Design-in guide - Philips Lighting

Design-in guide - Philips Lighting

Design-in guide - Philips Lighting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Design</strong>-<strong>in</strong> <strong>guide</strong><br />

<strong>Philips</strong> Fortimo LED Twistable Downlight Module (TDLM) Gen 2<br />

1100 lm and 2000 lm 120 VAC modules

Contents<br />

Introduction 3<br />

Information and support 3<br />

Introduction to the Fortimo LED Twistable DLM Module Gen 2 4<br />

Applications 4<br />

Product description 4<br />

Classification 4<br />

About the module 4<br />

Generation 2 5<br />

LEDs power<strong>in</strong>g Fortimo LED Twistable DLM Module Gen 2 6<br />

What is LED? 6<br />

LED packag<strong>in</strong>g 7<br />

B<strong>in</strong>n<strong>in</strong>g 7<br />

Mid-power LED 7<br />

M<strong>in</strong>iaturization 7<br />

Important recommendations and warn<strong>in</strong>gs 8<br />

<strong>Design</strong>-<strong>in</strong> phase 8<br />

<strong>Design</strong>-<strong>in</strong> and manufactur<strong>in</strong>g phase 8<br />

Module replaceability 8<br />

Warn<strong>in</strong>gs 8<br />

Mechanical characteristics 9<br />

Mechanical construction of the Fortimo LED Twistable<br />

DLM Module Gen 2 9<br />

Dimensions of the Fortimo LED Twistable<br />

DLM Module Gen 2 range 9<br />

Dimensions of the BJB lampholders 10<br />

Dimensions of the Stucchi lampholders 10<br />

Dimensions of the Ideal lampholders 11<br />

Light<strong>in</strong>g characteristics 12<br />

Light distribution 12<br />

Optical files 12<br />

Spectral light distribution diagram 1100 lm 13<br />

Spectral light distribution diagram 2000 lm 13<br />

Polar <strong>in</strong>tensity diagram 1100 lm 14<br />

Polar <strong>in</strong>tensity diagram 2000 lm 14<br />

Colour consistency (SDCM) 15<br />

Reflector design 15<br />

Thermal management 16<br />

Operat<strong>in</strong>g temperatures 16<br />

Test requirements 16<br />

Maximum Temperature 16<br />

Critical measurements Tc po<strong>in</strong>t 16<br />

Case temperature 17<br />

Twistable with closed heat s<strong>in</strong>k 17<br />

Twistable with open heat s<strong>in</strong>k 17<br />

Operation under built-<strong>in</strong> conditions 18<br />

Thermal <strong>in</strong>terface 18<br />

Heats<strong>in</strong>k design 18<br />

Thermal Conductivity 19<br />

Emission 19<br />

Thermal de-rat<strong>in</strong>g system 19<br />

Size of heats<strong>in</strong>k & Thermal Interface Material 19<br />

Air flow 20<br />

Thermal model 20<br />

Analogy between electrical and thermal resistance 20<br />

Calculat<strong>in</strong>g your heat s<strong>in</strong>k 21<br />

Available <strong>in</strong>formation 21<br />

Heat s<strong>in</strong>k complementary partners 21<br />

Electrical design 22<br />

Wir<strong>in</strong>g 22<br />

Length of ma<strong>in</strong>s cable 22<br />

Start<strong>in</strong>g characteristics 22<br />

Low and overvoltage 22<br />

Inrush current 2 22<br />

Dimm<strong>in</strong>g 23<br />

Switch<strong>in</strong>g 23<br />

Quality 24<br />

Compliance and approval marks 24<br />

Susta<strong>in</strong>ability 24<br />

Conditions of acceptance 24<br />

IP rat<strong>in</strong>g, humidity and condensation 24<br />

Energy Star 24<br />

Titlke 24 24<br />

EMC 24<br />

Susta<strong>in</strong>ability 25<br />

Dur<strong>in</strong>g operation 25<br />

System disposal 25<br />

Contact Details 25<br />

2 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Introduction<br />

Thank you for choos<strong>in</strong>g the <strong>Philips</strong> Fortimo LED Twistable Downlight Module (TDLM)<br />

Gen 2. In this <strong>guide</strong> you will f<strong>in</strong>d the <strong>in</strong>formation required to design this module <strong>in</strong>to a<br />

lum<strong>in</strong>aire, plus valuable h<strong>in</strong>ts and tips.<br />

The product specifications and <strong>in</strong>formation regard<strong>in</strong>g the products <strong>in</strong> this document<br />

are subject to change without notice. All statements, <strong>in</strong>formation, and recommendations<br />

<strong>in</strong> this document are believed to be accurate but are presented “as-is”. Without any<br />

representations or warranties of any k<strong>in</strong>d, express or implied.<br />

This <strong>guide</strong> is presented solely for <strong>in</strong>formational purposes. Users take full responsibility<br />

for their application of any products.<br />

This <strong>guide</strong> is designed solely for use by eng<strong>in</strong>eers, light<strong>in</strong>g designers and other<br />

professional with<strong>in</strong> the light<strong>in</strong>g <strong>in</strong>dustry only.<br />

Information and support<br />

This <strong>guide</strong> tells you all about this system.<br />

If you require any further <strong>in</strong>formation or support please consult your local <strong>Philips</strong> office<br />

or please consult your <strong>Philips</strong> account representative.<br />

The advantages of LEDs have been known for 40 years:<br />

• Energy Efficient – uses less power (w) than conventional light<strong>in</strong>g<br />

• Long life – low ma<strong>in</strong>tenance cost<br />

• Robustness – high reliability<br />

• Saturated colors – maximum visual effect<br />

• Cool beam – no heat<strong>in</strong>g of illum<strong>in</strong>ated products<br />

