Norinco, your partner every day - IPC Teknik AB

Norinco, your partner every day - IPC Teknik AB

Norinco, your partner every day - IPC Teknik AB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Norinco</strong>,<br />

<strong>your</strong> <strong>partner</strong> <strong>every</strong> <strong>day</strong><br />

Our culture of forging long-term <strong>partner</strong>ships is our key strength. With this catalogue containing <strong>Norinco</strong>s complete<br />

modular range of products, we aim to support our customers by responding to their needs and specifications.<br />

We offer our <strong>partner</strong>s a global service and technical expertise based on our development capacity.<br />

EJIW<br />

NORINCO UK<br />

NORINCO FRANCE<br />

NORINCO IBERICA<br />

NORINCO DEUTSCHLAND<br />

NORFOND<br />

NORSTEEL<br />

NORINCO ITALIA<br />

NORLONG<br />

NORCOMP<br />

EJ AMÉRICA<br />

LATINA<br />

NORINCO develops, produces, and markets the most<br />

extensive ranges of solutions in ductile cast iron,<br />

galvanised steel and aluminium for:<br />

- Municipal castings & accessories<br />

- Telecommunications and cable networks<br />

- Major projects such as tunnels, exhibition halls,<br />

ports and airports<br />

- Watertight networks: MODULAR Ermatic® range<br />

A few figures on NORINCO:<br />

- 4 industrial sites producing more than<br />

120 000 tons<br />

- 8 commercial subsidiaries<br />

- Customers in more than 140 countries across<br />

5 continents<br />

- More than 1000 employees<br />

<strong>Norinco</strong> has been a member of EJ GROUP since 2004.<br />

Headquartered in East Jordan, Michigan, USA, the EJ<br />

GROUP with manufacturing facilities in North America,<br />

Europe and Asia, multiple research and development centers,<br />

and a global network of subsidiaries, distributors<br />

and agents, offers global resources to local markets<br />

throughout the world.<br />

Some of our references throughout the world<br />

Telecommunications and cable:<br />

France Telecom, Telecom Italia, Infratelitalia,<br />

Fastweb, Metroweb, Wind, Colt, AEM<br />

Telecomunicazioni, Telefónica, ONO, Deutsche<br />

Telekom, SingTel, PLDT, Portugal Telecom, TELKOM,<br />

INDOSAT, TELKOMEL, Kingston Communications,<br />

PACIFICTEL Ecuador, CTC Telefónica Chile..<br />

Airports:<br />

Heathrow (UK), Madrid Barajas (Spain), Roissy CDG<br />

(France) Dublin (Ireland), Frankfurt, Stuttgart,<br />

Munich (Germany), Athens (Greece), Dubaï<br />

International (UAE), Linate Milan Milan Malpensa,<br />

Ezeiza ( Argentina), Miami International Airport<br />

(USA), Johannesburg International Airport (South<br />

Africa), Sangster International Airport...<br />

Ports and other major projects: Dubaï Dock (UAE),<br />

Portsmouth (UK), Dunkerque, Rouen (France),<br />

Trieste (Italy), Valencia (Spain), Channel tunnel,<br />

Disneyland Paris, TGV train stations, Bilbao<br />

Exhibition Centre, etc.<br />

www.norinco.fr

CLASS<br />

E 600<br />

EN 124: 1994<br />

Access covers and frames features p.3<br />

Assisted opening p.5<br />

Quality assurance p.7<br />

Other solutions p.9<br />

Classification p.11<br />

Selection guide p.12<br />

NORINCO will not be responsible under any<br />

circumstances for having suggested a place<br />

of installation by use of this brochure.<br />

s u m m a r y<br />

1/2/3 PART COVERS ..............p.13<br />

Class B125<br />

recessed covers for concrete infill p.15<br />

with solid top anti-slip surface p.17<br />

Class C 250<br />

recessed covers for concrete infill p.19<br />

with solid top anti-slip surface p.21<br />

Class D 400<br />

recessed covers for concrete infill p.23<br />

with solid top anti-slip surface p.25<br />

Class E 600<br />

recessed covers for concrete infill p.27<br />

with solid top anti-slip surface p.29<br />

Class F 900<br />

recessed covers for concrete infill p.31<br />

with solid top anti-slip surface p.33<br />

DUCT COVERS ................................p.35<br />

Class B125<br />

recessed covers for concrete infill p.37<br />

