Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

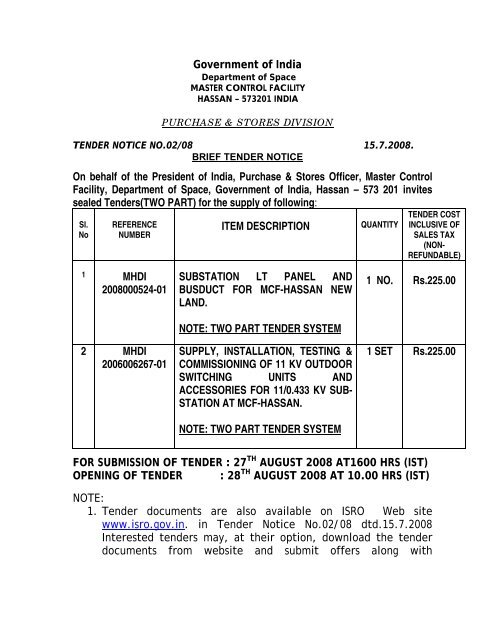

Government of India<br />

Department of Space<br />

MASTER CONTROL FACILITY<br />

HASSAN – 573201 INDIA<br />

PURCHASE & STORES DIVISION<br />

TENDER NOTICE NO.02/08 15.7.2008.<br />

BRIEF TENDER NOTICE<br />

On behalf of the President of India, Purchase & Stores Officer, Master Control<br />

Facility, Department of Space, Government of India, Hassan – 573 201 invites<br />

sealed Tenders(TWO PART) for the supply of following:<br />

Sl.<br />

No<br />

REFERENCE<br />

NUMBER<br />

ITEM DESCRIPTION<br />

QUANTITY<br />

TENDER COST<br />

INCLUSIVE OF<br />

SALES TAX<br />

(NON-<br />

REFUNDABLE)<br />

1 MHDI<br />

2008000524-01<br />

2 MHDI<br />

2006006267-01<br />

SUBSTATION LT PANEL AND<br />

BUSDUCT FOR MCF-HASSAN NEW<br />

LAND.<br />

NOTE: TWO PART TENDER SYSTEM<br />

SUPPLY, INSTALLATION, TESTING &<br />

COMMISSIONING OF 11 KV OUTDOOR<br />

SWITCHING UNITS AND<br />

ACCESSORIES FOR 11/0.433 KV SUB-<br />

STATION AT MCF-HASSAN.<br />

NOTE: TWO PART TENDER SYSTEM<br />

1 NO. Rs.225.00<br />

1 SET Rs.225.00<br />

FOR SUBMISSION OF TENDER : 27 TH AUGUST 2008 AT1600 HRS (IST)<br />

OPENING OF TENDER : 28 TH AUGUST 2008 AT 10.00 HRS (IST)<br />

NOTE:<br />

1. Tender documents are also available on <strong>ISRO</strong> Web site<br />

www.isro.gov.in. in Tender Notice No.02/08 dtd.15.7.2008<br />

Interested tenders may, at their option, download the tender<br />

documents from website and submit offers along with

prescribed tender cost (in form of Demand Draft) as per details<br />

in the tender notification.<br />

2. Tender fee shall be acceptable only in the form of demand draft<br />

drawn in favour of Accounts Officer, Master Control Facility,<br />

payable at Hassan. No other mode of payment for tender fee is<br />

acceptable.<br />

: 2 :<br />

3. Vendors/firms name and tender number shall be indicated on<br />

the reverse side of the Demand Draft.<br />

4. While requesting for tender documents, please do not<br />

superscribe tender number and due date on the envelop.<br />

Instead indicate “Request for Tender Documents”.<br />

5. Demand Draft should not be dated prior to the date of<br />

advertisement/intimation/website (separate requests and<br />

demand draft shall be sent for each tender document).<br />

6. MCF will not be responsible for non-receipt of tender<br />

documents/offers due to postal/delay/loss in transit.<br />

7. Quotations received without payment of tender fee will be<br />

treated as unsolicited.<br />

8. Detailed specification, terms and conditions are furnished in the<br />

tender documents<br />

10.The offer should be valid for a period of Ninety days from the<br />

date of opening.<br />

11.Quotations received after the due date and time will not be<br />

considered.<br />

12.While submitting your offer, please superscribe tender number<br />

and due date on the envelope, addressed to Purchase & Stores<br />

Officer (P), Master Control Facility, Government of India,<br />

Department of Space, Hassan- 573201.<br />

13.If tender opening date happens to be public holiday tender will<br />

be opened on the next working day.<br />

14.Request for the extension of the due date will not be<br />

considered.<br />

15.Purchase & Stores Officer, MCF reserves the right to accept or<br />

reject any tenders in part or full without assigning any reasons<br />

thereof.<br />

16.Those who do not utilize the website shown at clause 01 above<br />

can buy the Tender documents from Purchase & Stores Officer,

Master Control Facility, Department of Space, Hassan-573 201,<br />

on payment of Non-refundable tender fee as indicated above,<br />

on all working days.<br />

PURCHASE & STORES OFFICER

Instructions<br />

Scope of work<br />

Master Control Facility – Hassan<br />

SUBSTATION LT PANEL & BUSDUCT FOR MCF - HASSAN NEW LAND<br />

General requirements<br />

Make<br />

Calibration<br />

Technical specifications<br />

Design standards<br />

complies to<br />

: The offer shall be submitted in two parts.<br />

-Techno-commercial with Un-priced bid.<br />

-Financial offer as per enclosed format.<br />

: GA drawing of the LT panel to be furnished with super imposed SLD and<br />

busbar configuration or proposed dimension of the panel to be furnished.<br />

: Make for all the items in BOM shall be furnished.<br />

: Deviation if any, to be mentioned clearly w.r.t switchgears, mechanical &<br />

electrical specification.<br />

: Each page of the tender document to be signed with seal.<br />

: 10 years of experience in executing similar panels.<br />

: ISO 9001 certified<br />

: CPRI type test certificate for the 50-kA short circuit test shall be<br />

enclosed for panel and bus-duct.<br />

: The offer will not be considered if the submittals are not as per the<br />

above instructions.<br />

: Design, manufacture, testing, supply, installation & commissioning of the<br />

substation LT panel including bus ducts indoor & outdoor as per the SLD<br />

considering applicable mechanical & electrical safety standards.<br />

: Panel fabrication and integration of switchgears shall be as per the<br />

approved General Assembly drawing.<br />

: Routine test of the panels at works prior to dispatch as per IS.<br />

: Input & output power cables termination is not in the scope of the supplier.<br />

: Integration of LT panel sections & interfacing control cables & accessories<br />

at site & functional testing is in the scope of the supplier.<br />

: Any one make of switchgear among the specified in bill of material only to<br />

be selected and used in the panel.<br />

: Make of switchgear should be same, i.e., make of SDFUs of all ratings<br />

should be same and make of ACBs of all ratings should be same, similarly<br />

for other items.<br />

: Any left out or additional requirements of switchgears, spares and control<br />

accessories shall be included.<br />

: Protective devices, Relays & Current Transformers calibration to be carried<br />

out by NABL accredited party other than manufacturer.<br />

: National Electrical Code (NEC-NFPA 70)<br />

: National Electrical Manufacturers Association (NEMA)<br />

: National Fire Protection Association (NFPA 75) and latest IE rules.<br />

Electrical requirements<br />

Rating<br />

: 2.0 MVA, Bus bar continuous current carrying capacity shall be 120% of<br />

the rated 2.0 MVA at 380 VAC.<br />

Input<br />

: 380 to 440VAC at 50 Hz, 3-phase, four-wire-plus-ground.<br />

Output<br />

: 240 / 415 VAC 3-phase, four-wire-plus-ground, wye configuration.<br />

Operating PF : From 0.5 lead to 0.5 lagging.<br />

Short time rating : Short time withstand current 50 kA RMS for 1 sec.<br />

Semi Modular substation LT panel –Specification 1

Master Control Facility – Hassan<br />

Environmental requirements<br />

: Storage temperature range shall be 0° to + 85°C<br />

: Operating temperature range shall be 0° to 50°C<br />

: Operation shall be reliable in an environment with 0% to 95% noncondensing<br />

RH.<br />

Fabrication<br />

Panel design<br />

: Semi-modular design concept shall be adopted for panel fabrication.<br />

: Free standing, floor mounting and suitable for indoor installation.<br />

: Profile should have holes of standard size punched at standard pitch<br />

throughout the length.<br />

: The L / U / square tubular frame shall be assembled with die casted<br />

corners / tripods or baying clamp for three-dimensional flexibility in design<br />

configuration.<br />

: Mounting plate’s -Mild steel, 2 mm, epoxy polyester powder coated.<br />

: Fixtures for mounting switchgears shall provide flexibility for adjustments in<br />

