerned with the protection of Accumulator Circuits. This is particularly<br />

well suited <strong>for</strong> dynamic brake charging circuits where pressure clipping and quick<br />

discharge of energy is often needed.<br />

Hitch (Lift Control)<br />

As tractor power and sophistication increases, so do the flow rates. <strong>HydraForce</strong> SPCL16-30 valves gives precise control<br />

up to 150 lpm (40 gpm) while holding the loads with extremely low leakage. <strong>HydraForce</strong> RV10-28 and RVD50-20 relief<br />

valves limit the shock pressure peaks whilst having very low leakage and hysteresis.<br />

Rear Hitch Control Circuit<br />

SP16-20<br />

Rear Hitch<br />

0 to150 LPM<br />

A<br />

Proportional Hitch Control Circuit<br />

SP10-20<br />

CV10-20<br />

RVD50-20<br />

SPCL10-30<br />

RV10-20<br />

SP10-20<br />

LS10-41<br />

T<br />

LS<br />

IN<br />

150 LPM MAX<br />

EP10-S35<br />

CV08-20<br />

Front & Rear Hitch Control Circuit<br />

Steering Flow<br />

FRONT HITCH<br />

A : 0 - 150 LPM<br />

LS<br />

REAR HITCH LIFT<br />

B : 0 - 150 LPM<br />

UP10-40<br />

Excess Flow<br />

Load Sense<br />

RVD50-20<br />

RVD50-20<br />

to Auxiliary<br />

Functions<br />

SP16-20<br />

CV16-20<br />

CV16-20<br />

SP16-20<br />

EC16-42<br />

RV08-20 Valve<br />

(Set higher than UP Valve)<br />

EHPR98-T35A<br />

LS06-B30<br />

EHPR98-T35A<br />

• Primary Flow to the brake section of<br />

the circuit<br />

• Auxiliary Flow diverted to the<br />

directional function<br />

IN<br />

150 LPM MAX<br />

PE12-S67H<br />

8 9

AUXILIARY FUNCTIONS<br />

Hitch<br />

Plow<br />

Traction Control<br />

Tractors per<strong>for</strong>m a multitude of tasks. Plowing, planting,<br />

baling, load-handling or harvesting can be done<br />

with greater speed and power with the right hydraulic<br />

controls. Here are some <strong>HydraForce</strong> solutions<br />

<strong>for</strong> tractor auxiliary functions.<br />

Pilot Valves Guide the Flow<br />

Just as tractors per<strong>for</strong>m a multitude of functions,<br />

<strong>HydraForce</strong> pilot valves guide a multitude of flows.<br />

These valves have an integral, waterproof solenoid<br />

coil.<br />

SV98-T39, T40<br />

For low pressure pilot systems, the SV98-T39 and<br />

SV98-T40 valves are an economical choice. The T39<br />

is a three way valve and the T40 is a four way.<br />

EHPR98-T33, T35 and T38<br />

These proportional pressure control valves come in<br />

several sizes to control from 4 lpm (1.05 gpm) to 18<br />

lpm (5 gpm) and two pressure ranges - 10.3 bar 1500<br />

psi) or 241 bar (3500 psi). They are drop-in style,<br />

flange mounted, direct-acting, and can be infinitely<br />

adjusted using a variable electric input.<br />

TS98-T34<br />

For demanding applications with high flow, the TS98-<br />

T34 proportional pressure reducing valve can be used<br />

as a pressure limiting device. It’s a spool-type, drop in<br />

proportional valve that can be infinitely adjusted.<br />

EH Reducing/ Relieving<br />

Proportional Control<br />

TS98-T34<br />

30 lpm/8 gpm<br />

30 bar/435 psi<br />

EHPR Reducing/ Relieving<br />

Proportional Control<br />

EHPR98-T33<br />

3.8 lpm/1 gpm<br />

241 bar/3500 psi<br />

Max. Reducing<br />

Pressure: 31 bar/450 psi<br />

EHPR98-T35<br />

