Modulating temperature regulating unit for heating and ... - Caleffi

Modulating temperature regulating unit for heating and ... - Caleffi

Modulating temperature regulating unit for heating and ... - Caleffi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Modulating</strong> <strong>temperature</strong> <strong>regulating</strong> <strong>unit</strong><br />

<strong>for</strong> <strong>heating</strong> <strong>and</strong> cooling<br />

with distribution kit <strong>for</strong> primary circuit<br />

171 series<br />

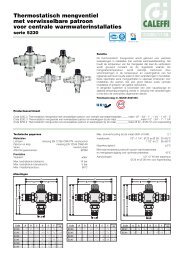

Product range<br />

Function<br />

The <strong>temperature</strong> <strong>regulating</strong> <strong>unit</strong> with the distribution kit <strong>for</strong> the primary<br />

circuit is made to be used in mixed systems: radiant panels <strong>and</strong><br />

radiators or fan coils, in combination with distribution manifolds <strong>for</strong><br />

radiant panels.<br />

The modulating <strong>temperature</strong> <strong>regulating</strong> <strong>unit</strong>, comprehensive of<br />

digital <strong>temperature</strong> regulator, controls the <strong>temperature</strong> of the<br />

medium sent to the panels according to the actual thermal load.<br />

In this particular series, the <strong>temperature</strong> is regulated by a dedicated<br />

hydraulic <strong>unit</strong> equipped with a specific motorised three-way valve.<br />

The function of the kit is to distribute a portion of the medium<br />

flowing from the primary boiler circuit to the <strong>heating</strong> or cooling<br />

elements.<br />

It is supplied with manifolds with built-in shut-off <strong>and</strong> balacing<br />

valves <strong>and</strong> a differential by-pass kit <strong>for</strong> the primary circuit. This<br />

accessory is essential when there is a primary circuit circulation<br />

pump <strong>and</strong> the radiator circuits or fan coils are controlled by<br />

thermostatic or thermo-electric valves.<br />

Patent application No. MI2006A 001935.<br />

Reference Documentation<br />

- Tech. brochure 01144 Pre-assembled distribution manifolds <strong>for</strong><br />

radiant panel systems 668...S1 series<br />

Code 1715.2 003 <strong>Modulating</strong> <strong>regulating</strong> <strong>unit</strong> <strong>for</strong> <strong>heating</strong> <strong>and</strong> cooling with distribution kit <strong>for</strong> primary circuit, with UPS 25-60 pump<br />

Code 1715.4 003 <strong>Modulating</strong> <strong>regulating</strong> <strong>unit</strong> <strong>for</strong> <strong>heating</strong> <strong>and</strong> cooling with distribution kit <strong>for</strong> primary circuit, with UPS 25-80 pump<br />

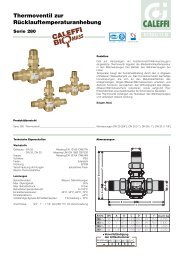

Technical specifications<br />

Materials<br />

Regulating <strong>unit</strong> with motorised three-way valve<br />

Body: brass EN 1982 CB753S<br />

Headwork: brass EN 12164 CW614N<br />

Obturator: stainless steel<br />

Seals:<br />

Flow adapter <strong>unit</strong><br />

EPDM<br />

Body:<br />

Primary circuit by-pass kit<br />

brass EN 1982 CB753S<br />

Body: brass EN 1982 CB753S<br />

By-pass valve: POM<br />

Spring:<br />

Shut-off valves<br />

stainless steel<br />

Body: brass EN 12165 CW617N<br />

Ball: brass EN 12164 CW614N, chrome plated<br />

Primary circuit distribution manifolds<br />

Flow manifold<br />

Body:<br />

Flow rate <strong>regulating</strong> valve<br />

brass EN 1982 CB753S<br />

Obturator: brass EN 12164 CW614N<br />

Hydraulic seals:<br />

Return manifold<br />

EPDM<br />

Body:<br />

Shut-off valve<br />

brass EN 1982 CB753S<br />

Stem: stainless steel<br />

Obturator <strong>and</strong> seals: EPDM<br />

Springs: stainless steel<br />

Control knob: ABS<br />

REGI STERED BSI EN ISO 9001:2000<br />

Per<strong>for</strong>mance<br />

CALEFFI<br />

01154/07 GB<br />

Medium: water, glycol solutions<br />

Max. percentage of glycol: 30%<br />

Control <strong>temperature</strong> range: 7–78°C<br />

Primary inlet <strong>temperature</strong> range: 5–100°C<br />

Max. working pressure: 10 bar<br />

Panel manifolds differential by-pass setting: 25 kPa (2.500 mm w.g.)<br />

Primary circuit differential by-pass setting: 10 kPa (1.000 mm w.g.)<br />

Primary circuit manifold inside diameter: Ø 27 mm<br />

Temperature gauge scale: 0–80°C<br />

Pressure gauge scale: 0–10 bar<br />

Connections: - primary circuit: 3/4” M<br />

- to <strong>regulating</strong> <strong>unit</strong>: 1” F with nut<br />

- panel circuit outlets: 3/4” M - Ø 18 mm<br />

- outlet centre distance: 50 mm<br />

- primary circuit manifold outlets: 3/4” M - Ø 18 mm<br />

- outlet centre distance: 50 mm<br />

Panel circuit differential by-pass graph<br />

Δp (mm w.g.)<br />

5000<br />

2000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

0,1<br />

Cert. n° FM 21654<br />

2<br />

0,2<br />

5<br />

UNI EN ISO 9001:2000<br />

Cert. n° 0003<br />

0,5<br />

10<br />

1<br />

20<br />

Δp (kPa)<br />

50<br />

45<br />

2<br />

40<br />

35<br />

30<br />

25<br />

20<br />

Flow rate<br />

(l/min) (m3/h)