X, Y & Z-axis.<br />

: The panel shall have easily removable and interchangeable sections.<br />

: Horizontal busbars are to be located at the top of the panel.<br />

: Stainless steel high tensile strength fasteners shall be used for panel.<br />

: Stainless steel fasteners set of high tensile strength (consisting of<br />

hexagonal bolt –1 no, flat washers –2 nos, spring washers –1 no and<br />

hexagonal nut –1 no) shall be provided for each termination point.<br />

: The length of the hexagonal bolt shall be adequate for insertion of 3 lugs of<br />

requisite rating.<br />

: Required service clearances shall be provided to carry out preventive and<br />

remedial maintenance from front and rear side.<br />

: The panel shall be naturally convection-cooled & shall allow continuous<br />

full-load operation, maintaining the temperatures within tolerance level of<br />

components.<br />

: Each bus bar compartment should have a barrier with 1.6 mm thick<br />

galvanized coated & painted with fire resistance paint.<br />

: Proper fixing arrangement shall be made for mounting metering &<br />

protection current transformers.<br />

: The degree of protection for the panel shall be IP 31<br />

Panel dimension<br />

Width<br />

: As per design requirement.<br />

Depth<br />

: Shall not be more than 1200 mm<br />

Height<br />

: Shall not be more than 2400 mm (including plinth)<br />

Plinth<br />

: Shall be 100 / 50 mm height<br />

Ground clearance : Minimum ground clearance for switchgear mounting shall be 350 mm<br />

including plinth.<br />

Weight / Sq. mm : Distributed floor weight shall be less than 1225 kg sq. m.<br />

Switchgears<br />

operation<br />

Plinth<br />

: Switchgears are to be mounted in such a way its handle operation shall<br />

confirm to per IS 4237<br />

-ON Closing –Clockwise i.e., Vertically upward<br />

-OFF Opening –Anti-clockwise i.e., Vertically down ward<br />

: The panel shall be supplied along with base plinth of 100 / 50 –mm height<br />

for each transportable modular section and shall be made of C – channel<br />

forming sectional ‘Box’.<br />

Semi Modular substation LT panel –Specification 2

Master Control Facility – Hassan<br />

Door<br />

Cable<br />

compartment<br />

Bus duct<br />

: Doors shall be with concealed hinges and flush type locks.<br />

: Doors that are bolted for busbar chambers should be flush in design such<br />

that the bolt head and the door surface are in one level.<br />

: Doors shall be of 2 mm thick CRCA sheet.<br />

: High quality door gasket should be used for dust and vermin proof.<br />

: Each bolt shall have plastic washers on the inner side of the door such that<br />

the bolt will remain with the door on removal of the door.<br />

: The switch handle shall be interlocked such that the door of enclosure<br />

cannot be opened unless the switch is in OFF position, however,<br />

mechanical interlock defeat mechanism has to be provided.<br />

: All rear doors shall be of hinged type with locking arrangement at three<br />

places (top, middle and bottom).<br />

: All horizontal and vertical bus bars chamber covers shall be of bolted type.<br />

: Hinged doors shall be provided for all switchgear compartments.<br />

: Stiffeners are to be provided for all rear doors for mechanical strength.<br />

: Cable entry gland plates shall be provided at the bottom.<br />

: Each gland plate shall be chrome plated with 3mm thickness & adequately<br />

supported.<br />

: Independent, detachable gland plates for each cable considering 2 cables /<br />

outlet shall be provided at the cable compartments & terminal chamber.<br />

: Liberal space shall be provided in the cable compartment as well as switch<br />

compartment to facilitate termination of cables.<br />

: Provision shall be made for proper clamping of the cables above the<br />

glands and cable clamps to avoid weight of cables acting directly on the<br />

termination.<br />

: Wide cable alley shall be provided for easy bending and termination of<br />

cables. (Bending radii =R>=12 x overall diameter of cables)<br />

: Non-segregated, bus ducts having 3 phase & neutral bus bars housed in<br />

common galvanized zinc sheet metallic enclosure.<br />

: Degree of protection for the bus duct shall be IP 54, outdoor bus duct<br />

section shall be of double roof type. The top cover should be of rain<br />

canopy type.<br />

: Busbar material –High-purity electrolyte Aluminium confirming to latest<br />

IS standard.<br />

: Bus duct rating shall be 2000A at 415 VAC, 50 Hz.<br />

: Short circuit withstand capacity –50 kA (rms) for 1 sec, Confirming to IEC<br />

IS-8623-2.<br />

: Insulation material –PVC sleeved of suitable class & insulation.<br />

: Neutral bus bar rating shall be 50% of the phase cross section.<br />

: Earth busbar of tinned copper size 35 x 4 mm shall be fitted outside the<br />

duct on either side through out the length.<br />

: Bus duct enclosure shall be fabricated with CRCA electro galvanized,<br />

1.8-mm thick sheet with epoxy polyester powder coating, inner surface to<br />

be painted with flame proof fire retardant paint.<br />

: Transformer terminal to be connected with flexible joints to the palm<br />

connector through bi-metal shim.<br />

: All supporting structure materials shall be of GI (hot dip).<br />

: Standard accessories to be used as per the system requirement like,<br />

expansion joint at every bends, phase cross over, rubber bellow,<br />

marshalling cabinet, adopter at transformer and panel end & wall frame.<br />

: The total requirement of indoor & outdoor bus duct length will be provided<br />

at the time of approval of GA drawing.<br />

Semi Modular substation LT panel –Specification 3

Painting<br />

Surface treatment<br />

Type<br />

External Finish<br />

Internal Finish<br />

Master Control Facility – Hassan<br />

: Triple surface treatment<br />

Phosphating, Electrophoretic dipcoat-priming and Powder coating<br />

: Epoxy polyester powder coated<br />

: Mat or Gloss<br />

: Flame proof Fire retardant paint<br />

Color : Outer surface of the panel –Siemens gray. (color code IS: 952)<br />

: Plinth –Black<br />

: Inner surface of the panel –Fire resistance paint.<br />

: Bus duct – Siemens gray (color code IS: 952)<br />

Busbar System<br />

Material<br />

: High-purity electrolyte Aluminium complying to IS 5082-1981, 63401-WP<br />

Confirming to : DIN 1759, DIN 40 500 and relevant bus bar IS standard<br />

Ele. Conductivity : 100% as per IAC Standard<br />

Main busbar rating : 120 % of 2.0 MVA, continuous current rating<br />

Distribution busbar : 120 % of the switchgear rating connected<br />

N –busbar rating : 50% of the phase busbar rating<br />

Busbar system : TPN-E<br />

Busbar<br />

arrangement<br />

Phase sequence<br />

Normal service<br />

condition<br />

: If the number of busbars per phase exceeds more than three, then<br />

interleaved system shall be adopted. The phase sequence will be N-R1-<br />

Y1-B1-R2-Y2-B2 to minimize skin, proximity, power loss and temperature rise.<br />

: The phase sequence of buabars arrangement shall be N-R-Y-B from rear to front.<br />

: Should not raise 40 0 C above ambient temperature as per IS 4237<br />

(Considering Max ambient air temp. not exceeding 40 0 C at an altitude 992 MSL)<br />

Auxiliary Busbar System<br />

Material<br />

: High-purity electrolyte Aluminium complying to IS 5082 -1981, 63401-WP<br />

Size<br />

: As per design requirement.<br />

Control power : 24 VDC & 230 VAC<br />

Location<br />

: Top front or rear top front chamber of the panel.<br />

Supports / tap-off : Integrated busbar supports and tap-off system shall be adopted.<br />

Safety<br />

: Auxiliary busbars shall be insulated & sleeved.<br />

Bus bars supporting insulators<br />

Material<br />

: Self-extinguishing moulded Fiberglass reinforced thermosetting plastic or<br />

equivalent.<br />

Properties : Higher mechanical strength, High dielectric strength<br />

: High temperature with stand capability, Non flammable<br />

: Non hygroscopic & Ribbed construction to prevent tracking<br />

Supporting : Individual supports for each phase shall be used to eliminate risk of<br />

tracking between phases.<br />

Busbars protection<br />

Separate chamber : Horizontal and vertical busbar should be enclosed in a separate chamber.<br />

