data sheet - Index S.p.A.

data sheet - Index S.p.A.

data sheet - Index S.p.A.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EPOEMULSIO AB<br />

TWO-PART EPOXY WATER BASED EMULSION<br />

FIELD OF USE FOR 4 TH DIVISION PRODUCTS<br />

PROBLEM<br />

Concrete flooring showing surface degradation as a result of continuous wear is becoming dusty. To<br />

overcome this situation it will be necessary to apply an anti-dust coating.<br />

DESCRIPTION<br />

EPOEMULSIO is a two-part product<br />

containing water soluble pigmented<br />

epoxy resins.<br />

FIELDS OF USE<br />

EPOEMULSIO is used to impregnate<br />

concrete flooring when a surface<br />

is required which is easy to clean,<br />

dust-free and impermeable to oils<br />

and aggressive liquids.<br />

It is ideal for garages, warehouses,<br />

covered carparks.<br />

EPOEMULSIO is used to protect<br />

concrete from aggressive chemically<br />

saturated water in drainage pipes<br />

and as a bonding primer coat when<br />

painting asbestos cement panels<br />

with ELASTOLIQUID water-based liquid<br />

coatings.<br />

SUBSTRATE PREPARATION<br />

Surfaces to be waterproofed must<br />

be thoroughly clean and free from<br />

crumbling or loose particles. Any<br />

traces of oil or grease must be removed<br />

using chemical cleaners or<br />

by mechanically sanding. Any holes,<br />

fissures and cavities must be restored<br />

using Resisto Unifix mortar.<br />

APPLICATION<br />

Carefully mix part A with part B until<br />

a smooth compound is obtained.<br />

The first coat must be diluted with<br />

approximately 10% water and the<br />

COVERAGE<br />

Consumption per coat: 150-200 g/m 2 .<br />

PRECAUTIONS<br />

application may be carried out using<br />

a brush, roller or spray. It is advisable<br />

to apply two overlapping coats.<br />

1<br />

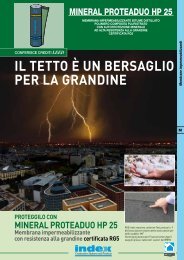

METHOD OF USE<br />

1. Application by brush<br />

2. Application by roller<br />

• Do not apply on surfaces with<br />

traffic carriage of heavy means.<br />

• Clean tools with water immediately<br />

after use.<br />

• Mix the two components together<br />

well before use.<br />

• If the finished surface is exposed to<br />

sunlight it should be noted that light<br />

colours show a slight yellowing<br />

and the surface has a crumbling<br />

effect but this does not affect the<br />

resistance of the product.<br />

• For previously treated surfaces,<br />

carry out tests in order to evaluate<br />

potential adhesion difficulty.<br />

• Concrete flooring must have suitable<br />

vapour barriers.<br />

• Do not apply wet surfaces or<br />

even on surfaces having superficial<br />

water veil.<br />

• Keep the product away from sunlight.<br />

SAFETY REGULATIONS<br />

• EPOEMULSIO is a two-component<br />

product based on pigmented<br />

water-soluble epoxy resins.<br />

• May cause sensitivity when in contact<br />

with the skin.<br />

• In case of contact with the eyes<br />

wash immediately and thoroughly<br />

with water and call the doctor.<br />

• In case of contact with the skin<br />

wash immediately with suitable<br />

cream such as Kerocleanse 22.<br />

• Wear protective garments and suitable<br />

gloves and protect eyes and<br />

face.<br />

2<br />

4 th DIVISION<br />

2 nd LINE

EPOEMULSIO AB<br />

COMPONENT A<br />

Appearance<br />

semi-thick liquid<br />

Colour<br />

white or grey<br />

COMPONENT B<br />

Appearance<br />

liquid<br />

Colour<br />

colourless<br />

EPOEMULSIO AB<br />

Mix ratio: COMPONENT A : COMPONENT B = 1 : 1<br />

Appearance<br />

semi-thick liquid<br />

Colour<br />

white or grey<br />

Specific weight (Volumetric mass) A+B<br />

1.2±0.05 kg/litre<br />

Dry residue A+B 52±2%<br />

Flammability<br />

>100°C<br />

Drying time (UR 65% - T +20°C)<br />

• dust dry<br />

3 hours<br />

• touch dry<br />

7 hours<br />

• complete hardening<br />

7 days<br />

Repaintable at + 20°C<br />

after 15 hours<br />

Utilisation time at +20°C (Pot life)<br />

approx. 4 hours<br />

Permeabilità al vapore per spessori di 200µ 7.5 g/m 2 /24h<br />

Vapour permeability for thicknesses of 200 µ 320 m of air<br />

Fire resistance class in accordance<br />

with SW1 fire prevention<br />

SE5<br />

Shelf life in original packaging<br />

12 months<br />

AB<br />

H O<br />

2<br />

TECHNICAL CHARACTERISTICS<br />

+ 5°C<br />

D.P.I.<br />

ring the numerous possible uses and the possible interference of conditions or<br />

elements beyond our control, we assume no responsibility regarding the results<br />

which are obtained. The purchasers, of their own accord and under their own responsibility,<br />

must establish the suitability of the product for the envisaged use.<br />

TWO-COMPONENT<br />

WATERPROOF<br />

WATER-BASED<br />

MIX<br />

MECHANICALLY<br />

SPRAY<br />

APPLICATION<br />

APPLY<br />

BY BRUSH<br />

APPLY<br />

BY ROLLER<br />

MINIMUM APPLICATION<br />

TEMPERATURE<br />

KEEP AWAY<br />

FROM FROST<br />

WEAR PROTECTIVE<br />

CLOTHING<br />

Grafiche Leardini - 3000 - 12/2000<br />

ADVANTAGES<br />

• Does not contain solvents.<br />

• Good strengthening effect, dust-free.<br />

• Resists chemically aggressive water.<br />

Via G. Rossini, 22<br />

37060 Castel D’Azzano (VR) - Italy<br />

Tel. 045.8546201 - Fax 045.512444<br />

INTERNET: http://www.index-spa.com - E-MAIL: index.export@index-spa.it<br />

PRODUCT<br />

PACKAGING<br />

2,5 kg cans (component A)<br />

2,5 kg cans (component B)<br />

• FOR ANY FURTHER INFORMATION OR ADVICE ON PARTICULAR APPLICATIONS, CONTACT OUR TECHNICAL OFFICE<br />

• IN ORDER TO CORRECTLY USE OUR PRODUCTS, REFER TO INDEX TECHNICAL SPECIFICATIONS<br />

Restoration of damp<br />

masonry using dampproofing<br />

renders<br />

Waterproofing with<br />

vapour permeable cements<br />

Concrete refurbishment<br />

TOTAL QUALITY<br />

Q.S. ISO 9001<br />

The figures shown are average indicative figures relevant to current production<br />

and may be changed or updated by INDEX S.p.A at any time without previous<br />

warning. The advice and technical information provided, is what results from our<br />

best knowledge regarding the properties and the use of the product. Conside<br />

© INDEX S.p.A.