Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HEXAFIX<br />

The clever mixing<br />

tool system<br />

Tool-free mixing tool<br />

change-over – fast –<br />

simple – easy<br />

Advantages:<br />

n Different stirrers can be used<br />

according to the viscosity of the<br />

material<br />

n Easy to clean stirrers – clean tools<br />

make a good impression on your<br />

customers<br />

n Easy and safe to transport,<br />

without the stirrers fitted<br />

n Every mixer with a M-14 connection<br />

can be converted to HEXAFIX<br />

with ease using the retrofit adapter<br />

(Art. No. 49.517-000).<br />

Collomix Rühr- und Mischgeräte GmbH<br />

Daimlerstraße 9 · 85080 Gaimersheim · Postfach 1146<br />

85078 Gaimersheim · Deutschland<br />

Phone +49 (0) 84 58 / 32 98-0 · Fax +49 (0)84 58 / 32 98 30<br />

www.collomix.com · info@collomix.de<br />

Subject to technical change<br />

EN 45.043-011<br />

Stirrers /<br />

Material<br />

Material:<br />

Liquid<br />

▼<br />

Mixture:<br />

Liquid<br />

Material:<br />

Powdery or<br />

semiliquid<br />

▼<br />

Mixture:<br />

Spreading<br />

Material:<br />

Powdery<br />

▼<br />

Mixture:<br />

Plastic /<br />

Compact<br />

n Paint<br />

n Dispersion<br />

n Lacquer<br />

n Glazings<br />

n Paste<br />

n Coverings<br />

n Epoxy-resin<br />

n Leveling materials<br />

n Fillers<br />

n Thick plasters<br />

n Sealing compounds<br />

n Thin-bed mortar<br />

n Adhesive mortar<br />

n Grouting compounds<br />

n Concrete<br />

n Screed<br />

n Tile adhesive<br />

n Epoxy-resin + sand<br />

n Gypsum plaster<br />

n Fibrated mortar<br />

n Plaster<br />

KRK FM LX<br />

AR DLX KR<br />

WK MK MKN<br />

Mixing quantity<br />

in kg<br />

Type/<br />

ø in mm<br />

- 2 KRK 60 S 10 mm<br />

10 - 15 KRK 80 S 10 mm<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

- 5 FM 60 S 10 mm<br />

5 - 10 FM 80 S 10 mm<br />

10 - 20 FM 100 S 13 mm<br />

15 - 30 FM 120 S 13 mm<br />

10 - 20 FM 100 M 14<br />

20 - 30 FM 120 HF<br />

5 - 10 LX 90 S 10 mm<br />

10 - 15 LX 120 S 13 mm<br />

15 - 25 LX 120 M 14<br />

20 - 35 LX 150 M 14<br />

15 - 25 LX 120 HF<br />

20 - 50 DLX 120 HF<br />

40 - 65 DLX 150 HF<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

5 - 15 KR 90 S 13 mm<br />

15 - 25 KR 120 S 13 mm<br />

15 - 25 KR 120 M 14<br />

20 - 35 KR 140 M 14<br />

30 - 50 KR 160 M 14<br />

15 - 25 KR 120 HF<br />

20 - 35 KR 140 HF<br />

30 - 50 KR 160 HF<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

4 - 7 WK 70 S 10 mm<br />

7 - 10 WK 90 S 10 mm<br />

10 - 15 WK 100 S 13 mm<br />

10 - 15 WK 120 S 13 mm<br />

10 - 15 WK 120 M 14<br />

15 - 30 WK 140 M 14<br />

- 50 WK 160 M 14<br />

10 - 15 WK 120 HF<br />

15 - 30 WK 140 HF<br />

- 50 WK 160 HF<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

5 - 15 MK 100 S 13 mm<br />

15 - 25 MK 120 M 14<br />

25 - 40 MK 140 M 14<br />

30 - 60 MK 160 M 14<br />

15 - 25 MK 120 HF<br />

25 - 40 MK 140 HF<br />

30 - 60 MK 160 HF<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

15 - 25 MKN 120 M 14<br />

25 - 40 MKN 140 M 14<br />

30 - 60 MKN 160 M 14<br />

15 - 25 MKN 120 HF<br />

25 - 40 MKN 140 HF<br />

30 - 60 MKN 160 HF<br />

Hand-held mixer<br />

drill chuck<br />

connection / mm<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

HEXAFIX ®<br />

Collomatic<br />

Automatic mixers for<br />

a wide spectrum of<br />

applications<br />

AOX - S<br />

(Art. No. 37.123 – 230V*)<br />

A rotary mixer with a high-speed mixing<br />

mechanism and scraper; mixing tub with<br />

separate motor, ideal for thin-bed mortar,<br />

adhesives, fillers, coverings, mortar, etc.<br />

Max. capacity: 40 liters;<br />

Speed: 750 rpm<br />

POX - S<br />

(Art. No. 37.124 – 230V*)<br />

The mixing tool is permanently fixed and<br />

the mixing tub rotates. For conventional<br />

plastic mortar and lime cement plasters,<br />

screed with a lightweight aggregate, dry<br />

mortar and paving jointing compounds;<br />

Max. 40 liters; subject to viscosity;<br />

Speed: 50 rpm<br />

TMS 2000<br />

(Art. No. 37.110 – 230V*)<br />

Compact and rugged mixer with a 3-arm<br />

mixing tool, ideal for material supplied in<br />

sacks; for numerous types of mortar,<br />

screed, concrete (16 mm), adhesives;<br />

Max. capacity: 80 liters;<br />

Speed: 42 rpm<br />

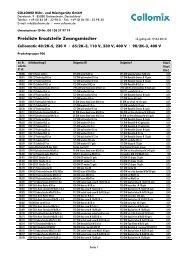

Forced-action mixers<br />

XM 2- 650<br />

(Art. No. 39.014 – 230 V*, 1.1 kW)<br />

XM 2- 650<br />

(Art. No. 39.016 – 400 V, 1.5 kW)<br />

XM 3- 900<br />

(Art. No. 39.015 – 400 V, 1.5 kW)<br />