Sleeving<br />

: Horizontal busbars, vertical busbars, switchgear input busbars and<br />

switchgears output busbar are to be totally sleeved with color coded heat<br />

shrunk PVC to protect against accidental contact and tracking caused by<br />

dust, humidity and vermin.<br />

Semi Modular substation LT panel –Specification 4

Shrouds<br />

Cabling<br />

Separate chamber<br />

Safety interlock<br />

Doors<br />

Wiring<br />

Specification<br />

Confirming to : IS: 694 / 1990<br />

Size & Rating<br />

Connectors<br />

Cage clamps<br />

Ferruling<br />

Meters & Relays<br />

Communication<br />

devices<br />

Master Control Facility – Hassan<br />

: All joints on horizontal busbars shall be provided with shrouds or insulated<br />

to provide a completely insulated system.<br />

: The cabling chamber for the panel shall be at the rear side of the panel.<br />

: It should be separated from the busbar zone and switchgear compartment.<br />

: The control cables and terminals are to be mounted in a separate<br />

compartment. (Below ACB compartment / away from power cables).<br />

: The door cannot be opened unless the breaker is in ‘Isolated position’.<br />

: The door cannot be opened unless MCCB / SDFU is in OFF position.<br />

: Defeat facility shall be provided to facilitate testing / inspection for all<br />

switchgears.<br />

: HFFR unilay, pre twisted single core multi strand electrolyte grade,<br />

annealed copper cable,<br />

: 1.5 sq-mm, 1.1 Kv grade shall be used for all control / interlock wiring.<br />

: 2.5 sq-mm, 1.1 Kv grade shall be used for all CT related wiring.<br />

: Power cable of suitable size for SDFUs / MCBs of rating up to 63 A.<br />

: Color of the cable shall be Gray for control wiring.<br />

: Mating type male-female connectors and holders shall be used between<br />

each transportable section for control wiring.<br />

: Din rail mounting, cage clamp terminal connectors shall be used for all<br />

control and power wiring up to 63A.<br />

: Standard ferruling concept shall be followed for clear identification of<br />

control circuit wiring as per IS 375 mentioned below.<br />

-Letter ‘A’ – CT for primary protection excluding O/C<br />

-Letter ‘B’ –CT for busbar protection<br />

-Letter ‘C’ –CT for O/C including E/F & instantaneous<br />

-Letter ‘D’ –CT for metering & voltage control.<br />

-Letter ‘E’ –Reference voltage for instrument metering & protection<br />

-Letter ‘F’ – Reference voltage for voltage control<br />

-Letter ‘G’ – Reference voltage for synchronizing<br />

-Letter ‘H’ –AC & AC/DC supplies Numbers –1 to 69 for S’gears & Gen.<br />

-Letter ‘J’ – DC supply<br />

-70 to 99 for Transformers<br />

-Letter ‘K’ – Closing & tripping control circuit – Any no. 1 upward<br />

-Letter ‘L’ – Alarm & indication – Any no. 1 upward<br />

-Letter ‘M’ – Auxiliary & motor control devices –1 to 19 for Switchgears, 20<br />

to 69 for Generators & 70 to 99 for Transformers<br />

-Numbers 10 to 29 – R phase<br />

-Numbers 30 to 49 – Y phase<br />

-Numbers 50 to 69 – B phase<br />

-Numbers 70 to 89 – Residual & Neutral CT &<br />

-Numbers 90 –Earth wire directly connected to earth bar.<br />

: For DC bus -Positive –Red, -Negative –Blue<br />

: Auxiliary power supply shall be taken independently through MCBs from<br />

auxiliary busbars.<br />

: Communication points of all communicable devices (viz., ACB releases,<br />

digital TVM & protective relays) shall be wired with twisted pair cable to<br />

the common compartment.<br />

Semi Modular substation LT panel –Specification 5

Trip circuit<br />

Indicating lamps<br />

CTs wiring<br />

MCBs input power<br />

Master Control Facility – Hassan<br />

: ACBs / MCCBs shunt trip power supply shall be taken independently<br />

through MCBs from auxiliary busbars.<br />

: Wiring for presence of input power, ACBs / MCCBs ON / OFF and fault trip<br />

status indication.<br />

: Isolators for digital TVM & shorting links for analog meters shall be used.<br />

: Multiple MCB’s input power supply should be tapped through 125A SDFU<br />

for short circuit protection.<br />

Name plates / stickers<br />

Name plate : Nameplates for Transformers & Generators incomers and each outgoing<br />

feeder outlets shall be provided.<br />

: Each nameplate shall contain feeder no, switchgear rating and<br />

nomenclature.<br />

: Nameplates size, design, and color combination and nomenclature for<br />

each output feeder will be furnished during approval of drawing.<br />

: The approved SLD of the panel shall be screen-printed / computerized<br />

print over an A3 size 2 mm thick aluminum sheet or foam board. It shall be<br />

fixed at top-center of the panel.<br />

Laminated stickers : Laminated stickers of suitable size with good quality adhesive shall be<br />

fixed at each terminal blocks, meters, relays on the inner side for clear<br />

Panel specification<br />

plate<br />

Grounding / Earthing<br />

Type<br />

Panel earth bus<br />

Switchgear<br />

Panel doors<br />

Meters / relays<br />

Inspection / Testing<br />

First stage<br />

inspection<br />

Final inspection &<br />

testing<br />

identification.<br />

: The panel shall have the specification plate as per the IS reference<br />

standard 2675<br />

-Rated voltage AC or DC Hz<br />

-Total number of outgoing ways / feeders<br />

-Rated current of each outgoing feeders<br />

-Number of poles<br />

-Manufacturer name / Trade mark / Address<br />

-Customer PO reference and date<br />

-Year of manufacturing<br />

: Two-point ground in accordance with the recommendations of IEEE<br />

Standard and the requirements of the NEC.<br />

: High-purity electrolyte copper E-Cu 57 busbar of size 50x6 mm should be<br />

run all along the width of the panel at front or rear bottom surface.<br />

: All ACBs and switchgears body shall be earthed by 25x3 mm copper strip.<br />

: Doors shall be earthed, if electrical equipment (meters / relays / lamps)<br />

mounted by a yellow green 2.5 Sq. mm wire lugged at both ends.<br />

: All meters / relays shall be earthed to the profile by a yellow green 2.5 Sq.<br />

mm wire lugged at both ends.<br />

: Mechanical -structural fabrication after approval of GA drawing.<br />

: Verification of components as per PO bill of material.<br />

: Minor modifications in mechanical / electrical changes pointed out by MCF<br />

inspecting officer shall be carried out, if necessary, without additional cost.<br />

: After integration of switchgears and wiring.<br />

: Inspection and testing as per checklist.<br />

: Calibrated testing & measuring instruments are to be used for routine test.<br />

: Any deviations from the specifications or in testing shall be attended &<br />

offered for re-inspection.<br />

Semi Modular substation LT panel –Specification 6

Documentation<br />

Comprising<br />

Warranty<br />

Master Control Facility – Hassan<br />

: Party to submit the PDR document for approval with in 45 days after<br />

receiving the <strong>purchase</strong> order.<br />

: PDR document shall contain –SLD, GA drawing with superimposed busbar<br />

configuration, Structural details of panel / bus duct, Make and Catalogue<br />

number of switchgears & accessories, Control circuit drawing and Delivery<br />

schedule.<br />

: As built GA, SLD, Control drawing & busbar layout configuration in A3 size.<br />

