Rapid Microwave-Assisted Solid Phase Peptide Synthesis

Rapid Microwave-Assisted Solid Phase Peptide Synthesis

Rapid Microwave-Assisted Solid Phase Peptide Synthesis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1592<br />

<strong>Rapid</strong> <strong>Microwave</strong>-<strong>Assisted</strong> <strong>Solid</strong> <strong>Phase</strong> <strong>Peptide</strong> <strong>Synthesis</strong><br />

<strong>Rapid</strong> Máté <strong>Microwave</strong>-<strong>Assisted</strong> <strong>Solid</strong> <strong>Phase</strong> <strong>Peptide</strong> <strong>Synthesis</strong>Erdélyi,<br />

a,b Adolf Gogoll* a<br />

a Department of Organic Chemistry, Uppsala University, Box 531, 751 21 Uppsala, Sweden<br />

Fax +46(18)512524; E-mail: mate@kemi.uu.se, adolf@kemi.uu.se<br />

b Department of Medicinal Chemistry, Uppsala University, Box 574, 751 23 Uppsala, Sweden<br />

Fax +46(18)4714474<br />

Received 20 May 2002<br />

Dedicated to Prof. Hans-J. Schäfer on the occasion of his 65 th birthday<br />

Abstract: A microwave-assisted, rapid solid phase peptide synthesis<br />

procedure is presented. It has been applied to the coupling of<br />

sterically hindered Fmoc-protected amino acids yielding di- and<br />

tripeptides. Optimized conditions for a variety of coupling reagents<br />

are reported. <strong>Peptide</strong>s were obtained rapidly (1.5–20 min) and without<br />

racemization.<br />

Key words: SPPS, microwave, amino acids, peptide coupling, solid-phase<br />

Since Merrifield’s pioneering work on solid phase peptide<br />

synthesis (SPPS), peptide preparation has almost exclusively<br />

been performed on resin. 1 The generation of combinatorial<br />

libraries has caused a renaissance and growth of<br />

interest in solid supported chemistry. Parallel to the developments<br />

in combinatorial chemistry, it has been shown<br />

that the use of microwave heating can be advantageous in<br />

a large variety of organic reactions. 2 However, there have<br />

been only very few reports on the use of microwave heating<br />

in combination with solid phase synthesis, 3 possibly<br />

due to the requirement of special heavy-walled vials for<br />

microwave irradiation that makes resin handling rather<br />

complicated, and problems to control reaction conditions.<br />

In particular, enhancement of SPPS by the use of microwave<br />

heating has so far received little attention. <strong>Peptide</strong><br />

synthesis performed in a kitchen microwave oven was<br />

published in 1991. 4 However, the procedure described by<br />

Wang et al is not easily reproducible, because of the use<br />

of a commercial microwave oven for irradiation, and the<br />

lack of temperature control. The couplings were made using<br />

symmetric amino acid anhydrides or pre-formed Nhydroxybenzotriazole<br />

activated esters, yielding 2–4 fold<br />

reaction rate enhancements. In general, peptide chemistry<br />

is today limited to room temperature conditions, originating<br />

from the general belief of the heat-sensitivity of peptide<br />

coupling reagents (Table).<br />

Here, we describe a microwave-enhanced, rapid (1.5–20<br />

min) procedure for the coupling of sterically hindered<br />

amino acids on solid phase. The optimized conditions for<br />

a variety of common coupling reagents yielded a significant<br />

rate increase. Single mode irradiation with monitoring<br />

of temperature, pressure and irradiation power versus<br />

<strong>Synthesis</strong> 2002, No. 11, Print: 22 08 2002.<br />

Art Id.1437-210X,E;2002,0,11,1592,1596,ftx,en;C01802SS.pdf.<br />

© Georg Thieme Verlag Stuttgart · New York<br />

ISSN 0039-7881<br />

SPECIAL TOPIC<br />

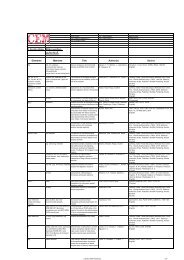

Table Coupling Times and Temperatures for <strong>Peptide</strong> <strong>Synthesis</strong> on<br />