Digital controller<br />

Three-point type<br />

Electric supply: 230 V - 50 Hz<br />

Power consumption: 3 VA<br />

Protection class: IP 40<br />

Actuator<br />

Three-point type<br />

Electric supply: 230 V - 50 Hz<br />

Operating time: 50 s (rotation 120°)<br />

Power consumption: 8 VA<br />

Auxiliary micro contact rating: 0,8 A<br />

Protection class: IP 44<br />

Max. ambient <strong>temperature</strong>: 55°C<br />

Protective cover: self-extinguishing VO<br />

Flow/return <strong>temperature</strong> probes<br />

NTC type<br />

Working range: -10–125°C<br />

Time constant: 2,5 s<br />

Response: 10.000 Ω at 25°C<br />

Two-wire cable with 1/8” M connection<br />

Safety thermostat<br />

Factory set: 55°C ±3°C<br />

Protection class: IP 55<br />

Contacts rating: 10 A / 240 V<br />

Pump<br />

Three-speed pump: model UPS 25-60/UPS 25-80<br />

Material: Body: cast iron GG 15/20<br />

Electric supply: 230 V - 50 Hz<br />

Maximum ambient humidity: 95%<br />

Max. ambient <strong>temperature</strong>: 80°C<br />

Protection class: IP 44<br />

Pump centre distance: 130 mm<br />

Pump connections: 1 1/2” with nut<br />

Dimensions<br />

code<br />

700<br />

270÷410<br />

129 105<br />

CALEFFI<br />

150052<br />

Tras<strong>for</strong>matore<br />

AC 230V<br />

D E<br />

50Hz<br />

V<br />

3/4”<br />

with ups 25-60 pump<br />

with ups 25-80 pump<br />

Radiator outlets<br />

Panel outlets<br />

A<br />

CALEFFI<br />

150051<br />

Convertitore<br />

AC 24V 50Hz<br />

AC 230V<br />

6(2)A T50<br />

415 50<br />

A<br />

1715E2 003<br />

-<br />

3<br />

5<br />

765<br />

3<br />

2<br />

4<br />

bar<br />

1<br />

5<br />

0 6<br />

CL 2.5<br />

con <strong>for</strong>me norme ISPESL<br />

40<br />

30 50<br />

20 60<br />

10<br />

70<br />

0 80<br />

°C<br />

40<br />

30 50<br />

20 60<br />

10<br />

70<br />

0 80<br />

°C<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

CAMERA<br />

CALEFFI<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1715F2 003<br />

-<br />

3<br />

6<br />

815<br />

CALEFF<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

HOBBY BAGNO<br />

SOGGIORNO<br />

WC<br />

CALEFFI<br />

5 outlets 8 outlets 12 outlets<br />

SOGGIORNO<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

CALEFFI<br />

800<br />

1715G2 003<br />

-<br />

3<br />

7<br />

865<br />

CAMERA<br />

CALEFF<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

Speed<br />

3<br />

2<br />

1<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

HOBBY BAGNO<br />

SOGGIORNO<br />

WC<br />

CALEFFI<br />

1715H2 003<br />

-<br />

3<br />

8<br />

915<br />

Head available at the <strong>regulating</strong> <strong>unit</strong> connections<br />

H (m w.g.)<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

0,5<br />

Insulation<br />

Material: closed cell exp<strong>and</strong>ed PE-X<br />

Thickness: 15 mm<br />

Density: - inner part: 30 kg/m3 - outer part: 50 kg/m3 Thermal conductivity (DIN 52612):<br />

Coefficient of resistance to the diffusion<br />

0°C: 0,038 W/(m·K)<br />

40°C: 0,045 W/(m·K)<br />

of water vapour (DIN 52615): >1300<br />

Working <strong>temperature</strong> range: 0–100°C<br />

Reaction to fire (DIN 4102): Class B2<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1<br />