• No UV or IR – wide application possibilities<br />

• Low-voltage operation – more safety, ease of use<br />

• Mercury-free – care for the environment<br />

The use of LEDs has implications for light<strong>in</strong>g manufacturers <strong>in</strong> terms of differences <strong>in</strong><br />

solid-state light<strong>in</strong>g usage compared with traditional lamps: for example how to design<br />

given the constant improvements <strong>in</strong> specifications: how to provide the necessary heat<br />

s<strong>in</strong>k and how to deal with variations <strong>in</strong> flux and/or color. The <strong>Philips</strong> Fortimo LED<br />

Twistable Downlight Module addresses these differences and facilitates easy adoption of<br />

LED technology for the lumen packages, 1100 lm to 2000 lm.The system is designed for<br />

<strong>in</strong>tegration <strong>in</strong> lum<strong>in</strong>aires. This technical application <strong>guide</strong> addresses the relevant issues to<br />

support and facilitate the work of specifiers and light<strong>in</strong>g system designers.<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 3

Introduction to the Fortimo LED Twistable<br />

Downlight Module (TDLM) Gen 2<br />

Applications<br />

<strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 has been primarily designed for<br />

<strong>in</strong>door applications but may, <strong>in</strong> certa<strong>in</strong> circumstances, be used <strong>in</strong> certa<strong>in</strong> damp location<br />

(provided all applicable laws and regulations are followed, <strong>in</strong>clud<strong>in</strong>g UL 1598).<br />

The <strong>Philips</strong> Fortimo LED TDLM, as the name suggests, is designed and <strong>in</strong>tended for<br />

general downlight <strong>in</strong> accordance with North American lum<strong>in</strong>aire standard, UL 1598.<br />

TDLM 1100 lm Module<br />

1<br />

Examples of applications <strong>in</strong>clude:<br />

• Hospitality (hotels representative areas such as receptions, boardrooms,<br />

restaurants, etc.)<br />

• Cruise ships (corridors, cab<strong>in</strong>s)<br />

• Public build<strong>in</strong>gs (schools, c<strong>in</strong>emas, theaters, exhibition halls)<br />

• Office (Corridors, reception/lobbies, wait<strong>in</strong>g area)<br />

• Urban outdoor light<strong>in</strong>g (ground light<strong>in</strong>g, post-top lanterns)<br />

• Retail (corridors, general wait<strong>in</strong>g area, dress<strong>in</strong>g room area, mall facades)<br />

Product description<br />

To operate a system the follow<strong>in</strong>g products are needed:<br />

• A <strong>Philips</strong> Fortimo LED TDLM Module Gen 2<br />

• A heats<strong>in</strong>k (sold separately)<br />

• A reflector (depend<strong>in</strong>g on the application) (sold separately)<br />

• Lampholder (sold separately)<br />

TDLM 2000 lm Module<br />

Classification<br />

The <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 can be used <strong>in</strong>:<br />

• Non Class 2 system (lum<strong>in</strong>aire heat s<strong>in</strong>k must be grounded)<br />

• Neither the <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 nor its<br />

lampholder can be used for wet location applications. So if an OEM decides to use<br />

the system <strong>in</strong> a lum<strong>in</strong>aire for outdoor applications, the OEM is solely responsible<br />

for relevant approbation design as well as compliance with any and all laws,<br />

standards and regulations.<br />

About the module<br />

The protective hous<strong>in</strong>g allows easy handl<strong>in</strong>g dur<strong>in</strong>g transport and <strong>in</strong>stallation. It<br />

also protects the LEDs from direct access/damage once mounted, and ensures the<br />

appropriate safety distance between the LEDs and any metal objects (for example<br />

a reflector). The connector allows quick and easy <strong>in</strong>stallation and replacement of<br />

the module.<br />

4 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Generation 2<br />

<strong>Philips</strong> is cont<strong>in</strong>uously improv<strong>in</strong>g its Fortimo products.<br />

The second generation of the Fortimo LED Twistable Downlight Modules has been<br />

developed to enable LED adoption and upgrades very easily. The range aimed at energy<br />

efficiency has a very good Total Cost of Ownership and is easy to <strong>in</strong>stall. There is no<br />

tra<strong>in</strong><strong>in</strong>g and tool<strong>in</strong>g required result<strong>in</strong>g <strong>in</strong> low ma<strong>in</strong>tenance thus reduced runn<strong>in</strong>g costs<br />

over the lifetime of the lum<strong>in</strong>aire.<br />

This range changed from remote phosphor to white LEDs to help deliver better<br />

efficiency. The quality of LEDs does not require the phosphor plate anymore. The<br />

modules will cont<strong>in</strong>ue to ensure the same high quality.<br />

F<strong>in</strong>ally, the 1100 lumen module is Zhaga 1 certified, the full range of TDLMs will be Zhaga<br />

certified from Q2-2013 onwards.<br />

<strong>Philips</strong> Fortimo Twistable Module types<br />

The range of Twistable Gen 2 Modules<br />

Fortimo LED TDLM 1100 827 120V G2<br />

Fortimo LED TDLM 1100 830 120V G2<br />

Fortimo LED TDLM 1100 835 120V G2<br />

Fortimo LED TDLM 2000 827 120V G2<br />

Fortimo LED TDLM 2000 830 120V G2<br />

Fortimo LED TDLM 2000 835 120V G2<br />

Note: Lampholder for both 1100 lm module and 2000 lm module are available at our<br />

complementary partners BJB and Ideal Industries.<br />

Note: 277 volt and 4000K CCT Modules will be available later <strong>in</strong> 2013<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 5

LEDs power<strong>in</strong>g Fortimo LED Twistable<br />

Downlight Module Gen 2<br />

The development of Light Emitt<strong>in</strong>g Diodes (LEDs) is progress<strong>in</strong>g at such a pace that they<br />

are rapidly ga<strong>in</strong><strong>in</strong>g a majority of use for light<strong>in</strong>g applications. To most people, the term<br />

LED still only means the small <strong>in</strong>dicator lights that show whether the TV set is switched<br />

on. These t<strong>in</strong>y light sources barely emit enough light to make themselves visible. In the<br />