Rink’s Amide Resin Employing a Variety of Coupling Reagents a<br />

Coupling Reagent PyBOP Mukaiyama’s<br />

Reagent<br />

TBTU HATU<br />

Reaction time (min) 20 10 10 1.5<br />

Temperature (°C) 110 130 110 110<br />

Solvent DMF CH 2Cl 2 DMF DMF<br />

a The average pressure for reactions performed in DMF and CH2Cl 2<br />

was 1–2 bar and 6–8 bar, respectively.<br />

time was used throughout, making the procedure highly<br />

reproducible.<br />

Our goal was to investigate the compatibility of HATU, 5a<br />

TBTU, 5b PyBOP5c and Mukaiyama’s reagent5d mediated<br />

couplings at high temperatures. Reaction conditions for<br />

the synthesis of a small tripeptide containing the three<br />

most hindered natural amino acids (Fmo-Thr-Val-Ile-<br />

NH2), and the Fmoc-Ala-Ile-NH2 or Fmoc-Thr-Ile-NH2 dipeptides were optimized. The coupling of Fmoc-protected<br />

amino acids on polystyrene resin using Rink amide<br />

linker was performed. No degradation of the solid support<br />

was observed. Fast Fmoc-deprotection steps (15 minutes)<br />

were conducted at room temperature, and the coupling<br />

steps were performed using microwave irradiation. All<br />

coupling steps were monitored by qualitative ninhydrin<br />

test6 and by LC-MS investigation of peptides cleaved<br />

from small amounts of the resin. Our optimized conditions<br />

are shown in the Table.<br />

The azobenzotriazole derivatives have shown an increased<br />

coupling efficiency with increasing temperature<br />

up to 110 °C. At higher temperatures the decomposition of<br />

the reagents was indicated by the colour change of the reaction<br />

mixtures. In contrast with the usual SPPS procedures<br />

where double or triple coupling steps are needed for<br />

completion, under microwave conditions, coupling was<br />

complete already in a few minutes after a single coupling<br />

step.<br />

The absence of racemization during the high temperature<br />

treatment of amino acids in the presence of a base (i-<br />

Pr2NEt) was investigated by LC-MS and 1H NMR. The<br />

presence of only one peak in the chromatogram (Figure 1)<br />

of the synthesized peptides suggested the absence of dias-

SPECIAL TOPIC <strong>Rapid</strong> <strong>Microwave</strong>-<strong>Assisted</strong> <strong>Solid</strong> <strong>Phase</strong> <strong>Peptide</strong> <strong>Synthesis</strong> 1593<br />

Figure 1 The LC-MS chromatogram of Fmoc-Ala-Ile-NH 2 prepared by PyBOP mediated couplings at 110 °C.<br />

tereomeric compounds. The 1H NMR spectrum of this<br />

material containing a single set of signals of the oligopeptide<br />

suggested the presence of only one diastereomer. As<br />

an example, the aliphatic region of the 1H NMR spectrum<br />

of a synthesized dipeptide is shown in Figure 2.<br />

The efficiency of the solid phase methodology was limited<br />

by the need of transfer between different reaction vessels<br />

to perform the coupling and washing steps. The high<br />

pressure generated by volatile components during reac-<br />

tions carried out with microwave irradiation makes the<br />

use of special heavy-walled vials highly recommendable.<br />

However, these vials are not suitable for filtration. Therefore,<br />

the reaction mixtures were transferred for washing<br />

and deprotection steps into plastic columns equipped with<br />

a polypropylene frit, causing some loss of resin. Moderate<br />

yields could therefore be obtained for the synthesis of the<br />

di- (PyBOP: 60%; Mukaiyama’s reagent: 35%; TBTU:<br />

41%; HATU 24%) and tripeptides (PyBOP: 48%; Mu-<br />

Figure 2 The aliphatic region of the 1 H NMR spectrum of Fmoc-Ala-Ile-NH 2 showing the presence of one diastereomer after microwave<br />

assisted synthesis (PyBOP mediated couplings at 110 °C).<br />

<strong>Synthesis</strong> 2002, No. 11, 1592–1596 ISSN 0039-7881 © Thieme Stuttgart · New York

