Quick Disconnect Couplings for - Colder Products Company

Quick Disconnect Couplings for - Colder Products Company

Quick Disconnect Couplings for - Colder Products Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

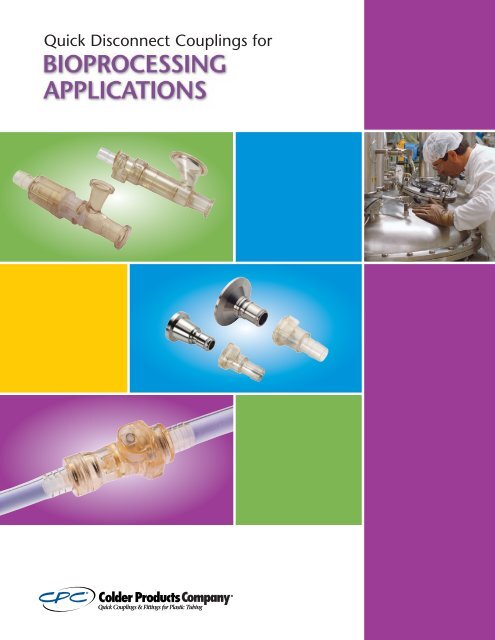

<strong>Quick</strong> <strong>Disconnect</strong> <strong>Couplings</strong> <strong>for</strong>

2<br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong><br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> is the worldwide leader in the design and manufacture of<br />

quick disconnect couplings that allow flexible tubing to be quickly and easily<br />

connected and disconnected. These specially-engineered solutions lend flexibility,<br />

control and safety to a broad range of<br />

applications. <strong>Colder</strong>’s connections make<br />

systems cleaner, drier and safer, while<br />

adding new value and functionality to<br />

smaller-scale applications.<br />

<strong>Colder</strong> supports its product lines and<br />

literature with an interactive Web site.<br />

The site showcases new product<br />

innovations and technologies, and<br />

provides easy, immediate access to<br />

product and industry in<strong>for</strong>mation,<br />

application tools and more.<br />

Visit www.colder.com <strong>for</strong>:<br />

■ In<strong>for</strong>mation and literature on <strong>Colder</strong> product lines and technologies<br />

• Bioprocessing<br />

• Medical Device & Equipment<br />

• High Purity & Chemical Management<br />

• Industrial<br />

• IdentiQuik Technology<br />

• Food, Beverage & Water<br />

■ Validation reports<br />

Medical Device Chemical<br />

Management<br />

■ Steam-Thru ® movies<br />

■ Downloadable CAD drawings<br />

■ Online tools and selector guides<br />

■ In<strong>for</strong>mation on custom applications<br />

■ Direct connections to <strong>Colder</strong> engineers<br />

On-line Catalogs and Literature<br />

Industrial Smart Technology<br />

Food, Beverage & Water<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

Advantages of Disposable Systems<br />

Increase Productivity<br />

The reliability of single-use systems result in increased productivity through the<br />

reduction of system downtime associated with cleaning and cleaning validation.<br />

Reducing downtime of key processes allows manufacturers to increase output while<br />

also decreasing time to market.<br />

Add Flexibility<br />

Flexibility is an equally important factor as processors strive to increase<br />

productivity and prepare facilities <strong>for</strong> new drugs. Unlike hard-plumbed piping<br />

systems, disposable systems can be easily modified <strong>for</strong> alternative media handling.<br />

For instance, the implementation of single-use technologies can increase<br />

production capacity at an existing facility where traditional fixed systems would<br />

normally require costly facility expansion.<br />

Minimize Risk<br />

Reducing risks continues to be a fundamental concern in the bioprocessing<br />

industry. Media contamination can lead to product quality issues. Subsequently,<br />

expensive reprocessing activities are often required to prevent the loss of a valuable<br />

batch of media. Contamination risk becomes an even larger concern as companies<br />

are now conducting more multi-product manufacturing. In addition to having a<br />

negative effect on operational efficiency, cross-contamination can negatively<br />

impact a company’s reputation. The integration of single-use systems can help<br />

minimize this possibility.<br />

Reduce Cost<br />

Cost savings include the reduced chemical and utility expenses of cleaning and<br />

labor. Capital savings on new construction can be attributed to disposable systems<br />

because upfront capital requirements are reduced due to lower equipment and<br />

floor space needs. Finally, existing facilities can reduce WFI requirements<br />

associated with traditional systems.<br />

Reliable, flexible, compatible, sterile.<br />

<strong>Colder</strong> – first choice in connections.<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

3

4<br />

How to Integrate Disposables into<br />

your Stainless Steel World<br />

Today’s biopharm manufacturers are pressured to improve production yields, decrease<br />

time to market and increase multi-product manufacturing within single facilities. In<br />

response they are increasingly incorporating disposable connections into their<br />

production processes. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>’s Steam-Thru ® and SaniQuik <br />

Connections provide innovative solutions <strong>for</strong> integrating disposable systems with<br />

manufacturers’ existing processing equipment.<br />

Steam-Thru ® Connections<br />

The Steam-Thru Connection’s patented three-port design allows steam to pass<br />

directly through the lower ports to “steam on” to stainless equipment. After the SIP<br />

cycle is completed, the connector’s valve is actuated, creating a sterile flow path to<br />

single-use systems. Media can then be safely transferred without the cleaning and<br />

validation concerns associated with reusable components.<br />

The new Steam-Thru II builds upon this proven technology by offering the flexibility<br />

of “steam on” and “steam off” functionality. The innovative design allows the valve<br />

to be returned to the steam position enabling a second SIP cycle following media<br />

transfer. The “steam off” disconnection of disposable systems minimizes crosscontamination<br />

risks associated with reusable components.<br />

Steam-Thru Benefits<br />

• Provides a sterile connection between hard-plumbed and<br />

disposable systems<br />

• Sterilize prior to removal from equipment<br />

(Steam-Thru II)<br />

• Eliminates need <strong>for</strong> laminar flow hoods<br />

• Disposable design saves time and money by eliminating<br />

unnecessary cleaning procedures<br />

• Reduces cleaning and validation issues associated with reusable components<br />

• Ideal <strong>for</strong> use in feeding, cell harvesting and sampling applications<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

SaniQuik Connections<br />

SaniQuik connections provide a quick and easy link between stainless equipment and<br />

single-use bag systems, tube sets or sampling systems. SaniQuik’s integral sanitary<br />

termination attaches directly to hard-plumbed systems with a sanitary gasket and<br />

tri-clover clamp. Once attached to equipment the connection’s integral<br />

coupling adaptor provides the interface to disposable systems which<br />

incorporate widely accepted <strong>Colder</strong> MPC or MPX couplings. SaniQuik<br />

not only decreases connection time it also allows tube sets to be<br />

specified with disposable plastic couplings in place of the more<br />

expensive stainless steel sanitary fittings.<br />

Sanitary Series <strong>Couplings</strong><br />

SaniQuik Benefits<br />

• Provides a quick and easy link between<br />

disposable systems and existing stainless steel<br />

processing equipment<br />

• Connects to hard-plumbed systems with<br />

standard sanitary gasket and tri-clover clamp<br />

• Mates with <strong>Colder</strong>’s MPC and MPX disposable<br />

couplings<br />

• Increases operational efficiency<br />

• Withstands multiple sterilization cycles<br />

• Reduces sanitary gasket replacements<br />

• Ideal <strong>for</strong> use in feeding, cell harvesting, and<br />

sampling applications<br />

In addition to the SaniQuik, <strong>Colder</strong> offers the Sanitary Series<br />

which allows a quick and easy connection between the hard<br />

plumbed and disposable systems. The Sanitary Series is a costeffective<br />

plastic disposable solution <strong>for</strong> connecting to existing<br />

sanitary terminations.<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

5

6<br />

Bioprocessing <strong>Couplings</strong><br />

PAGE10<br />

PAGE12<br />

PAGE14<br />

PAGE16<br />

Table of Contents<br />

<strong>Couplings</strong> connected and shown actual size (approximate).<br />

For additional terminations and configurations, see product pages.<br />

Cv values are expressed in English based on gpm and psi and in metric (shown in parentheses) based on lpm and bar.<br />

