Material safety data sheet (MSDS)

Material safety data sheet (MSDS)

Material safety data sheet (MSDS)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

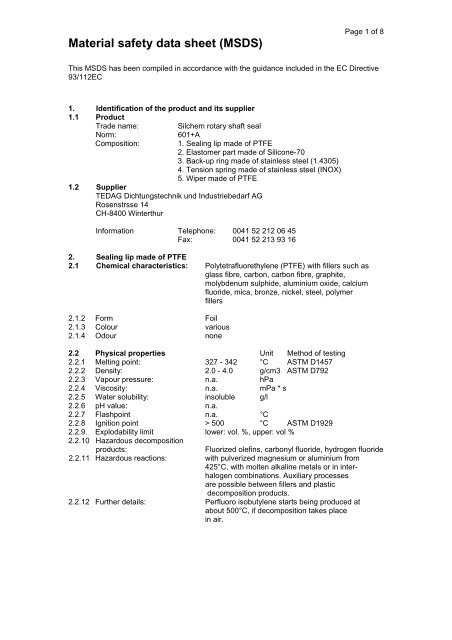

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 1 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

1. Identification of the product and its supplier<br />

1.1 Product<br />

Trade name: Silchem rotary shaft seal<br />

Norm: 601+A<br />

Composition: 1. Sealing lip made of PTFE<br />

2. Elastomer part made of Silicone-70<br />

3. Back-up ring made of stainless steel (1.4305)<br />

4. Tension spring made of stainless steel (INOX)<br />

5. Wiper made of PTFE<br />

1.2 Supplier<br />

TEDAG Dichtungstechnik und Industriebedarf AG<br />

Rosenstrsse 14<br />

CH-8400 Winterthur<br />

Information Telephone: 0041 52 212 06 45<br />

Fax: 0041 52 213 93 16<br />

2. Sealing lip made of PTFE<br />

2.1 Chemical characteristics: Polytetrafluorethylene (PTFE) with fillers such as<br />

glass fibre, carbon, carbon fibre, graphite,<br />

molybdenum sulphide, aluminium oxide, calcium<br />

fluoride, mica, bronze, nickel, steel, polymer<br />

fillers<br />

2.1.2 Form Foil<br />

2.1.3 Colour various<br />

2.1.4 Odour none<br />

2.2 Physical properties Unit Method of testing<br />

2.2.1 Melting point: 327 - 342 °C ASTM D1457<br />

2.2.2 Density: 2.0 - 4.0 g/cm3 ASTM D792<br />

2.2.3 Vapour pressure: n.a. hPa<br />

2.2.4 Viscosity: n.a. mPa * s<br />

2.2.5 Water solubility: insoluble g/l<br />

2.2.6 pH value: n.a.<br />

2.2.7 Flashpoint n.a. °C<br />

2.2.8 Ignition point > 500 °C ASTM D1929<br />

2.2.9. Explodability limit lower: vol. %, upper: vol %<br />

2.2.10 Hazardous decomposition<br />

products: Fluorized olefins, carbonyl fluoride, hydrogen fluoride<br />

2.2.11 Hazardous reactions: with pulverized magnesium or aluminium from<br />

425°C, with molten alkaline metals or in interhalogen<br />

combinations. Auxiliary processes<br />

are possible between fillers and plastic<br />

decomposition products.<br />

2.2.12 Further details: Perfluoro isobutylene starts being produced at<br />

about 500°C, if decomposition takes place<br />

in air.

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 2 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

2.3 Transport<br />

Not a hazardous product as defined in transport regulations<br />

2.4 Regulations<br />

This product is not subject to identification requirements in accordance with EC directive<br />

67/548<br />

2.5 Safety precautions, storage and handling<br />

2.5.1 Personal <strong>safety</strong> equipment in the event of a fire:<br />

Breathing equipment: Wear breathing apparatus in the event of dust<br />

Eye protection: Safety glasses<br />

Hand protection: Safety gloves<br />

2.5.2 Hygiene practice:<br />

General protective measures:<br />

Do not breath in vapours given off by hot polymer.<br />

2.5.3 Protection from fire and explosion:<br />

The product cannot be ignited and is self-extinguishing.<br />

2.5.4 Disposal:<br />

Can be dumped provided local authority regulations are observed. Can be incinerated<br />

provided local authority regulations are observed, if HF is removed through gas<br />

washing.<br />

2.6 Precautions to be taken in the event of accidents and fires<br />

2.6.1 After spillage, leakage or fire:<br />

Pick up using <strong>safety</strong> gloves<br />

2.6.2 Suitable extinguishers:<br />

Water, carbon dioxide, foam, dry powder<br />

2.6.3 First aid:<br />

Inhalation:<br />

After inhaling fumes from fires or decomposition products following a mishap, go out<br />

into the fresh air. For severe effects call a doctor. See also paragraph 2.7.<br />