1594 M. Erdélyi, A. Gogoll SPECIAL TOPIC<br />

kaiyama’s reagent: 65%; TBTU: 31%; HATU 42%). The<br />

efficiency of the solid phase methodology including the<br />

loading (PyBOP, i-Pr2NEt, DMF, 110 °C), cleavage (95%<br />

TFA in CH2Cl2) and purification (preparative LC-MS)<br />

steps was determined by attachment and cleavage of a single<br />

Fmoc-Ile to the resin, yielding 60% of the expected<br />

product. The efficiency of the methodology might be increased<br />

by instrumental improvements, e.g., by the development<br />

of heavy-walled vials more compatible with the<br />

handling of resins used in solid phase synthesis.<br />

This synthetic method will be of considerable interest for<br />

incorporation of sterically hindered and deactivated nonnatural<br />

amino acids in peptide synthesis on solid phase.<br />

All reactions were conducted in heavy-walled glass Smith Process<br />

Vials sealed with aluminum crimp caps fitted with a silicon septum.<br />

The inner diameter of the vial filled to the height of 3.5 cm was 1.3<br />

cm. The microwave heating was performed in a Smith Synthesizer single mode microwave cavity producing continuous irradiation at<br />

2450 MHz (Personal Chemistry AB, Uppsala, Sweden). Reaction<br />

mixtures were stirred with a magnetic stir bar during the irradiation.<br />

The temperature, pressure and irradiation power were monitored<br />

during the course of the reaction. The average pressure during the<br />

reaction run in DMF was 1�2 bar, for the reactions run in CH2Cl2 it<br />

was 6–8 bar. After completed irradiation, the reaction tube was<br />

cooled with high-pressure air until the temperature had fallen below<br />

39 °C (ca. 2 min). 1H NMR spectra were recorded for CD3CN solutions<br />

at 400 MHz (Jeol JNM EX400 spectrometer) at r.t. Chemical<br />

shifts are referenced indirectly to TMS via the residual solvent signal<br />

(� =2.10). The 1H NMR spectra of all synthesized compounds<br />

have been fully assigned using data from phase-sensitive DQF-<br />

COSY7 and NOESY8 experiments. The ESI-MS spectra of the peptides<br />

were obtained with a Finnigan ThermoQuest AQA mass spectrometer<br />

(ESI 30eV, probe temperature 100 °C) equipped with a<br />

Gilson 322-H2 GradientPump system, an SB-C18 analytical and an<br />

SB-C8 (5 �m, 21.2 mm, 150 mm) preparative column. A H2O– MeCN–formic acid (0.05%) mobile phase was used with a gradient<br />

of 20%�80% MeCN during 7 minutes on the analytical column,<br />

and 30–80 minutes on the preparative column.<br />

The starting materials were purchased from commercial suppliers<br />

and were used without purification with the exception of CH2Cl2 which was freshly distilled over calcium hydride. Fmoc-Ala, Fmoc-<br />