Steam-Thru ®<br />

Connections<br />

STC2020200<br />

MPC Series<br />

MC22004T03M & MPC17006T03<br />

MPX Series<br />

MPX22839M & MPX17839<br />

SaniQuik Connections<br />

SQCX222424M<br />

Straight<br />

Thru<br />

Single<br />

Shutoff<br />

Double<br />

Shutoff<br />

Non-Spill<br />

Material: Medical-Grade Polysulfone<br />

Tubing Range: 3/8" & 1/2" ID (9.5mm & 12.7mm)<br />

Sanitary Size: 3/4" mini and 1-1/2" maxi<br />

Feature: Disposable; innovative design<br />

Cv~8.0 (115.00) max<br />

Material: Medical-Grade ABS,<br />

Polycarbonate and Polysulfone<br />

Tubing Range: 1/4" & 3/8" ID (6.4mm & 9.5mm)<br />

Feature: Reusable coupling<br />

Cv~5.5 (79.25) max<br />

Material: Medical-Grade Polycarbonate<br />

and Polysulfone<br />

Tubing Range: 3/8" and 1/2" ID<br />

(9.5mm and 12.7mm)<br />

Feature: Reusable coupling with higher flow<br />

Cv~14.2 (204.60) max<br />

Material: 316 Stainless<br />

Tubing Range: 1/4" to 1/2" ID<br />

(6.4mm and 12.7mm)<br />

Sanitary Size: 3/4" mini and 1-1/2" maxi<br />

Feature: Transition from stainless sanitaries<br />

to disposable MPC/MPX bodies<br />

Cv~14.2 (204.60) max<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

Bioprocessing <strong>Couplings</strong><br />

PAGE18<br />

Table of Contents (continued)<br />

Straight<br />

Thru<br />

Single<br />

Shutoff<br />

<strong>Couplings</strong> connected and shown actual size (approximate).<br />

For additional terminations and configurations, see product pages.<br />

Double<br />

Shutoff<br />

Cv values are expressed in English based on gpm and psi and in metric (shown in parentheses) based on lpm and bar.<br />

MPU Series<br />

MPU171239 & MPU221239M<br />

Material: Medical-Grade Polysulfone<br />

Tubing Range: 3/4" ID (19.0mm)<br />

Feature: Large flow capacity<br />

Cv~20.9 (301.14) max<br />

Non-Spill<br />

PAGE17 Sanitary Series<br />

MPC22006T39M & MPC3301239<br />

Material: Medical-Grade Polysulfone<br />

Tubing Range: 1/4" & 3/8" ID <strong>for</strong> insert<br />

(6.4mm & 9.5mm)<br />

Sanitary Size: 3/4" mini & 1" maxi<br />

(19.0mm & 25.4mm)<br />

Feature: Attaches directly to sanitary<br />

hardware assemblies<br />

Cv~5.5 (79.25) max with MPC<br />

inserts and 14.2 (204.60) max<br />

with MPX inserts<br />

PAGE19<br />

HFC39 Series<br />

HFC22639M & HFCD17839M<br />

Material: Medical-Grade Polysulfone<br />

Tubing Range: 1/4", 3/8" & 1/2" ID<br />

(6.4mm, 9.5mm & 12.7mm)<br />

Feature: Automatic shutoff valves<br />

Cv~1.6 (23.05) max<br />

Cv~1.5 (21.61) max<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

7

8<br />

High Purity ChemQuik ® and DrumQuik ® Series<br />

PAGE20<br />

PAGE21<br />

Technical In<strong>for</strong>mation<br />

PAGE22<br />

Custom Solutions<br />

PAGE23<br />

Table of Contents (continued)<br />

<strong>Couplings</strong> connected and shown actual size (approximate).<br />

For additional terminations and configurations, see product pages.<br />

Cv values are expressed in English based on gpm and psi and in metric (shown in parentheses) based on lpm and bar.<br />

CQG06 Series<br />

CQGD06200108 & CQGD06100108<br />

DrumQuik ®<br />

MODULAR Series<br />

(shown with shipping plugs installed)<br />

DrumQuik ® photos not to scale<br />

Sterilization Methods and Guide<br />

Special Application Capabilities<br />

Straight<br />

Thru<br />

Single<br />

Shutoff<br />

Wetted Material: Natural, Virgin Polypropylene<br />

Tubing Range: 3/8", 1/2", & 3/4" OD<br />

(9.5mm, 12.7mm & 19.0mm)<br />

Feature: Pressure-balanced design<br />

Cv~2.7 (38.90) max<br />

Wetted Material: Virgin Polypropylene or PTFE<br />

(shown with couplings installed)<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Double<br />

Shutoff<br />

Non-Spill<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

Steam-Thru ® Connections<br />

Ease The Transition<br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> advances steam-in-place technology with the<br />

introduction of Steam-Thru ® Connections. The innovative design allows a quick<br />

and easy sterile connection between biopharmaceutical processing equipment and<br />

disposable bag and tube assemblies.<br />

The Steam-Thru Connection’s patented three-port design allows steam to pass<br />

directly through the lower ports to “steam on” to stainless equipment. After the<br />

SIP cycle is completed, the connector’s valve is actuated, creating a sterile flow<br />

path to single-use systems. Media can then be safely transferred without the<br />

cleaning and validation concerns associated with reusable components.<br />

The new Steam-Thru II builds upon this proven technology by offering the<br />

flexibility of “steam on” and “steam off” functionality. The innovative design<br />

allows the valve to be returned to the steam position enabling a second SIP cycle<br />

following media transfer. The “steam off” disconnection of disposable systems<br />

minimizes cross-contamination risks associated with reusable components.<br />

Today’s biopharmaceutical manufacturers are meeting the challenges of increased<br />

productivity, reduced costs and decreased time to market with the help of <strong>Colder</strong>’s<br />

