Driveability Corner - MOTOR Information Systems

Driveability Corner - MOTOR Information Systems

Driveability Corner - MOTOR Information Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Driveability</strong> <strong>Corner</strong><br />

<strong>Driveability</strong> diagnosis is rarely simply checking DTCs, reading a fault<br />

tree, then replacing a defective part. It’s wise to follow a consistent<br />

diagnostic routine, especially when no codes are recorded.<br />

Mark<br />

Warren<br />

smwarren@motor.com<br />

Afriend asked for some help<br />

on a troublesome Nissan. It<br />

seems that intermittently<br />

the Nissan would go full<br />

rich, blow black smoke and<br />

run very poorly. Of course,<br />

no codes. We all do logical no-code diagnosis,<br />

plotting our own map for diagnostics.<br />

This is a good example of creating that diagnostic<br />

strategy.<br />

The black smoke was a likely indicator the<br />

engine was running rich, but it never hurts<br />

to have confirmation with a gas analyzer. My<br />

friend had bypassed this test and watched<br />

the scan tool when the problem was occurring.<br />

The injector pulse width jumped to<br />

20mS when the problem occurred.<br />

The diagnosis always starts with a list of<br />

possibilities and a process of elimination.<br />

There are two paths through the possibilities—first,<br />

the most likely failures that<br />

could cause the problem, and second, the<br />

easiest to test. Judgment dictates which<br />

comes first. Would you test fuel pressure<br />

first or use the scan tool you already connected<br />

to check for codes?<br />

It does look like a bad input is causing<br />

the fuel injector pulse width (IPW) to go<br />

way too long. For this exercise, let’s list the<br />

other possibilities, not associated with a bad<br />

fuel delivery input. They are:<br />

•High fuel pressure.<br />

•Leaking injector.<br />

•Purge system (evap) issue.<br />

In our diagnosis, we don’t see cause and<br />

effect; we see effect (running rich) and<br />

have to backtrack to the cause. The IPW<br />

calculation is the end of the line for a number<br />

of inputs to the powertrain control<br />

module (PCM). Let’s run through some<br />

continued on page 14<br />

Screen capture : Mark Warren<br />

12 February 2013

<strong>Driveability</strong> <strong>Corner</strong><br />

possible defective inputs that would<br />

cause this problem:<br />

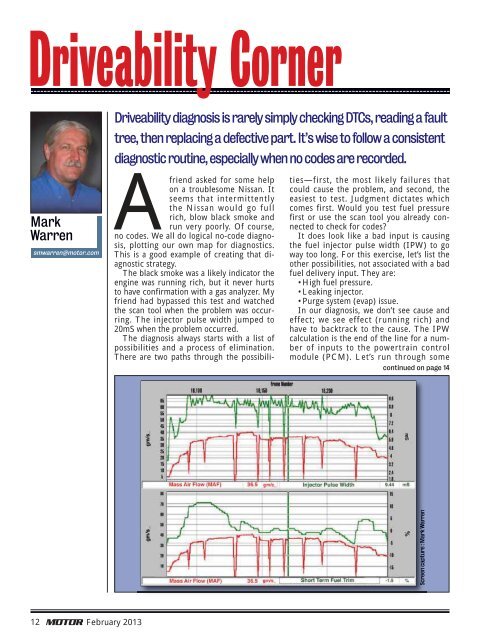

Mass Airflow (MAF) Sensor. In<br />

the scan capture of a defective<br />

MAF signal shown on page 12, note<br />

the dropouts in the MAF signal<br />

(green in the top graph), the corresponding<br />

drops in IPW (red) and<br />

the drop in short-term fuel trim<br />

(red, in the lower graph).<br />

In this example, of course, the<br />

drop caused a lean condition, which<br />

is more common than a rich condition<br />

on this Nissan. Our Nissan’s<br />

MAF signal was perfect when the<br />

defect occurred.<br />

Oxygen Sensors. Next, did the<br />

O 2 sensors respond correctly when<br />

the problem was not occurring and<br />

when it occurred? According to the<br />

information provided to me, they<br />

ranged correctly in response to a<br />

snap throttle test when the problem<br />

was not occurring and stuck rich<br />

when the Nissan ran rich. Don’t<br />

forget to test the postcatalyst O 2<br />

sensor; generally, the trim authority<br />

for the rear O 2 sensor is limited and<br />

cannot create such a dramatic rich<br />

condition. But on some vehicles,<br />

the rear O 2 sensor has unlimited authority<br />

and can cause a stuck-rich or<br />

stuck-lean condition.<br />

Temperature Sensor. Start disconnecting<br />

temperature sensors on<br />

late-model vehicles and you’ll note<br />

that when running, the temp sensor<br />

generally has no effect on determining<br />

fuel delivery. This is unlike<br />

the early days when the temp sensor<br />

had unlimited authority and an<br />