Ile, Fmoc-Val, PyBOP, and Rink amide MBHA resin were obtained<br />

from Novabiochem, Fmoc-Thr(t-Bu)-OH from Alexis Biochemicals<br />

(USA). TBTU was from Richelieu Biotechnologies (Canada).<br />

HATU was purchased from PE Biosystems (United Kingdom). Trifluoroacetic<br />

acid (99%), N,N-diisopropylethylamine (redistilled<br />

99.5%), and piperidine (99%) were from Aldrich (Germany). DMF<br />

was obtained from Fluka (Denmark).<br />

Fmoc-Thr-Val-Ile-NH 2 (1); Method A<br />

Procedure I<br />

Rink amide resin (300 mg, 0.78 mmol/g, 0.234 mmol) was treated<br />

with 20% piperidine in DMF (5 mL for 10 and 5 minutes) in a column<br />

equipped with polypropylene frit placed in an overhead mixer.<br />

The soln was then drained, and the resin was washed with DMF (3<br />

� 5 mL) and CH 2Cl 2 (3 � 5 mL).<br />

Procedure II<br />

The resin from procedure I was transferred into a Smith Process<br />

Vial and Fmoc-Ile (248 mg, 0.70 mmol), PyBOP (343 mg, 0.70<br />

mmol), i-Pr2NEt (0.25 mL, 1.40 mmol) and DMF (3 mL) was added.<br />

The mixture was irradiated in a microwave cavity at 110 °C for<br />

20 min. Then, the mixture was transferred into a column equipped<br />

<strong>Synthesis</strong> 2002, No. 11, 1592–1596 ISSN 0039-7881 © Thieme Stuttgart · New York<br />