: Meters / Protective Relays operating manuals.<br />

: Meters / protective Relays test and Calibration certificates.<br />

: Metering / Protection CT calibration certificates<br />

: Bill of actual material used with make, cat no and quantity.<br />

: Routine / Acceptance test results as per standard.<br />

: Specific instructions for installation and operation / maintenance<br />

procedures.<br />

: Document shall be supplied in duplicate with hardbound cover having<br />

printed title.<br />

: The entire document is to be copied & supplied in CD.<br />

: Against defects in material and workmanship<br />

: 12 months from the date of commissioning or<br />

: 18 months from the date of supply and acceptance which ever is earlier.<br />

Functional requirements<br />

Inter lock<br />

: Electrical & Mechanical interlock between T1 & T2 shall be provided.<br />

: The bus couplers BC1 & BC2 shall not close if there is power on either<br />

side of the bus.<br />

: The bus couplers BC3 & BC4 shall close if the DG systems are running in<br />

synchronizing mode.<br />

: The bus couplers BC3 & BC4 shall not close if the DG systems are<br />

running in solo mode of operation.<br />

: The differential trip potential free contact shall be made available to trip the<br />

diesel engine also.<br />

: The detailed interlock / operational scheme in auto / manual mode of<br />

operation will be provided during PDR<br />

ACBs<br />

: Shall be received from the manufacturer with all its accessories in pre<br />

wired condition as per the bill of material.<br />

: Incoming & outgoing busbar termination orientation should be ordered as<br />

per the panel requirement.<br />

Bus coupler (BC2)<br />

Interposing relays<br />

Auxiliary contacts<br />

: Bus coupler BC2 section shall be kept with a gap of 750 mm on either side<br />

to have separation from utility & captive sources.<br />

: Control power supply to interposing relays (24 VDC) shall be taken through<br />

modular fuse holder with HRC fuse links.<br />

: Transformer and Generator side change over contacts wiring shall be<br />

terminated separately in mains and generator side compartments.<br />

: Change over contacts, aux. contacts wiring of Transformers, Generators &<br />

Bus couplers shall be terminated to separate terminal blocks with TB no<br />

for clear identification.<br />

: Each terminal connector to be numbered and their input & output details to<br />

be provided.<br />

: All auxiliary contacts of ACBs, Relays, MCCBs and CT outputs shall be<br />

brought to cage clamps / mating type male-female connectors.<br />

Semi Modular substation LT panel –Specification 7

Master Control Facility – Hassan<br />

Phase sequence<br />

indicator<br />

DG auxiliary<br />

system<br />

Emergency Power<br />

OFF (EPO)<br />

Modes of<br />

operation<br />

Neutral contactor<br />

: PSI shall be provided with spring return type ON / OFF selector switch.<br />

: All DG auxiliary motor control circuits are to be placed under respective<br />

DG incoming air circuit breaker compartments.<br />

: EPO switch shall shut down the unit by activating the shunt trip of the<br />

ACBs in local & remote operation.<br />

: Manual operation<br />

: Solo operation and<br />

: Automatic operation<br />

: Solo mode operation<br />

− DG neutral Contactor to close automatically before closing of respective<br />

DG breaker.<br />

− Neutral Contactor to trip after tripping of respective DG’s.<br />

− Selector switch for enabling / disabling the neutral contactor shall be<br />

provided.<br />

: Parallel operation<br />

-Only master DG neutral contactor should be ON.<br />

-Master DG neutral tripping shall trip all DG circuit breakers.<br />

Semi Modular substation LT panel –Specification 8

Master Control Facility – Hassan<br />

Sn Description Make Qty<br />

A Switchgears & Control accessories<br />

1<br />

Air Circuit Breakers -ACB<br />

Rated operational voltage -415V 50Hz AC, 3 Pole, Electrical Draw Out type,<br />

Type of closing: Stored energy (Motor operated), Motor voltage: 240 VAC,<br />

Closing electromagnet: 240 VAC, Wiring scheme: 3Ph, 4 wire, Auto reset,<br />

Door interlock, Castle lock with key, Rated insulation voltage: 690 VAC,<br />

Utilization category -B. Ultimate breaking capacity (Icu) at 415V, 50Hz –65<br />

kA rms, Service breaking capacity (Ics) at 415V, 50Hz -65 kA, Short time<br />

withstand capacity (Icw) for 1 second: 65 kA rms, Making capacity (Icm) at<br />

415V, 50Hz -143 kA peak,<br />

Microcontroller based, true RMS sensing protection and control release<br />

capable of offering OL, SC and EF protection with variable current and time<br />

delay settings, selectable I 2 t based curves for short time and earth fault<br />

zones, self powered with % loading / LCD display. Confirming to IS 13947<br />

(Part 2) / IEC 60947-2<br />

Accessories: Auxiliary contacts: 6NO+6NC / 4 NO+4NC, Safety shutters /<br />

Inter phase barriers, Shunt release: 24 VDC, UV release: 240 VAC,<br />

Operation counter, Mechanical interlock kit, Terminal orientation / adopters -<br />

As per<br />

requirement.<br />

Make: L&T U-Power / Schneider MG-Masterpact / Siemens, Sentron-WL<br />

1a Rated Current: 800 A for Generator 3<br />

1b Rated Current: 1600 A for Transformer 2<br />

2<br />

Air Circuit Breakers -ACB (For bus couplers BC1 to BC4)<br />

Rated operational voltage -415V 50Hz AC, 3 Poles, Electrical Draw Out type,<br />

Type of closing: Stored energy type (Motor operated), Motor voltage: 240 VAC,<br />

Closing electromagnet: 240 VAC, Wiring scheme: 3Ph, 4 wire, Auto reset, Door<br />

interlock, Castle lock with key, Rated insulation voltage: 690 VAC, Utilization<br />

category -B<br />

Ultimate breaking capacity (Icu) at 415V, 50Hz –65 kA rms, Service breaking<br />

capacity (Ics) at 415V, 50Hz -65 kA, Short time withstand capacity (Icw) for 1<br />

second: 65 kA rms, Making capacity (Icm) at 415V, 50Hz -143 kA peak.<br />

Confirming to IS 13947 (Part 2) / IEC 60947-2.<br />

Accessories: Auxiliary contacts: 4NO+4NC, Safety shutters / Inter phase barriers,<br />

Shunt release: 24 VDC, UV release: 240 VAC, Operation counter, Terminal<br />

orientation / adopters: As per requirement<br />

Make: Make: L&T U-Power / Schneider MG-Masterpact / Siemens, Sentron-WL<br />

2a Rated Current: 1600 A 2<br />

2b Rated Current: 2500 A 1<br />

2c Rated Current: 3200 A 1<br />

Semi Modular substation LT panel –Specification 9

Master Control Facility – Hassan<br />

3<br />

Microcontroller based UV & OV Relays (For T1 & T2)<br />

Voltage Vn -110/240/415V settable at site, 50 Hz +/- 2.5 Hz, Auxiliary power<br />

supply: 24-110V AC/DC, Settings -Fault Voltage Vs -OV mode: 105-180% of<br />

Vn in steps of 5%, UV mode: 95-20% of Vn in steps of 5%, High Set Vhs -OV<br />

mode 110-180% of Vn in steps of 10%, -UV mode: 90-20% of Vn in steps of<br />

10%, Trip Time Characteristics -Normal Inverse NI -3.5 Sec in OV mode &<br />

5.7 in UV mode, Defnite Time -01, 10 and 100 Secs, Accuracy -+/- 5% of Vn,<br />

Auxiliary Contacts - 2 Pairs of self reset C/O contacts, Mounting -Panel<br />

mounting (Flush) type, Relay operation should not be affected by stray<br />

magnetic field. Make: L&T Model MV12A or equivalent in Siemens / Areva<br />

T&D / ASEA Brown Boveri<br />

4<br />

4<br />

Protection Relay (For T1 & T2)<br />

3Ph OC+EF+highset, Communication and breaker control with RS 485, Micro<br />

Controller based, LS OC (20-200% step 5%) HS O/C (0.2-40) in step of 0.2 In<br />

or disable & LS EF (5-80% step 5%), HS EF (0.1 to 20) on step of 0.1 On or<br />

disable, HS delay (0.1 to 2 Sec) step 0.01 sec or instantaneous, Draw out<br />

type, Auto doubling of HS, relay co-ordination, self testing & display of<br />

parameters, Site selectable trip time characteristics (NI, VI, EI & Definite<br />

Time), TMS 0.1-1.6 step 0.05, Auxiliary contacts 2NO+2NC, Auxiliary supply:<br />

24-110V AC/DC, CT Rating: 5A. Make: L&T Model MC61C or equivalent in<br />

Siemens / Areva T&D / ASEA Brown Boveri<br />

2<br />

5<br />

Digital Meter (For T1, T2, G1, G2 & G3)<br />

True RMS measuring meter to read L-L/L-N voltage, Current per phase /<br />

neutral current, Frequency, Phase rotation / Vmax. and current demand per<br />

phase, Vmin. per phase, %age of load circular bar graph. Capable of<br />

measuring power parameters viz., kW & kWh, kVA & kVAh, kVAr & kVARh,<br />

import & export etc., The meter shall be capable of reading the voltage as<br />

well as current (THD) Harmonic, Three phase at once, bright LED display.<br />

Communication port –RS 485 and Industrial standard communication<br />

protocol – MODBUS, Auxiliary power supply: 24 VDC. Make: Satec<br />

PM130EH<br />

5<br />

6<br />

7<br />

Differential Protection Relay (For G1, G2 & G3)<br />

Device code: 87, 50/51, 50LBB, 64S / 87N, Design: Numeric, Functions:<br />

Generator differential, bias % with dual adjustable slope, OC, stator EF & CB<br />

failure protection, Features: 1A or 5A site selectable, display of parameters,<br />

waveform capture feature, built in supervision & RS485 port, 4 C/O, S/R or<br />

H/R or time delay 1 C/O for self supervision, Flush mounting draw out type,<br />