Skin contact:<br />

After contact with molten polymer, apply cooling quickly, using cold water. Do not try<br />

to pull polymer off of the skin. Call a doctor.<br />

Eye contact:<br />

Rinse with water.<br />

Swallowing:<br />

No risk to health.<br />

2.6.4 Further details<br />

The ALT (Approximate Lethal Temperature) of PTFE is 400°C. The ALT is the<br />

temperature at which the decomposition products would kill one in four rats, after they<br />

had been exposed to it for four hours.<br />

In the event of fire, wear breathing apparatus that is independent of ambient air.<br />

Wear neoprene gloves when handling charred remains from the fire.

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 3 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

2.7 Details for toxicology<br />

Inhalation of the polymer’s thermal decomposition products (e.g. by inhaling in<br />

contaminated tobacco) can cause ’polymer fever’ with accompanying flu-like symptoms.<br />

These symptoms generally do not occur until two or more hours after smoking the<br />

contaminated tobacco and subside over the next 36 to 48 hours. Experience indicates<br />

that there is no lasting or cumulative effect.<br />

Limiting values of effects:<br />

Breathable dust: MAK = 6 mg/m 3 (as fine dust) (1988)<br />

Hydrogen fluoride: MAK = 3 ml/ m 3 = 2 mg/m 3 , inrush limiting, cat. I (1988)<br />

Soot: TLV-TWA = 3.5 g/m 3 (ACGIH, 88-89)<br />

Mica: TLV-TWA = 3 g/m 3 (ACGIH, 88-89)<br />

Nickel (in the form of<br />

breathable dust): TRK = 0.5 mg/m 3 (1988)<br />

2.8 Details for ecology<br />

Before use, take heed of the <strong>safety</strong> information for this Silchem shaft seal, which you can<br />

obtain from your TEDAG adviser.<br />

3. Elastomer part made of Silicon-70<br />

3.1 Chemical<br />

characteristics Vulcanized rubber mixture MQ 70<br />

(On a silicon-rubber base)<br />

3.1.1 Form: solid<br />

3.1.2 Colour: white<br />

3.1.3 Odour: typical<br />

3.2 Physical properties Unit Testing method<br />

3.2.1<br />

3.2.2<br />

Melting point<br />

Density:<br />

n.a.<br />

1.36<br />

°C<br />

g/cm 3<br />

DIN 53479<br />

3.2.3 Vapour press. (20°C): n.a.<br />

3.2.4 Viscosity: n.a.<br />

3.2.5 Solubility in<br />

water (20°C): insoluble<br />

3.2.6 pH value (g/l H2O): n.a.<br />

3.2.7 Flashpoint n.a. °C<br />

3.2.8 Ignition point n.a. °C<br />

3.2.9 Explosion limit: lower: n.a. vol %, upper: n.a. vol %<br />

3.2.10 Stability and reactivity: No reactivity under normal conditions.<br />

3.3 Transport<br />

Not a hazardous product as defined in transport regulations

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 4 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

3.3 Regulations<br />

3.4.1 Contains identifying marks and hazard signs<br />

R sets: R :<br />

S sets: S :<br />

3.4.2 Special identification of certain<br />

preparations:<br />

3.4.3 National regulations:<br />

3.4.4 VbF class:<br />

3.4.5 Technical instructions for air<br />

3.4.6 Ground water hazard class: 0<br />

3.4.7 Other regulations<br />

3.5 Safety precaution, storage and handling<br />

3.5.1 Personal <strong>safety</strong> equipment in the event of fire<br />

Breathing protection: Wear breathing apparatus in the event of<br />

free dust<br />

Eye protection: Safety glasses<br />

Hand protection: Safety gloves<br />

3.5.2 Work hygiene<br />

Health hazard when inhaled and when in contact with the skin.<br />

Do not eat, drink or smoke when working.<br />

Wash hands thoroughly with soap and water before breaks and immediately after<br />

handling the product. Use barrier creams.<br />

Breathing protection: Not required<br />

Hand protection: Barrier cream<br />

Eye protection: Not required<br />

Body protection: Not required<br />

3.5.3 Storage class (CEA/VCI) 11 combustible solids<br />

3.6 Precautions to be taken in the event of accidents and fires<br />

3.6.1 Suitable extinguishers:<br />

Water, foam, dry extinguishers. carbon dioxide (CO2)<br />

3.6.2 Unsuitable extinguishers:<br />

3.6.3 Special hazard from decomposition products.<br />

Heavy smoke. Where there is a shortage of air, products of oxygen deficiency like<br />

carbon monoxide can be formed. Use breathing apparatus independent of outside air.<br />

