Couplings for the food industry - SCHMIDT-KUPPLUNG

Couplings for the food industry - SCHMIDT-KUPPLUNG

Couplings for the food industry - SCHMIDT-KUPPLUNG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Couplings</strong> <strong>for</strong> <strong>the</strong> <strong>food</strong> <strong>industry</strong><br />

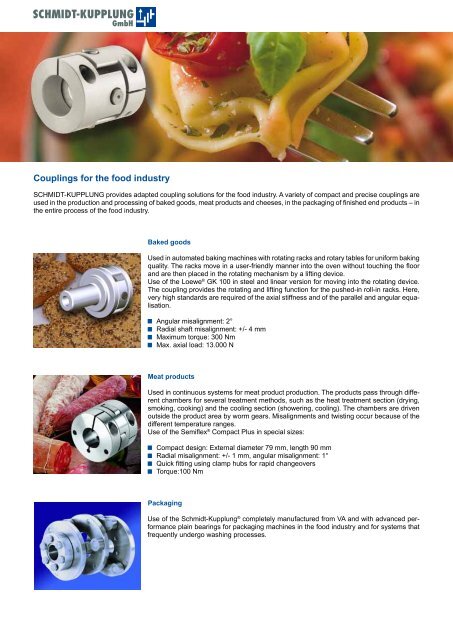

<strong>SCHMIDT</strong>-<strong>KUPPLUNG</strong> provides adapted coupling solutions <strong>for</strong> <strong>the</strong> <strong>food</strong> <strong>industry</strong>. A variety of compact and precise couplings are<br />

used in <strong>the</strong> production and processing of baked goods, meat products and cheeses, in <strong>the</strong> packaging of finished end products – in<br />

<strong>the</strong> entire process of <strong>the</strong> <strong>food</strong> <strong>industry</strong>.<br />

Baked goods<br />

Used in automated baking machines with rotating racks and rotary tables <strong>for</strong> uni<strong>for</strong>m baking<br />

quality. The racks move in a user-friendly manner into <strong>the</strong> oven without touching <strong>the</strong> floor<br />

and are <strong>the</strong>n placed in <strong>the</strong> rotating mechanism by a lifting device.<br />

Use of <strong>the</strong> Loewe ® GK 100 in steel and linear version <strong>for</strong> moving into <strong>the</strong> rotating device.<br />

The coupling provides <strong>the</strong> rotating and lifting function <strong>for</strong> <strong>the</strong> pushed-in roll-in racks. Here,<br />

very high standards are required of <strong>the</strong> axial stiffness and of <strong>the</strong> parallel and angular equalisation.<br />

Angular misalignment: 2°<br />

Radial shaft misalignment: +/- 4 mm<br />

Maximum torque: 300 Nm<br />

Max. axial load: 13.000 N<br />

Meat products<br />

Used in continuous systems <strong>for</strong> meat product production. The products pass through different<br />

chambers <strong>for</strong> several treatment methods, such as <strong>the</strong> heat treatment section (drying,<br />

smoking, cooking) and <strong>the</strong> cooling section (showering, cooling). The chambers are driven<br />

outside <strong>the</strong> product area by worm gears. Misalignments and twisting occur because of <strong>the</strong><br />

different temperature ranges.<br />

Use of <strong>the</strong> Semiflex ® Compact Plus in special sizes:<br />

Compact design: External diameter 79 mm, length 90 mm<br />

Radial misalignment: +/- 1 mm, angular misalignment: 1°<br />

Quick fitting using clamp hubs <strong>for</strong> rapid changeovers<br />

Torque:100 Nm<br />

Packaging<br />

Use of <strong>the</strong> Schmidt-Kupplung ® completely manufactured from VA and with advanced per<strong>for</strong>mance<br />

plain bearings <strong>for</strong> packaging machines in <strong>the</strong> <strong>food</strong> <strong>industry</strong> and <strong>for</strong> systems that<br />

frequently undergo washing processes.

| Scope of Per<strong>for</strong>mance |<br />

PRODUCTS<br />

Semiflex ® Schmidt-Kupplung ® Controlflex ® Omniflex ® Loewe ® GK<br />

The compact<br />

precision coupling with<br />

high per<strong>for</strong>mance<br />

The precision<br />

coupling <strong>for</strong> an<br />

extreme offset<br />

The ideal coupling<br />

<strong>for</strong> shaft<br />

encoders<br />

The coupling<br />

<strong>for</strong> maximum<br />

torque<br />

The coupling<br />

with high axial<br />

stiffness<br />

Sector-specific designs<br />

Our know-how in drive technology is based<br />

on 45 years of experience. We understand<br />

<strong>the</strong> applications in <strong>the</strong> most diverse sectors<br />

and provide specially tailored coupling designs.<br />

Application-specific solutions<br />

We provide coupling solutions adapted precisely to application-specific requirements,<br />

with special emphasis on customer proximity and orientation combined<br />

with technical creativity.<br />

We support <strong>the</strong> user in each phase of conception and implementation of a project<br />

and give priority to optimisation of <strong>the</strong> individual drive train.<br />

Besides expert advice – also gladly provided on location – we offer additional<br />

services such as FEM analysis, coordination of prototypes and preparation of<br />

rapid prototyping models, as well as confirmation of <strong>the</strong> calculated design data on<br />

modern test benches.<br />

Wilhelm-Mast-Straße 15 · 38304 Wolfenbüttel<br />

Fon 0 5331 9552-500 · Fax 0 5331 9552-552<br />

info@schmidt-kupplung.com · www.schmidt-kupplung.com