with solid top anti-slip surface p.39<br />

Class C 250<br />

recessed covers for concrete infill p.41<br />

with solid top anti-slip surface p.43<br />

Class D 400<br />

recessed covers for concrete infill p.45<br />

with solid top anti-slip surface p.47<br />

Class E 600<br />

recessed covers for concrete infill p.49<br />

with solid top anti-slip surface p.51<br />

Class F 900<br />

recessed covers for concrete infill p.53<br />

with solid top anti-slip surface p.55<br />

MULTIPLE BEAM COVERS ...p.57<br />

Class B125<br />

recessed covers for concrete infill p.59<br />

with solid top anti-slip surface p.61<br />

Class C 250<br />

recessed covers for concrete infill p.63<br />

with solid top anti-slip surface p.65<br />

Class D 400<br />

recessed covers for concrete infill p.67<br />

with solid top anti-slip surface p.69<br />

Class E 600<br />

recessed covers for concrete infill p.71<br />

with solid top anti-slip surface p.73<br />

Class F 900<br />

recessed covers for concrete infill p.75<br />

with solid top anti-slip surface p.77<br />

Installation recommendations.............................p.79<br />

Concrete infill of covers .....................................p.85<br />

Operation of Ermatic® covers ............................p.86<br />

Ductile iron ......................................................p.87<br />

www.norinco.fr

ERMATIC® ACCESS COVERS AND FRAMES FEATURES<br />

Ermatic® is a comprehensive and highly specified range of access covers for diverse underground services<br />

Sewerage: inspection pits for sludge chambers, access shafts for large plants.<br />

Telecommunications: cable jointing chambers.<br />

Electricity: lighting, signals, transformer pits, cable joint boxes.<br />

Potable water, gas, district heating, valve chambers, manifold chambers and meter chambers<br />

In the following environments:<br />

Airports and ports,<br />

Railways,<br />

Power stations,<br />

Water treatment and purification plants,<br />

Manufacturing plants,<br />

Industries,<br />

Exhibition centres, leisure parks, tunnels, Stadiums...<br />

Ermatic® assures protection against damage, debris or aggressive chemicals, and allows designers to<br />

conceal underground services, maximising productive use of the unobstructed surface.<br />

Modular construction<br />

The use of modular elements gives a vast range of sizes<br />

rame elements (side frames and end plates) are assembled using bolts and aluminium joints to provide<br />

linear openings for even the longest ducts.<br />

Above clear opening spans of 1200 mm, Ermatic® units employ removable beams supported in boxes<br />

which are fixed to the frames. This permits the construction of units to suit the largest openings.<br />

1/2/3 – part unit<br />

Duct cover<br />

Multiple unit with<br />

removable beams<br />

Stability and sealing<br />

The horizontal and vertical faces of the cover and frame are machined to give metal-to-metal contact between the seating faces, within a tolerance<br />

of 0.2 mm.<br />

Stability: when correctly installed, Ermatic® products are non-rocking, silent under traffic and prevent the ingress of dust and debris.<br />

Sealing: the addition of a film of grease to the machined contact faces of the cover and frame renders the Ermatic® cover watertight<br />

under normal rainwater conditions.<br />

Machined<br />

contact faces<br />

3<br />

www.norinco.fr

ES<br />

Environment, security, ergonomics, the Ermatic® range benefits from the advanced technology of the<br />

<strong>Norinco</strong> Group:<br />

aesthetics of the project is enhanced: the covers can be recessed to receive a similar material to the<br />

surround,<br />

rapid and easy access for maintenance and development of the network,<br />

security reinforced by the strength and stability of the covers.<br />

GENERAL PRESENTATION<br />

Types of surface finish available<br />

Designed for a wide range of applications, The Ermatic® range offers a choice of covers<br />

to suit <strong>every</strong> specification of performance and/or appearance.<br />