Rugged forced-action mixer for the<br />

highest professional requirements.<br />

Two different mixing speeds for low<br />

and high viscosity materials, especially<br />

2-component products; high hourly<br />

throughput rates thanks to short mixing<br />

times; settable timer; changeable mixing<br />

tub;<br />

Capacity: 50 or 70 liters.<br />

Accessories: Trolley for moving the tub<br />

around easily.<br />

* 110 volts versions also available<br />

MIXING<br />

TECHNOLOGY<br />

FOR<br />

PROFESSIONALS<br />

M I X I N G T E C H N O L O G Y

Experience<br />

Collomix<br />

Collomix -<br />

when it comes to mixing<br />

Collomix products have been offering<br />

service-proven reliability on building<br />

sites for over 35 years. Many professionals<br />

swear by the innovative and<br />

reliable products from Collomix for their<br />

daily work. Our products have earned<br />

an outstanding reputation for durability,<br />

ruggedness and meeting the highest<br />

professional requirements.<br />

No two mixing jobs are the<br />

same. Given the diversity<br />

of materials and areas of<br />

application involved,<br />

wherever possible a coordinated<br />

range of products with suitable<br />

technology is required in order<br />

to be able to deliver optimum mixing<br />

results every time.<br />

Collomix offers a professional<br />

range of machines and tools for<br />

mixing work on the building site.<br />

For the best mixing results:<br />

n When choosing your stirrer, base your decision on the properties<br />

of the material you intend to mix.<br />

n Make sure in particular that you take account of the different<br />

mixing actions of the mixing tools: clockwise (from the bottom<br />

up), anticlockwise (from the top down).<br />

n The diameter of the stirrer and the size of the mixing tub have a<br />

major influence on mixing volume and time.<br />

n Use a clean mixing tub which is suitable for the quantity of material<br />

to be mixed. Pour the water into the tub first, then the powder<br />

mixture. Only fill the tub up to 2 / 3 of its height.<br />

n Select the drive unit (hand-mixer / power drill) in accordance<br />

with the diameter of the stirrer and the volume and viscosity of<br />

the material you intend to mix.<br />

n Make sure you always achieve lump-free mixing results.<br />

Collomix products are recommended by leading material<br />

manufacturers.<br />

You will find a mine of the very latest useful and up-to-date<br />

information, data sheets and videos along with information about<br />

spare parts and repairs at: www.collomix.de<br />

State of the art mixing – mixing for professionals:<br />

by completely redesigning the machine we made it<br />

possible to use the most powerful motor and gear unit components.<br />

To guarantee lasting operational safety and reliability<br />

even under the toughest conditions.<br />

Outstanding design:<br />

evolutionary and futuristic product<br />

design which exudes power,<br />

effectiveness and ruggedness;<br />

with excellent functionality and<br />

ease of maintenance.<br />

Optimized<br />

ergonomics:<br />

an improved working<br />

height means that the<br />

operator stands upright<br />

while working;<br />

ergonomically shaped<br />

handles; effortless.<br />

3 performance classes<br />

– 2 connection systems:<br />

HEXAFIX / M14<br />

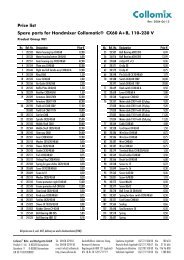

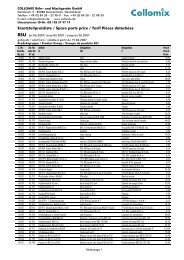

Art. No. Type Voltage* Wattage RPM Stirrers Mixing load<br />

under load in liters<br />

HEXAFIX<br />

20.400 Xo 1 HF 230 1010 -680 WK 120 HF -40<br />

20.412 Xo 4 HF 230 1300 -450/-620 WK 140 HF -65<br />

20.424 Xo 4 HF 230 1300 -450/-620 MK 140 HF -65<br />

20.436 Xo 6 HF 230 1600 -410/-580 MK 160 HF -90<br />

M14<br />

20.406 Xo 1 M 230 1010 -680 WK 120 M -40<br />

20.418 Xo 4 M 230 1300 -450/-620 WK 140 M -65<br />

20.430 Xo 4 M 230 1300 -450/-620 MK 140 M -65<br />

20.442 Xo 6 M 230 1600 -410/-580 MK 160 M -90<br />

DUO<br />

20.201 CX 22 DUO 230 1000 -400/-520 MKD 120 HF -50<br />

20.251 CX 44 DUO 230 1400 -350/-500 MKD 140 HF -90<br />

* 110 volts versions also available<br />

Hand-held mixers<br />

DUO<br />

CX-DUO with RSU mixer stand<br />

Heavy work –<br />

made lighter<br />

The counter-rotating hand-held mixer<br />

makes lots of mixing jobs easier and<br />

quicker. There is no counter-torque on<br />

the user and the machine is easy to<br />

move even in heavy and viscous material.<br />

You can generally count on being<br />

finished in just half the time. That's<br />

modern mixing!