5.7 lpm/1.5 gpm<br />

103 bar/1500 psi<br />

With the '-T35A' option,<br />

241 bar/3500 psi per<strong>for</strong>mance<br />

can be achieved.<br />

Max. Reducing<br />

Pressure: 20 bar/290 psi<br />

EHPR98-T38<br />

19 lpm/5 gpm<br />

241 bar/3500 psi<br />

Max. Reducing<br />

Pressure: 31 bar/450 psi<br />

Hydraulic Power<br />

Take-off with Flow<br />

Sharing<br />

<strong>HydraForce</strong> Auxiliary<br />

Function Circuits provide<br />

precise control of flows<br />

<strong>for</strong> balers, crop harvesters,<br />

and other auxiliary<br />

equipment.<br />

Higher productivity requires<br />

higher flows, and<br />

<strong>HydraForce</strong> cartridge<br />

valves can handle flows<br />

up to 300 lpm (79 gpm).<br />

When the flow demand<br />

exceeds the system<br />

supply, flow sharing can<br />

help maintain effective<br />

control.<br />

SP16-20<br />

EC16-32<br />

A<br />

0 - 150 lpm<br />

IN<br />

0 - 150 lpm<br />

Load Sense Boost<br />

Higher flows and shorter response times are<br />

possible with load sense boosting. When lower<br />

flows are adequate <strong>for</strong> the job, reduce standby<br />

pressures to save power.<br />

Hydraulic PowerTake-Off with Flow Sharing Circuit<br />

CV06-B20<br />

EP16-S35<br />

LS<br />

SP12-20<br />

B<br />

0 - 100 lpm<br />

CV06-B20<br />

CV06-B20<br />

EP12-S35<br />

SP10-20<br />

Hitch Release and Power Lift<br />

C<br />

0 - 60 lpm<br />

CV06-B20<br />

EP10-S35<br />

Positioning and attaching the rear lift hitch attachment<br />

from the cab gives increased productivity and improved<br />

operator com<strong>for</strong>t and safety.<br />

Load Sense Boost Circuit<br />

Hitch Release with Power Lift Circuit<br />

LS SIGNALS IN<br />

A<br />

B<br />

C<br />

D<br />

A<br />

B C D<br />

Solenoid Selector Valves<br />

SV98-T39<br />

30 lpm/8 gpm<br />

45 bar/650 psi<br />

E-H BOOST<br />

LS - OUT<br />

LS10-50<br />

P<br />

T<br />

SP10-57C<br />

SP10-57C<br />

LS - IN<br />

SV98-T40<br />

30 lpm/8 gpm<br />

45 bar/435 psi<br />

EHPR08-33xx<br />

P<br />

LS - OUT<br />

LS06-30<br />

10 11

VALVES AND ELECTRONIC CONTROLS<br />

SPCL16-40<br />

Proportional Directional Control,<br />

4-Port, Normally Closed with Check<br />

Isolated Load Sense<br />

HSPEC16-30<br />

Proportional Flow Control Valve with<br />

Integral Compensator<br />

Electronic Controls<br />

Model ECU-0710<br />

Up to 27 inputs, consisting of digital, pulse, current<br />

measuring feedback and analog. A total of seven<br />

output configurations can be set, including six PWM<br />

or digital high-side drivers and a single low-side<br />

driver.<br />

Model ECU-2415<br />

Up to 39 digital, pulse, current measuring feedback<br />

and analog inputs along with 24 outputs consisting of<br />

up to 24 PWM or digital high-side drivers.<br />

Flow: 152 lpm/40 gpm<br />

Pressure: 250 bar (3625 psi)<br />

HSV10-47C<br />

High Pressure Spool 4-Port,<br />

3-Position, Closed Center<br />

Flow: 132 lpm/35 gpm<br />

Pressure: 350 bar (5075 psi)<br />

RVCV56-20<br />

Relief, Directing Acting Poppet with<br />

Reverse Flow Check<br />

Model ECU-2032<br />

Up to 52 inputs and 20 outputs consisting of up to<br />

eight PWM or 20 digital high-side drivers.<br />

Model ECU-2820<br />

Up to 52 inputs and 28 outputs consisting of up to 24<br />