3.6.4 Water contaminated by being used for extinguishing is to be collected and kept<br />

separate.<br />

Sweep up and send for disposal in suitable containers.<br />

3.6.5 After inhaling: not applicable<br />

3.6.6 After swallowing: No particular advice required<br />

3.6.7 After skin contact: Wash thoroughly using soap and water<br />

3.6.8 After contact with eyes: Wash thoroughly using plenty of water<br />

3.6.9 General <strong>safety</strong> precautions are to be observed for handling chemicals.

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 5 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

3.7 Details for toxicology<br />

No particular advice required<br />

Values relevant to classification<br />

2.9 Details for ecology<br />

This product is not biologically degradable. Due to its consistency it is not possible for<br />

particles to disperse into the environment. On current thinking, negative ecological<br />

effects are not anticipated.<br />

3.8 Notes on disposal<br />

3.9.1 Product<br />

3.9.2 Waste key number<br />

LAGA: 57501 waste rubber<br />

3.9.3 Packaging<br />

Can be stored with household refuse or incinerated together<br />

with it, so long as national regulations are heeded and after<br />

consultation with the person running the disposal site and the<br />

appropriate authorities.<br />

4 Back-up ring made of stainless steel (1.4305)<br />

4.1 Chemical<br />

characteristics: Product in accordance with EC Directive 67/548/EEC in the<br />

form of a solid alloy, containing nickel.<br />

4.1.2 Composition: Chrome (Cr) up to 35%<br />

Nickel (Ni) up to 80%<br />

Manganese (Mn) up to 10%<br />

Molybdenum (Mo) up to 10%<br />

Iron (Fe) remainder<br />

4.1.3 Shape: ring<br />

4.1.4 Outward appearance: solid<br />

4.1.5 Odour: none<br />

4.2 Physical properties Unit Method of testing<br />

4.2.1 Melting point: 1300-1500 °C<br />

4.2.2 Density (20°C): 7.7 - 8.3 g/cm 3<br />

4.2.3 Vapour pressure n.a.<br />

4.2.4 Solubility in:<br />

Water insoluble<br />

Oil insoluble<br />

4.2.5 Flashpoint n.a.<br />

4.2.6 Flammability <strong>Material</strong> is non-flammable<br />

4.2.7 Self-ignition: <strong>Material</strong> cannot self-ignite<br />

4.2.8 Explosive properties: <strong>Material</strong> cannot self-ignite<br />

4.2.9 Oxidation properties n.a.<br />

4.2.10 Thermal volume<br />

Expansion: 12 l 10 -8 - 18 l 10 -8 °C -1 (mean value up to 20 - 100°C)

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 6 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

4.2.10.1 Heat conductibility<br />

at 20°C 11 - 16 W/(m l °C)<br />

4.2.10.2 Specific resistance<br />

At room temperature: approx. 0.8 :µΩm<br />

4.2.13 Magnetic properties:<br />

Duplex, ferrite and martensite stainless steels are<br />

ferromagnetic. Permeability at 20°C: typically 10-<br />

200. Austenitic stainless steels are not<br />

ferromagnetic, but can display a small amount of<br />

ferromagnetism due to the slight quantities of ferrite.<br />

Permeability at 20°C: 1.005-1.1<br />

4.3 Transport<br />

No special precautions are to be taken. Harmless goods.<br />

4.4 Regulations<br />

Local laws and regulations in force are to be carefully heeded and complied with.<br />

This product has been classified as category 3 in accordance with the EC directive<br />