Steam-Thru Connections.<br />

FEATURES BENEFITS<br />

Innovative three-port design Allows a true steam-through SIP process<br />

Eliminates “dead legs” where bacteria can grow<br />

Eliminates the need <strong>for</strong> laminar flow hoods<br />

Patented valve design Creates “steam-on” sterile connection<br />

Allows “steam-off” sterile disconnection<br />

Permits high media flow rate<br />

Thumb latch/Tear-away sleeve Provides visual indicator of process stage<br />

Secures valve position<br />

Industry standard terminations Speeds connection to the process equipment<br />

Connects to popular sizes of flexible tubing<br />

Medical-grade polysulfone Meets USP Class VI biocompatibility<br />

Animal-free materials<br />

Compatible with standard sterilization methods<br />

Single-use design Saves time and money by eliminating unnecessary<br />

cleaning procedures<br />

Reduces cleaning and validation issues associated<br />

with reusable components<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

59

10<br />

Steam-Thru ® Process<br />

Steam Position Flow Position<br />

Tear-Away<br />

Sleeve<br />

Steam-Thru ® II<br />

Process<br />

*An audible “click” and the visual indicator of the raised thumb latch<br />

provide assurance that the valve is locked in the flow or steam position.<br />

Steam On Position Flow Position<br />

Steam Off Position<br />

To Steam Trap<br />

Steam<br />

Flow<br />

To Steam Trap<br />

Process<br />

Equipment<br />

Steam flows from the process equipment<br />

through the Steam-Thru II creating a<br />

“steam on” sterile connection.<br />

Transition to Flow<br />

Once the “steam on”<br />

cycle is complete and<br />

the steam trap has been<br />

closed, simply press the<br />

thumb latch to allow the<br />

valve to be moved down<br />

to the flow position.<br />

Steam<br />

Flow<br />

Process<br />

Equipment<br />

Steam flows from the process equipment<br />

through the Steam-Thru to sterilize the<br />

connection. With the tear-away sleeve in<br />

place, the transfer of fluid to or from the<br />

bioreactor is prevented.<br />

Single-Use<br />

Bag or Tubing<br />

Assembly<br />

From<br />

Media Flow OR<br />

Once the valve is locked in the flow<br />

position a sterile flow path has been<br />

created allowing media transfer.<br />

To<br />

Single-Use<br />

Bag or Tubing<br />

Assembly<br />

Thumb latch<br />

recessed during<br />

valve transition<br />

Media Flow<br />

Process<br />

Equipment<br />

Transition to Steam<br />

Process<br />

Equipment<br />

When the tear-away sleeve is removed, and<br />

the Steam-Thru is actuated, the connection<br />

to the steam trap is disabled and a sterile<br />

flow path is established between the process<br />

equipment and the disposable system.<br />

To Steam Trap<br />

Steam<br />

Flow<br />

Once the valve is locked in the steam<br />

position, complete a second SIP cycle to<br />

“steam off” the connection.<br />

Once media transfer<br />

is complete, simply<br />

press the thumb<br />

latch to allow the<br />

valve to be moved<br />

back up to the<br />

steam position.<br />

Process<br />

Equipment<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

From<br />

To<br />

OR

Steam-Thru ® Specifications<br />

Pressure:<br />

Steam position: Up to 30 psi, 2.07 bar (Steam-Thru);<br />

35 psi, 2.41 bar (Steam-Thru II)<br />

Flow position: Vacuum to 20 psi, 1.38 bar<br />

Temperature:<br />

Steam position: Up to 130° C (266° F) <strong>for</strong> 60 minutes<br />

(Steam-Thru); Up to 135° C (275° F) <strong>for</strong> 60 minutes<br />

(Steam-Thru II)<br />

Flow position: 4° C to 40° C (39° F to 104° F)<br />

Typical Flow Rate:<br />

Cv = 3.3 - 3.4 (Steam-Thru 3/8" hose barb);<br />

Cv = 4.1 - 4.5 (Steam-Thru 1/2" hose barb);<br />

Cv = 5.2 - 8.0 (Steam-Thru II 1/2" hose barb)<br />

Materials:<br />

Connection: Polysulfone, USP Class VI<br />

Seals: Silicone (clear), platinum-cured, USP Class VI<br />

Tear-away sleeve: Polyethylene or polycarbonate<br />

(Steam-Thru only)<br />

Steam-Thru Configurations<br />

Polysulfone with Polyethylene Sleeve<br />

Steam-Thru II Configurations<br />

Sterilization:<br />

Gamma: Up to 50 kGy gamma irradiation<br />

Autoclave: At 128° C (265° F) <strong>for</strong> 30 minutes, up to<br />

two cycles (applies only to part numbers STC1700500-<br />

STC1700800)<br />

SIP process: Up to 130° C (266° F) <strong>for</strong> 60 minutes<br />

(Steam-Thru); Up to 135° C (275° F) <strong>for</strong> 60 minutes<br />

(Steam-Thru II)<br />

Tubing sizes: 3/8" and 1/2" ID (Steam-Thru)<br />

9.5mm and 12.7mm ID<br />

1/2" ID (Steam-Thru II)<br />

12.7mm ID<br />

PART NO. TERMINATIONS A B C D E<br />

STC1700000 3/4" x 3/4" sanitary x 1/2” HB 1.20 (30.5) 2.00 (50.8) 0.89 (22.6) 5.09 (129.3) 4.44 (112.8)<br />

STC1700100 3/4”x 3/4” sanitary x 3/8” HB 1.20 (30.5) 2.00 (50.8) 0.60 (15.2) 4.80 (121.9) 4.15 (105.4)<br />

STC1700200 3/4" x 1-1/2" sanitary x 1/2” HB 1.20 (30.5) 2.00 (50.8) 0.89 (22.6) 5.09 (129.3) 4.44 (112.8)<br />

STC1700300 3/4”x 1-1/2” sanitary x 3/8” HB 1.20 (30.5) 2.00 (50.8) 0.60 (15.2) 4.80 (121.9) 4.15 (105.4)<br />

Polysulfone with Autoclavable Polycarbonate Sleeve<br />

All measurements are in inches (millimeters).<br />

PART NO. TERMINATIONS A B C D E<br />

STC1700500 3/4" x 3/4" sanitary x 1/2” HB 1.20 (30.5) 2.00 (50.8) 0.89 (22.6) 5.09 (129.3) 4.44 (112.8)<br />

STC1700600 3/4”x 3/4” sanitary x 3/8” HB 1.20 (30.5) 2.00 (50.8) 0.60 (15.2) 4.80 (121.9) 4.15 (105.4)<br />

STC1700700 3/4" x 1-1/2" sanitary x 1/2” HB 1.20 (30.5) 2.00 (50.8) 0.89 (22.6) 5.09 (129.3) 4.44 (112.8)<br />

STC1700800 3/4”x 1-1/2” sanitary x 3/8” HB 1.20 (30.5) 2.00 (50.8) 0.60 (15.2) 4.80 (121.9) 4.15 (105.4)<br />

All measurements are in inches (millimeters).<br />

PART NO. TERMINATIONS A B C D E<br />

STC2020000 3/4" x 3/4" sanitary x 1/2" HB 1.42 (36.1) 2.40 (61.0) .89 (22.6) 6.84 (173.7) 5.93 (150.6)<br />

STC2020200 3/4" x 1-1/2" sanitary x 1/2" HB 1.42 (36.1) 2.40 (61.0) .89 (22.6) 6.85 (173.7) 5.93 (150.6)<br />