PWM or digital high-side drivers and up to four digital<br />

low-side drivers.<br />

Flow: 37.9 lpm/10 gpm<br />

Pressure: 350 bar (5075 psi)<br />

EHPR98-T3x<br />

Proportional, Reducing / Relieving,<br />

Drop-in<br />

1<br />

2<br />

Flow: 115 lpm/30 gpm<br />

Pressure: 420 bar (6100 psi)<br />

TSxx-27<br />

Proportional Pressure Control, Pilot-<br />

Operated Relief<br />

CORETEK PROGRAMMABLE<br />

MACHINE CONTROLLERS<br />

The new CoreTek line of general-purpose programmable<br />

controllers can be used as stand-alone<br />

controllers or integrated with other CAN networked<br />

devices. They are designed to withstand the environmental<br />

demands of mobile off-highway equipment<br />

applications. They feature flexible input and<br />

output configuration and are capable of driving up to<br />

3.0 amps per output pin.<br />

CoreTek controllers are fully sealed within a compact<br />

cast aluminum housing. Operating temperature<br />

range is -40° to +70°C (-40° to 158°F) and no external<br />

cooling or heat dissipation is required.<br />

SENSOR VALVES<br />

Select <strong>HydraForce</strong> valves can be<br />

ordered with an integral position<br />

sensing option capable of<br />

transmitting an on or off signal.<br />

This new sensing solution was<br />

designed <strong>for</strong> interchangeable use<br />

with existing <strong>HydraForce</strong> cartridge<br />

valves, is compatible with manual<br />

override options and uses an<br />

industry standard cavity.<br />

Flow: 18.9 lpm/5.0 gpm<br />

Pressure: 241 bar (3500 psi)<br />

Flow: up to 189 lpm/50 gpm<br />

Pressure: 241 bar (3500 psi)<br />

Our Breadth of Product<br />

As the largest manufacturer of hydraulic cartridge valves in the world, <strong>HydraForce</strong> offers an extensive range of solenoid,<br />

electro-proportional, directional, flow, and pressure control valves. In 2011, more than 200 new valves were introduced,<br />

including many high pressure and multi-function models. Cartridge valves <strong>for</strong> flow rates up to 379 lpm/100 gpm and<br />

operating pressures up to 350 bar/5,000 psi are sold individually, with housings or in manifold blocks. Valves can be<br />

custom-designed or standard product.<br />

<strong>HydraForce</strong> designs, manufactures and supports valve, manifold and accessory products supported by heavy duty<br />

electronic machine control capabilities.<br />

To request a free hydraulic integrated circuit (HIC) consultation, please visit:<br />

http://info.hydra<strong>for</strong>ce.com/Free-Custom-Circuit-Consultation/<br />

CoDeSys TM Programming<br />

CoDeSys or Controlled Development System is a<br />

complete development environment <strong>for</strong> Programmable<br />

Machine Controllers. The editors and debugging<br />

functions are based on the proven development<br />

program environments of advanced programming<br />

languages (such as Visual C++).<br />

CoDeSys software is available as a free download<br />

from <strong>HydraForce</strong>:<br />

http://www.hydra<strong>for</strong>ce.com/Electronics/<br />

CoDeSys software: Copyright © 3S - Smart Software Solutions GmbH<br />

HEAVY DUTY SENSORS<br />

<strong>HydraForce</strong> has accurate sensors designed <strong>for</strong> off-road applications.<br />