open sensor would cause a stuckrich<br />

condition.<br />

Throttle Position Sensor. A<br />

wide-open throttle command may<br />

cause a rich condition, but this is<br />

pretty unlikely. On a throttle-bywire<br />

system, the system is moni-<br />

tored very closely for safety reasons<br />

and will always set a code. Also, the<br />

redundancy in the system would<br />

never allow this rich condition to<br />

occur.<br />

Crank and Cam Sensors. The<br />

crank and cam sensors time and sync<br />

the injector signal. Corrupted signals<br />

can cause double-injection events or<br />

other strange behavior. An oscilloscope<br />

is mandatory here, but any<br />

aberration in a tach or rpm input<br />

may signal a problem in this area.<br />

Power and Grounds. These<br />

guys can never be left out of almost<br />

any no-code diagnosis. The effect of<br />

bad power or grounds can be wideranging<br />

and extreme. After seven<br />

years or 70,000 miles of vehicle use,<br />

issues in this area become more<br />

common.<br />

Crank Signal. I know of a similar<br />

intermittent running-rich case<br />

where the PCM received an inter-<br />

Circle #13<br />

14 February 2013

mittent crank signal while running.<br />

During crank, generally the PCM<br />

commands extra fuel for starting.<br />

The crank signal wire from the<br />

starter on this vehicle was intermittently<br />

shorting to 12 volts, signaling<br />

the computer that cranking/starting<br />

was occurring. The computer obviously<br />

did not have a rationality test<br />

to compare the crank signal to current<br />

rpm and commanded fuel enrichment.<br />

This is one of those crazy problems<br />

right out of left field. Using an<br />

eight-trace scope to monitor many<br />

signals and extreme persistence<br />

fixed this problem. The advantage<br />

of the eight-trace scope is for monitoring<br />

and eliminating the most<br />

likely possibilities during the intermittent<br />

event.<br />

Vehicle Speed Sensor. I had a<br />

computer-controlled Honda many<br />

years ago that gave me fits over a<br />

pig-rich condition. The O 2 sensors<br />

worked fine. When I restricted fuel<br />

they went lean, and they correctly<br />

indicated rich when the Honda ran<br />

rich. I could turn in the idle mixture<br />

screw and watch the gas analyzer<br />

go lean and then watch as the<br />

system commanded it back rich.<br />

The system was commanding this<br />

vehicle rich. The question was:<br />

Why? The customer request was to<br />

fix the emissions problem and, after<br />

the cost was known, look at the<br />

speedometer and estimate the cost<br />

to repair it as well. After two days of<br />

no luck with the fueling problem, I<br />

decided to look at the speedometer<br />

issue just to have some repair success<br />

with this vehicle. The vehicle<br />

speed sensor (VSS) on the back of<br />

the transmission was bad and cost<br />

about 25 bucks. I fixed the speedo<br />

and took the vehicle for a test drive<br />

to confirm the repair. Lo and behold,<br />

the fueling problem was fixed!<br />

It turns out this Honda had a catalytic<br />

converter strategy that drove<br />

the system rich if the vehicle remained<br />

stationary (no VSS signal)<br />

for more than two minutes with the<br />

engine running. It seems these vehicles<br />

had a problem with the converters<br />

getting hot at idle and burning<br />

the carpet in the vehicle. After<br />

sitting and not moving, with no<br />

VSS, the system went rich to cool<br />

and unlight the catalytic converter.<br />

With a failed VSS, the system was<br />

stuck in this mode.<br />

There was a code set for the VSS.<br />

Even if a code seems logically unrelated<br />

to your problem, take a hard<br />

look at that component and consider<br />

making the fix.<br />

Remember, a logical diagnostic<br />

procedure, thinking out of the box<br />

and a good dose of luck never hurt<br />

in the diagnostic hunt.<br />

Circle #14<br />

February 2013<br />

15