with a polypropylene frit using a Pasteur pipette. The soln was<br />

drained and the resin was washed with DMF (3 � 5 mL) and CH 2Cl 2<br />

(3 � 5 mL). The completion of the coupling was confirmed by Kaisers<br />

test.<br />

Thereafter, Fmoc-deprotection was performed using procedure I as<br />

described above.<br />

Procedure III<br />

The resin from procedure I was transferred into a Smith Process<br />

Vial and Fmoc-Val (238 mg, 0.70 mmol), PyBOP (343 mg, 0.70<br />

mmol), i-Pr2NEt (0.25 mL, 1.40 mmol) and DMF (3 mL) was added.<br />

The coupling was performed using procedure II as described<br />

above. The completion of the coupling was confirmed by Kaisers<br />

test and by cleavage of a small amount of the resin with 95% TFA<br />

in CH2Cl2 and analytical LC-MS investigation of the cleaved peptide.<br />

Thereafter, Fmoc-deprotection was performed using procedure<br />

I as described above.<br />

The resin was transferred into a Smith Process Vial and Fmoc-<br />

Thr(t-Bu) (279 mg, 0.70 mmol), PyBOP (343 mg, 0.70 mmol), i-<br />

Pr2NEt (0.23 mL, 1.32 mmol) and DMF (3 mL) was added. The<br />

mixture was irradiated using procedure II, the completion of reaction<br />

was confirmed by procedure III.<br />

Procedure IV<br />

Finally, the tripeptide was cleaved from the resin using 95% TFA in<br />

CH2Cl2 (2 hours). The soln was separated from the resin by filtration,<br />

the resin was washed with additional CH2Cl2 (5 mL) and the<br />

combined phases were concentrated on a rotatory evaporator. The<br />

residue was then dissolved in MeCN (1–2 mL) and was purified on<br />

preparative LC-MS yielding 1 as a white solid (63 mg, 0.11 mmol,<br />

48%).<br />

Method B<br />

Rink amide resin (300 mg, 0.78 mmol/g, 0.234 mmol) was deprotected<br />

using procedure I. The resin was transferred into a Smith Process<br />

Vial and Fmoc-Ile (248 mg, 0.70 mmol), 2-fluoro-1-methylpyridinium<br />

tosylate (210 mg, 0.70 mmol), i-Pr 2NEt (0.25 mL, 1.40<br />

mmol) and DMF (3 mL) was added and the subsequent synthesis<br />

steps followed the procedure described for Method A, with the exception<br />

of the coupling times and temperature (10 minutes at 130<br />

°C), yielding as a white solid (83 mg, 0.15 mmol, 65%) 1.<br />

Method C<br />

Rink amide resin (300 mg, 0.78 mmol/g, 0.234 mmol) was deprotected<br />

using procedure I. The resin was transferred into a Smith Process<br />

Vial and Fmoc-Ile (248 mg, 0.70 mmol), TBTU (225 mg, 0.70<br />

mmol), i-Pr 2NEt (0.25 mL, 1.40 mmol) and DMF (3 mL) was added<br />

and the subsequent synthesis steps followed the procedure described<br />

for Method A, with exception of the coupling times (10<br />

minutes at 110 °C), yielding 1 as a white solid (41 mg, 0.075 mmol,<br />

31%).<br />

Method D<br />

Rink amide resin (301 mg, 0.73 mmol/g, 0.232 mmol) was deprotected<br />

using procedure I. The resin was transferred into a Smith Process<br />

Vial and Fmoc-Ile (233 mg, 0.66 mmol), HATU (156 mg, 0.66<br />

mmol), i-Pr 2NEt (0.23 mL, 1.32 mmol), DMF (3 mL) was added<br />

and the subsequent synthesis steps followed the procedure described<br />

for Method A, with exception of the coupling times (1.5<br />

min. at 110 °C), yielding 1 as a white solid (129 mg, 0.098 mmol,<br />

42%).<br />

1 H NMR (400 MHz, CD3CN): � = 7.83 (d, J = 7.2 Hz, 2 H, Fmoc),<br />

6.67 (br d, J = 7.6 Hz, 2 H, Fmoc), 7.42 (ddd, J = 1.2, 7.6, 7.6 Hz, 2<br />

H, Fmoc), 7.34 (ddd, J = 1.2, 7.2, 7.6 Hz, 2 H, Fmoc), 7.15 (br d, 1<br />

H, NH-Val), 6.80 (br d, 1 H, NH-Ile), 6.35 (br s, 1 H, NH), 6.08 (br<br />

d, 1 H, NH-Thr), 5.79 (br s, 1 H, NH), 4.33 (dd, J = 5.9, 7.3 Hz, 1<br />

H, CH �-Val), 4.31 (d, J = 6.6 Hz, 2 H, CH 2-Fmoc), 4.24 (t, J =6.6

SPECIAL TOPIC <strong>Rapid</strong> <strong>Microwave</strong>-<strong>Assisted</strong> <strong>Solid</strong> <strong>Phase</strong> <strong>Peptide</strong> <strong>Synthesis</strong> 1595<br />

Hz, 1 H, CH-Fmoc), 4.17 (dd, J = 6.8 Hz, 1 H, CH�-Ile), 4.06–4.14<br />

(m, 2 H, CH�-Thr, CH�-Thr), 1.7–1.81 (m, 2 H, CH�-Val, CH�-Ile), 1.44 (m, 1 H, CH2�(a)-Ile), 1.26 (d, J =Hz, 3 H, CH3-Thr),1.10 (m,<br />

1 H, CH2�(b)-Ile), 0.8–0.9 (m, 12 H, CH3�-Ile, CH3�-Ile, CH3�-Val). ESI-MS: m/z = 553 (M + 1) + , 536, 522, 423, 179.<br />

