Betonbloc - Sedpa

Betonbloc - Sedpa

Betonbloc - Sedpa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MANUFACTURE<br />

Manufacturing the blocks<br />

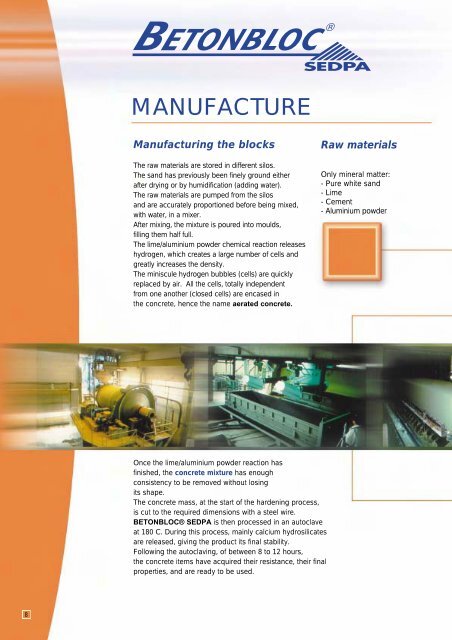

The raw materials are stored in different silos.<br />

The sand has previously been finely ground either<br />

after drying or by humidification (adding water).<br />

The raw materials are pumped from the silos<br />

and are accurately proportioned before being mixed,<br />

with water, in a mixer.<br />

After mixing, the mixture is poured into moulds,<br />

filling them half full.<br />

The lime/aluminium powder chemical reaction releases<br />

hydrogen, which creates a large number of cells and<br />

greatly increases the density.<br />

The miniscule hydrogen bubbles (cells) are quickly<br />

replaced by air. All the cells, totally independent<br />

from one another (closed cells) are encased in<br />

the concrete, hence the name aerated concrete.<br />

Raw materials<br />

Only mineral matter:<br />

- Pure white sand<br />

- Lime<br />

- Cement<br />

- Aluminium powder<br />

Once the lime/aluminium powder reaction has<br />

finished, the concrete mixture has enough<br />

consistency to be removed without losing<br />

its shape.<br />

The concrete mass, at the start of the hardening process,<br />

is cut to the required dimensions with a steel wire.<br />

BETONBLOC® SEDPA is then processed in an autoclave<br />

at 180 C. During this process, mainly calcium hydrosilicates<br />

are released, giving the product its final stability.<br />

Following the autoclaving, of between 8 to 12 hours,<br />

the concrete items have acquired their resistance, their final<br />

properties, and are ready to be used.<br />

8