Solid top cover with uniform anti-slip surface<br />

This cover offers unequaled performance whilst being lighter than recessed covers of a comparable size<br />

when filled with concrete. Installation costs are reduced and the performance is not influenced by the quality<br />

of the concrete infill.<br />

Cover recessed for concrete infill<br />

In classes B 125 and C 250, the ribs are positioned below the surface of the cover to permit the installation of thin<br />

paving.This type of cover is particularly suited to large openings where aesthetic considerations are a priority.<br />

The concrete infill is undertaken in accordance with the requirements of EN124 and with <strong>Norinco</strong>’s<br />

specifications detailed in this brochure (see page 85)<br />

Other types:<br />

Covers recessed for small element paving for pedestrian areas (see pages 20 - 42 - 64)<br />

Cover with central removable plug (see pages 22 and 34)<br />

Painting<br />

Covers and frames: painted with water soluble black paint except for machined surfaces and surfaces<br />

in contact with concrete. Where products are delivered in a dismantled condition, all machined<br />

surfaces are coated with a protective film.<br />

Handling with ease<br />

Covers slide in and out of the frame along greased, machined seatings, requiring no vertical lift.<br />

Ermatic® key: ergonomically assists with safety. Further reduces the effort required to remove and replace<br />

covers.<br />

Universal keyways<br />

For use with many different types of common lifting keys.<br />

Fitted with polyethylene blanking plugs to prevent the entry of debris or concrete.<br />

Ribs extend below the underside of the cover<br />

To protect the machined seatings, the reinforcing webs are deeper than the cover. This also prevents<br />

any greased surfaces coming into contact with the floor (except for some B 125 recessed covers). (see<br />

handling page 86)<br />

Locking of the covers<br />

In order to ensure an easier and more optimised installation of our Ermatic® systems, it has been<br />

decided to supply all the products in D400 systematically locked. For E600 and F900 productslocking<br />

is recommended for the same reasons.<br />

Adjusting bolts<br />

In order to facilitate the levelling of Ermatic® systems, adjusting bolts are supplied with<br />

the products. These bolts will allow, if necessary, to adjust the height of the system to the<br />