Auxiliary supply 24-110V AC/DC. Make: L&T Model MD32G or equivalent in<br />

Siemens / Areva T&D / ASEA Brown Boveri<br />

Switch Disconnector Fuse Units (SDFU)<br />

Triple Pole with isolable Neutral (TPN), 415V, 50 Hz, Panel mounting type<br />

interrior version with operating mechanism and handle without HRC fuse<br />

links. Confirming to IS 13947 (Part 3), Accessories: Terminal shrouds, Fuse<br />

shrouds, Fuse barriers<br />

Make: L&T F-Line FNX series / Schneider MG Fupact SDF / Siemens -<br />

Sentron Superswitch<br />

3<br />

7a Rating: 630 Amps 15<br />

Semi Modular substation LT panel –Specification 10

Master Control Facility – Hassan<br />

7b Rating: 400 Amps 5<br />

7c Rating: 250 Amps 6<br />

8<br />

DIN TYPE HRC Fuse Links (For 7a, 7b & 7c)<br />

Rated Voltage: 415V, 50 Hz, DIN fuse Type -HN, Confirming to IS 13703,<br />

Low let through energy, High breaking Capacity of 100 kA at 415V with blown<br />

indication. Make shall be of SDFU selected or recommended by the SDFU<br />

manufacturer.<br />

8a Suitable for 630A SDFU, Rating: 500A 45<br />

8b Suitable for 400A SDFU, Rating: 315A 15<br />

8c Suitable for 250A SDFU, Rating: 200A 18<br />

9<br />

Ammeter (For all outgoing feeders)<br />

Type: Moving Iron, AC application, Size: 96x96, Flush mounting, Uniform<br />

scale <strong>division</strong>, Accuracy class 1%, CT operated 5A. Make: L&T Rishab / AE /<br />

MECO / Nippon / Havells<br />

9a Range: 0 - 600 A 15<br />

9b Range: 0 - 400 A 5<br />

9c Range: 0 - 250 A 6<br />

10<br />

Ammeter Selector switches (For LT panel)<br />

Cam operated, No of poles: 1 pole with 3 CT with OFF, Current rating -10 A,<br />

Operating angle -90 0 , panel mounting type, R-Y-B-OFF and AMMETER<br />

engraved front plate, Front plate size -60 mm, 4 hole front panel mounting.<br />

Make: L&T-Salzer / Kaycee / Schneider / Siemens<br />

26<br />

11<br />

Phase Sequence Indicator (For T1 & T2)<br />

Rotating disc type electro mechanical, Operating voltage: 50-500V, Operating<br />

frequency: 25-60 Hz, Size: 96x96 mm, Flush mounting. Make: L&T Rishab /<br />

AE / MECO / Nippon / Havells<br />

2<br />

12<br />

Current Transformers -Metering<br />

Rated secondary current -5A, Accuracy class -1%, Rated frequency -50Hz,<br />

Type - Resin cast, Shape -Circular / Rectangular with mounting accessories,<br />

Rated insulation level of CT -3 kV rms, Confirming to IS 2705. Make: L&T /<br />

Rishab / Schneider / Kappa / Kalpa / AE<br />

12a Rated primary current 1600 A, Rated burden -5 VA (For T1 & T2) 6<br />

12b Rated primary current 800 A, Rated burden -5 VA (For G1 & G2) 9<br />

12c Rated primary current 600 A, Rated burden -5 VA 45<br />

12d Rated primary current 400 A, Rated burden -5 VA 15<br />

12e Rated primary current 250 A, Rated burden -5 VA 18<br />

13<br />

Current Transformer -Protection (for T1 & T2)<br />

Rated primary current 1600A, Rated secondary current -5A, Rated burden -<br />

10VA, Accuracy -5P10, Rated frequency -50Hz, Type -Resin cast, Circular /<br />

Rectangular with fixing accessories, Rated insulation level of CT -3 kV rms,<br />

Confirming to IS 2705. Make: L&T / Rishab / Schneider / Kappa / Kalpa / AE<br />

6<br />

14<br />

Miniature Circuit Breakers (For AC control circuits)<br />

Single pole, Rating 4A, Breaking capacity 10A, confirming to IS 8828 -1996,<br />

Type 'B' tripping characteristic. Make: L&T -Hager / Siemens / Schneider /<br />

MDS -Legrand / GE having ISI mark<br />

As<br />

required<br />

Semi Modular substation LT panel –Specification 11

Master Control Facility – Hassan<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

Ultra Safe Modular Fuse Holders (For DC control circuits)<br />

Single pole, Suitable for 14x51 cylindrical HRC fuse links, Din rail mounting<br />

type, Confirming to IEC 269-2-1, 'Finger safe' under IEC standards to an IP-2<br />

grade of protection, Blown fuse indicators for each pole. Make; Siemens /<br />

Schneider / Ferraz-Shamutt / Telemecanique<br />

HRC Fuse Links (For DC control circuit)<br />

Rating: 4A, Nominal Voltage: 415VAC, Breaking capacity: 80kA at 415VAC,<br />

P.F. of 0.15, Confirming to IS: 9224 1979. Cylindrical type of size 14 x 51<br />

mm. Make: Siemens / Schneider / Ferraz-Shamutt / Telemecanique<br />

CT Shorting isolator (for T1, T2, G1, G2 & G3 -Satec meter)<br />

Triple pole isolator, Rating: 16A. Make: L&T -Hager / Siemens / Schneider /<br />

MDS -Legrand / GE / ABB<br />

CT Shorting Terminals (for LT panel outgoing feeders)<br />

Terminal connector, 800 VAC grade, Suitable for termination of cable from<br />

0.08 to 4 sq mm, Rating -32A, Colour -Grey, Din rail mounting type, Material<br />

-modified Nylon 6.6 free of halogens, flurocarbons etc., Continuous operating<br />

temperature -105 degree C, Electrolytic copper Ecu. Make: WAGO or<br />

equivalent in Connectwell / Salzer<br />

Change Over, ON / OFF, Auto / Manual Switch<br />

(For Neutral contactor, PSI) Rating: 10A, Switching angle 90 degree, Flush<br />

mounting type, Rated operational voltage -440VAC, Frame size -48 mm.<br />

Make: L&T-Salzer / Kaycee / Siemens / Schneider<br />

Breaker Control Switch (TNC)<br />

Frame size - 88 mm, Lever handle, shall be lockable in neutral position, Front<br />

mounting with grey colour, handle black colour, Engraved 'Trip', Neutral' &<br />

'Close', IP 40 protection. Make: L&T-Salzer / Kaycee / Siemens / Schneider<br />

25<br />

25<br />

5<br />

As<br />

required<br />

As<br />

required<br />

9<br />

21<br />

22<br />

23<br />

24<br />

Power Contactor (For G1, G2 & G3 Neutral)<br />

Utilization category AC-3 at 415 V, 50 Hz, 3 Ph, Auxiliary contact 2NO+2NC, Coil<br />

voltage: 240 VAC, Confirming to IS13947 (Part 4 / Sec.1) and IEC 60947-4-1,<br />

Rating: 400A, Rated insulation voltage: 690V AC. Make: L&T / Schneider -TM /<br />

Siemens / ABB<br />

Emergency Push button<br />

The local EPO shall include a non-illuminated "Emergency Power Off"<br />

pushbutton. Pressing the EPO switch shall immediately shut down the unit by<br />

activating the shunt trip of the all main input and bus coupler circuit breakers.<br />

Make: L&T-ESBEE / Siemens / Schneider / ABB / Tecnic<br />

Flasher with beeper / Indicator banks (For T1, T2, G1 to G3)<br />

Amber colour flasher cum beeper for fault trip indication & alarm with<br />

acknowledgement. Make: MIMIC / Schneider / Rittal<br />

Indicating Lamps<br />

(For T1, T2, G1, G2, G3 RYB indicatios, ACBs ON/OFF indications, Fault trip<br />

indications) Type: LED, Ribbed lens with trim collar anodised bright, Flush<br />

head, Input supply voltage 250VAC, 50 Hz. Color cade should be Red,<br />

Yellow, Blue & Green. Make: L&T-ESBEE / Siemens / Vaishnav / Tecnic /<br />

Schneider / ABB<br />

3<br />

1<br />

5<br />

As<br />

required<br />

Semi Modular substation LT panel –Specification 12

Master Control Facility – Hassan<br />

25<br />

26<br />

Actuators (Illuminated)<br />

Type: LED, Ribbed lens with trim collar anodised bright, Colour code shall be<br />