Fortimo LED Twistable Downlight Module Gen 2 system, multi-die white LEDs are used.<br />

This package enables high efficiency, high lumens, and m<strong>in</strong>imum CRI of 80. 3<br />

What is LED?<br />

LEDs are solid-state devices, built up from crystall<strong>in</strong>e layers of semiconductor material.<br />

The light generation process makes use of the special electronic properties of crystall<strong>in</strong>e<br />

semiconductors <strong>in</strong> a process called <strong>in</strong>jection lum<strong>in</strong>escence.<br />

In brief, this means the <strong>in</strong>jection of charged particles by an electric field from one<br />

semiconductor layer <strong>in</strong>to another, where they are able to relax to a lower- energy state<br />

by emitt<strong>in</strong>g visible light. LEDs produce narrow light spectra. The bandwidth rema<strong>in</strong>s<br />

limited to a few tens of nanometers, and is therefore perceived by the human eye as a<br />

s<strong>in</strong>gle, deeply saturated color. LEDs are now available <strong>in</strong> all wavelengths of the visible<br />

spectrum; yellow is the only region <strong>in</strong> which no high-power LED is currently available.<br />

White light can be produced by comb<strong>in</strong><strong>in</strong>g LEDs of different colors (for <strong>in</strong>stance red,<br />

green and blue), or by apply<strong>in</strong>g phosphor coat<strong>in</strong>gs on blue or ultraviolet LEDs. Like many<br />

other lamps, LEDs cannot be connected directly to the ma<strong>in</strong>s. The LEDs have to be<br />

operated at a stabilized low voltage, which is provided by driver electronics.<br />

However, LEDs do not need ignition and can be switched on/off with<strong>in</strong> milliseconds.<br />

LEDs do not generate nearly as much heat as many other lamps, but that does not mean<br />

that thermal design is not important. LEDs do produce heat when they operate, and are<br />

themselves relatively sensitive to temperature. Thermal considerations are therefore<br />

very important aspects of lum<strong>in</strong>aire design that <strong>in</strong>corporates LEDs.<br />

6 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

LED packag<strong>in</strong>g<br />

The bare LED die is still a very sensitive and fragile device that must be handled <strong>in</strong> a<br />

clean room environment. Before br<strong>in</strong>g<strong>in</strong>g them outside, they must be packaged. The<br />

light flux of conventional LEDs, for example those used as <strong>in</strong>dicator lights on TV sets,<br />

is severely limited by the amount of heat generated. In practice, conventional LED<br />

packages are limited to about 0.15 W at most, and emit only a few lumens. The LEDs<br />

used <strong>in</strong> Fortimo LED Twistable Downlight Module Gen 2 are middle power s<strong>in</strong>gle-die<br />

packaged, composed of blue dies with phosphor.<br />

B<strong>in</strong>n<strong>in</strong>g<br />

The subject of b<strong>in</strong>n<strong>in</strong>g should be expla<strong>in</strong>ed because of its importance <strong>in</strong> LED system<br />

design. As <strong>in</strong> other semiconductor manufactur<strong>in</strong>g processes, <strong>in</strong> LED production the<br />

number of parameters of the epitaxial process is very large and the process w<strong>in</strong>dow<br />

small (for example, the temperature must be controlled to with<strong>in</strong> 0.5 °C (

Important recommendations and warn<strong>in</strong>gs<br />

Warn<strong>in</strong>gs<br />

• Follow <strong>in</strong>stallation rules explicitly<br />

• Inspect each product before <strong>in</strong>stallation<br />

• Do not <strong>in</strong>stall damaged LED modules<br />

The follow<strong>in</strong>g recommendations and warn<strong>in</strong>gs should be followed dur<strong>in</strong>g the various<br />

phases of use of the Fortimo LED Twistable Downlight Module Gen 2:<br />

<strong>Design</strong>-<strong>in</strong> phase<br />

Lum<strong>in</strong>aire manufacturers must conform to the <strong>in</strong>ternational standards for lum<strong>in</strong>aire<br />

design (UL/CSA1598- lum<strong>in</strong>aires).<br />

<strong>Design</strong>-<strong>in</strong> and manufactur<strong>in</strong>g phase<br />

• Do not use damaged or defective contacts or hous<strong>in</strong>gs.<br />

• Ensure proper heat management to help guarantee the lifetime of the module.<br />

Module replaceability<br />

The module can be easily replaced without deconnect<strong>in</strong>g the ma<strong>in</strong>s<br />

8 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Mechanical characteristics<br />

Mechanical construction of the Fortimo LED Twistable Downlight Module Gen 2<br />

The module can operate by us<strong>in</strong>g the ma<strong>in</strong> components below:<br />

• Fortimo LED TDLM Gen 2<br />

• Lampholder<br />

Note: the Fortimo LED Twistable Downlight Module Gen 2 1100 lm module and<br />

respective lampholders are Zhaga compliant 1<br />

Dimensions of the Fortimo LED Twistable Downlight Module Gen 2 range<br />

(dimensions <strong>in</strong> mm)<br />

Twistable Gen 2 1100 lm Top view<br />

Twistable Gen 2 2000 lm Top view<br />

Twistable Gen 2 1100 lm side view<br />

Twistable Gen 2 2000 lm side view<br />

Note: at the backside of each Fortimo LED Twistable Downlight Module Gen 2, you’ll f<strong>in</strong>d<br />

thermal <strong>in</strong>terface material for optimal thermal contact to a heats<strong>in</strong>k. Important: Do not<br />

remove the thermal pad.<br />

Twistable Gen 2 1100 lm top view<br />

Twistable Gen 2 2000 lm top view<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 9

Mechanical characteristics<br />

Note: Optical w<strong>in</strong>dow is same for both modules (1100 and 2000 lm).<br />