Fmoc-Ala-Ile-NH 2 (2); Method A2<br />

Rink amide resin (300 mg, 0.73 mmol/g, 0.235 mmol) was deprotected<br />

using procedure I. Then, the resin was transferred into a<br />

Smith Process Vial and Fmoc-Ile (233 mg, 0.66 mmol), PyBOP<br />

(343 mg, 0.70 mmol), i-Pr 2NEt (0.23 mL, 1.32 mmol), DMF (3 mL)<br />

was added and the loading of resin was made following procedure<br />

II (110 °C, 15 min), the confirmation of the completion of the reaction<br />

was made following procedure III. Fmoc-deprotection (procedure<br />

I) was followed by the coupling of Fmoc-Ala (205 mg, 0.66<br />

mmol) in the presence of PyBOP (343 mg, 0.70 mmol), i-Pr 2NEt<br />

(0.23 mL, 1.32 mmol) and DMF (3 mL) following procedure III<br />

(110 °C, 15 min). This step was repeated due to the incomplete coupling<br />

observed by the Kaisers test. The resin was washed with portions<br />

of DMF (3 � 5 mL), portions of CH 2Cl 2 (3 � 5 mL) and the<br />

dipeptide was cleaved following procedure IV yielding 2 as a white<br />

solid (56 mg, 0.132 mmol, 60%).<br />

Method B2<br />

Rink amide resin (301 mg, 0.78 mmol/g, 0.235 mmol) was deprotected<br />

using procedure I. The resin was transferred into a Smith Process<br />

Vial and Fmoc-Ile (233 mg, 0.66 mmol), 2-fluoro-1-methylpyridinium<br />

tosylate (210 mg, 0.70 mmol), i-Pr 2NEt (0.23 mL, 1.32<br />

mmol), DMF (3 mL) was added and the subsequent steps were<br />

made following Method A2 with the exception of the reaction times<br />

and temperature (110 °C, 10 min) yielding 2 as a white solid (35 mg,<br />

0.083 mmol, 35%).<br />

Method C2<br />

Rink amide resin (299 mg, 0.78 mmol/g, 0.233 mmol) was deprotected<br />

using procedure I. Then, the resin was transferred into a<br />

Smith Process Vial and Fmoc-Ile (233mg, 0.66 mmol), TBTU (225<br />

mg, 0.70 mmol), i-Pr 2NEt (0.23 mL, 1.32 mmol) and DMF (3 mL)<br />

was added and the subsequent steps were made following Method<br />

A2 with the exception of the reaction times and temperature (110<br />

°C, 10 min) yielding 2 as a white solid (41 mg, 0.097 mmol, 41%).<br />

1 H NMR (400 MHz, CD3CN): � = 7.83 (d, J = 7.7 Hz, 2 H, Fmoc),<br />

7.67 (br d, J = 7.3 Hz, 2 H, Fmoc), 7.42 (ddd, J = 1.2, 7.7, 7.7 Hz, 2<br />

H, Fmoc), 7.33 (ddd, J = 1.2, 7.3, 7.7 Hz, 2 H, Fmoc), 6.78 (br d,<br />

J = 7.7 Hz, 1 H, NH-Ile), 6.34 (br s, 1 H, NH), 6.08 (br d, J =5.9<br />

Hz, 1 H, NH-Ala), 5.75 (br s, 1 H, NH), 4.32 (d, J = 7.0 Hz, 2 H,<br />

CH2-Fmoc), 4.24 (t, J = 7.0 Hz, 1 H, CH-Fmoc), 4.16 (dd, J =5.8,<br />

8.0 Hz, 1 H, CH�-Ile), 4.09 (dq, J = 5.9, 7.0 Hz, 1 H, CH�-Ala), 1.77<br />

(m, 1 H, CH�-Ile), 1.42 (m, 1 H, CH2�(a)-Ile), 1.39 (d, J =7.0 Hz, 3<br />

H, CH3-Ala), 1.09 (m, 1 H, CH2�(b)-Ile), 0.87 (d, J = 6.8 Hz, 3 H,<br />

CH3�-Ile), 0.84 (t, J = 7.4 Hz, 3 H, CH3�-Ile). ESI-MS: m/z = 424 (M + 1) + , 407, 379, 179.<br />