A<br />

A<br />

C<br />

E<br />

E<br />

D<br />

= Actuated Length<br />

D<br />

= Actuated Length<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

C<br />

B<br />

B<br />

11

12<br />

MPC Series <strong>Couplings</strong><br />

Material: Medical-Grade Polycarbonate and Polysufone<br />

MPC Series couplings add ease of use and security to your most<br />

critical fluid handling applications. Choose from a full line of<br />

connectors and configurations, including pressure sealing caps and<br />

plugs in sizes to fit 1/4” and 3/8” tubing. MPC couplings offer<br />

optional locking sleeves to further guard against accidental<br />

disconnects.<br />

FEATURES BENEFITS<br />

Ergonomic thumb latch Easy to operate–even with gloved hands<br />

Audible “click” when connected Assures connection is secure<br />

Meets USP Class VI criteria, and<br />

MEM elution, agarose overlay and<br />

hemolysis in vitro (see page 22)<br />

Acceptable <strong>for</strong> a wide variety of applications<br />

Sterilizable by autoclave, Et0, Reusable, yet economical enough to allow<br />

e-beam, or gamma (see page 22) disposability<br />

Coupling halves can be rotated<br />

when connected<br />

Reduces tube kinks<br />

Thin, tapered barb minimizes dead Minimizes fluid turbulence and decreases<br />

space between tubing and coupling area <strong>for</strong> particle entrapment<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Bodies<br />

Polycarbonate<br />

In-Line<br />

Hose Barb<br />

In-Line<br />

Hose Barb with Lock<br />

Polysulfone<br />

In-Line<br />

Hose Barb<br />

In-Line<br />

Hose Barb with Lock<br />

Tethered Caps & Plugs<br />

PVC<br />

Applications may include:<br />

• Cell culture media<br />

packaging and transfer lines<br />

• Harvest and collection<br />

applications<br />

• Buffer solutions<br />

• Tube sets<br />

• Urology drainage/collection<br />

systems<br />

• Hypo/hyperthermia blankets<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPC17004T03 .93 (23.6) 1.30 (33.0) .60 (15.2)<br />

3/8" ID 9.5mm .290" MPC17006T03 .93 (23.6) 1.30 (33.0) .60 (15.2)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPCK17004T03 .99 (25.2) 1.30 (33.0) .60 (15.2)<br />

3/8" ID 9.5mm .290" MPCK17006T03 .99 (25.2) 1.30 (33.0) .60 (15.2)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPC17004T39 .93 (23.6) 1.30 (33.0) .60 (15.2)<br />

3/8" ID 9.5mm .290" MPC17006T39 .93 (23.6) 1.30 (33.0) .60 (15.2)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPCK17004T39 .99 (25.2) 1.30 (33.0) .60 (15.2)<br />

3/8" ID 9.5mm .290" MPCK17006T39 .99 (25.2) 1.30 (33.0) .60 (15.2)<br />

MATERIALS TUBING SIZE PART NO. DESCRIPTION<br />

Soft, flexible, For use with MPC coupling MPC30L Leash plug <strong>for</strong> MPC body<br />

medical-grade PVC inserts and bodies MPC32L Leash cap <strong>for</strong> MPC insert<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

MPC Series Specifications<br />

Polycarbonate and Polysulfone<br />

Pressure: Vacuum to 60 psi, 4.14 bar<br />

Temperature: -40° F to 300° F, Polysulfone<br />

-40° C to 148.9° C<br />

-40° F to 250° F, Polycarbonate<br />

-40° C to 121° C<br />

Materials:<br />

Main components: Polysulfone (amber), USP Class VI<br />

Polycarbonate (purple tint), USP Class VI<br />

Locking sleeves: Polysulfone (white)<br />

Seals: Silicone (clear), platinum-cured, USP Class VI<br />

Tubing Sizes: 1/4" and 3/8" ID<br />

6.4mm and 9.5mm ID<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Inserts<br />

Polycarbonate<br />

Silicone Seal<br />

USP Class VI<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

Sealing Caps<br />

Polycarbonate<br />

Polysulfone<br />

Sealing Plugs<br />

Polycarbonate<br />

Silicone Seal<br />

USP Class VI<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPC22004T03M .60 (15.2) 1.30 (33.0) .61 (15.5)<br />

3/8" ID 9.5mm .290" MPC22006T03M .60 (15.2) 1.30 (33.0) .61 (15.5)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPC22004T39M .60 (15.2) 1.30 (33.0) .61 (15.5)<br />

3/8" ID 9.5mm .290" MPC22006T39M .60 (15.2) 1.30 (33.0) .61 (15.5)<br />

SEALING CAP SEALING CAP W/LOCK HEIGHT LENGTH<br />

MPC32003 MPCK32003 .93 (23.6) 1.30 (33.0)<br />

SEALING CAP SEALING CAP W/LOCK HEIGHT LENGTH<br />

MPC32039 MPCK32039 .99 (25.2) 1.30 (33.0)<br />

SEALING PLUG HEIGHT LENGTH<br />

MPC30003M .75 (19.1) 1.24 (31.5)<br />

SEALING PLUG HEIGHT LENGTH<br />

MPC30039M .75 (19.1) 1.24 (31.5)<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

13

14<br />

MPX Series <strong>Couplings</strong><br />

Material: Polycarbonate and Polysulfone<br />

MPX Series couplings add ease of use and security to your most<br />

critical fluid handling applications. Choose from a full line of<br />

connectors and configurations, including pressure sealing caps and<br />

plugs in sizes to fit 3/8” and 1/2” tubing. MPX couplings offer<br />

optional locking sleeves to further guard against accidental<br />

disconnects.<br />

FEATURES BENEFITS<br />

Ergonomic thumb latch Easy to operate–even with gloved hands<br />

Audible “click” when connected Assures connection is secure<br />

Meets USP Class VI criteria, and<br />

MEM elution, agarose overlay and<br />

hemolysis in vitro (see page 22)<br />

Acceptable <strong>for</strong> a wide variety of applications<br />

Sterilizable by autoclave, Et0, Reusable, yet economical enough to allow<br />

e-beam, or gamma (see page 22) disposability<br />

Coupling halves can be rotated<br />

when connected<br />

Reduces tube kinks<br />

Thin, tapered barb minimizes dead Minimizes fluid turbulence and decreases<br />

space between tubing and coupling area <strong>for</strong> particle entrapment<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Bodies<br />

Polycarbonate<br />

In-Line<br />

Hose Barb<br />

In-Line<br />

Hose Barb with Lock<br />

Polysulfone<br />

In-Line<br />

Hose Barb<br />

In-Line<br />

Hose Barb with Lock<br />

Applications may include:<br />

• Cell culture media<br />

packaging and transfer lines<br />

• Harvest and collection<br />

applications<br />

• Buffer solutions<br />

• Tube sets<br />

• Flexible bag systems<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/2" ID 12.7mm .500" MPX17803 1.28 (32.5) 1.96 (49.8) .89 (22.6)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/2" ID 12.7mm .500" MPXK17803 1.28 (32.5) 1.96 (49.8) .89 (22.6)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/2" ID 12.7mm .500" MPX17839 1.28 (32.5) 1.96 (49.8) .89 (22.6)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/2" ID 12.7mm .500" MPXK17839 1.28 (32.5) 1.96 (49.8) .89 (22.6)<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

MPX Series Specifications<br />

Pressure: Vacuum to 60 psi, 4.14 bar<br />

Temperature: -40° F to 300° F, Polysulfone<br />

-40° C to 148.9° C<br />

-40° F to 250° F, Polycarbonate<br />

-40° C to 121° C<br />

Materials:<br />

Main components: Polysulfone (amber), USP Class VI;<br />

Polycarbonate (purple tint), USP Class VI<br />

Locking sleeves: Polysulfone (white)<br />

Seals: Silicone (clear), platinum-cured, USP Class VI<br />

Tubing Sizes: 3/8" to 1/2" ID<br />

9.5mm to 12.7mm ID<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Inserts<br />