Dimensions of the BJB lampholders<br />

(dimensions <strong>in</strong> mm)<br />

Dimensions of the Stucchi lampholders<br />

(dimensions <strong>in</strong> mm)<br />

Twistable TDLM Module Gen 2 Twistable DLM Module Gen 2<br />

1100 lm – BJB 1100 lm – Stucchi<br />

Twistable DLM Module Gen 2 Twistable DLM Module Gen 2<br />

2000 lm – BJB 2000 lm – Stucchi<br />

10 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Dimensions of the Ideal lampholders (dimensions <strong>in</strong> mm)<br />

1100lm<br />

2000lm<br />

Assemble the lampholder on your heats<strong>in</strong>k with 3 M3 screws<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 11

Light<strong>in</strong>g characteristics<br />

Light distribution<br />

The light distribution of the Fortimo TDLM is near lambertian and can be used for a<br />

multitude of applications. The light distribution can best be controlled us<strong>in</strong>g a specular/<br />

near-specular reflector.<br />

Optical files<br />

On the <strong>Philips</strong> website (www.philips.com/ledmodulesna) optical files can be downloaded<br />

<strong>in</strong> the follow<strong>in</strong>g formats: IES, <strong>in</strong>clud<strong>in</strong>g a file with Ray-sets.<br />

Photometric files can be used to check the modules far-field <strong>in</strong>tensity distribution.<br />

The <strong>in</strong>itial reflector or lum<strong>in</strong>aire design can be carried out us<strong>in</strong>g a lambertian emitter<br />

to ga<strong>in</strong> simulation speed. The f<strong>in</strong>al design should always be verified us<strong>in</strong>g a simulation<br />

executed with a rayset for the Fortimo Twistable Downlight Module.<br />

Spectral light distribution diagram 1100 lm module<br />

Spectral light distribution diagram 2000 lm module<br />

12 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Spectral light distribution diagram 1100 lm module<br />

Spectral light distribution diagram 2000 lm module<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 13

Light<strong>in</strong>g characteristics<br />

Polar <strong>in</strong>tensity diagram 1100 lm<br />

Polar <strong>in</strong>tensity diagram 2000 lm<br />

Note: TDLM Gen 2 can be operated at a max of 65C at the Tc po<strong>in</strong>t and ma<strong>in</strong>ta<strong>in</strong><br />

specified light output. TDLM Gen 2 can be operated at a max of 70C at the Tc po<strong>in</strong>t, but<br />

14 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

will result <strong>in</strong> 2% light loss.<br />

Color consistency (SDCM)<br />

The target specification of the <strong>Philips</strong> Fortimo LED Twistable TDLM Module Gen 2<br />

range for colour consistency is with<strong>in</strong> 4 SDCM 2 ellipse <strong>in</strong>side ANSI quadrangle. SDCM<br />

stands for Standard Deviation of Color Match<strong>in</strong>g and the value 4 refers to the size of an<br />

ellipse around the black body locus.<br />

Note: <strong>Philips</strong> ma<strong>in</strong>ta<strong>in</strong>s a tolerance of ± 0,005 on x, y color po<strong>in</strong>ts measurements.<br />

This figure shows color targets for the different color temperatures of the Fortimo<br />

LED Twistable Downlight Module Gen 2 Modules. These are specified <strong>in</strong> the operat<strong>in</strong>g<br />

conditions (Tc 65 °C). In the application a color shift is possible if the Tc temperature is<br />

significantly lower than <strong>in</strong> these targets.<br />

Reflector design<br />

The reflector design can be done by the OEM or can be supplied by a<br />

complementary partner.<br />

If the OEM wants to design its own reflector, raysets can be downloaded from the<br />

Fortimo website (www.philips.com/ledmodules). If more support is needed, please<br />

contact the key account manager or your local <strong>Philips</strong> sales representative.<br />

Different reflector suppliers have designed a reflector that fits the <strong>Philips</strong> Fortimo<br />

LED Twistable Downlight Module Gen 2; Jordan, ACL, Alux Luxar and NATA. These<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 15

Thermal management<br />

companies can be contacted via their website.<br />

The critical thermal management po<strong>in</strong>ts for the module and driver are set out <strong>in</strong> this<br />

chapter <strong>in</strong> order to facilitate the design-<strong>in</strong> of Fortimo LED Twistable Downlight Module<br />

Gen 2. Keep<strong>in</strong>g these thermal po<strong>in</strong>ts <strong>in</strong> m<strong>in</strong>d will help to ensure optimal performance<br />

and lifetime of the system.<br />

Operat<strong>in</strong>g temperatures – Def<strong>in</strong>itions<br />

• Module temperature: temperature measured on the Tc po<strong>in</strong>t of the module<br />

• Ambient temperature: temperature outside the lum<strong>in</strong>aire<br />

Temperature test po<strong>in</strong>t at bottom PCB<br />

Module Type 1100 lm 2000 lm<br />

Max Tcase 70 °C (all CCTs) 70 °C (all CCTs)<br />

Max Thermal Power at thermal <strong>in</strong>terface @ 2700 K 10.6W 19.1W<br />

Max Thermal Power at thermal <strong>in</strong>terface @ 3000 K 9.7 W 18.5W<br />

Max Thermal Power at thermal <strong>in</strong>terface @ 3500 K 9.7W 18.4W<br />

Tambient 45°C 45°C<br />

Test requirements<br />

The test results of T case and T ambient case of the Module <strong>in</strong> open air or <strong>in</strong> the<br />

standard wooden box will give different results. The worst case test is the wooden box<br />

with T ambient 45 ºC.<br />

Temperature measurements should only be performed when the lum<strong>in</strong>aire is thermally<br />

stable, which may take 0.5 to 2 hours depend<strong>in</strong>g on the thermal capacity of the<br />

lum<strong>in</strong>aire. For all measurements such as temperature, lum<strong>in</strong>ous flux and power, a<br />

stabilization period of at least half an hour must be allowed before any reliable data can<br />

be obta<strong>in</strong>ed. Measurements must be performed by means of thermocouples that are<br />

firmly glued to the surface (and not, for example, secured with adhesive tape).<br />