67/548 EEC with the following comment "suspected of being carcinogenic".<br />

Hazard category: Xn harmful<br />

Risk category: R40 possibility of irreversible harm<br />

R43 possibility of sensitizing through skin contact<br />

4.5 Safety precautions, storage and handling<br />

4.5.1 Safety precautions<br />

No particular <strong>safety</strong> equipment required.<br />

Breathing protection: Not applicable<br />

Eye protection: Not applicable. (possibility of injury, e.g. due to sharp<br />

edges, etc.)<br />

Hand protection Not applicable. (possibility of injury, e.g. due to sharp<br />

edges, etc.)<br />

4.5.2 Work hygiene<br />

Wash hands before breaks and immediately after handling the product.<br />

4.5.3 Fire and explosion precautions:<br />

No particular precautions necessary<br />

4.5.4 Storage, storeroom and container requirements<br />

No particular planning for storerooms and containers<br />

4.5.5 Environmental protection precautions<br />

Not to be permitted into the environment.<br />

4.5.6 Disposal<br />

This product should be sent for recycling as far as is possible, since it constitutes<br />

a valuable raw material for the production of stainless steel.

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 7 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

4.6 Precautions for accidents and fire<br />

4.6.1 After spillage, leakage or fire:<br />

The product is non-flammable<br />

Pick up mechanically and take in suitable containers for disposal.<br />

In connection with this product there are no hazards or precautions, should this<br />

product be located near a fire.<br />

4.6.2 First aid:<br />

Consult a doctor in the event of debility or continuing eye irritation.<br />

Inhaling:<br />

Not applicable<br />

Ingestion:<br />

Not applicable<br />

Contact with eyes:<br />

Not applicable. (Injury possible as a result of sharp edges etc, for example.)<br />

Skin contact:<br />

Not applicable. (Injury possible as a result of sharp edges etc, for example.)<br />

After contact with hot steel, cool of with cold water.<br />

4.6.3 Further details<br />

Usual precautions for fires involving metals.<br />

4.7 Details for toxicology<br />

This product contains nickel, which has been classified in the EC directive 67/548/EEC<br />

as a substance that is carcinogenic when inhaled or absorbed (Category 3, i.e. gives<br />

cause for concern for people …The available details are however not suitable for<br />

carrying out a satisfactory judgement.<br />

The definitions of the product directive 88/379/EEC mean that all compounds,<br />

solutions and alloys with at least 1% nickel content, in the absence of other regulations,<br />

are to be classified in the same manner.<br />

According to our knowledge however, neither in epidemiological examination nor<br />

in animal testing was there any report of exposure to the product having caused any<br />

carcinogenic effects. Long-term experience with the product in the most varied of<br />

applications has proven that these very resistant materials are outstandingly suitable<br />

where hygiene is of paramount importance.<br />

Nickel is likewise classified as a skin sensitizer through longer contact with the<br />

skin of a few people (e.g. through wearing jewellery).<br />

The product does, however, normally cause no allergic reactions at all.<br />

Such solid products cannot be inhaled or absorbed and therefore do not<br />

represent a toxic hazard.<br />

During mechanical processing, flame cutting or welding, stainless steel dust or<br />

vapours can be formed, which contain oxides of its constituents. Over a long period of<br />

time, inhalation of an excess of particles suspended in air can have repercussions for<br />

health, which primarily affect the lungs. Examination of workers exposed to nickel<br />

powder, dust and gases as a result of the production of nickel alloys and stainless steels,<br />

have, however, indicated no danger of cancer of the respiratory tract.

<strong>Material</strong> <strong>safety</strong> <strong>data</strong> <strong>sheet</strong> (<strong>MSDS</strong>)<br />

Page 8 of 8<br />

This <strong>MSDS</strong> has been compiled in accordance with the guidance included in the EC Directive<br />

93/112EC<br />

4.7.1 Acute oral or<br />

inhalatory toxicity: Not applicable<br />

4.7.2 Acute dermatological<br />

toxicity: Not applicable<br />

4.7.3 Acute irritation or causticity<br />

Of the skin or eyes: None<br />

4.8 Details for ecology<br />

No knowledge of harmful consequences. No precautions necessary. The product is<br />

normally inert in watery solutions.<br />

5. Wiper<br />

Details as for item 2<br />

6. Other details<br />

The <strong>data</strong> and details given in this <strong>MSDS</strong> are based on our current knowledge. They are<br />

not however to be construed as a guarantee for any particular product attributes and<br />

establish no legal and contractually valid connections.<br />

This <strong>MSDS</strong> was published on the 26 th of October 2000 by TEDAG Dichtungstechnik und<br />

Industriebedarf AG.<br />

Legend: n.a. = not applicable