Polycarbonate<br />

Silicone Seal<br />

USP Class VI<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

Sealing Caps<br />

Polycarbonate<br />

Polysulfone<br />

Sealing Plugs<br />

Polycarbonate<br />

Silicone Seal<br />

USP Class VI<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

3/8" ID 9.5mm .375" MPX22603M .85 (21.6) 1.90 (48.3) .94 (23.9)<br />

1/2" ID 12.7mm .500" MPX22803M .85 (21.6) 1.90 (48.3) .94 (23.9)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

3/8" ID 9.5mm .375" MPX22639M .85 (21.6) 1.90 (48.3) .89 (22.6)<br />

1/2" ID 12.7mm .500" MPX22839M .85 (21.6) 1.90 (48.3) .89 (22.6)<br />

SEALING CAP SEALING CAP W/LOCK HEIGHT LENGTH<br />

MPX32003 MPXK32003 1.28 (32.5) 1.67 (42.4)<br />

SEALING CAP SEALING CAP W/LOCK HEIGHT LENGTH<br />

MPX32039 MPXK32039 1.28 (32.5) 1.67 (42.4)<br />

SEALING PLUG HEIGHT LENGTH<br />

MPX30003M 1.10 (27.9) 1.66 (42.2)<br />

SEALING PLUG HEIGHT LENGTH<br />

MPX30039M 1.10 (27.9) 1.66 (42.2)<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

15

16<br />

SaniQuik Connections<br />

Material: 316 Stainless<br />

<strong>Colder</strong>’s new SaniQuik connection answers the question of how<br />

to integrate disposables with your existing stainless processing<br />

equipment. This integral sanitary termination attaches to hardplumbed<br />

systems with tri-clover clamps. Once attached it permits<br />

quick and easy connection to single-use bag systems, manifolds<br />

or tube sets which incorporate <strong>Colder</strong> disposable couplings.<br />

SaniQuik connections reduce sanitary gasket replacement,<br />

enabling cost-effective media transfer solutions <strong>for</strong> feeding,<br />

harvesting or sampling applications.<br />

FEATURES BENEFITS<br />

316 stainless Withstands multiple sterilization cycles<br />

1-1/2” and 3/4” sanitary Connects to hard plumbed systems with<br />

standard terminations sanitary gasket and tri-clover clamps<br />

Compatible with MPC and <strong>Quick</strong> and easy connections to industry<br />

MPX Series standard plastic couplings used on<br />

disposable bag and tube sets<br />

Integral coupling adaptor <strong>Disconnect</strong>ing coupling reduces sanitary<br />

gasket replacement<br />

USP Class VI platinum-cured Meets industry material compatibility<br />

silicone seal requirements<br />

SaniQuik Specifications<br />

Pressure: Vacuum to 60 psi, 4.14 bar<br />

Temperature: -40° F to 300° F (-40° C to 148.9° C)<br />

Sterilization: Autoclave<br />

Applications may include:<br />

• Flexible bags<br />

• Media transfer lines<br />

• Bioreactor feeding<br />

• Cell harvesting<br />

• Stainless and glass<br />

vessel filling<br />

• Chromatography<br />

• Filtration<br />

Materials:<br />

Main component: 316 stainless<br />

Seals: Silicone (clear), platinum-cured, USP Class VI<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

SaniQuik Connections<br />

PART NUMBER MATING COUPLING BODY SANITARY SIZE SANITARY BORE HEIGHT LENGTH<br />

SQCC221212M MPC Series 3/4" 3/4" .89" (22.6) 1.39" (35.3)<br />

SQCC222424M MPC Series 1-1/2" 1-1/2" 1.98" (50.3) 1.50" (38.1)<br />

SQCX221212M MPX Series 3/4" 3/4" .89" (22.6) 1.54" (39.1)<br />

SQCX222416M MPX Series 1-1/2" 1" 1.98" (50.3) 1.50" (38.1)<br />

SQCX222424M MPX Series 1-1/2" 1-1/2" 1.98" (50.3) 1.50" (38.1)<br />

Mates with: MPC Polycarbonate and Polysulfone bodies and sealing caps (see pages 12 and 13)<br />

and MPX Polycarbonate and Polysulfone bodies and sealing caps (see pages 14 and 15).<br />

Replacement Seals<br />

Silicone (clear), Platinum-cured USP Class VI<br />

PART NO. MATING SANIQUIK <br />

143700 SQCC221212M, SQCC222424M<br />

934000 SQCX221212M, SQCX222416M, SQCX222424M<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

Sanitary Series<br />

Material: Polysulfone<br />

Sanitary couplings attach directly to popular 3/4" mini and<br />

1" maxi size sanitary connections, eliminating the need <strong>for</strong><br />

cumbersome adapters or tubing assemblies. Direct attachment<br />

allows faster connection to and disconnection from installed,<br />

rigid and flexible piping systems.<br />

FEATURES BENEFITS<br />

Attaches directly to sanitary Eliminates the need <strong>for</strong> cumbersome adapters<br />

hardware assemblies or tubing; provides thumb latch convenience<br />

3/4" mini & 1" maxi sanitary Popular sanitary sizes can now be used with<br />

termination sizes the convenience of the <strong>Colder</strong> quick disconnect<br />

<strong>Colder</strong> sanitary couplings attach Installed with your existing hardware and<br />

to your sanitary connections with provides a reliable, secure seal<br />

standard gaskets and clamps<br />

USP Class VI polysulfone material Provides durability, compatible with your<br />

existing processes and can be sterilized <strong>for</strong><br />

reusability (see page 22)<br />

Sanitary Series Specifications<br />

Pressure: Vacuum to 60 psi, 4.14 bar<br />

Temperature: -40° F to 300° F, -40° C to 148.9° C<br />

Termination Size: 3/4” mini and 1” maxi<br />

19.0mm and 25.4mm<br />

Applications may include:<br />

• Piping systems<br />

• Bioreactors<br />

• Fermentation systems<br />

• Bioprocessing labs<br />

• Cell culture media transfer<br />

• Filtration equipment<br />

Materials:<br />

Main components: Polysulfone (amber tint)<br />

Seals (mating insert)*: Silicone (clear), platinum-cured,<br />

USP Class VI<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Bodies<br />

Polysulfone<br />

Coupling Inserts<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

*Mating inserts detailed on this page are polysulfone.<br />

MPC and MPX mating inserts are available in<br />

polycarbonate. Please refer to pages 12 – 15 of this<br />

catalog <strong>for</strong> further in<strong>for</strong>mation.<br />

**QD sanitary couplings are compatible with both<br />

stainless steel and plastic clamps. Clamps and<br />

gaskets are referenced <strong>for</strong> illustration and are not<br />

available through <strong>Colder</strong>.<br />

SANITARY SIZE SANITARY O.D. PART NO. HEIGHT LENGTH<br />

3/4" Mini 1.0" 25.4mm MPC3301239 .98 (24.9) 1.40 (35.6)<br />

1" Maxi 1.5" 38.1mm MPC3301639 1.50 (38.1) 1.40 (35.6)<br />

3/4" Mini 1.0" 25.4mm MPX3301239 1.28 (32.5) 1.70 (43.2)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm .210" MPC22004T39M .60 (15.2) 1.30 (33.0) .61 (15.5)<br />