Maximum Temperature<br />

Because LEDs are temperature-sensitive, LED modules require a different approach<br />

with respect to the maximum permissible component temperature. This is different than<br />

most other types of light sources. Some of the LED modules have a shut down circuit<br />

when temperature becomes to high.<br />

The Fortimo LED Twistable Downlight Module Gen 2 has no shut down circuit and<br />

therefore requires proper thermal design.<br />

Critical measurements Tc po<strong>in</strong>t<br />

For LEDs the junction temperature is the critical factor for operation. S<strong>in</strong>ce there is a<br />

direct relation between the case temperature and the LED junction temperature it is<br />

sufficient to measure the bottom side of the module. The critical po<strong>in</strong>t is on the back<br />

surface of the LED module. If the case temperature (Tc) at the critical measurement<br />

po<strong>in</strong>t is too high (exceed<strong>in</strong>g 70°C), the performance of the LEDs will be adversely<br />

affected, for example <strong>in</strong> terms of light output, lifetime or lumen ma<strong>in</strong>tenance.<br />

16 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Case temperature<br />

To ensure the performance and to enable temperature measurement <strong>in</strong> a lum<strong>in</strong>aire,<br />

a Tcase po<strong>in</strong>t has been def<strong>in</strong>ed at the back surface on the Fortimo Twistable Downlight<br />

Module Gen 2.<br />

Module with closed heat s<strong>in</strong>k<br />

Where to pay attention?<br />

• Tcase can be measured on the heat s<strong>in</strong>k, either by mak<strong>in</strong>g a v-groove <strong>in</strong> the<br />

heat s<strong>in</strong>k (Tcase 1) OR mak<strong>in</strong>g a drill hole <strong>in</strong> the heat s<strong>in</strong>k (Tcase 2) (glu<strong>in</strong>g the<br />

thermocouple-wire to the heat s<strong>in</strong>k is strongly recommended).<br />

• The Thermal Interface Material (TIM) stays on the twist and makes thermal contact<br />

with the heat s<strong>in</strong>k.<br />

Module with open heat s<strong>in</strong>k<br />

Where to pay attention?<br />

• Tcase can be measured on the heat s<strong>in</strong>k, by mak<strong>in</strong>g a v-groove <strong>in</strong> the heat<br />

s<strong>in</strong>k (Tcase 1) (glu<strong>in</strong>g the thermocouple-wire to the heat s<strong>in</strong>k is strongly<br />

recommended).<br />

• The Thermal Interface Material (TIM) stays on the twist and makes thermal contact<br />

with the heat s<strong>in</strong>k.<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 17

Thermal management<br />

Operation under built-<strong>in</strong> conditions<br />

The heat produced by LED module <strong>in</strong> the lum<strong>in</strong>aire (or similar hous<strong>in</strong>g) must be<br />

dissipated to the surround<strong>in</strong>gs. If a lum<strong>in</strong>aire is physically <strong>in</strong>sulated by a ceil<strong>in</strong>g, wall<br />

or <strong>in</strong>sulation blanket, the heat produced cannot easily be dissipated. This will result <strong>in</strong><br />

heat<strong>in</strong>g of the LED module <strong>in</strong> the lum<strong>in</strong>aire, which <strong>in</strong> turn can have an adverse effect on<br />

system performance and lifetime. For optimum performance and lifetime it is important<br />

that: air can flow freely around the lum<strong>in</strong>aries; and airflow through the lum<strong>in</strong>aire, around<br />

the modules, has a positive effect on temperature control and hence on performance<br />

and lifetime.<br />

Thermal <strong>in</strong>terface<br />

In the Fortimo LED the thermal <strong>in</strong>terface is already attached on the module.<br />

Do not remove the thermal <strong>in</strong>terface material.<br />

Heats<strong>in</strong>k design<br />

To ensure that hous<strong>in</strong>g temperatures do not exceed the specified maximum values, a<br />

lum<strong>in</strong>aire can act as an additional heat s<strong>in</strong>k. The applicable heat transport mechanisms<br />

are conduction via the heat s<strong>in</strong>k and convection and thermal radiation to the<br />

surround<strong>in</strong>gs. The objective of this chapter is not to <strong>in</strong>dicate exactly how to calculate<br />

a heat s<strong>in</strong>k, but to give some <strong>guide</strong>l<strong>in</strong>es on how to improve its performance. Although<br />

a heat s<strong>in</strong>k can have many (complex) shapes, the follow<strong>in</strong>g discussion is based on a<br />

disk type of heat s<strong>in</strong>k. The results for square plates, etc., may be similar provided the<br />

surface areas are equal. The type of material used has a relatively large <strong>in</strong>fluence on<br />

the f<strong>in</strong>al result. For example, a comparison of the thermal conductivity (k) of copper<br />

with that of corrosion- resistant steel (see table left) shows that a substantially smaller<br />

heat s<strong>in</strong>k can be made with copper. In practice the best material for heat s<strong>in</strong>ks is (soft)<br />

alum<strong>in</strong>um. The thickness (d) of the heat s<strong>in</strong>k disk is also of major importance. Assum<strong>in</strong>g<br />

the use of different heat s<strong>in</strong>ks of the same diameter but made from different materials,<br />

the same effect <strong>in</strong> terms of temperature difference will be achieved if the product of<br />

thermal conductivity (k) and disk thickness (d) is constant. This means a similar result<br />

is obta<strong>in</strong>ed with a disk of 1 mm copper, 2 mm alum<strong>in</strong>um, 4 mm brass, 8 mm steel or 26<br />

mm corrosion-resistant steel. Increas<strong>in</strong>g the diameter, and thereby also the surface area,<br />

of the heat s<strong>in</strong>k disk also leads to an improvement, but the effect is smaller for larger<br />

diameters and depends on the thermal conductivity (k) of the material and the thickness<br />