final level and correct any possible defects of the civil work.<br />

www.norinco.fr<br />

4

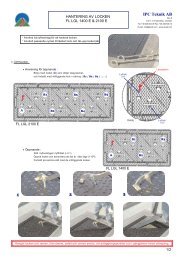

NEW<br />

HINGES & GAS ASSISTED OPENING SYSTEM<br />

ON THE COVERS TO EASE HANDLING<br />

Advantages<br />

Particularly recommended for frequent use<br />

Minimize effort when opening the covers<br />

Cover watertightness is conserved<br />

Original specifications of product are conserved<br />

Standard gas assisted opening systems are protected<br />

gas assisted opening system<br />

Projects: contact us<br />

Hinge of Ermatic® covers:<br />

principle and opening order of covers<br />

changing of standard dimensions<br />

clear opening<br />

height overall dimension<br />

1 2<br />

PL (a) =<br />

OL (a) - 180 mm<br />

PL (b) =<br />

OL (b) - 150 mm<br />

150<br />

500<br />

125<br />

1 2<br />

200<br />

chamber clear opening<br />

200<br />

ladder positioning<br />

5<br />

www.norinco.fr

System available on Ermatic®<br />

solid top covers Class D 400 -<br />

class E600 - class F900<br />

Hinges and gas assisted<br />

opening system will be soon<br />

available on Ermatic® covers<br />

class B125 and class C250<br />

GENERAL PRESENTATION<br />

opening provided by ergonomic key<br />

NOTE : for duct and beam multiple covers<br />

technical assistance provided on site<br />

Operation<br />

Options<br />

Stainless steel gas strut or spring loaded<br />

struts<br />

Deployable safety barrier<br />

Fall protection safety grid<br />

opening order of hinged covers<br />

Integral skirt supporting the struts and<br />

acting as shuttering<br />

Motorised opening of covers<br />

www.norinco.fr<br />

6

Beste lung :<br />

PRODUKT<br />

150<br />

0<br />

80<br />

Chc key<br />

NORFOND<br />

COVER<br />

70<br />

NORFOND<br />

1/ 25<br />

NORFOND<br />

GROUPE NORINCO<br />

www.norinco.fr<br />

685<br />

<strong>Norinco</strong> Deutschland GmbH<br />

Einemstrafle 5<br />

D-10787 Berlin<br />

Tel. +49-30-2 51-0<br />

Fax +49-30-2 0 51-2 9<br />

170<br />

20<br />

150<br />

1455<br />

450<br />

250<br />

Datum :<br />

250<br />

DETAILS<br />

3/3<br />

PRODUKT<br />

ERMATICÆ ER5R199214VCHC Artikelnummer : 515075<br />

Bestellung :<br />

0<br />

Beschreibung :<br />

ERMATICÆ D400 Fl‰chenabdeckung zur bauseitigen Betonf¸llung verriegelt CHC<br />

Gewicht :<br />

1503 Kg<br />

÷ffnungsrichtung<br />

0<br />

470<br />

L‰nge gesamt :<br />

Breite gesamt :<br />

450<br />

Shu tering<br />

360<br />

Frame<br />

2350<br />

2360<br />

Wa l boxe<br />

500<br />

E<br />

MA<br />

R<br />

TIC<br />

O<br />

E<br />

MA<br />

R<br />

TIC<br />

O<br />

RE<br />

TAM<br />

CI<br />

O<br />

2140<br />

NORFOND<br />

600 600 600<br />

A<br />

B<br />

C<br />

500<br />

O<br />

O<br />

Maflstab : Erstellt von : Datum : - Angaben zu Gewicht, Grˆ{fle sind unverbindlich.<br />