0,40<br />

0,30<br />

0,20<br />

CALEFFI<br />

1<br />

1,5<br />

Power consumption<br />

2<br />

3<br />

I P n<br />

(A) (W) (rpm)<br />

1000<br />

90<br />

65<br />

45<br />

1715I2 003<br />

-<br />

3<br />

9<br />

985<br />

2<br />

UPS 25-60<br />

2,5<br />

G (m 3 /h)<br />

1800<br />

1100<br />

700<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1715L2 003<br />

1715L4 003<br />

3<br />

10<br />

1035<br />

1200<br />

A A 110÷150<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

CAMERA<br />

HOBBY BAGNO<br />

SOGGIORNO<br />

WC<br />

CALEFFI<br />

CAMERA<br />

CALEFF<br />

(kPa)<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

3<br />

H (m w.g.)<br />

(kPa)<br />

8 80<br />

UPS 25-80<br />

7 70<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

Speed<br />

CALEFFI<br />

0,5<br />

3<br />

2<br />

1<br />

1<br />

1<br />

1,5<br />

2 3<br />

1,04<br />

0,92<br />

0,63<br />

1715M2 003<br />

1715M4 003<br />

3<br />

11<br />

1085<br />

2<br />

2,5<br />

I P n<br />

(A) (W) (rpm)<br />

245<br />

210<br />

140<br />

3<br />

3,5<br />

G (m 3 /h)<br />

2450<br />

1500<br />

700<br />

1715N2 003<br />

1715N4 003<br />

3<br />

12<br />

1135<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

4

Characteristic components<br />

1 Digital controller <strong>for</strong> <strong>heating</strong> <strong>and</strong> cooling<br />

2 Three-way mixing valve<br />

3 Three-point actuator<br />

4 Three-speed circulation pump UPS 25-60<br />

Three-speed circulation pump UPS 25-80<br />

5 Flow <strong>temperature</strong> probe<br />

6 Return <strong>temperature</strong> probe<br />

7 Adjustable drain cock<br />

Hydraulic diagram<br />

BF<br />

1 10<br />

8<br />

4<br />

15<br />

6<br />

2<br />

3<br />

11<br />

BR<br />

BOILER<br />

FLOW<br />

CALEFFI<br />

150052<br />

Tras<strong>for</strong>matore<br />

15<br />

AC 230V<br />

D E<br />

50Hz<br />

V<br />

BOILER<br />

RETURN<br />

11<br />

RT<br />

T<br />

11<br />

CALEFFI<br />

150051<br />

Convertitore<br />

C<br />

AC 24V 50Hz<br />

AC 230V<br />

6(2)A T50<br />

1<br />

12<br />

12<br />

10<br />

8<br />

9<br />

3<br />

3<br />

2<br />

4<br />

bar<br />

1<br />

5<br />

0 6<br />

7<br />

ST<br />

CL 2.5<br />

con<strong>for</strong>me norme ISPESL<br />

40<br />

30 50<br />

20 60<br />

10<br />

70<br />

0 80<br />

°C<br />

4<br />

40<br />

30 50<br />

20 60<br />

10<br />

70<br />

0 80<br />

°C<br />

5<br />

13<br />

2<br />

SYSTEM<br />

FLOW<br />

SYSTEM<br />

RETURN<br />

6<br />

8 Safety thermostat<br />

9 Flow <strong>and</strong> return <strong>temperature</strong> gauges with pocket<br />

10 Pressure gauge<br />

11 Primary circuit shut-off valves<br />

12 Distribution manifolds with built-in valves <strong>for</strong> primary circuit<br />

13 Primary circuit differential by-pass kit<br />

14 Max. RH% control probe<br />

15 Max. RH% control components<br />

9<br />

5<br />

9<br />

7<br />

14<br />

9<br />

12<br />

13<br />

14<br />

Flow manifold<br />

equipped with flow<br />

meters <strong>and</strong><br />

balacing valves<br />

SF<br />

SR<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

CAMERA<br />

CALEFFI<br />

CAMERA<br />

CALEFFI<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

SOGGIORNO<br />

Return manifold<br />

equipped with<br />

shut-off valves.<br />

SOGGIORNO<br />

T<br />

RT<br />

ST<br />

C<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

WC<br />

WC<br />

Digital controller<br />

Trans<strong>for</strong>mer/Convertor<br />

Adjustable drain cock<br />

Temperature gauge<br />

Temperature probe<br />

Humidity % probe<br />

Room thermostat<br />

Safety thermostat<br />

Ball shut-off valve<br />

Motorised three-way valve<br />

Pressure gauge<br />

Pump<br />

CALEFFI<br />

End fittings with<br />

multi-position ball valves,<br />

automatic air vent,<br />

differential by-pass kit<br />

<strong>and</strong> fill/drain hose connection.<br />

CALEFFI<br />

Differential by-pass

Operating principle<br />

The medium <strong>temperature</strong> is regulated<br />

by a three-way mixing valve with a<br />

sector obturator comprehensive of an<br />

actuator managed by a specific<br />

digital controller.<br />

The controller receives the signal from<br />

two probes, flow probe on the mixing<br />

valve outlet <strong>and</strong> probe from the panel<br />

circuit return, <strong>and</strong> it controls the<br />

movement of the valve.<br />

The flow in the valve is regulated by a<br />

shaped obturator (1) that, by turning,<br />

closes or opens the hot water flow ports<br />

(2) <strong>and</strong> the water returning ports from<br />

the circuit (3) to adjust the desired flow<br />

<strong>temperature</strong>.<br />

Even if the secondary circuit thermal<br />

load or the inlet <strong>temperature</strong> from the<br />

boiler change, the mixing valve<br />

automatically adjusts the flow rates<br />

until it obtains the optimal flow<br />

<strong>temperature</strong>.<br />

Construction details<br />

Regulating <strong>unit</strong> body<br />

The valve body, containing the thermal <strong>regulating</strong> device, is made<br />

