Coestherm® Coesklima Superk®

Coestherm® Coesklima Superk®

Coestherm® Coesklima Superk®

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ASSEMBLY AND INSTALLATION INSTRUCTIONS<br />

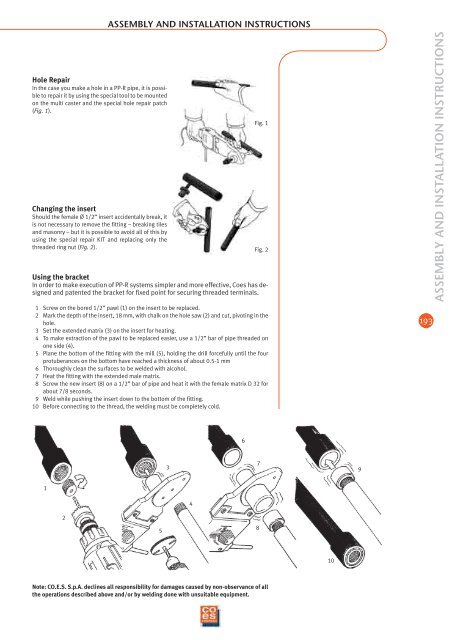

Hole Repair<br />

In the case you make a hole in a PP-R pipe, it is possible<br />

to repair it by using the special tool to be mounted<br />

on the multi caster and the special hole repair patch<br />

(Fig. 1).<br />

Fig. 1<br />

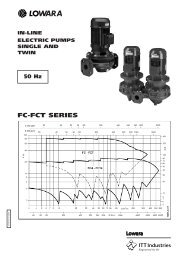

Changing the insert<br />

Should the female Ø 1/2” insert accidentally break, it<br />

is not necessary to remove the fitting – breaking tiles<br />

and masonry – but it is possible to avoid all of this by<br />

using the special repair KIT and replacing only the<br />

threaded ring nut (Fig. 2). Fig. 2<br />

Using the bracket<br />

In order to make execution of PP-R systems simpler and more effective, Coes has designed<br />

and patented the bracket for fixed point for securing threaded terminals.<br />

1 Screw on the bored 1/2” pawl (1) on the insert to be replaced.<br />

2 Mark the depth of the insert, 18 mm, with chalk on the hole saw (2) and cut, pivoting in the<br />

hole.<br />

3 Set the extended matrix (3) on the insert for heating.<br />

4 To make extraction of the pawl to be replaced easier, use a 1/2” bar of pipe threaded on<br />

one side (4).<br />

5 Plane the bottom of the fitting with the mill (5), holding the drill forcefully until the four<br />

protuberances on the bottom have reached a thickness of about 0.5-1 mm<br />

6 Thoroughly clean the surfaces to be welded with alcohol.<br />

7 Heat the fitting with the extended male matrix.<br />

8 Screw the new insert (8) on a 1/2” bar of pipe and heat it with the female matrix D 32 for<br />

about 7/8 seconds.<br />

9 Weld while pushing the insert down to the bottom of the fitting.<br />

10 Before connecting to the thread, the welding must be completely cold.<br />

193<br />

ASSEMBLY AND INSTALLATION INSTRUCTIONS<br />

6<br />

3<br />

7<br />

9<br />

1<br />

4<br />

2<br />

5<br />

8<br />

10<br />

Note: CO.E.S. S.p.A. declines all responsibility for damages caused by non-observance of all<br />

the operations described above and/or by welding done with unsuitable equipment.