Our temperature sensors are thermistor style with padded resistors.<br />

ERT 120 – Output Signal: 5427.9 to 436.3 ohms<br />

Our pressure sensors have 1% total error band accuracy, are IP67 rated.<br />

ERP035 – <strong>for</strong> pressure ranges up to 35 bar (500 psi)<br />

ERP414 – <strong>for</strong> higher pressures up to 414 bar (6000 psi)<br />

12 13

OUR STORY<br />

Our Story<br />

The <strong>HydraForce</strong> story began in 1985 when the company<br />

was founded near Chicago by several partners who saw<br />

the mobile equipment industry’s need <strong>for</strong> quality hydraulic<br />

cartridge valves and manifolds delivered in a timely and<br />

responsive manner. They also saw the potential <strong>for</strong><br />

engineering innovation and design flexibility offered by<br />

cost-effective and space-saving cartridge valves and<br />

hydraulic integrated circuits.<br />

Since its founding, <strong>HydraForce</strong> continues to be a<br />

privately held company as it has grown to several<br />

manufacturing locations in North America, Europe and<br />

Asia, with a network of 120 stocking distributors who can<br />

offer local support across the globe.<br />

To maintain our core competency of speed to market,<br />

<strong>HydraForce</strong> has invested in application technical support<br />

tools including i-Design, our free hydraulic system design<br />

sofware, which integrates seamlessly with 3rd party<br />

simulation software, monthly webinars on new products<br />

and application tips, and an online product catalog.<br />

All <strong>HydraForce</strong> products carry a five-year limited<br />

warranty against defects in material and workmanship.<br />

<strong>HydraForce</strong> Vision<br />

To Be An Independent<br />

Provider Of Innovative<br />

Technical Solutions<br />

That Can Change The<br />

World<br />

Mission Statement<br />

To Provide Our Customers<br />

With The Highest Quality<br />

Hydraulic Valves And The<br />

Most Responsive Customer<br />

Support In The World<br />

Our Quality and Manufacturing Guarantee<br />

All three <strong>HydraForce</strong> plants in North America, Europe<br />

and Asia follow the same manufacturing processes and<br />

standards to ensure global consistency in product quality.<br />

• All products 100% tested<br />

• Use of Lean and Six Sigma practices<br />

• New product introduction tools such as:<br />

• Advanced Product Quality Planning (APQP)<br />

• Production Part Approval Process (PPAP)<br />

• Failure Mode and Effect Analysis (FMEA)<br />

• Statistical Process Control (SPC)<br />

• Continuous improvement through Kaizen<br />

• Responsive delivery with Kanban throughput system<br />

<strong>HydraForce</strong> Timeline<br />

1985<br />

<strong>HydraForce</strong> is created<br />

on principles of highest<br />

quality and customer<br />

response<br />

1988<br />

Achieved Ford Q1<br />

quality certification<br />

on first audit<br />

1991<br />

Achieved<br />

ISO 9001<br />

1993<br />

Achieved<br />

QS9000<br />

2006<br />

Received<br />

ISO 14001:2004<br />

2008<br />

Opened<br />

office in<br />

India<br />

2012<br />

To date, 13 patents<br />

have been awarded<br />

<strong>for</strong> innovative valve<br />

designs<br />

Received ISO 13849<br />

1985 1988 1990 1991 1995 2000 2005 2010 2011 2015 2020<br />

1989<br />

Opened<br />

European<br />

operation<br />

Worldwide Support<br />

1993<br />

Moved into<br />

Lincolnshire<br />

operation<br />

1997<br />

Expanded global<br />

headquarters<br />

by 50,000 sqft &<br />

opened Plant #2<br />

1999<br />

<strong>HydraForce</strong><br />

became #1 global<br />

manufacturer<br />

of cartridge valves<br />

2001<br />

Expanded global<br />

headquarters<br />

by 70,000 sqft &<br />

built new 50,000 sqft<br />

EU Operation<br />

2010<br />

Formalized 2015<br />

Strategic Plan &<br />

paid off all long<br />

term debt<br />

2011<br />

Opened 4th global<br />

mfg operation in<br />

China<br />

2005<br />

Opened offices<br />

in Korea, and<br />

China<br />

ISO 9001<br />

Continue<br />

global<br />

expansion<br />

MANUFACTURING<br />

TECHNICAL SALES<br />

DISTRIBUTION & SUPPORT<br />

14 15