out of a single casting with connections to the primary <strong>and</strong><br />

secondary circuits. A specific internal channel carries the system<br />

return medium to the <strong>regulating</strong> valve, making it possible <strong>for</strong> the <strong>unit</strong><br />

to be smaller in size <strong>and</strong> easy to connect.<br />

Reduced head losses<br />

The three-way mixing valve is equipped with a special obturator acting<br />

on calibrated water orifices. This ensures a high flow rate <strong>and</strong> a reduced<br />

size, while maintaining accurate <strong>temperature</strong> control, with no swinging<br />

due to sudden changes in thermal load.<br />

Electrical connections<br />

The actuator is<br />

electrically connected<br />

through an external<br />

plug-socket system with<br />

a protective rubber cap.<br />

This system does not<br />

require opening the lid<br />

to connect the cables.<br />

In this way, replacing<br />

the actuator (should this<br />

ever be necessary) is<br />

particularly easy to do.<br />

Manual opening<br />

By removing the actuator, the valve can be opened-closed manually<br />

by using a screwdriver.<br />

Regulating way - primary inlet<br />

Fully closed Fully open<br />

c l o s e<br />

open<br />

open<br />

c l o s e<br />

1<br />

3<br />

2<br />

PRIMARY<br />

INLET<br />

SECONDARY<br />

FLOW<br />

PRIMARY<br />

RETURN<br />

SECONDARY<br />

RETURN<br />

Flow <strong>unit</strong><br />

The flow <strong>unit</strong> is made out of a single casting with the necessary<br />

ports to connect with the functional components such as the safety<br />

thermostat, <strong>temperature</strong> gauge, pressure gauge, drain valve <strong>and</strong><br />

flow <strong>temperature</strong> probe.<br />

30<br />

20<br />

10<br />

0<br />

40<br />

°C<br />

50<br />

60<br />

70<br />

80

Distribution <strong>and</strong> differential by-pass kit <strong>for</strong> primary circuit<br />

Operation<br />

The distribution <strong>and</strong> differential by-pass kit <strong>for</strong> the primary circuit<br />

enables controlling the flow supplied to the <strong>heating</strong> or cooling<br />

elements connected be<strong>for</strong>e the outlet to the panel circuit <strong>regulating</strong><br />

<strong>unit</strong>.<br />

It is composed of distribution manifolds with built-in <strong>regulating</strong> <strong>and</strong><br />

shut-off valves, <strong>and</strong> the differential by-pass kit <strong>for</strong> the primary circuit.<br />

Primary circuit distribution manifolds<br />

The distribution manifolds are equipped with:<br />

- flow rate <strong>regulating</strong> valves built into the flow manifold. In this way<br />

it is possible to set the right flow rate <strong>and</strong> balance the various<br />

connected circuits.<br />

- shut-off valves built into the return manifold. The same circuits can<br />

be automatically shut off by using the thermo-electric controls.<br />

Δp (mm w.g.)<br />

1000<br />

500<br />

200<br />

100<br />

900<br />

800<br />

700<br />

600<br />

450<br />

400<br />

350<br />

300<br />

250<br />

180<br />

160<br />

140<br />

120<br />

90<br />

80<br />

70<br />

60<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

0,1<br />

2<br />

0,2<br />

5<br />

Flow rate <strong>regulating</strong> valve fully open<br />

Shut-off valve<br />

Kv<br />

5,40<br />

4,10<br />

Δp (kPa)<br />

10<br />

Kv 0,01<br />

540<br />

410<br />

Primary circuit by-pass kit<br />

The by-pass kit permits hydraulic separation between the primary <strong>and</strong> secondary circuits. This hydraulic separation optimizes the operation of<br />

the secondary circuit at the panels thus preventing the influence on the secondary circuit by any primary circuit flow rate variation. In this case,<br />

the flow rate through the respective circuits depends solely on the pump flow rate characteristics, preventing reciprocal influence due to their<br />

coupling in series. Two possible conditions of hydraulic balance are described here. The component is typically sized in order to have the<br />

following working rate:<br />

G primary = G secondary (inlet to the mixing valve) + G <strong>heating</strong> elements<br />

G primary maximum recommended: 1,5 m 3 /h<br />

0,5<br />

10<br />

- Kv = flow rate in m 3 /h <strong>for</strong> a loss of head of 1 bar<br />

- Kv 0,01 = flow rate in l/h <strong>for</strong> a loss of head of 1 kPa<br />

Gp<br />

Primary<br />

1<br />

Gs<br />

Gprimary > Gsecondary<br />

20<br />

Secondary<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4,5<br />

4<br />

3,5<br />

3<br />

2,5<br />

2<br />

1,8<br />

1,6<br />

1,4<br />

1,2<br />

1<br />

0,9<br />

0,8<br />

0,7<br />

0,6<br />

0,5<br />

0,45<br />

0,4<br />

0,35<br />

0,3<br />

0,25<br />

0,2<br />

0,18<br />

0,16<br />

0,14<br />

0,12<br />

0,1<br />

2<br />

Flow rate<br />

(l/min) (m3/h) Hydraulic characteristics of flow rate <strong>regulating</strong> valve<br />