1/ 20<br />

at 14/04/2006<br />

NORFOND<br />

<strong>Norinco</strong> Deutschland GmbH<br />

- ƒnderungen<br />

Dieses Dokument<br />

vorbehalten.<br />

ist Eigentum von Norfond und darf nicht ohne<br />

Einemstrafle 5<br />

- Freie<br />

GROUPE NORINCO<br />

Erlaubnis Verbreitung.<br />

D-10787 Berlin<br />

weitergegeben oder vervielf‰ltigt werden.<br />

www.norinco.fr Tel. +49-30-200 51-0 Fax +49-30-200 51-299<br />

norinco@norinco-germany.com<br />

E<br />

MA<br />

R<br />

TIC<br />

O<br />

E<br />

MA<br />

R<br />

TIC<br />

O<br />

RE<br />

TAM<br />

CI<br />

Alle Grˆ{flenangaben in mm.<br />

Rahmen und Deckel aus Guss<br />

GS 500-7 gem‰{fl ISO 1083<br />

O<br />

O<br />

D<br />

E<br />

F<br />

2140<br />

540<br />

170<br />

O<br />

O<br />

O<br />

E<br />

MA<br />

R<br />

TIC<br />

O<br />

E<br />

MA<br />

R<br />

TIC<br />

O<br />

RE<br />

TAM<br />

CI<br />

O<br />

G<br />

H<br />

I<br />

O<br />

O<br />

2/3<br />

O<br />

PLAN<br />

1/3<br />

"EM" Bedienungsschl¸ssel<br />

(2 Stk.)(nicht im Lieferumfang)<br />

QUALITY ASSURANCE<br />

A fully European production<br />

Expertise in design<br />

As per ISO 9001: 2000<br />

As per the exact requirements of clients.<br />

Following EN124: 1994 standard and others standards.<br />

Expertise in production<br />

Material: Ductile (or SG) cast iron.<br />

Products are 100% ductile iron, recyclables<br />

NORFOND<br />

PARIS<br />

Total integration of <strong>every</strong> manufacturing process.<br />

Control manufacturing process and final assessment.<br />

Expertise in customer network<br />

Comprehensive commercial service.<br />

ISO 9001<br />

Ermatic® products are fully conceived and produced<br />

in a European foundry .<br />

Norfond is certified by third parties for conformity to<br />

ISO 9001. This quality management is recognised as a<br />

reference for design, development, production, installation<br />

and after-sales service.<br />

Rapid supply of documentation.<br />

Technical assistance:<br />

At the design stage: from conception<br />

to installation, experts are available to<br />

assist with the selection<br />

of suitable products, including<br />

the provision of drawings of covers<br />

and rebates for ducts and beamed<br />

multiple covers.<br />

During Installation: for<br />

the correct installation of<br />

large or complex covers,<br />

the production centre can<br />

provide,upon request,<br />

skilled technicians to assist<br />

with the installation process.<br />

After-sales service.<br />

Section on frame bar and cover<br />

SG Iron to ISO 1083 / EN1563, Grade 500-7<br />

ERMATICÆ ER5R199214VCHC Artikelnummer : 515075<br />

110 Clear Opening<br />

Peripheral reservation<br />

Stainle st el Chc screw<br />

Stainle st el washer<br />

Neoprene washer<br />

Longitudinal section on beam and boxes<br />

icht, Grˆ{fle sind unverbindlich.<br />

Angaben zu Gew<br />

- ƒnderungen vorbehalten.<br />

- Freie Verbreitung.<br />

TRANSVERSE SECTION ON BEAM<br />

Beam IPE360<br />

Leve ling bolts<br />

Leve ling st el shims<br />

Clear Opening<br />

REMOV<strong>AB</strong>LE BEAM IPE360<br />

170 Clear Opening<br />

170<br />

Erste lt von :<br />

at 14/04/2006<br />

<strong>Norinco</strong> Deutschland GmbH<br />

Einemstrafle 5<br />

Dieses Dokument ist Eigentum von Norfond und<br />

D-10787 Berlin<br />

GROUPE NORINCO Tel darf nicht ohne Erlaubnis weitergegeben oder vervielf‰ltigt werden.<br />

