Tyre Update - Chem-Trend

Tyre Update - Chem-Trend

Tyre Update - Chem-Trend

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Tyre</strong> <strong>Update</strong><br />

Feb. 2012 | <strong>Chem</strong><strong>Trend</strong>.com<br />

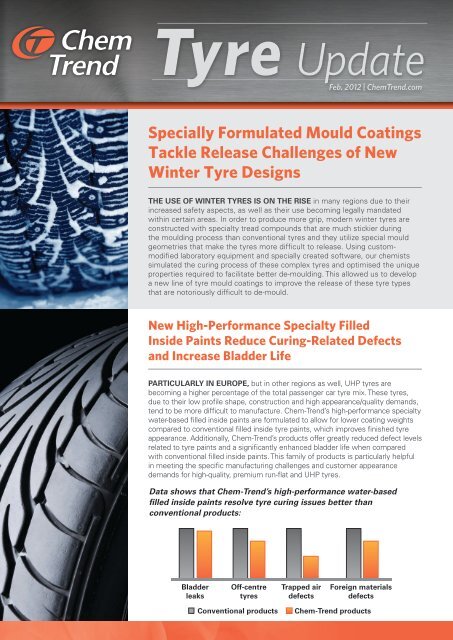

Specially Formulated Mould Coatings<br />

Tackle Release Challenges of New<br />

Winter <strong>Tyre</strong> Designs<br />

THE USE OF WINTER TYRES IS ON THE RISE in many regions due to their<br />

increased safety aspects, as well as their use becoming legally mandated<br />

within certain areas. In order to produce more grip, modern winter tyres are<br />

constructed with specialty tread compounds that are much stickier during<br />

the moulding process than conventional tyres and they utilize special mould<br />

geometries that make the tyres more difficult to release. Using custom-<br />

modified laboratory equipment and specially created software, our chemists<br />

simulated the curing process of these complex tyres and optimised the unique<br />

properties required to facilitate better de-moulding. This allowed us to develop<br />

a new line of tyre mould coatings to improve the release of these tyre types<br />

that are notoriously difficult to de-mould.<br />

New High-Performance Specialty Filled<br />

Inside Paints Reduce Curing-Related Defects<br />

and Increase Bladder Life<br />

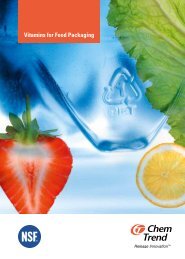

PARTICULARLY IN EUROPE, but in other regions as well, UHP tyres are<br />

becoming a higher percentage of the total passenger car tyre mix. These tyres,<br />

due to their low profile shape, construction and high appearance/quality demands,<br />

tend to be more difficult to manufacture. <strong>Chem</strong>-<strong>Trend</strong>’s high-performance specialty<br />

water-based filled inside paints are formulated to allow for lower coating weights<br />

compared to conventional filled inside tyre paints, which improves finished tyre<br />

appearance. Additionally, <strong>Chem</strong>-<strong>Trend</strong>’s products offer greatly reduced defect levels<br />

related to tyre paints and a significantly enhanced bladder life when compared<br />

with conventional filled inside paints. This family of products is particularly helpful<br />

in meeting the specific manufacturing challenges and customer appearance<br />

demands for high-quality, premium run-flat and UHP tyres.<br />

Data shows that <strong>Chem</strong>-<strong>Trend</strong>’s high-performance water-based<br />

filled inside paints resolve tyre curing issues better than<br />

conventional products:<br />

Bladder<br />

leaks<br />

Off-centre<br />

tyres<br />

Trapped air<br />

defects<br />

Foreign materials<br />

defects<br />

Conventional products <strong>Chem</strong>-<strong>Trend</strong> products

Room Temperature Curing<br />

Bladder Coating Helps<br />

Improve Bladder Life<br />

ALL TYRE COMPANIES would like to improve<br />

bladder life as it would provide for a significant cost<br />

savings, not only in terms of bladder costs, but<br />

also in available production time for the press. In<br />

this era of tight credit, all companies are looking to<br />

maximize the ROI on their assets and save costs.<br />

Increasing bladder life can help in both regards.<br />

Unlike most curing bladder coatings that need to<br />

be baked on to the bladder, <strong>Chem</strong>-<strong>Trend</strong> offers a<br />

bladder coating that cures at room temperature in<br />

two hours. A highly durable, high abrasion-resistant<br />

film provides protection to the bladder surface<br />

against chemical and abrasive attack. <strong>Chem</strong>-<strong>Trend</strong><br />

customers are recording a bladder life increase<br />

of up to 40% and fewer curing-related defects.<br />

Treated bladders can be folded and packaged for<br />

shipment to other plants. Coated bladders may<br />

be stored for periods up to one year without any<br />

effect on the performance of the film.<br />

Around the World, Around the Clock -<br />

Global Locations to Serve You Locally<br />

THE TYRE BUSINESS HAS ALWAYS BEEN GLOBAL, but in recent<br />

years, tyre companies have been placing more and more focus on the<br />

BRIC emerging countries in terms of investment. As tyre manufacturers<br />

build plants in regions all over the world and strive to make sure that they<br />

produce to the same high-quality standards no matter where they are<br />

located, the need for strong global suppliers becomes tantamount.<br />

<strong>Chem</strong>-<strong>Trend</strong> operates from offices and manufacturing facilities in all<br />

industrialized regions of the world, ensuring that our sales and technical<br />

service experts are available locally to our customers.<br />

As part of our ongoing focus to meet the specific needs of our tyre<br />

manufacturing customers around the globe, we are increasing production<br />

capacity in our facilities in China and South America. New equipment and<br />

new production vessels will increase the production capacity of our worldleading<br />

tyre products at key regional manufacturing units. This means<br />

shorter lead times and faster response for tyre manufacturers in these<br />

regions. Production capacity will also increase at facilities in Europe to<br />

provide added benefits to the supply chain.<br />

Release Innovation for Performance,<br />

Dependability and Value<br />

THE TYRE INDUSTRY IS CONSTANTLY CHANGING.<br />

New regulations, trends and technologies all affect your process.<br />

Our technical and manufacturing experts visit plant floors around the<br />

globe every day and understand these challenges.<br />

As the only global supplier completely focused on mould processing<br />

solutions, <strong>Chem</strong>-<strong>Trend</strong> has the insight to solve your tyre production<br />

challenges, improve quality, reduce costs and boost productivity.<br />

<strong>Chem</strong>-<strong>Trend</strong> is the go-to solution for the tyre industry’s biggest<br />

challenges, including scrap, downtime for maintenance, air bleed and<br />

poor startup.<br />

<strong>Chem</strong>-<strong>Trend</strong> is focused on release products that offer:<br />

• Lower scrap and defect rates<br />

• Longer curing bladder life<br />

• Cleaner moulds<br />

• Optimal finished tyre appearance<br />

• Excellent slip and release properties<br />

<strong>Chem</strong>-<strong>Trend</strong> offers a globally integrated network of experienced,<br />

knowledgeable, and insightful production and technical experts in<br />

all major manufacturing regions around the world.<br />

Find out how <strong>Chem</strong>-<strong>Trend</strong> can solve your tyre production challenges,<br />

improve quality, reduce costs and boost productivity. Contact us today!<br />

<strong>Chem</strong><strong>Trend</strong>.com