(d).Thermal radiation can also form a substantial part of the total heat transfer, and is of<br />

the same order as for convection. This depends strongly on the emission coefficient of<br />

the surface, which lies between 0 and 1. For example, a polished alum<strong>in</strong>um surface has<br />

a very low emission coefficient, while that of a pa<strong>in</strong>ted surface is very high. For passive<br />

cool<strong>in</strong>g, high emission coefficient is preferred.<br />

18 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

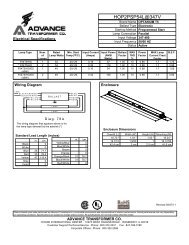

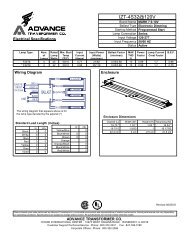

Thermal Conductivity<br />

Material<br />

W/mK<br />

Copper 400<br />

Alum<strong>in</strong>ium 200<br />

Brass 100<br />

Steel 50<br />

Corrosion-resistant steel 15<br />

Emission<br />

Material Surface Emission coefficient<br />

Alum<strong>in</strong>ium New/polished 0.04 – 0.06<br />

Oxidized 0.2 – 0.3<br />

Anodized 0.8<br />

Steel Pa<strong>in</strong>ted 0.8 – 0.95<br />

New/Polished 0.03 – 0.07<br />

Heavy oxidized 0.7 – 0.8<br />

Thermal de-rat<strong>in</strong>g system<br />

The Fortimo LED Twistable Downlight Module Gen 2 has no shutdown circuit and<br />

therefore requires proper thermal design.<br />

Size of heats<strong>in</strong>k & Thermal Interface Material (TIM)<br />

The module conta<strong>in</strong>s a built-<strong>in</strong> heat spreader. The module must be connected to the<br />

heat s<strong>in</strong>k with a thermal <strong>in</strong>terface material (TIM) <strong>in</strong> between which makes sure of a<br />

perfect contact between the module and the heat s<strong>in</strong>k. The module has a thermal power<br />

that needs to be taken away. The spreader at the back of the module is the contact<br />

area for the external heat s<strong>in</strong>k. The performance (life time and amount of light) of the<br />

module depends heavily on the thermal management. Therefore the temperature of the<br />

test po<strong>in</strong>t (Tc) is important. Dur<strong>in</strong>g the thermal design process, the aim is to keep the<br />

Tc temperature at the stated range. Thermal Interface Materials (TIM) are thermally<br />

conductive materials, which are applied to <strong>in</strong>crease Thermal contact conductance<br />

across jo<strong>in</strong>ted solid surfaces, such as between microprocessors and heats<strong>in</strong>ks, <strong>in</strong> order<br />

to <strong>in</strong>crease thermal transfer efficiency. Without a TIM the heat that is generated by<br />

the module cannot be managed effectively by the heat s<strong>in</strong>k. This will result <strong>in</strong> poor<br />

performance or total failure of the module or fixture.<br />

Please note that <strong>in</strong> an assembly scenario where metal screws are not used to fix the<br />

heat s<strong>in</strong>k to the module, then a non-isolated thermal <strong>in</strong>terface material (also known as<br />

electrically conductive TIMs) must be used to ensure proper ground<strong>in</strong>g.<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 19

Thermal management<br />

Air flow<br />

Before start<strong>in</strong>g with any calculation, an important po<strong>in</strong>t to consider is the airflow. In<br />

general hot air is mov<strong>in</strong>g upwards with relatively low speed. The form and position of<br />

the heat s<strong>in</strong>k is <strong>in</strong>fluenc<strong>in</strong>g the airflow. If the f<strong>in</strong>s are perpendicular to the airflow which<br />

reduces the efficiency of the heat s<strong>in</strong>k. This situation should be avoided.<br />

A better way to position the f<strong>in</strong>s is to have the f<strong>in</strong>s parallel to the airflow direction.<br />

Clos<strong>in</strong>g the top of the profile will reduce the efficiency of the heat s<strong>in</strong>k as well, and<br />

should be avoided dur<strong>in</strong>g design and <strong>in</strong>stallation.<br />

Thermal model<br />

Standard STATIC thermal situations can be modelled with so-called thermal resistances.<br />

These resistances behave like electrical resistors. Below the analogy between electrical<br />

and thermal resistors is expla<strong>in</strong>ed. Where on the left the electrical units are mentioned,<br />

on the right the thermal equivalent is set. With a known voltage difference at a certa<strong>in</strong><br />

current it is possible to calculate an electrical resistor with Ohm’s law. The same is<br />

possible with a thermal resistor. If the temperature difference and the thermal power is<br />

known, the thermal resistance can be calculated with thermal Ohm’s law.<br />

Analogy between electrical and thermal resistance<br />

Thermal model<br />

20 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Calculat<strong>in</strong>g your heat s<strong>in</strong>k<br />

We start with a thermal calculation formula:<br />

Formula (f1) the relation between temperature difference, thermal power and thermal<br />

resistance. With this formula the needed thermal resistance can be calculated when the<br />

thermal power and temperature difference are known.<br />

Formulas:<br />

Thermal: Δ T = Rth x Pth (f1)<br />

Next we gather all available <strong>in</strong>formation, as can be found <strong>in</strong> the datasheet, application<br />

details and design choices.<br />

Below we calculate the needed thermal resistance of the heat s<strong>in</strong>k, such that <strong>in</strong> typical<br />

situations, the typical temperature of the test po<strong>in</strong>t Tc, is below its maximum.<br />

Available <strong>in</strong>formation<br />

Tc-max = 70ºC<br />

Pth- Twistable DLM 2000 lm, 3000 K = 19.1 W<br />

Tambient-max <strong>in</strong> application = 50ºC<br />

Below we show an example of how to calculate the needed thermal resistance of the<br />

heat s<strong>in</strong>k, such that <strong>in</strong> worst case situations, the maximum temperature of the test po<strong>in</strong>t<br />