www.norinco.fr . +49-30-200 51-0 Fax +49-30-200 51-299<br />

norinco@norinco-germany.com<br />

A le Grˆ{flenangaben in mm.<br />

1990<br />

Beste lung :<br />

1990<br />

PRODUKT<br />

540<br />

ERMATICÆ ER5R199214VCHC Artikelnummer : 515075<br />

250<br />

NORFOND<br />

250<br />

1990<br />

VERMAflUNG<br />

- Angaben zu Gewicht, Grˆ{fle sind unverbindlich.<br />

- ƒnderungen vorbehalten.<br />

- Freie Verbreitung.<br />

600 600 750<br />

Maflstab : Erste lt von : Datum :<br />

at 14/04/2006<br />

norinco@norinco-germany.com<br />

Dieses Dokument ist Eigentum von Norfond und darf<br />

nicht ohne Erlaubnis weitergegeben oder vervielf‰ltigt werden.<br />

Products are made from 100% ductile iron:<br />

Ductile iron provides reliability and strength. Ductile iron<br />

is produced by converting the inherently brittle grey cast<br />

iron, by the addition of magnesium before pouring. This<br />

gives a material with high flexibility, particularly resistant to<br />

forces and shock. (See p. 87)<br />

ISO 14001<br />

Environmental responsibility, conformity<br />

with standards, compliance with laws<br />

and a resolutely eco-friendly approach<br />

are all factors strengthening NORINCO’s<br />

reputation, its image and its growth<br />

potential. Protecting the environment<br />

is at the heart of our strategy.<br />

NORFOND is ISO 14001 certified since<br />

2008.<br />

7<br />

www.norinco.fr

COVER AND FRAME CONFORMITY<br />

EN124 Standard<br />

Ermatic® Range<br />

GENERAL PRESENTATION<br />

Determines the following characteristics of covers and frames:<br />

Principles of construction: frame depth, depth of insertion, seatings,<br />

surface condition etc.<br />

Material used for the manufacture of covers.<br />

Testing regime: test loads and permanent set limits<br />

All Ermatic® covers are designed to meet all the<br />

requirements of the EN124 standard.<br />

All Ermatic® covers are manufactured from ductile iron according<br />

to ISO 1083 and EN 1563.<br />

All solid top covers and recessed B125/C250/D400/E600<br />

covers are tested in the as-cast condition and meet all the test criteria<br />

of the EN124 standard. F900 recessed covers and<br />

ER6R ...120 attain resistance characteristics after filling with<br />

concrete, complying with EN124 standards and the recommendations<br />

on page 85.<br />

Loading and conformity certificates in accordance with the requirements<br />

of EN124<br />

The dimensions of removable beams in multiple units are<br />

derived from the following French<br />

specifications<br />

Ermatic® B 125: .....................Loading 500 daN/m 2<br />

Ermatic® C 250: ..............CCTG volume 61 - clause 2<br />

Ermatic® D 400: ..............CCTG volume 61 - clause 2<br />

Ermatic® E 600/F 900: ....................ADP and STBA<br />

Requires a quality system equivalent to ISO 9002.<br />

Requires that products are clearly marked with the mark<br />

of a certification body.<br />

The design and manufacture of Ermatic® covers is undertaken<br />

within one facility operating a quality system certified by third party<br />

to ISO 9001.<br />

The EN124 standard is limited to covers with a clear<br />

opening dimension 1000 mm. Consequently, units above this<br />

dimension, particularly those that utilise removable beams, are<br />

outside the scope of EN124. However, some 1,2 and 3 part solid<br />

top units, from which multiples are constructed, carry third party<br />

certification to conform with the requirements of EN124 (please<br />

consult us for further information).<br />

Product characteristics are dependent upon correct installation in accordance with the recommendations on p. 79.<br />

Drawings, photos, dimensions and weights are given as an indication without any contractual value. Our policy is one of<br />

continuous product improvement, we reserve the right to modify product specifications without prior notice.<br />

www.norinco.fr<br />

8

OTHER TECHNICAL SOLUTIONS<br />

<strong>Norinco</strong> also has other ranges of innovative products for all applications.<br />

<strong>Norinco</strong>'s commercial and technical departments work together to consider specific product development studies in close<br />

collaboration with clients. If you have any such project where the ideal Ermatic® cover is not depicted in this catalogue,<br />