Kv (m3 Adjustment<br />

position<br />

/h)<br />

2 turns 0,22<br />

3 turns 1,30<br />

4 turns 3,20<br />

5 turns 4,70<br />

F.O. 5,40<br />

Differential valve<br />

The differential valve is used to control the head in the primary<br />

distribution circuit. It aids the flow circulation towards the <strong>heating</strong> or<br />

cooling elements <strong>and</strong> limits overpressure if there are thermostatic or<br />

thermo-electric valves.<br />

The differential valve has a fixed setting that cannot be changed.<br />

It is preset to 10 kPa, mean value <strong>for</strong> the loss of head in the primary<br />

circuit.<br />

Δp (mm w.g.) Δp (kPa)<br />

20<br />

2000<br />

1800<br />

1600<br />

1400<br />

1200<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

0,1<br />

2<br />

Gp<br />

Primary<br />

0,2<br />

Kv 0,01 (l/h)<br />

22<br />

130<br />

320<br />

470<br />

540<br />

5<br />

0,5<br />

10<br />

Gprimary < Gsecondary<br />

1<br />

Gs<br />

5 mm<br />

20<br />

Secondary<br />

18<br />

16<br />

14<br />

12<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

2<br />

Flow rate<br />

(l/min) (m3/h)

Digital regulator<br />

2 7 3 4 8 1<br />

10 11 12 9 6 5<br />

The front panel identifies the following functions:<br />

1) Three-digit LCD indicating: the measured or calculated<br />

<strong>temperature</strong> <strong>and</strong> the settings of the delays programmed in the<br />

system.<br />

• Temperature range displayed: 0–99°C with resolution 0,1°C.<br />

2) Regulator On/Off function selector.<br />

3) Mixer on opening: LED on.<br />

4) Mixer on closing: LED on.<br />

5) Selector <strong>for</strong> setting the flow <strong>temperature</strong>.<br />

• Temperature range 7–78°C<br />

Factory configuration: - <strong>heating</strong>: max 50°C<br />

- cooling: min 14°C<br />

6) Return probe selector.<br />

• Probe off: OFF<br />

• Probe on: ON<br />

Factory configuration: ON<br />

7) Pump working (ON): LED on steady.<br />

8) T.S. LED safety <strong>temperature</strong>. Continuously ON when the limit<br />

signalled by the safety thermostat or by the safety humidostat is<br />

reached. Continuously ON even if the flow/return sensors<br />

malfunction (see flow/return sensor paragraph).<br />

9) Heating/cooling function switch<br />

10) Trimmer <strong>for</strong> maximum pulse duration on the valve.<br />

Adjustable 0,2–6 s. Factory configuration: 2,5 s.<br />

Pulse value calculation:<br />

Tpulse (s) =<br />

Example:<br />

Tactuator rotation = 120 s<br />

Tpulse = 120/40 = 3 s<br />

Actuator rotation time (s)<br />

40<br />

11) Return probe reading delay time trimmer.<br />

Adjustable 1–360 s. Factory configuration: 20 s.<br />

12) Valve-motor mechanical delay recovery trimmer.<br />

Adjustable 1–30 s. Factory configuration: 13 s.<br />

Operation<br />

The regulator receives the signal from the room thermostat to switch the<br />

pump on <strong>and</strong> to control the mixing valve.<br />

The regulator acts on the mixing valve following two operating logics,<br />

depending on the state of activation of the return sensor.<br />

Set point regulation: return probe off. Selector 6) OFF.<br />

In this case the flow <strong>temperature</strong> TM is kept constant at the value set<br />

with the selector 5) in both <strong>heating</strong> <strong>and</strong> cooling. This setting is shown<br />

on the display 1).<br />

<strong>Modulating</strong> regulation: return probe on. Selector 6) ON.<br />

In this case the flow <strong>temperature</strong> TM is changed according to the<br />

<strong>temperature</strong> measured by the return probe TR. In this way the actual<br />

thermal efficiency of the slab is kept under control <strong>and</strong>, as a result,<br />

the room’s thermal load as well. This minimizes the system’s thermal<br />

response times.<br />

TRset = TMset - 35% (TMset - 20°C)<br />

TMcalculated = TMset + (TRset - TR)<br />

Example:<br />

TM set = 40°C<br />

TR set = 40 - 0,35 · (40 - 20) = 33°C<br />

TM calculated = 40 + (33 - TR)<br />

The new value of TM calculated is shown on the display 1) with a<br />

side bar.<br />

At each update of the TM calculated, the TM measured is displayed<br />

<strong>for</strong> 5 s, thereafter the new TM calculated is shown again.<br />

TM modification stops when TR reaches TRset. The return probe is not active in the cooling function.<br />