Tc, is below its maximum.<br />

Calculation of total maximum thermal resistance: (f1)<br />

ΔT - Tlmb = 70 – 45 = 25ºC<br />

Rth = ΔT / Pth = 25/19 = 1.31 K/W<br />

Now we know the thermal resistance of the needed heat s<strong>in</strong>k. This heat s<strong>in</strong>k dimension<br />

is such that at maximum power and maximum ambient temperature claimed by the<br />

lum<strong>in</strong>aire makers, the temperature of the test po<strong>in</strong>t Tc should be below 70°C. This<br />

assures that lifetime, color temperature, and light output will be accord<strong>in</strong>g to specifications.<br />

The heat s<strong>in</strong>k dimension can be smaller if the lum<strong>in</strong>aire maker claims a Tambient-max less<br />

than 45ºC. Calculation would be carried out accord<strong>in</strong>g to a similar methodology.<br />

Interested <strong>in</strong> the heats<strong>in</strong>k complementary partners:<br />

Three of the heats<strong>in</strong>k partners that have been work<strong>in</strong>g with <strong>Philips</strong> are Nuventix,<br />

AVC, and Sunon. All three have made heats<strong>in</strong>ks specifically for Fortimo LED Twistable<br />

Downlight Modules accord<strong>in</strong>g to the reference heats<strong>in</strong>k design from <strong>Philips</strong>.<br />

The follow<strong>in</strong>g are suggestions of products that can be used with certa<strong>in</strong> <strong>Philips</strong> Fortimo<br />

LED Twistable Downlight Modules. References to these products does not constitute<br />

their endorsement by <strong>Philips</strong>. <strong>Philips</strong> makes no warranties regard<strong>in</strong>g these products and<br />

assumes no legal liability or responsibility for loss or damage result<strong>in</strong>g from the use of<br />

the <strong>in</strong>formation here<strong>in</strong>.<br />

• www.avc.com.tw<br />

• www.nuventix.com<br />

• www.sunoueurope.com<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 21

Electrical design<br />

Wir<strong>in</strong>g<br />

The ma<strong>in</strong>s supply cale must be connected to the lampholder.<br />

The earth connector needs to be connected to the heats<strong>in</strong>k/lum<strong>in</strong>aire because the<br />

Fortimo LED Twistable Downlight Module Gen 2 is specified as class I.<br />

The lampholder is screwed with 3x M3 metal screws to the heats<strong>in</strong>k.<br />

In an assembly scenario where metal screws are not used to fix the heat s<strong>in</strong>k to the<br />

module, then a non-isolated thermal <strong>in</strong>terface material (also known as electrically<br />

conductive TIMs) must be used to ensure proper ground<strong>in</strong>g.<br />

Length of ma<strong>in</strong>s cable<br />

The length of the ma<strong>in</strong>s supply cable from the module is approximately 25 cm. The<br />

length of the extension cable outside of the lum<strong>in</strong>aire is not specified.<br />

Start<strong>in</strong>g characteristics<br />

The system can be switched on <strong>in</strong> milliseconds, which is a general characteristic<br />

of LED based systems. Unlike conventional CFL’s, there is no observable<br />

start up time.<br />

Low and overvoltage<br />

The modules can withstand a voltage fluctuation of +/- 10% with no safety<br />

issue and no abnormal early failures.<br />

Inrush current<br />

The current that flows dur<strong>in</strong>g the very first few milliseconds when switch<strong>in</strong>g on a<br />

lum<strong>in</strong>aire or an entire light<strong>in</strong>g <strong>in</strong>stallation is called the <strong>in</strong>rush current. This current<br />

is very important when mak<strong>in</strong>g the right choice of switch gear and fus<strong>in</strong>g, e.g. circuit<br />

breakers, m<strong>in</strong>iature circuit breakers (MCB). The <strong>in</strong>rush current is determ<strong>in</strong>ed <strong>in</strong> part by<br />

the circuitry <strong>in</strong> use and <strong>in</strong> part by the properties of the ma<strong>in</strong>s supply, viz. the ma<strong>in</strong>ssupply<br />

impedance and the supply-cable resistance. The moment of switch<strong>in</strong>g <strong>in</strong> relation<br />

to the s<strong>in</strong>e wave of the supply voltage also determ<strong>in</strong>es the value of the <strong>in</strong>rush current.<br />

The highest <strong>in</strong>rush current is when the driver is connected to the ma<strong>in</strong>s at the peak of<br />

the ma<strong>in</strong>s voltage.<br />

22 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Product Ma<strong>in</strong>s <strong>in</strong>put power (W) Inrush current (A) Half time value (µs)<br />

Twist 1100 lm 16.5 1.52 45<br />

Twist 2000 lm 29.5 2.0 50<br />

Product B16 B10 C16 C10<br />

Twist 1100 lm 40 40 40 40<br />

Twist 2000 lm 40 38 40 38<br />

Recommended maximum number of modules to be connected to a circuit breaker type<br />

Note: Numbers could slightly differ depend<strong>in</strong>g on the circuit breaker and amount of<br />

modules <strong>in</strong>stalled on a circuit breaker.<br />

Dimm<strong>in</strong>g<br />

The <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 is lead<strong>in</strong>g edge dimmable.<br />

Please contact your <strong>Philips</strong> sales representative for the most up-to-date dimmer<br />

compatibility list.<br />

Switch<strong>in</strong>g<br />

The maximum number of switch<strong>in</strong>g cycles at each case temperature up to which the<br />

modules reaches B10L0 at 35khrs:<br />

Max. cycles to B10L0 Twist NAM 1100lm Twist NAM 2000lm<br />

Tcase=70C 4000-4500 3500-4000<br />

Tcase=65C 6000-6500 5000-5500<br />

Tcase=55C 10000-12000 8500-9500<br />

Notes: <strong>Philips</strong> ma<strong>in</strong>ta<strong>in</strong>s a tolerance of ± 6.5% on lum<strong>in</strong>ous flux, ± 2% on CRI<br />

measurements and ± 5% on CCT measurements.<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 23