3/8" ID 9.5mm .290" MPC22006T39M .60 (15.2) 1.30 (33.0) .61 (15.5)<br />

3/8" ID 9.5mm .375" MPX22639M .85 (21.6) 1.90 (48.3) .89 (22.6)<br />

1/2" ID 12.7mm .500" MPX22839M .85 (21.6) 1.90 (48.3) .89 (22.6)<br />

<strong>Quick</strong> <strong>Disconnect</strong> Sanitary<br />

Coupling attaches to sanitary<br />

connector or hardware**<br />

3/4" mini and<br />

1" maxi sizes<br />

Clear polysulfone<br />

provides flow visibility Leak-free<br />

silicone o-ring<br />

Thumb latch design<br />

provides quick disconnect<br />

with <strong>Colder</strong> insert<br />

Inserts available <strong>for</strong><br />

use with 1/4", 3/8"<br />

and 1/2" size tubing<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

17

18<br />

MPU Series <strong>Couplings</strong><br />

Material: Medical-Grade Polysulfone<br />

The MPU’s twist-to-connect design features an easy-to-use<br />

locking mechanism that guards against accidental disconnects<br />

and provides a reliable, secure connection. A 3/4" hose barb<br />

provides smooth, rapid media transfer.<br />

FEATURES BENEFITS<br />

3/4" hose barb Facilitates rapid fill and empty of<br />

bioprocessing bags<br />

Audible “click” when connected Assures connection is secure<br />

Locking feature Guards against accidental disconnect<br />

Medical-grade polysulfone Compatible with popular sterilization methods,<br />

yet economical enough to allow disposibility<br />

Sharp barb end Minimizes fluid turbulence and dead space<br />

Shrouded, leak-free seal and Protects valuable fluids and eliminates<br />

smooth, internal flow path potential to contaminate fluid path<br />

Low profile Offers ease of use and handling<br />

Lightweight Removes extra weight from assemblies<br />

MPU Series Specifications<br />

Pressure: Vacuum to 35 psi, 2.41 bar<br />

Temperature: -40° F to 300° F, -40° C to 148.9° C<br />

Tubing Sizes: 3/4” ID, 19mm ID<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Body<br />

Polysulfone<br />

In-Line<br />

Hose Barb<br />

Coupling Insert<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

Sealing Cap<br />

Polysulfone<br />

Sealing Plug<br />

Polysulfone<br />

Applications may include:<br />

• Laboratory tubing<br />

connections<br />

• Cell culture media packaging<br />

and transfer lines<br />

• Harvest and collection<br />

applications<br />

• Diagnostic manufacturing<br />

• Compression therapy cuffs<br />

Materials:<br />

Main components: Polysulfone (amber tint), USP Class VI<br />

Seals: Silicone (clear), platinum-cured, USP Class VI<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

3/4'' ID 19mm .710" MPU171239 1.75 (44.5) 2.37 (60.2) 1.50 (38.1)<br />

TUBING METRIC EQ. FLOW PART NO. HEIGHT LENGTH TERM. LENGTH<br />

3/4'' ID 19mm .710" MPU221239M 1.56 (39.6) 2.88 (73.2) 1.50 (38.1)<br />

DESCRIPTION PART NO. HEIGHT LENGTH<br />

Cap <strong>for</strong>: MPU221239M MPU32039 1.75 (44.5) .79 (20.1)<br />

DESCRIPTION PART NO. HEIGHT LENGTH<br />

Plug <strong>for</strong>: MPU171239 MPU30039M 1.56 (39.6) 1.38 (35.1)<br />

Sharp hose barb minimizes<br />

fluid turbulence<br />

All USP Class VI<br />

flow path Shrouded seal reduces<br />

potential <strong>for</strong> contamination<br />

Latch guards against<br />

accidental disconnect<br />

USP Class VI silicone<br />

o-rings<br />

Smooth<br />

internal flow<br />

path reduces<br />

catch points<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

HFC39 Series High Flow<br />

<strong>Couplings</strong><br />

Material: Medical-Grade Polysulfone<br />

HFC39 couplings feature automatic shutoff valves, and offer a<br />

cost-effective replacement <strong>for</strong> expensive, heavy, stainless steel<br />

connectors or fittings. HFC’s medical-grade polysulfone meets the<br />

most stringent requirements such as USP Class VI, MEM elution,<br />

agarose overlay, hemolysis in vitro, and USP physicochemical tests.<br />

FEATURES BENEFITS<br />

Automatic shutoff valves Stops flow and eliminates need <strong>for</strong> awkward<br />

pinch clamps<br />

Audible “click” when engaged Confidence of a secure connection<br />

USP Class VI polysulfone material Physical strength, durability and an excellent<br />

replacement <strong>for</strong> stainless steel<br />

Sterilizable by autoclave, Et0, Reusable and compatible with your existing<br />

E-beam, or gamma (see page 22) processes<br />

Lightweight Removes extra weight from assemblies<br />

HFC39 Series Specifications<br />

Pressure: Vacuum to 125 psi, 8.62 bar<br />

Temperature: -40° F to 280° F, -40° C to 137.8° C<br />

Tubing Sizes: 1/4", 3/8" and 1/2" ID<br />

6.4mm, 9.5mm and 12.7mm ID<br />

Patent Protected<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Applications may include:<br />

• Bioprocessing<br />

• Laboratory tubing<br />

connections<br />

• Cell culture media transfer<br />

• Kidney dialysis equipment<br />

• Pharmaceutical equipment<br />

• Diagnostic manufacturing<br />

Materials:<br />

Main components: Polysulfone (amber tint), USP Class VI<br />

Seals: Silicone (clear), platinum-cured, USP Class VI<br />

Springs: 316 stainless steel<br />

All measurements are in inches (millimeters) unless otherwise noted. Tubing must meet stated inside diameters.<br />

Coupling Bodies<br />

Polysulfone<br />

In-Line<br />

Hose Barb<br />

Coupling Inserts<br />

Polysulfone<br />

Silicone Seal<br />

USP Class VI<br />

TUBING METRIC EQ. FLOW STRAIGHT THRU SHUTOFF HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm ID 1/4" HFCD17439M 1.44 (36.6) 2.82 (71.6) .65 (16.5)<br />

3/8" ID 9.5mm ID 3/8" HFCD17639M 1.44 (36.6) 2.82 (71.6) .65 (16.5)<br />

1/2" ID 12.5mm ID 3/8" HFCD17839M 1.44 (36.6) 2.82 (71.6) .65 (16.5)<br />

TUBING METRIC EQ. FLOW STRAIGHT THRU SHUTOFF HEIGHT LENGTH TERM. LENGTH<br />

1/4" ID 6.4mm ID 1/4" HFC22439M HFCD22439M 1.00 (25.4) 2.02 (51.3) .65 (16.5)<br />

3/8" ID 9.5mm ID 3/8" HFC22639M HFCD22639M 1.00 (25.4) 2.02 (51.3) .65 (16.5)<br />

1/2" ID 12.5mm ID 3/8" HFC22839M HFCD22839M 1.00 (25.4) 2.02 (51.3) .65 (16.5)<br />