Curve correction graph with return probe<br />

TM;TR<br />

(°C)<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

Designed flow<br />

<strong>temperature</strong><br />

TM Set<br />

TM Calculated<br />

TM Calculated<br />

50% 100% 150%<br />

➩<br />

TR Set Return <strong>temperature</strong><br />

designed<br />

Flow <strong>temperature</strong><br />

limit<br />

TM<br />

Flow<br />

<strong>temperature</strong><br />

Designed<br />

thermal load %<br />

Display<br />

The three-digit LCD displays the following parameters:<br />

- flow <strong>temperature</strong> set with selector 5).<br />

After 5 s the measured flow <strong>temperature</strong> appears.<br />

- measured flow <strong>temperature</strong>, with return sensor off.<br />

- calculated flow <strong>temperature</strong>, with return sensor on.<br />

- maximum duration of pulse on the valve, selectable via trimmer 10).<br />

Displayed <strong>for</strong> 5 s.<br />

- return <strong>temperature</strong> acquisition delay time, selectable via trimmer 11).<br />

Displayed <strong>for</strong> 5 s.<br />

- valve-motor mechanical delay recovery, selectable via trimmer 12).<br />

Displayed <strong>for</strong> 5 s

Back panel<br />

CALEFFI<br />

M 230 V~ 50÷60 Hz<br />

~<br />

μ 5(2) A / 250 V~<br />

1 2 3 4 5 6<br />

1 2 3 4 5 6<br />

L N<br />

SA SR TA TS<br />

230 V~ IN OUT Apre Chiude<br />

13 14 15 16 17 18<br />

On the back panel there are terminals <strong>for</strong> the electrical connections<br />

of the various components.<br />

Electric supply<br />

1 Electric supply 230 V~ “Live”<br />

2 Electric supply 230 V~ “Neutral”<br />

3 Ground/Earth<br />

Pump comm<strong>and</strong><br />

4 Ground/Earth<br />

5 Pump comm<strong>and</strong> 230 V~ “Live”<br />

6 Pump comm<strong>and</strong> 230 V~ “Neutral”<br />

Mixer comm<strong>and</strong><br />

7 Valve comm<strong>and</strong> <strong>for</strong> opening<br />

8 Common C<br />

9 Valve comm<strong>and</strong> <strong>for</strong> closing<br />

Auxiliary microswitch<br />

10 Auxiliary output N/O<br />

11 Auxiliary output common C<br />

12 Auxiliary output N/C<br />

Flow/return probe<br />

13 Flow <strong>temperature</strong> probe<br />

14 Common C<br />

15 Return <strong>temperature</strong> probe<br />

Ambient thermostat/safety thermostat<br />

16 Contact <strong>for</strong> ambient thermostat<br />

17 Contact <strong>for</strong> common C ambient thermostat / Contact <strong>for</strong> common C<br />

safety thermostat <strong>and</strong> humidity probe convertor<br />

18 Contact <strong>for</strong> safety thermostat <strong>and</strong> humidity probe convertor.<br />

Heating safety thermostat<br />

If the safety thermostat trips, on detecting a higher flow <strong>temperature</strong><br />

than the setting, the following state comes into operation: pump OFF,<br />

mixing valve closed. The thermostat contact is N/C; if the connection<br />

fails, the regulator is not on.<br />

Auxiliary microswitch<br />

The regulator is equipped with an auxiliary microswitch that can be<br />

used to control other devices.<br />

Example:<br />

When Heating, to turn the water heater on/off.<br />

N/O contact - Pump stationary - ambient thermostat OFF or safety<br />

thermostat on (water heater off).<br />

N/C contact - Pump on - ambient thermostat ON (water heater on).<br />

When Cooling, to turn the refrigerating <strong>unit</strong> on/off.<br />

N/O contact - Pump stationary - ambient thermostat OFF or RH%<br />

limit probe on (refrigerating <strong>unit</strong> off).<br />

N/C contact - Pump on - ambient thermostat ON (refrigerating <strong>unit</strong> on).<br />

Contact capacity: 5 A (230 V).<br />

Flow/return probe<br />

The flow/return <strong>temperature</strong> probes are the NTC type. If the probes<br />

detect an ohmic resistance corresponding to short circuiting, the<br />

following operating state comes into operation: pump OFF, mixing<br />

valve closed, LED 8) on steady.<br />

Sensor resistance values table<br />

°C Ω<br />

-20 97.060<br />

-15 72.940<br />

-10 55.319<br />

-5 42.324<br />

0 32.654<br />

5 25.396<br />

°C Ω<br />

10 19.903<br />

15 15.714<br />

20 12.493<br />

25 10.000<br />

30 8.056<br />

35 6.530<br />

13 14<br />

15 16 17 18<br />

°C Ω<br />

40 5.327<br />

45 4.370<br />

50 3.603<br />

55 2.986<br />

60 2.488<br />

65 2.083<br />

7 8 9 10 11 12<br />

7 8 9 10 11 12<br />

°C Ω<br />

70 1.752<br />

75 1.480<br />

80 1.255<br />

85 1.070<br />

90 915<br />

95 787<br />

°C Ω<br />

100 680<br />

105 592<br />

110 517<br />

115 450<br />

120 390<br />

125 340<br />

Flow <strong>temperature</strong> limit <strong>for</strong> <strong>heating</strong> <strong>and</strong> cooling<br />

