Application Note BIO-0001 Microwave Synthesis of ACP 65-74

Application Note BIO-0001 Microwave Synthesis of ACP 65-74

Application Note BIO-0001 Microwave Synthesis of ACP 65-74

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 1 <strong>of</strong> 2<br />

<strong>Microwave</strong> <strong>Synthesis</strong> <strong>of</strong> <strong>ACP</strong> <strong>65</strong>‐<strong>74</strong><br />

INTRODUCTION<br />

The application <strong>of</strong> microwave energy has<br />

proved to be a major enabling tool for many<br />

chemical reactions requiring energy input,<br />

and recently microwave irradiation has<br />

been applied to solid phase peptide<br />

synthesis. Peptide synthesis <strong>of</strong>ten suffers<br />

from long reaction times and low yields due<br />

to problems such as aggregation.<br />

<strong>Microwave</strong> energy can help break up these<br />

aggregates improving the synthesis quality<br />

while speeding up the synthesis rate. The<br />

acyl carrier protein (<strong>ACP</strong>) fragment <strong>65</strong>‐<strong>74</strong>,<br />

H‐Val‐Gln‐Ala‐Ala‐Ile‐Asp‐Tyr‐Ile‐Asn‐Gly‐<br />

OH, is a widely used standard model for<br />

demonstrating peptide synthesis efficiency.<br />

The presence <strong>of</strong> several hydrophobic<br />

residues, and in particular the hindered Val<br />

and Ile residues, can lead to poor coupling<br />

and deprotection reactions resulting in low<br />

yield and purity <strong>of</strong> the peptide.<br />

In this application note <strong>ACP</strong> <strong>65</strong>‐<strong>74</strong> is<br />

synthesized in good yield and purity using<br />

microwave irradiation for the deprotection,<br />

coupling, and final cleavage steps.<br />

MATERIALS AND METHODS<br />

Reagents<br />

All Fmoc amino acids were obtained from<br />

CEM Corporation and contained the<br />

following side chain protecting groups:<br />

Asn(Trt), Asp(OtBu), Gln(Trt), and Tyr(tBu).<br />

O‐(Benzotriazol‐1‐yl)‐N,N,N′,N′‐<br />

tetramethyluronium hexafluorophosphate<br />

(HBTU) and 1‐hydroxybenztriazole hydrate<br />

(HOBt) were also obtained from CEM<br />

Corporation. Fmoc‐Gly‐Wang resin was<br />

<strong>Application</strong> <strong>Note</strong> <strong>BIO</strong>‐<strong>0001</strong><br />

obtained from Novabiochem (San Diego,<br />

CA). Diisopropylethylamine (DIEA),<br />

piperidine, trifluoroacetic acid (TFA),<br />

triisopropylsilane (TIS), and 3,6‐dioxa‐1,8‐<br />

octanedithiol (DODT) were obtained from<br />

Sigma Aldrich (St. Louis, MO).<br />

Dichloromethane (DCM), N,N‐<br />

dimethylformamide (DMF), N‐<br />

methylpyrrolidine (NMP), anhydrous diethyl<br />

ether, acetic acid, HPLC grade water, and<br />

HPLC grade acetonitrile were obtained from<br />

VWR (West Chester, PA).<br />

Peptide <strong>Synthesis</strong><br />

The peptide was prepared using the CEM<br />

Liberty automated microwave peptide<br />

synthesizer on 0.164 g <strong>of</strong> Fmoc‐Gly‐Wang<br />

resin (0.61 meq/g substitution).<br />

Deprotection (20% piperidine with 0.1 M<br />

HOBt) was performed in two stages with an<br />

initial deprotection <strong>of</strong> 30 seconds followed<br />

by 3 minutes at 75 °C. Coupling reactions<br />

were performed with 5 fold excess Fmoc‐<br />

AA‐OH with 1:0.9:2 AA/HBTU/DIEA for 5<br />

minutes at 75 °C. Cleavage was performed<br />

using 92.5:2.5:2.5:2.5 TFA/water/TIS/DODT<br />

for 30 minutes at 38 °C. Following cleavage<br />

the peptide was precipitated and washed<br />

with diethyl ether.<br />

Peptide Analysis<br />

The peptide was analyzed on a Waters<br />

Atlantis C18 column (2.1 x 150 mm) at 214<br />

nm with a gradient <strong>of</strong> 5 – 95% MeCN (0.1%<br />

formic acid), 0 – 20 minutes. Mass analysis<br />

was performed using an LCQ Advantage ion<br />

trap mass spectrometer with electrospray<br />

ionization (Thermo Electron, Waltham, MA).

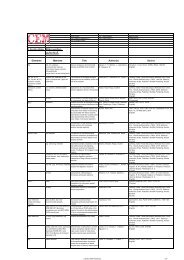

RESULTS AND DISCUSSION<br />

<strong>ACP</strong> <strong>65</strong>‐<strong>74</strong> was synthesized in 5 hours using<br />

microwave irradiation to accelerate the<br />

deprotection, coupling, and the peptide<br />

cleavage steps to give the peptide in 96%<br />

isolated yield and about 87% crude purity<br />

(Figure 1), and the product was confirmed<br />

by mass spectrometry (Figure 2).<br />

Figure 1: <strong>ACP</strong> <strong>65</strong>‐<strong>74</strong> crude chromatogram<br />

Page 2 <strong>of</strong> 2<br />

<strong>Application</strong> <strong>Note</strong> <strong>BIO</strong>‐<strong>0001</strong><br />

Figure 2: <strong>ACP</strong> <strong>65</strong>‐<strong>74</strong> mass spectrum<br />

CONCLUSIONS<br />

The application <strong>of</strong> microwave energy to<br />

solid phase peptide synthesis allows for<br />

much faster cycle times while driving<br />

deprotection and coupling reactions to<br />

completion. This leads to peptides with<br />

higher crude purity and improved yields<br />

including peptides with “difficult”<br />

sequences.