Fmoc-Thr-Ile-NH 2 (3); Method D3<br />

Rink’s amide resin (300 mg, 0.78 mmol/g, 0.234 mmol) was deprotected<br />

using procedure I. Then, the resin was transferred into a<br />

Smith Process Vial and Fmoc-Ile (248 mg, 0.70 mmol), HATU (166<br />

mg, 0.70 mmol), i-Pr 2NEt (0.25 mL, 1.40 mmol), DMF (3 mL) was<br />

added and the loading of the resin was made following procedure II<br />

(110 °C, 1.5 min), the confirmation of the completion of the reaction<br />

was made following procedure III. Fmoc-deprotection (procedure<br />

I) was followed by the coupling of Fmoc-Thr(t-Bu) (279 mg,<br />

0.70 mmol) in the presence of HATU (343 mg, 0.70 mmol), i-<br />

Pr 2NEt (0.23 mL, 1.32 mmol) and DMF (3 mL) following procedure<br />

III (110 °C, 1.5 min). The resin was washed with portions of<br />

DMF (3 � 5 mL), portions of CH 2Cl 2 (3 � 5 mL) and the dipeptide<br />

was cleaved following procedure IV yielding 3 as a white solid<br />

(25.4 mg, 0.06 mmol, 24%).<br />

1 H NMR (400 MHz, CD3CN): � = 7.83 (d, J = 7.5 Hz, 2 H, Fmoc),<br />

7.68 (br d, J = 7.0 Hz, 2 H, Fmoc), 7.42 (ddd, J = 1.2, 7.5, 7.5 Hz, 2<br />

H, Fmoc), 7.33 (ddd, J = 1.2, 7.0, 7.5 Hz, 2 H, Fmoc), 6.87 (br d,<br />

J = 8.4 Hz, 1 H, NH-Ile), 6.44 (br s, 1 H, NH), 5.99 (br d, J =5.9<br />

Hz, 1 H, NH-Thr), 5.85 (br s, 1 H, NH), 4.36 (d, J = 7.5 Hz, 2 H,<br />

CH2-Fmoc), 4.25 (t, J = 7.5 Hz, 1 H, CH-Fmoc), 4.22 (dd, J =5.9,<br />

8.4 Hz, CH�-Ile), 4.7�4.15 (m, 2 H, CH�-Thr, CH�-Thr), 1.83 (m, 1<br />

H, CH�-Ile), 1.45 (m, 1 H, CH2�(a)-Ile), 1.14 (m, 1 H, CH2�(b)-Ile), 1.08 (d, J = 6.0 Hz, 3 H, CH3�-Thr), 0.90 (d, J = 7.0 Hz, 3 H, CH3�- Ile), 0.87 (t, J = 7.7 Hz, 3 H, CH3�-Ile). ESI-MS: m/z = 454 (M + 1) + , 437, 409, 255, 214, 199.<br />

Efficiency of the <strong>Solid</strong> <strong>Phase</strong> Methodology<br />

