Massecuite conditioning, how to improve low raw massecuite curing.

Massecuite conditioning, how to improve low raw massecuite curing.

Massecuite conditioning, how to improve low raw massecuite curing.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

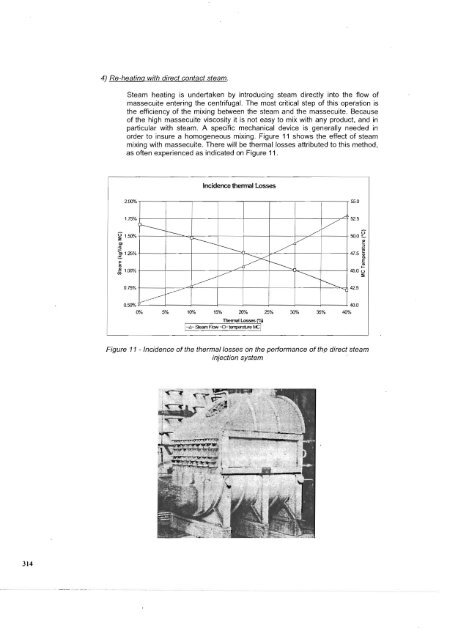

4) Re-heatinq with direct contact steam.<br />

Steam heating is undertaken by introducing steam directly in<strong>to</strong> the f<strong>low</strong> of<br />

<strong>massecuite</strong> entering the centrifugal. The most critical step of this operation is<br />

the efficiency of the mixing between the steam and the <strong>massecuite</strong>. Because<br />

of the high <strong>massecuite</strong> viscosity it is not easy <strong>to</strong> mix with any product, and in<br />

particular with steam. A specific mechanical device is . generally needed in<br />

order <strong>to</strong> insure a homogeneous mixing. Figure 11 s<strong>how</strong>s the effect of steam<br />

mixing with <strong>massecuite</strong>. There will be thermal losses attributed <strong>to</strong> this method,<br />

as often experienced as indicated on Figure 11 .<br />

Incidence thennal Losses<br />

2.00% 55.0<br />

1.75%<br />

I---- -::---..<br />

~1 . 50% /<br />

1-----,______. /"<br />

;><<br />

,.,.---:' ~<br />

0.75%<br />

o.SO% ~--------- ~--<br />

C><br />

-'"<br />

~<br />

~1 . 25%<br />

E<br />

co<br />

3; H XJ%<br />

~<br />

~<br />

~<br />

r-<br />

0% 5% 10% 15% 20% 25% 30% 35% 40%<br />

I-u- Steam RON -(}- terrpErnttre I>IC I<br />

V<br />

/<br />

52.5<br />

sooE<br />

..<br />

~<br />

::J<br />

0.<br />

Ẹ.<br />

47.5 :.<br />

...<br />

45.0 u<br />

::li:<br />

42 5<br />

40.0<br />

Figure 11 - In.cidence ofthe thermal losses on the performance of thfJ direct steam<br />

injection system<br />

314