Red & Green. Make: L&T-ESBEE / Siemens / Vaishnav / Tecnic / Schneider /<br />

ABB / GE Power Controls<br />

High speed relay (Master), (For T1, T2, G1 to G3)<br />

Auxiliary supply: 24 to 48 V DC, Type: VAJ, Model: VAJH-13YF-52B of<br />

Alstom or L&T / Siemens / Areva T&D / Brown Boveri<br />

As<br />

required<br />

5<br />

27<br />

Industrial plug in relays (T1, T2 & DG1 to DG3 -3 Nos each, BC1 to BC4 -2<br />

Nos each & NC1 to NC3 -1 No each)<br />

3 C/O contacts, 11 pin, circular pin arrangement, Continuous duty, Silver<br />

cadmium alloy Contacts, Contact rating 5A continuous @ 24 VDC, Contact min.<br />

power rating 1000 VA, Relay assembly shall be completely sealed in transparent<br />

enclosure, Led indication across coil while on relay pick up, Arc barriers shall be<br />

provided between the pole contacts, Mechanical test to push button shall be<br />

provided, Mechanical flag indication on relay status, Din rail mounted plug in<br />

socket for 11 pin relay. Make: PLA / Paramount / OEN / BCH / Siemens / ABB<br />

26<br />

28<br />

29<br />

30<br />

31<br />

32<br />

Control Cable (For control circuit wiring)<br />

HFFR, pre twisted single core multi strand electrolytic grade, annealed<br />

copper cable, Size: 1.0 sq. mm & 2.5 Sq. mm. Voltage grade: 1100VAC as<br />

per IS: 694 / 1990. Make: RR Kabel / Lapp / Finolex / L&T / V-Guard /<br />

Mysocables<br />

Power Cable<br />

HFFR, Pre twisted single core multi strand electrolytic grade, annealed<br />

copper cable, Voltage grade: 1100 VAC, as per IS: 694 / 1990, Size & colour<br />

of the cable should be selected according to the MCB / Switch-gear rating &<br />

standard Grey colour, to be crimped with coloured sleeve lugs heavy duty,<br />

Ring tonge type. Make: RR Kabel / Lapp / Finolex / L&T / V-Guard /<br />

Mysocables<br />

Din Rail<br />

Mounting Rails: C-channel shaped STD 32 mm, steel zinc passivated / plated<br />

Length: as required. Make: Connectwell / Rittal / Wago<br />

Terminal Connectors (For control circuit wiring)<br />

CAGE CLAMP Terminal connector, 800VAC grade, Suitable for termination<br />

of cable from 0.08 to 4 sq mm, Rating -32A, Colour -Grey, Din rail mounting<br />

type, Front Entry, Material -modified Nylon 6.6 free of halogens, flurocarbons<br />

etc., Continuous operating temperature -105 degree C. Make: WAGO<br />

Controls AWG28-12 cat no. 281-901or equivalent in Finolex / Connectwell /<br />

Elmex<br />

Terminal Connectors (For SDFU 63/32A, MCBs 63 to 10A)<br />

CAGE CLAMP Terminal connector, 800VAC grade, Suitable for termination<br />

of cable from 6-35 sq mm, Rating -125A, Colour - Grey, Including end plate,<br />

Din rail mounting type, Front Entry, Material -modified Nylon 6.6 free of<br />

halogens, flurocarbons etc., Continuous operating temperature -105 degree<br />

C. Make: WAGO controls AWG 8 - 2 Cat no. 285-601 or equivalent in Finolex<br />

/ Connectwell / Elmex<br />

As<br />

required<br />

As<br />

required<br />

As<br />

required<br />

As<br />

required<br />

As<br />

required<br />

Semi Modular substation LT panel –Specification 13

Master Control Facility – Hassan<br />

33<br />

34<br />

35<br />

36<br />

37<br />

Cable Ducts<br />

Manufactured from high impact rigid PVC, should not peel, chip or break, non<br />

inflammable, warp proof, non-britle, high di-electric strength (36 kV / mm),<br />

Temperature withstand capacity up to 70 degree C, Colour: Grey, Type B<br />

locking, width & deapth of the duct shall be selected according to the<br />

requirement and shall be uniform in size. Make: Salzer / Connectwell / Wago<br />

/ Elmex / Lapp<br />

Cable Ties<br />

Re-usable type, white coloured, Nylon cable ties, Length of the ties selected<br />

according to the requirement. Make: Any Reputed make<br />

Ferrules / Stickers<br />

Ferrules of suitable type, size shall be selected for each cable on both sides<br />

and for terminal blocks. Laminated stickers for marking Circuit breakers /<br />

SDFUs / Fuse links / Terminal blocks shall fixed as per the standard<br />

configuration<br />

Lugs<br />

Suitable insulated coloured heavy duty lugs made of tinned copper shall be<br />

used for control cable / SDFU upto 63A / MCB input output cable terminations<br />

as per the cable size. Make: Dowells/Multi/3D/Jainson<br />

High purity electrolyte Aluminium Busbars<br />

Rating: 2.0 MVA for main busbar, Aluminium bus bar complying to IS 5082<br />

1981, 63401-WP, suitable size and rating for vertical busbar system, suitabl<br />

size Busbar shall be selected for tapping from buabar to switchgears &<br />

switchgear to termination ends, The busbar thickness shall not be more than<br />

8 mm<br />

As<br />

required<br />

As<br />

required<br />

As<br />

required<br />

As<br />

required<br />

MS items, Fabrication, Insulators, Painting, Wiring and Testing as per the<br />

38<br />

enclosed technical specification enclosed.<br />

39 Sub-Total A<br />

B LV Busduct Indoor / Outdoor System<br />

40<br />

LV Busduct System<br />

Non-segregated, bus ducts having 3 phase & neutral busbars housed in a<br />

common Galvanized zinc sheet metallic enclosure. Degree of protection -<br />

IP54, Outdoor from Transformer (1MVA) to inside the building & Indoor from<br />

building to LT panel. Rating 415V, 2000A , Busbar material -Aluminium,<br />

complying to IS 5082 1981, 63401-WP. Short circuit withstand capacity -50<br />

kA (rms) for 1 sec, Confirming to IEC 439-2, IS-8623-2, Insulation material -<br />

Multi layer class F (155 degree) insulation, Earth busbar -Upto 50 % of<br />

phase cross section can be fitted outside, Enclosure material -1.6 mm CRCA<br />

with epoxy polyester powder coating, Standard accessories to be used as per<br />

the system requirement like, bends, expansion joints, flexible link, phase<br />

cross over, rubber bellow, marshalling cabinet, adopter at transformer and<br />

panel end & wall frame. The exact length of indoor, outdoor bus duct may be<br />

taken at site during panel fabrication.<br />

40a Indoor (15 meters approximately)<br />

40b Outdoor (20 meters approximately)<br />

R Meter<br />

R Meter<br />

Semi Modular substation LT panel –Specification 14

Master Control Facility – Hassan<br />

41 Sub-Total B<br />

C Installation & Commissioning of Substation LT Panel & bus-duct<br />

42<br />

Installation & Commissioning of LV bus-duct at site including steel supports &<br />

Installation & Commissioning of substation LT panel at site excluding power<br />

cable termination.<br />

Sub-<br />

Total C<br />

LS<br />

D<br />

Basic cost for the Substation LT panel and LT Bus duct<br />

Semi Modular substation LT panel –Specification 15

Master Control Facility. Hassan 573201<br />

Technical Specification For<br />

Supply, Installation, Testing &<br />

Commissioning of<br />

11KV Outdoor switching Units<br />

for<br />

11 / 0.433 kV Sub-station<br />

At<br />

MCF- HASSAN<br />

Contents<br />

Technical specifications & BOM – Page 1 to 20<br />

HT SLD Drg. – Page 21<br />

Earthing Drg. Page 22 & 23

GENERAL INSTRUCTIONS<br />

1. PRE QUALIFICATION<br />

a. The installer shall have minimum of 10years experience for the installation of MV<br />