The regulator enables selecting the maximum flow <strong>temperature</strong> <strong>for</strong><br />

<strong>heating</strong> <strong>and</strong> the minimum flow <strong>temperature</strong> <strong>for</strong> cooling. For this<br />

purpose, the regulator base contains specific dipswitches that enable<br />

setting different <strong>temperature</strong> limits.<br />

Factory configuration: - <strong>heating</strong> max 50°C<br />

- cooling: min 14°C.<br />

Dipswitch position-<strong>temperature</strong> limit table<br />

Setting Limit Limit<br />

Dipswitch maximum minimum<br />

0 0 0 50 14<br />

0 0 1 54 13<br />

0 1 0 58 12<br />

0 1 1 62 11<br />

1 0 0 66 10<br />

1 0 1 70 9<br />

1 1 0 74 8<br />

1 1 1 78 7<br />

ON<br />

1 2 3<br />

Position 1<br />

Position 0<br />

Maximum <strong>temperature</strong> limit <strong>for</strong> cooling<br />

When cooling, the flow <strong>temperature</strong> can be selected no higher than<br />

25°C.<br />

Relative humidity control<br />

When using the cooling regulator, it is necessary to use the specific<br />

relative humidity probe. This probe has the task of measuring the<br />

limit of relative humidity so as to prevent condensation in the<br />

cooling slab.<br />

It is set <strong>for</strong> RH=80 – 85%. On reaching the setting, it triggers the<br />

following operating state: pump ON, mixer closed.<br />

Humidity probe control<br />

At the start of each cooling season, the operating state of the probe<br />

must be checked by placing a moist wad of cotton wool on its<br />

surface; this will cause the mixer to close <strong>and</strong> the red LED point 8<br />

on the panel front to light up.<br />

Positioning the humidity probe<br />

Depending on the system characteristics, the humidity probe is<br />

located where there is the greatest risk of condensation. It is placed<br />

with the carbon portion upwards, as shown in the following<br />

diagrams.<br />

E<br />

Top side: carbon<br />

Bottom side: housed on the cooling surface<br />

Steps <strong>for</strong> correctly positioning the max RH%<br />

limit probe.<br />

The probe is secured to the manifold installed in<br />

the zone where you want to check that the relative<br />

humidity RH% cannot exceed the safety values. It<br />

is secured by means of the two clamps, using the<br />

specific holes.<br />

By controlling the following parameters it is<br />

possible to reach the maximum <strong>heating</strong> power<br />

delivered by the panel.<br />

- Minimum flow <strong>temperature</strong>, selectable via<br />

selector (5) on front panel.<br />

- Relative humidity RH% limit point, checked with<br />

relative humidity probe.<br />

- Ambient <strong>temperature</strong>, checked via ambient thermostat<br />

- Temperature <strong>and</strong> relative humidity of the ambient air, checked via<br />

fan coil or dehumidifier.<br />

Caution: The RH% limit probe is used to prevent any condensation<br />

from <strong>for</strong>ming. In rooms where there is cooling, there must always be<br />

suitable air treatment.<br />

E

Humidity probe connection<br />

230 V<br />

Room<br />

thermostat<br />

RT<br />

Application diagram<br />

We reserve the right to make changes <strong>and</strong> improvements to the products <strong>and</strong> related data in this publication, at any time <strong>and</strong> without prior notice.<br />