Quality<br />

Compliance and approval marks<br />

The <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 is UL/CSA-approved.<br />

To ensure lum<strong>in</strong>aire approval, the conditions of acceptance need to be fulfilled.<br />

Module-related data can be found <strong>in</strong> UL1993. All lum<strong>in</strong>aire manufacturers are advised<br />

to conform to the <strong>in</strong>ternational standards of lum<strong>in</strong>aire design (UL1598-Lum<strong>in</strong>aires).<br />

Susta<strong>in</strong>ability<br />

The <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 is RoHS compliant. 4<br />

Conditions of acceptance<br />

Details can be requested from your local sales representative.<br />

IP rat<strong>in</strong>g, humidity and condensation<br />

The Fortimo LED Twistable Downlight Module systems are build-<strong>in</strong> systems and<br />

therefore have no IP classification. They are not designed for operation <strong>in</strong> the open air.<br />

The OEM is responsible for proper IP classification and approbation of the lum<strong>in</strong>aire.<br />

The module has been developed and released for use <strong>in</strong> damp locations and not for<br />

locations where condensation is present.<br />

Warn<strong>in</strong>gs<br />

If there is a possibility that condensation<br />

could come <strong>in</strong>to contact with the modules,<br />

the system/lum<strong>in</strong>aire builder must take<br />

precautions to prevent this.<br />

Energy Star<br />

The product is listed <strong>in</strong> “The Certified Light<strong>in</strong>g Subcomponent Database” on Energy<br />

Star Website. The l<strong>in</strong>k is below:<br />

http://www.energystar.gov/<strong>in</strong>dex.cfm?c=light<strong>in</strong>g.pr_light<strong>in</strong>g_subcomponents<br />

California Title 24<br />

The product is far more efficient than what is required <strong>in</strong> California Title 24. With<br />

proper optical design at lum<strong>in</strong>arie level, the lum<strong>in</strong>arie will meet California Title 24. 5<br />

EMC<br />

Electromagnetic compatibility, EMC, is the ability of a device or system to operate<br />

satisfactorily <strong>in</strong> its electromagnetic environment without caus<strong>in</strong>g unacceptable<br />

<strong>in</strong>terference <strong>in</strong> practical situations. The module was tested <strong>in</strong> a reference lum<strong>in</strong>aire and<br />

no issues were observed.<br />

24 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

Susta<strong>in</strong>ability<br />

Warn<strong>in</strong>gs<br />

Cautions relat<strong>in</strong>g to use dur<strong>in</strong>g storage,<br />

transportation and operation. If this<br />

product is stored for a long time (more<br />

than one week), it should be stored <strong>in</strong> a<br />

dark place. Do not expose it to sunlight.<br />

The temperature should be ma<strong>in</strong>ta<strong>in</strong>ed at between -40 ~ +65 °C, and RH 5-95%.<br />

Dur<strong>in</strong>g operation<br />

<strong>Philips</strong> shall not be held responsible for any damage to the user aris<strong>in</strong>g from an<br />

accident or any other cause dur<strong>in</strong>g operation of the system if the absolute maximum<br />

rat<strong>in</strong>gs are exceeded.<br />

System disposal<br />

We recommend that the Fortimo LED Twistable Downlight Module and its components<br />

are disposed of <strong>in</strong> an appropriate way at the end of their (economic) lifetime. The<br />

modules are <strong>in</strong> effect normal pieces of electronic equipment conta<strong>in</strong><strong>in</strong>g components<br />

that are currently not considered to be harmful to the environment. We therefore<br />

recommend that these parts are disposed of as normal electronic waste, <strong>in</strong> accordance<br />

with all applicable federal, state and local laws and regulations.<br />

Other<br />

The product has not been evaluated for use with emergency exits.<br />

Contact Details<br />

For specific questions on our products, please contact our regional team.<br />

Footnotes:<br />

1 Philipe Fort<strong>in</strong>o LED Twistable Downlight Module is a Zhaga certified light eng<strong>in</strong>e. For more <strong>in</strong>formation<br />

visit www.zhagestandard.org.<br />

2 All production units fall betweem =/-0.2%<br />

3 +/- 3% variance with all CRI above 80<br />

4 Restrictions on Hazardous Substances (RoHS) is a European directive (2002/95/EC) designed to limit the<br />

content of 6 substances [lead, mercury, cadmium, hexavalent chromium, polybrom<strong>in</strong>ated biphenyls (PBB), and<br />

polybrom<strong>in</strong>ated diphenyl ethers (PBDE)] <strong>in</strong> electrical and electronic products For products used <strong>in</strong> North<br />

America compliance to RoHS is voluntary and self-certified<br />

5 Please refer to http://www.energy.ca.gov/title24/ for the latest requirements.<br />

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 25

26 <strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2

<strong>Design</strong> In Guide <strong>Philips</strong> Fortimo LED Twistable Downlight Module Gen 2 27

© 2013 <strong>Philips</strong> Light<strong>in</strong>g Electronics North America<br />

A Division of <strong>Philips</strong> Electronics North America Corporation<br />

All rights reserved.<br />

Pr<strong>in</strong>ted <strong>in</strong> the USA<br />

Form No. LE-6400-B<br />

<strong>Philips</strong> Light<strong>in</strong>g Electronics N.A.<br />

10275 West Higg<strong>in</strong>s Road<br />

Rosemont, IL 60018<br />

Tel: 800-322-2086 Fax: 888-423-1882<br />

Customer Support/Customer Care: 800-372-3331<br />

OEM Support: 866-915-5886<br />

www.philips.com/ledmodulesna