Rink amide resin (297 mg, 0.78 mmol/g, 0.232 mmol) was deprotected<br />

using procedure I. The resin was then transferred into a Smith<br />

Process Vial, Fmoc-Ile (251 mg, 0.70 mmol), PyBOP (343 mg, 0.70<br />

mmol), i-Pr2NEt (0.25 mL, 1.40 mmol), and DMF (3 mL) was added.<br />

The mixture was irradiated in a microwave cavity at 110 °C for<br />

15 minutes. Then, the mixture was transferred into a column<br />

equipped with a polypropylene frit and was washed following procedure<br />

II. The completion of the coupling was confirmed by Kaisers<br />

test. The resin was cleaved and purified following procedure IV<br />

yielding Fmoc-Ile-NH2 as a white solid (49 mg, 0.14 mmol, 60%).<br />

1 H NMR (400 MHz, CDCl3) � = 7.76 (d, J = 7.5 Hz, 2 H, Fmoc),<br />

7.57 (br d, J = 7.3 Hz, 2 H, Fmoc), 7.40 (dd, J = 7.3, 7.3 Hz, 2 H,<br />

Fmoc), 7.31 (dd, J = 7.3, 7.5 Hz, 2 H, Fmoc), 5.89 (br s, 1 H, NH),<br />

5.66 (br s, 1 H, NH), 5.36 (br d, J = 8.4 Hz, 1 H, NH-Ile), 4.42 (d,<br />

J = 6.7 Hz, 2 H, Fmoc-CH2), 4.20 (t, J = 6.7 Hz, 1 H, CH-Fmoc),<br />

4.07 (dd, J = 8.4, 8.4 Hz, 1 H, CH�-Ile), 1.89 (m, 1 H, CH�-Ile), 1.52<br />

(m, 1 H, CH�(a)-Ile), 1.13 (m, 1 H, CH�(b)-Ile), 0.8�1.0 (m, 6 H,<br />

CH3�-Ile, CH3�-Ile). ESI-MS: m/z = 353 (M+1) + .<br />

Acknowledgements<br />

We would like to thank Personal Chemistry AB for access to the<br />

Smith Synthesizer TM and Uppsala University for financial support.<br />

References<br />

(1) Merrifield, R. B. J. Am. Chem. Soc. 1963, 85, 2149.<br />

(2) Lindström, P.; Tierney, J.; Wathey, B.; Westman, J.<br />

Tetrahedron 2001, 57, 9225.<br />

(3) (a) Stadler, A.; Kappe, C. O. Eur. J. Org. Chem. 2001, 919.<br />

(b) Kuster, G.; Scheren, H. W. Tetrahedron Lett. 2000, 41,<br />

515. (c) Hoel, A. M. L.; Nielsen, J. Tetrahedron Lett. 1999,<br />

40, 3941. (d) Larhed, M.; Lindeberg, G.; Hallberg, A.<br />

Tetrahedron Lett. 1996, 37, 8219. (e) Lew, A.; Krutzik, P.<br />

O.; Hart, M. E.; Chamberlin, A. R. J. Comb. Chem. 2002, 4,<br />

95.<br />

(4) (a) Chen, S.-T.; Chiou, S.-H.; Wang, K.-T. J. Chin. Chem.<br />

Soc. 1991, 38, 85. (b) Yu, H.-M.; Chen, S.-T.; Wang, K.-T.<br />

J. Org. Chem. 1992, 57, 4781. (c) Chen, S.-T.; Tseng, P.-H.;<br />

Yu, H.-M.; Wu, C.-Y.; Hsiao, K.-F.; Wu, S.-H.; Wang, K.-<br />

T. J. Chin. Chem. Soc. 1997, 44, 169.<br />

(5) (a) HATU: O-(7-Azabenzotriazol-1-yl)-N,N,N�,N�tetramethyluronium<br />

hexafluoro-phosphate see: Carpino, L.<br />

A.; El-Faham, A.; Minor, C. A.; Albericio, F. J. Chem. Soc.,<br />

Chem Commun. 1994, 201. (b) TBTU: O-(Azabenzotriazol-<br />

1-yl)-N,N,N�,N�-tetramethyluronium tetrafluoro-borate see:<br />

Zimmer, S.; Hoffmann, E.; Jung, G.; Kessler, H. Liebigs<br />

Ann. Chem. 1993, 5, 497. (c) PyBOP: (Benzotriazol-1yloxy)-tripyrrolidinophosphonium<br />

hexa-fluorophosphate<br />

<strong>Synthesis</strong> 2002, No. 11, 1592–1596 ISSN 0039-7881 © Thieme Stuttgart · New York

1596 M. Erdélyi, A. Gogoll SPECIAL TOPIC<br />

see: Coste, J.; Le-Nguyen, D.; Castro, B. Tetrahedron Lett.<br />

1990, 31, 205. (d) Mukaiyama’s reagent: 2-fluoro-1methyl-pyridinium<br />

tosylate see: Mukaiyama, T.; Tanaka, T.<br />

Chem. Lett. 1976, 303.<br />

(6) Sarin, V. K.; Kent, S. B.; Tam, J. P.; Merrifield, R. B. Anal.<br />

Biochem. 1981, 117, 147.<br />

<strong>Synthesis</strong> 2002, No. 11, 1592–1596 ISSN 0039-7881 © Thieme Stuttgart · New York<br />

(7) (a) Wokaun, A.; Ernst, R. R. Chem. Phys. Lett. 1977, 52,<br />

407. (b) Shaka, A. J.; Freeman, R. J. Magn. Reson. 1983, 51,<br />

169.<br />

(8) (a) Kumar, A.; Ernst, R. R.; Wüthrich, K. Biochem. Biophys.<br />

Res. Commun. 1980, 95, 1. (b) Bodenhausen, G.; Kogler,<br />

H.; Ernst, R. R. J. Magn. Res. 1984, 58, 370.