CALEFFI<br />

CALEFFI CALEFFI<br />

150052<br />

Tras<strong>for</strong>matore<br />

D E<br />

V<br />

AC 230V<br />

50Hz<br />

24V<br />

LN ~ ~<br />

Controller<br />

cod. 161000<br />

150051<br />

Convertitore<br />

AC 24V 50Hz<br />

AC 230V<br />

6(2)A T50<br />

24V~<br />

1 2 3 4 5 6<br />

13 14 15 16 17 18<br />

13 14 15 16 17 18<br />

1 2 3 4 5 6<br />

7 8 9 10 11 12<br />

L N<br />

SA SR TA TS<br />

230 V~ IN OUT Open Close<br />

E/I<br />

CALEFFI<br />

150052<br />

150051<br />

Tras<strong>for</strong>matore<br />

Convertitore<br />

AC 24V 50Hz<br />

AC 230V<br />

AC 230V<br />

D E<br />

50Hz<br />

6(2)A T50<br />

V<br />

CALEFFI<br />

Safety<br />

thermostat<br />

3<br />

2<br />

4<br />

bar<br />

1<br />

5<br />

0 6<br />

c on<strong>for</strong>m en or me<br />

CL 2.5<br />

ISPES L<br />

40<br />

30 50<br />

20 60<br />

10<br />

70<br />

0 80<br />

°C<br />

40<br />

30 50<br />

20 60<br />

10<br />

70<br />

0 80<br />

°C<br />

ST<br />

1<br />

2<br />

3<br />

4 MIN<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

BBY BAGNO<br />

SOGGIORNO<br />

WC<br />

1<br />

1<br />

1<br />

1<br />

1<br />

2<br />

2<br />

2<br />

2<br />

2<br />

3<br />

3<br />

3<br />

3<br />

3<br />

4<br />

4<br />

4<br />

4<br />

4<br />

L/MIN<br />

L/MIN<br />

L/MIN<br />

L/MIN<br />

L/MIN<br />

CAMERA<br />

HOBBY BAGNO<br />

SOGGIORNO<br />

WC<br />

CALEFFI<br />

CALEFFI<br />

CAMERA<br />

HOBBY BAGNO<br />

SOGGIORNO<br />

WC<br />

CALEFF<br />

1<br />

2<br />

3<br />

4<br />

L/MIN<br />

CALEFFI<br />

Accessories<br />

738107<br />

1 2 3 4 5 6<br />

°C<br />

t1<br />

ON OFF<br />

t1/t2/t3<br />

°C<br />

t2<br />

- t1<br />

t❄<br />

- t2<br />

- t3<br />

0 2 4 6 8 10 12 14 16 18 20 22<br />

CALEFFI<br />

TH<br />

CALEFFI S.P.A. · I · 28010 FONTANETO D’AGOGNA (NO) · S.R. 229, N.25 · TEL. +39 0322 8491 R.A. · FAX +39 0322 863723<br />

· www.caleffi.com · info@caleffi.com ·<br />

© Copyright 2007 <strong>Caleffi</strong> S.P.A.<br />

Pump<br />

SPECIFICATION SUMMARIES<br />

The humidity probe is connected to the regulator by installing the<br />

trans<strong>for</strong>mer <strong>and</strong> convertor in between.<br />

If you want to monitor various zones at risk of condensation, the<br />

humidity probe must be connected to a suitable interface kit<br />

(trans<strong>for</strong>mer, convertor <strong>and</strong> humidity probe). Up to 12 convertors<br />

plus probes can be connected to a single trans<strong>for</strong>mer.<br />

124 x 90 x 21 mm<br />

Three-way valve<br />

Thermostatic valve<br />

Manual valve<br />

738<br />

Chrono-thermostat <strong>for</strong> ambient,<br />

battery operated.<br />

With self-learning program.<br />

Weekly programmable clock.<br />

With phone programmer.<br />

3 <strong>temperature</strong> levels + antifreeze.<br />

30 minutes minimum program.<br />

Lockshield<br />

Shut-off valve<br />

Clock<br />

TH Thermostat/Humidostat<br />

Code 1715.. 003<br />

<strong>Modulating</strong> <strong>temperature</strong> <strong>regulating</strong> <strong>unit</strong> <strong>for</strong> <strong>heating</strong> <strong>and</strong> cooling with distribution kit <strong>for</strong> primary circuit. Connections to the primary circuit<br />

3/4” M. Connections to the <strong>regulating</strong> <strong>unit</strong> 1” F with nut. Panel circuit outlet connections 3/4” M - Ø 18 mm. Primary circuit manifold outlet<br />

connections 3/4” M - Ø 18 mm. Medium: water <strong>and</strong> glycol solutions; Maximum percentage of glycol 30%. Control <strong>temperature</strong> range<br />

7–78°C. Maximum <strong>temperature</strong> at primary circuit inlet 100°C. Maximum working pressure 10 bar. Panel manifolds differential by-pass setting<br />

25 kPa. Primary circuit differential by-pass setting 10 kPa. Temperature gauge scale 0–80°C. Pressure gauge scale 0–10 bar. Complete with:<br />

flow manifold <strong>for</strong> panel system with 5 outlets (from 5 to 12) with brass body, flow rate <strong>regulating</strong> valve with flow meter with a scale of<br />

1–5 l/min; return manifold <strong>for</strong> panel system with 5 outlets (from 5 to 12) with brass body, shut-off valve. Regulating <strong>unit</strong> with motorised<br />

three-way valve, three-point actuator, electric supply 230 V - 50 Hz, protection class IP 44. Digital controller, electric supply 230 V - 50 Hz,<br />

comprehensive of probes measuring <strong>temperature</strong> of flow, return <strong>and</strong> relative humidity. Flow adapter <strong>unit</strong> with brass body. Primary circuit<br />

distribution manifolds with 3 outlets, brass body, flow rate <strong>regulating</strong> <strong>and</strong> shut-off valves. By-pass kit with brass body, POM differential<br />

by-pass valve <strong>and</strong> stainless steel spring. Shut-off valves with brass body <strong>and</strong> chrome plated brass ball. Safety thermostat: factory setting<br />

55°C ± 3°C, protection class IP 55, contact rating 10 A / 240 V. Three-speed circulation pump UPS 25-60 (<strong>and</strong> UPS 25-80), protection class<br />

IP 44. Pre-<strong>for</strong>med PE-X shell insulation <strong>for</strong> primary circuit. Supplied preassembled in a painted plate box with lock, depth adjustable from<br />

110 to 150 mm, including floor supports adjustable in height from 270 to 410 mm.<br />

Code<br />

TA