& HV Sub-station equipment's.<br />

b. The party shall have executed similar nature of work (preferably 2003 onwards)<br />

of not less than Rupees Fifty lakh.<br />

c. The bidder should have highly experienced & qualified Supervisor for similar<br />

work.<br />

1.1 Following Pre qualification document to be enclosed.<br />

d. List of major contracts executed with latest work order copy & completion<br />

certificate. document.<br />

e. Companies Profile.<br />

f. The bidder shall have necessary class of license to install and commission HT<br />

equipment's as per I.E. rules, State and Central Electricity Authority approval.<br />

g. Appropriate class of license including Supervisor license.<br />

h. Annual turnover & IT return.<br />

2. OFFER IN TWO PARTS<br />

2.1 Part one: Techno- Commercial.<br />

The Techno-Commercial offer shall contain all the technical compliance statement<br />

including details/data/information asked in our documents. Literature, original<br />

Catalogues/documents supporting the compliance, bidder’s Commercial terms and<br />

conditions to be furnished. The offer shall be restricted to the brands/make mentioned<br />

in the tender. The part one should consist of all the technical details without cost<br />

details. All the information/data/details asked should be furnished in the part one. No<br />

cost details shall be included in this bid.<br />

2.2 Part two: Financial bid<br />

This should contain parties’ best competitive price offer to us.<br />

Tax details must be mentioned clearly. The cost of the item shall be furnished in the<br />

Financial bid only as per the bill of material format enclosed.<br />

Bidders may contact MCF for clarifications if any before submitting their offer.<br />

Clause-by-Clause technical Specification compliance for our specification<br />

document should be furnished along with the bill of material. Deviations, if any,<br />

shall be indicated in the offer. Better features other than specified shall be<br />

highlighted. Party may indicate items which are essential to complete the overall<br />

requirement.<br />

Spares and optional items shall be indicated. (Separate price shall be mentioned in<br />

price bid).<br />

3. SPARES AND TOOLS<br />

The bidder has to specify the list of recommended spare for the substation for a<br />

period of 3 years, to be procured by us and indicate the unit rate and the details of the<br />

local dealer whom we should contact for the procurement for maintenance after the<br />

Page 1 of 23

guarantee period. All tools and operational spares for day – today operation of the<br />

switchgear should be included in the scope of this offer.<br />

4. WARRANTY<br />

System supplied shall be covered under a warranty period of not less than TWO<br />

years from the date of receipt of the material at our site.<br />

5. SAFETY<br />

All equipment and material shall be designed manufactured and tested in accordance<br />

with the latest applicable Indian Standard, IEC standard.<br />

The electrical installation shall met the requirement of Indian Electrically Rules as<br />

amended up to date relevant IS code of practices and Indian electricity act. In addition<br />

other rules of regulations applicable to the work shall be followed. It shall be the<br />

responsibility of the contractor to comply with all the safety norms and fulfill all the<br />

relevant acts. MCF will not be responsible for any untoward accidents for the party’s<br />

working personnel.<br />

6. WORK INSTRUCTIONS<br />

The qualified technicians shall do the installation works.<br />

Only the qualified electricians shall do the other Electrical works.<br />

The party shall bring all the necessary tools and instruments required for erection,<br />

installation, commissioning and testing.<br />

For all electrical works such as crimping, terminal connections, tinning… etc right<br />

size and proper tools shall be used.<br />

7. WORK SCHEDULE<br />

Preliminary design review (PDR)<br />

PDR document shall be submitted to MCF with in 15 days of receipt of <strong>purchase</strong><br />

order<br />

Submission of PDR after release of PO:<br />

Review and clearance of PDR:<br />

Delivery of materials at site from the date of site clearance:<br />

Erection / Installation:<br />

Testing & Commissioning and acceptance:<br />

Submission of all documentation:<br />

15 Days<br />

10 Days<br />

45 Days<br />

60 Days<br />

30 Days<br />

15 Days<br />

8. DOCUMENTATION<br />

a. Three sets of Operation & Maintenance instruction manual.<br />

b. Three sets of Service manual with detailed power and control wiring diagram,<br />

circuit diagram.<br />

c. Three sets of original Spare parts catalogue with part numbers<br />

d. List of recommended spares.<br />

e. Three sets in original Handing over document & as- build drawings in Auto CAD<br />

with soft copy in CDs<br />

Page 2 of 23

9. TRAINING<br />

The bidder shall arrange free of cost training at site for operating & maintenance<br />

personnel with proper documentation.<br />

10. INSPECTION & TESTING<br />

VCBs, LBS and isolators with enclosures will be inspected at works before despatch<br />

THE FOLLOWINGS ARE NOT IN THE SCOPE OF THIS<br />

TENDER.<br />

a. Supply of Distribution Transformer, HT Regulator, HT Cable laying and<br />

terminations<br />

b. Civil works<br />

c. Inspection fee for CEA & State electrical Inspectorate or to any other<br />

agencies.<br />

NOTE<br />

1. Party shall give clear compliance confirmation for all the Technical<br />

specifications at pages 1 to 23<br />

2. Detailed Technical catalogues to be enclosed<br />

Page 3 of 23

TECHNICAL SPECIFICATION FOR 11 kV OUT DOOR SWITCHING UNITS -<br />

(RING MAIN UNIT) RMU<br />

1. SCOPE<br />

The scope of the work includes Supply, Installation, Integration, Testing and<br />

Commissioning of 11 KV compact substation switching units with Remote<br />

monitoring facilities at site with all safety accessories, tools and tackles. The Outdoor<br />

switching yard / Sub-station shall be installed and tested as per IEC 60 – 1330<br />

and shall be confirmed for internal arc test wherever applicable. Operating methods<br />

of Pre-fabricated Load break switch and VCBs which are cable & Bus-bar connected<br />

to be operated from outdoor & indoor / local or remote for alternating current of<br />

primary rated voltage 11kV and for a transformer of maximum power 2 x 1000 kVA<br />

for services frequencies. The Pre-Fabricated LBS RMU cubicles to be situated<br />

outdoor at ground level on a raised platform at Free State condition.<br />

1.1 SPECIAL NOTE:<br />

a. The required substation shall meet the power flow diagram as per enclosed<br />

schematic Drg. No MCF/OL/HT-SLD/2007<br />

b. The scope includes supply of 11 KV Ring Main Unit with VCBs, LBS,<br />

including CTs & PTs, Lightning Arrestors, Control battery, control Panels<br />

protective devices and its inter face to Industrial PCs / SCADA / remote<br />

monitoring system<br />

c. Both incoming, LBSs and VCBs outgoing termination should be suitable for<br />

cable connection with Single / dual run of 3 CORE, 150 / 120 SQ.mm XLPE,<br />

armoured 11KV power cable.<br />

d. There should be explicit provisions of terminals for connecting earth leads.<br />

e. An integrated remote monitoring and control unit with each switchgears should<br />

have facility to interfaced with SCADA / SNMP or RS 485 interface and<br />

necessary software to run under windows operating system (OS) shall be<br />

supplied for M&C.<br />

f. Offer may be made separately for total SCADA system and SNMP or RS 485<br />

interface to PC with necessary software for remote monitoring / control<br />

g. Local metering and indication / Remote Manual operation and monitoring Panel<br />

for the functional and operational status of the switchgear.<br />

h. The details of approvals received from Electricity boards, CPRI, Central and<br />

local inspectorates etc also should be enclosed with the offer.<br />

i. Party should have variable Current injection kit at site for Testing of relays &<br />

other tripping devices. The instrument should be calibrated & certified by Govt.<br />

Approved agency. It shall be the responsibility of the party to test and<br />

demonstrate the safety tripping parameters during CEA & Electrical<br />

Inspectorate. The necessary fees towards CEA & Electrical Inspectorate<br />

inspection will be born by the Dept.<br />

j. Manual over-ride for all Auto system to be provided.<br />

k. Bidder may ask for technical clarification if required. The party has to<br />

provide a point-by-point confirmation of the technical features with<br />

catelogues, specifications and bill of materials provided in the tender. If this<br />