Clear polysulfone<br />

provides flow visibility<br />

Excellent laminar flow<br />

in both directions<br />

Shutoff valves <strong>for</strong><br />

automatic flow stop<br />

Push-button thumb latch<br />

<strong>for</strong> easy disconnects<br />

High-efficiency valves <strong>for</strong><br />

low pressure drop<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

USP Class VI<br />

silicone o-rings<br />

19

20<br />

ChemQuik ® CQG06 Series<br />

Material: Polypropylene<br />

The CQG06 Series is the lowest cost version of our pressurebalanced,<br />

non-spill, high purity couplings. Molded, virgin<br />

polypropylene, Viton ® seals, and a 100% springless and<br />

metal-free flow path provide broad chemical resistance. CQG06<br />

couplings offer exceptionally high flow capacity, allowing<br />

instant disconnects (and reconnects), even under pressure.<br />

FEATURES BENEFITS<br />

Non-spill design Ultimate protection from chemicals and<br />

fumes<br />

Pressure-balanced design Failsafe disconnect, even under pressure<br />

Springless flow path design Eliminates source of metallic contaminants<br />

Mechanical keying system Helps prevent accidental misconnects<br />

CQG06 Series Specifications<br />

Pressure: See graph<br />

Temperature: See graph<br />

Materials:<br />

Main components: Natural, virgin polypropylene<br />

Seals: Viton ® FKM, Simriz ® ChemQuik<br />

FFKM perfluoroelastomer (optional)<br />

Springs (non-wetted): Hastelloy C<br />

Flare nuts: PVDF<br />

® CQHD06 Flow Per<strong>for</strong>mance<br />

60 7.6 (lpm) 15.1 22.7 30.3 37.9 45.4<br />

4.14<br />

50<br />

3.44<br />

40<br />

2.75<br />

30<br />

2.07<br />

20<br />

Cv~1.6<br />

1.38<br />

10<br />

0.69<br />

Pressure Drop (psid)<br />

Lubricants: None used<br />

0<br />

0.0<br />

2.0 4.0 6.0 8.0 10.0 12.0<br />

Flow Rate (gpm)<br />

Spillage (air inclusion):

DrumQuik ® MODULAR<br />

Dispense System<br />

Material: Polypropylene and PTFE<br />

The easy-to-use DrumQuik ® chemical dispense system combines<br />

your choice of ChemQuik ® couplings with a modular dip-tubebased<br />

system <strong>for</strong> the extraction of aggressive or ultra-pure<br />

chemcials from drums and IBCs. This reliable, closed system<br />

increases operator safety and reduces downtime by eliminating<br />

dangerous spills and fumes.<br />

FEATURES BENEFITS<br />

Modular design Provides flexibility in system configuration<br />

Two-port system Eliminates fumes and allows N2 ports and recirculation<br />

Standard threads Fits common drum bungs<br />

DrumQuik Specifications (will vary based on couplings and container selected)<br />

Pressure: 0 to 45 psig, 0 to 3.10 bar<br />

Temperature: 0° F to 150° F, -17° C to 65° C;<br />

polypropylene limited to 32° F, 0° C<br />

Materials:<br />

Main components: Natural, virgin PTFE or polypropylene<br />

Dip-tube seal: FEP Encapsulated Viton ® FKM<br />

Vent check valve: PVDF with Hastelloy C spring, Viton ® seal<br />

Back flow check valve: See note below; PFA, Kalrez ® seal<br />

Seal kits: EPDM, Viton ® FKM, FEP Encapsulated Viton ®<br />

Lubricants: None used<br />

Coupling components: Dependent on coupling<br />

(see catalog <strong>for</strong> specifications)<br />

Standard <strong>Products</strong><br />

Drum Inserts<br />

Dip-Tubes<br />

Seal Kits<br />

Pipe Plugs<br />

Vent Check Valve (VCV)<br />

(prevents fumes from escaping)<br />

Back Flow Check Valve (BCV)<br />

(prevents return flow to drum)<br />

Construction Type: Modular drum insert bung and dip-tube<br />

Number of Ports: Two; one 3/4” female NPT liquid port and<br />

one 3/8” female NPT vent port (with backup seals)<br />

Drum Thread: Industry standard 2” buttress and 2” NPS<br />

(others available)<br />

Dip-Tube Length: 35.3” (897mm) or 55” (1397mm)<br />

(measured from sealing surface)<br />

NOTE: Some applications require the use of a back flow check valve (BCV)<br />

which prevents reverse flow when suction pump is turned off. <strong>Colder</strong><br />

recommends that the BCV be installed immediately downstream from the<br />

liquid line coupling body. Similarly, to allow air into drum, but prevent fumes<br />

from escaping, install a vent check valve (VCV) in vent port. Contact <strong>Colder</strong><br />

factory <strong>for</strong> assistance.<br />

DESCRIPTION PART NO.<br />

Bung, polypropylene, 3/4” NPT liquid port, 3/8” NPT vent, 2” buttress DQMDI2PP2BUT<br />

Bung, polypropylene, 3/4" NPT liquid port, 3/8” NPT vent, 2" NPS DQMDI2PTFE2NPS<br />

Bung, PTFE, 3/4” NPT liquid port, 3/8” NPT vent, 2” buttress DQMDI2PTFE2BUT<br />

Bung, PTFE, 3/4" NPT liquid port, 3/8" NPT vent, 2" NPS DQMDI2PP2NPS<br />

DESCRIPTION PART NO.<br />

Dip-tube, polypropylene, 35.3” (897mm) long from sealing surface DQMDTUBEPP35<br />

Dip-tube, polypropylene, 55” (1397mm) long from sealing surface DQMDTUBEPP55<br />

Dip-tube, PTFE, 35.3” (897mm) long from sealing surface DQMDTUBEPTFE35<br />

Dip-tube, PTFE, 55” (1397mm) long from sealing surface DQMDTUBEPTFE55<br />

DESCRIPTION PART NO.<br />

Complete seal kit (liquid and vent ports and bung), EPDM DQMSKITEPDM<br />

Complete seal kit (liquid and vent ports and bung), Viton ® DQMSKITVITON<br />

Complete seal kit (liquid and vent ports and bung), FEP encap, Viton ® DQMSKITFEPVITON<br />

DESCRIPTION PART NO.<br />

Hex pipe plug, 3/8” NPT, PFA material DQMPLUGPFA06<br />

Hex pipe plug, 3/8” NPT, PFA material DQMPLUGPFA12<br />

DESCRIPTION PART NO.<br />

For DrumQuik vent port DQMCKPVDF0206<br />

DESCRIPTION PART NO.<br />

Mount downstream of liquid coupling DQMCVPFA0308<br />

Applications may include:<br />

• Clean-in-place<br />

• Process chemical delivery<br />

from drums and IBC<br />

(tote) connections <strong>for</strong> CIP<br />

and process chemicals<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

21

22<br />

Technical In<strong>for</strong>mation<br />

Sterilization Methods<br />

PRODUCT SERIES MATERIAL AUTOCLAVE ETO GAMMA IRRADIATION E-BEAM<br />

MPC/MPX Polycarbonate YES* YES YES* YES*<br />

at 250° F <strong>for</strong> up to five cycles up to 50 Kilograys; up to 50 Kilograys;<br />

30 minutes, up coupling color shift to coupling color shift to<br />

to 10 cycles clear at 25 Kilograys clear at 25 Kilograys<br />

**Steam-Thru Polysulfone YES NO YES NO<br />

at 128° C (265° F) up to 50 Kilograys,<br />

<strong>for</strong> 30 minutes, up to <strong>for</strong> one cycle<br />

two cycles (applies only to part<br />

numbers STC1700500-1700800)<br />

MPC/MPX<br />

MPU<br />

<strong>Quick</strong> <strong>Disconnect</strong><br />

Sanitary<br />

HFC39<br />

**Steam-Thru ® Connections are compatible with SIP sterilization up to 30 psi and 266° F in combination with the gamma or autoclave<br />

sterilization methods as outlined above. <strong>Colder</strong> does not suggest the combination of all three sterilization methods on a single STC assembly.<br />