please contact us:<br />

Telecom and cable networks<br />

SG cast iron triangular covers and frames<br />

SG cast iron triangular covers and galvanised steel frames<br />

Class B125 - C250- D400 - E600 - F900<br />

Municipal castings<br />

SG cast iron covers and frames<br />

Class B125 - C250- D400 - E600 - F900<br />

SG cast iron gratings, duct gratings and kerb gully gratings<br />

Class F900 - E600 - D 400 - C250 - B125<br />

Other solutions<br />

Multiple access covers<br />

and frame with removable beams<br />

SG cast iron cover<br />

Galvanised steel frame<br />

Multiple access covers and frame with removable beams<br />

SG triangular cast iron standard or<br />

hinged cover / Galvanised steel frame<br />

Class B125- C250<br />

9<br />

www.norinco.fr

LOADING CLASSES AND THEIR APPLICATIONS<br />

GENERAL PRESENTATION<br />

PRÉSENTATION<br />

GÉNÉRALE<br />

The EN124 standard introduced the idea of<br />

groups and minimum class, depending on the place<br />

of installation of access covers and frames.<br />

Recommended Ermatic®<br />

GROUP 1 (class A 15 minimum)<br />

Design load: 15 kN<br />

Place of installation:<br />

Areas which can only be used by<br />

pedestrians and pedal cyclists.<br />

GROUP 2 (class B125 minimum)<br />

Design load: 125 kN<br />

Place of installation:<br />

Footways, pedestrian areas and<br />

comparable areas, car parks or car parking decks<br />

Ermatic® B125<br />

Place of installation:<br />

Group 2 and lower.<br />

GROUP 3 (class C250 minimum)<br />

Design load: 250 kN<br />

Place of installation:<br />

For gully tops installed in the area of kerbside channels of<br />

roads which when measured from the kerb edge, extend a<br />

maximum of 0.5 m into the carriageway and a maximum of<br />

0.2 m into the footway.<br />

GROUP 4 (class D400 minimum)<br />

Design load: 400 kN<br />

Place of installation:<br />

Carriageways of roads (including pedestrian streets), hard<br />

shoulders and parking areas for all types of road vehicles<br />

Ermatic® C250<br />

Place of installation:<br />

Group 3 and lower including parking<br />

areas for all types of road vehicles,<br />

forecourts and service areas.<br />

Ermatic® D400<br />

Place of installation:<br />

Group 4 and lower.<br />

GROUP 5 (class E600 minimum)<br />

Design load: 600 kN<br />

Place of installation:<br />

Areas imposing high wheel loads e.g. docks, aircraft<br />

pavements.<br />

Ermatic® E600<br />

Place of installation:<br />

Group 5 and lower.<br />

GROUP 6 (class F900 minimum)<br />

Design load: 900 kN<br />

Place of installation:<br />

Areas imposing particularly high wheel loads e.g. docks,<br />

aircraft pavements.<br />

Ermatic® F900<br />

Place of installation:<br />

Group 6 and lower.<br />

The selection of the appropriate class is the responsibility of the designer. Where there is any doubt,<br />

the stronger class should be selected.<br />

www.norinco.fr<br />

10

SELECTION GUIDE<br />

To cover chambers with clear openings (a x b)<br />

up to 3040 mm in lenght x 1 200 mm in width<br />

1/2/3 part covers<br />

Introduction...........................................................P.13<br />

Ermatic® B 125<br />

• Recessed for concrete infill ........................................P.15<br />

• With solid top anti-slip surface ...................................P.17<br />

Ermatic® C 250<br />

• Recessed for concrete infill.........................................P.19<br />

• With solid top anti-slip surface ...................................P.21<br />

Ermatic® D 400<br />

• Recessed for concrete infill.........................................P.23<br />

• With solid top anti-slip surface ...................................P.25<br />

Ermatic® E 600<br />

• Recessed for concrete infill.........................................P.27<br />

• With solid top anti-slip surface ...................................P.29<br />

Ermatic® F 900<br />

• Recessed for concrete infill.........................................P.31<br />

• With solid top anti-slip surface ...................................P.33<br />

clear opening: a<br />

X<br />

3 660 mm<br />

0<br />

1 200 mm 5 180 mm<br />

clear opening: b<br />

X<br />

(please consult us)<br />

11<br />

www.norinco.fr

SELECTION GUIDE<br />

In order to select the ideal Ermatic® cover it is necessary<br />

to consider:<br />

• The required surface condition of the covers (P4)<br />

• Loading classes and their application (P.10)<br />

and finally, the characteristics of the<br />

chamber or duct to be covered.<br />

To cover ducts with clear openings (b) lower than<br />

1 200 mm<br />

Duct covers<br />

Introduction...........................................................P.35<br />

Ermatic® B 125<br />

• Recessed for concrete infill.........................................P.37<br />

• With solid top anti-slip surface ....................................P.39<br />

Ermatic® C 250<br />

• Recessed for concrete infill.........................................P.41<br />

• With solid top anti-slip surface ....................................P.43<br />

Ermatic® D 400<br />

• Recessed for concrete infill.........................................P.45<br />

• With solid top anti-slip surface ....................................P.47<br />

Ermatic® E 600<br />

• Recessed for concrete infill.........................................P.49<br />

• With solid top anti-slip surface ....................................P.51<br />

Ermatic® F 900<br />

• Recessed for concrete infill.........................................P.53<br />

• With solid top anti-slip surface ....................................P.55<br />

clear opening<br />

(a x b)<br />

To cover large chambers with clear openings (a x b)<br />

greater than 1 200 x 1 200 mm<br />

up to 3 660 x 5180 mm.<br />

For sizes in excess of this, please consult us.<br />

Multiple covers with removable beams<br />

Introduction...........................................................P.57<br />

Ermatic® B 125<br />

• Recessed for concrete infill.........................................P.59<br />

• With solid top anti-slip surface ....................................P.61<br />

Ermatic® C 250<br />

• Recessed for concrete infill.........................................P.63<br />

• With solid top anti-slip surface ....................................P.65<br />

Ermatic® D 400<br />

• Recessed for concrete infill.........................................P.67<br />

• With solid top anti-slip surface ....................................P.69<br />

Ermatic® E 600<br />

• Recessed for concrete infill.........................................P.71<br />

• With solid top anti-slip surface ....................................P.73<br />

Ermatic® F 900<br />

• Recessed for concrete infill.........................................P.75<br />

• With solid top anti-slip surface ....................................P.77<br />

12<br />

www.norinco.fr<br />

12