Polysulfone YES* YES YES* YES*<br />

at 270° F <strong>for</strong> up to five cycles up to 50 Kilograys up to 50 Kilograys<br />

60 minutes,<br />

up to 25 cycles<br />

MPC Tethered Vinyl NO YES YES YES<br />

Caps and Plugs up to 5 cycles up to 50 Kilograys up to 50 Kilograys<br />

*<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> did not conduct any sterilization test above 50 Kilograys. Bodies and inserts<br />

should remain uncoupled during autoclave sterilization. Manufacturer’s specifications <strong>for</strong> materials<br />

stated above may differ from <strong>Colder</strong>’s actual test results. Et0 cycle parameters available upon request.<br />

Working pressures and other technical in<strong>for</strong>mation have been prepared from actual test results and<br />

other data considered to be reliable. Sterilization process outcomes vary substantially depending on<br />

equipment and specific process. <strong>Colder</strong> represents the sterilization methods in<strong>for</strong>mation as reference<br />

only. Since so many factors affect the sterilization capability of a material, it is the customer’s<br />

responsibility to test <strong>Colder</strong> products under their own sterilization conditions.<br />

Biocompatibility Testing<br />

MPC/MPX, Steam-Thru, MPU, QD Sanitary, and HFC39 satisfy stringent<br />

requirements such as USP Class VI criteria, as well as MEM elution, agarose<br />

overlay, hemolysis in vitro, and USP physicochemical tests. Test results<br />

available upon request.<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.

Still Looking <strong>for</strong> the Perfect Solution?<br />

Even with thousands of standard quick disconnect couplings available, we know you still may not have<br />

found the precise part you need. That’s why, <strong>for</strong> more than 28 years, <strong>Colder</strong>’s Application Engineering Team<br />

has worked with customers around the world to design custom coupling solutions to solve their specific<br />

problems and improve their products’ per<strong>for</strong>mance. <strong>Colder</strong> has solid modeling capabilities, prototype<br />

equipment, an expansive test lab, and thousands of solutions. Combine that with our years of experience<br />

and a “can do” attitude, and there is no need <strong>for</strong> you to design your solution alone.<br />

Consider a Custom-Designed Connector When:<br />

■ A quick disconnect will add value to your product, making it easier to use and more reliable<br />

■ Your requirements cannot be met by a standard <strong>Colder</strong> product<br />

■ Unique requirements, budgets or timing warrant your designer’s collaboration with <strong>Colder</strong>’s<br />

Application Engineering Team<br />

Remember, standard catalog items generally have the advantage of quick availability<br />

and many times, lower cost, with no initial investment of time or money.<br />

However, depending on your volumes and technical requirements, it may make<br />

sense to work with our Application Engineering Team to design a unique<br />

solution tailored <strong>for</strong> your needs.<br />

Custom-designed products are exclusively produced <strong>for</strong> a specific customer. These proprietary products might not be <strong>for</strong> sale.<br />

Contact your local distributor <strong>for</strong> special application couplings.<br />

Call toll free 1-800-444-2474 or visit us at www.colder.com<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, <strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office.<br />

23

<strong>Colder</strong> Patent Statement:<br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> takes pride in<br />

its innovative quick disconnect coupling<br />

solutions, many of which have been<br />

awarded United States and international<br />

patents. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> has a<br />

strong tradition of leadership in the quick<br />

disconnect market, and aggressively<br />

pursues and protects its proprietary<br />

in<strong>for</strong>mation and intellectual property. In<br />

cases where it is practical and as a benefit<br />

to its customers, <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong><br />

has licensed its proprietary technology.<br />

Please contact <strong>Colder</strong> <strong>Products</strong> to discuss<br />

your unique needs.<br />

SaniQuik is a trademark with the US Patent<br />

and Trademark Office.<br />

ChemQuik ® , DrumQuik ® and Steam-Thru ® are<br />

registered trademarks and with the US Patent<br />

and Trademark Office.<br />

Chemraz ® is a registered trademark of<br />

Greene, Tweed & Co. Simriz ® is a registered<br />

trademark of Freudenberg-NOK. Teflon ®<br />

is a registered trademark of DuPont Dow<br />

Elastomers. Viton ® is a registered trademark<br />

of DuPont Dow Elastomers. Dyneon is a<br />

trademark of 3M-Hoechst.<br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong><br />

1001 Westgate Drive<br />

St. Paul, Minnesota 55114<br />

U.S.A.<br />

Phone: 651-645-0091<br />

Fax: 651-645-5404<br />

Toll Free: 800-444-2474<br />

info@colder.com<br />

www.colder.com<br />

Distributed By:<br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> GmbH<br />

Schmalweg 50<br />

D-55252 Mainz-Kastel<br />

Germany<br />

Phone: +49-6134-2878-0<br />

Fax: +49-6134-287828<br />

cpcgmbh@colder.com<br />

www.colder.com<br />

<strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> Limited<br />

Room 1503, 15/F, SBI Center<br />

54 – 58 Des Voeux Road Central<br />

Hong Kong<br />

Phone: 852-2987-5272<br />

Fax: 852-2987-2509<br />

asiapacific@colder.com<br />

www.colder.com<br />

<strong>Colder</strong> Warranty Statement: <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> warrants its products against defects in workmanship and materials <strong>for</strong> a period of<br />

12 months from the date of sale by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> to its initial customer (regardless of any subsequent sale of the products).<br />

This warranty is void if the product is misused, altered, tampered with or is installed or used in a manner that is inconsistent with <strong>Colder</strong><br />

Product <strong>Company</strong>’s written recommendations, specifications and/or instructions, or fails to per<strong>for</strong>m due to normal wear and tear. <strong>Colder</strong><br />

<strong>Products</strong> <strong>Company</strong> does not warrant the suitability of the product <strong>for</strong> any particular application. Determining product application suitability<br />

is solely the customer's responsibility. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> is not liable <strong>for</strong> special, indirect, incidental, consequential or other damages<br />

including, but not limited to, loss, damage, personal injury, or any other expense directly or indirectly arising from the use of or inability to<br />

use its products either separately or in combination with other products. ALL OTHER WARRANTIES EXPRESS OR IMPLIED, WHETHER ORAL,<br />

WRITTEN OR IN ANY OTHER FORM, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A<br />

PARTICULAR PURPOSE, ARE EXPRESSLY EXCLUDED.<br />

The sole and exclusive remedy under this warranty is limited, at the option of <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, to replacement of the defective<br />

product or an account credit in the amount of the original selling price. All allegedly defective <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong> products must be<br />

returned prepaid transportation to <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>, together with in<strong>for</strong>mation describing the product's application and<br />

per<strong>for</strong>mance, unless otherwise authorized in writing by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>.<br />

Copyright © 2004-2006 by <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>. All rights reserved. <strong>Colder</strong> <strong>Products</strong> <strong>Company</strong>,<br />

<strong>Colder</strong> <strong>Products</strong> and CPC are registered trademarks with the US Patent & Trademark Office. LICP54 11/06 DG/2M Printed in the U.S.A