Page 4 of 23

is not furnished, the tender is liable to be rejected without further<br />

communications.<br />

l. Any deviations / improved technical features of the product should be clearly<br />

brought out in the offer.<br />

2. SYSTEM DETAILS:<br />

Refer schematic drawing enclosed for incoming Feeders detail and system<br />

configuration. schematic Drg. No MCF/OL/HT-SLD/2007<br />

2.1 OUTDOOR & INDOOR SWITCHING UNIT BILL OF MATERIALS<br />

Sl.<br />

No<br />

1.<br />

Item description Qty Remarks<br />

LOAD BREAK SWITCH 1 MVA Regulator Feeder RMU<br />

module<br />

Make: Switch Gears tested & Approved by CPRI<br />

Installation Location- Outdoor<br />

Rating - 400 amps continuos<br />

HRC Fuse rating - 100 amps with striker for three phase<br />

tripping.<br />

Application - For 11 kV, 1MVA HT Regulator input, Out put &<br />

Bypass switching<br />

Bus bar- Copper Bus Bar arrangement for XLPE 120/150 sq.mm<br />

dual run cable termination<br />

Earth switch - with making capacity & necessary interlock with<br />

isolating device.<br />

Shunt trip – 24 V d.c<br />

Indication - local and remote ON/OFF indicators.<br />

Aux. Contacts - required 6 NO & 6 NC<br />

Enclosure: To be supplied with 3 module RMU out door<br />

enclosure IP 55<br />

Spares: HT HRC Fuses 100A – 1No. per LBS<br />

2. VACUUM CIRCUIT BREAKER 1 MVA Transformer Feeder<br />

RMU module<br />

Switch Gear Make: AREVA T&D / Schneider (MG) / ABB /<br />

Andrew Yule / Crompton Greaves / Siemens only<br />

2.0 VCB<br />

Application: - 1 MVA Transformer (11 / 0.433 kV) switching<br />

Installation Location - Indoor<br />

Rated voltage - 12 kV<br />

Rated Frequency - 50 Hz<br />

Rated continuos current - 630 amps<br />

Rated interrupting current - 26.3 kA<br />

Rated making current - 65.5 kA<br />

Rated short time current for 3 sec. - 26.3 kA<br />

Operating duty - 0 - 0.3 sec - CO 3 min - CO<br />

Power frequency withstand voltage - 28 kV<br />

3 Nos Out door<br />

cubicle to<br />

be arranged<br />

as per<br />

drawing<br />

2 Nos.<br />

Indoor<br />

cubicle to<br />

be arranged<br />

as per<br />

drawing<br />

(BOM<br />

mentioned<br />

Sl 2.0 to<br />

2.11 is for<br />

individual<br />

VCB<br />

modules)<br />

Page 5 of 23

Impulse withstand voltage - 75 kV<br />

Busbar rating - 120 % of rated continuos current<br />

Application - 1MVA Transformer switching<br />

Integral Earth switch – required<br />

Type: Horizontal draw out type with cradle assembly & metal<br />

ramp<br />

Operation -<br />

Spring closing mechanism - Electrical motor operated OR<br />

Solenoid<br />

Breaker Closing - Manual & Electrical through TNC switch /<br />

closing coil (110 V a.c derived from P.T)<br />

Under voltage release - 110 V a.c derived from P.T<br />

Shunt trip coil - 24 V d.c<br />

Safety interlock 7 locking facility – Required<br />

……………………………………………………………………<br />

2.1 Metering: Digital TVM for measuring power parameters,<br />

energy, harmonic parameters etc.,. with SNMP / RS 485 output<br />

interface. Software for remote M&C shall be supplied.<br />

Make: Satec. Model : PM 130 EH<br />

Analog Voltmeter, Size: 96 x 96 with selector switch<br />

Max. demand type Analog Ammeter ; Size: 96 x 96 with selector<br />

switch<br />

Phase sequence meter Size: 96 x 96 with selector switch<br />

……………………………………………………………………<br />

2.2 Protection Relay: Microprocessor based transformer<br />

protection relay with SNMP / RS 485 output interface.<br />

Features: 3 PHASE OVER CURRENT, EARTH FAULT RELAY +<br />

THERMAL FOR TRANSFORMER, 20-110V AC/DC<br />

Device code: 50/51, 46, 49<br />

Design: Numeric<br />

Functions: Low set and High set Over current<br />

Low set and High set Earth Fault with site selectable Trip<br />

characteristics, Definite inverse time tripping Thermal overload.<br />

Display of parameters, built in self supervision, RS 485 Port<br />

communication<br />

Make: L&T, Model: IM 30 T<br />

Software for remote M&C shall be supplied.<br />

……………………………………………………………………<br />

2.3 Master trip relay: High speed Relay with manual reset<br />

Type VAJH 13, Alstom make<br />

………………………………………………………………….<br />

2.4 Metering & protection CT's - Resin cast dry type<br />

Single phase, 2 core<br />

Ratio – 75-150/ 5 - 5 A<br />

Core - 1: Class - 1.0 15 VA<br />

Core II - Class 5P10, 15 VA<br />

Suitable for STC of 26.3 kA for 1 sec<br />

…………………………………………………………………….<br />

VCB BOM<br />

mentioned<br />

Sl 2.0 to<br />

2.11 is for<br />

individual<br />

VCB<br />

modules<br />

Page 6 of 23

2.5 PT. - Resin cast dry type<br />

Draw out type<br />

3 phase 11000 / 110 (delta/star)<br />

Burden - 100 VA Class - 1.0<br />

………………………………………………………………..…<br />

2.6 Breaker panel Indication:-<br />

Breaker ON - RED<br />

Breaker OFF - GREEN<br />

Auto trip indication - AMBER<br />

Spring Charge - BLUE<br />

Trip Circuit healthy – White<br />

…………………………………………………………………..<br />

2.7 Accessories.<br />

Mechanical counter, Space Heater with Thermostat, Fuse and<br />

ON/Off switch<br />

Aux. relays for Transformer high temperature alarm & trip, remote<br />

trip/indication for PC interface etc.<br />

Cubicle illumination lamp CFL 18 W retrofit type 230 V a.c<br />

T - N - C switch<br />

Electronic Hooter 24 V d.c Multi tone type<br />

Anti pumping contactor<br />

Emergency OFF Push Button Local & Remote<br />

………………………………………………………………….<br />

2.8 Spares: Spring charging motor –1, U/V& Shunt trip –1 each<br />

………………………………………………………………….<br />

2.9 Mimic diagram: An operating mimic diagram shall be<br />

provided on the front side of each cubicle.<br />

………………………………………………………………….<br />

2.10 Enclosuer: Metal Clad; IP - 54; Module suitable to inter face<br />

other modules with Bus coupler Module, Panel shall have<br />

compartment for housing VCB, CT, PT, Relays and cable<br />

chambers for each VCB. RMUs shall be Internal arc tested; Fully<br />

insulated. Fully compartmentalized sheet steel enclosure with<br />

automatic safety shutters, G.I foundation bolts with provision for<br />

terminating 2 x 120 sq.mm XLPE cable using Raychem heat<br />

shrinkable type end termination kit.<br />

…………………………………………………………………..<br />

2.11 Paint - Light Admirality Grey - 631 IS5 Powder coated<br />

smooth glossy finish.<br />

VCB BOM<br />

mentioned<br />

Sl 2.0 to<br />

2.11 is for<br />

individual<br />

VCB<br />

modules<br />

Page 7 of 23

3. VACUUM CIRCUIT BREAKER Bus Coupler RMU<br />

Application: - Bus coupler at 11kV bus<br />

Enclosuer: Metal Clad; IP - 54; Internal arc tested; Fully<br />

insulated. Fully compartmentalized sheet steel enclosure with<br />

automatic safety shutters, G.I foundation bolts with provision for<br />

terminating 1 x 120 sq.mm XLPE cable using Raychem heat<br />

shrinkable type end termination kit.<br />

Service - Indoor<br />

Paint - Light Admirality Grey - 631 IS5 Powder coated smooth<br />

glossy finish.<br />

Rated voltage - 12 kV<br />

Rated Frequency - 50 Hz<br />

Rated continuos current - 630 amps<br />

Rated interrupting current - 26.3 kA<br />

Rated making current - 65.5 kA<br />

Rated short time current for 3 sec. - 26.3 kA<br />

Operating duty - 0 - 0.3 sec - CO 3 min - CO<br />

Power frequency withstand voltage - 28 kV<br />

Impulse withstand voltage - 75 kV<br />

Busbar rating - 120 % of rated continuos current<br />

Operation -<br />

Spring closing mechanism - Electrical motor operated OR<br />

Solenoid<br />

Breaker Closing - Manual & Electrical through TNC switch.<br />

Shunt trip coil - 24 V d.c<br />

Safety interlock & locking facility - Required<br />

Breaker panel Indication:-<br />

Breaker ON - RED<br />

Breaker OFF - GREEN<br />

Accessories.<br />

Mechanical counter, Space Heater with Thermostat, Fuse and<br />

ON/Off switch<br />

Aux. relays for remote trip/indication for PC interface etc Cubicle<br />

illumination lamp CFL 18 W retrofit type 230 V a.c<br />

T - N - C switch<br />

Anti pumping contactor<br />

Mimic diagram: An operating mimic diagram shall be provided<br />

on the front side of each cubicle.<br />

Enclosure: IP 54. Identical for inter facing above two Panels<br />

4 Earthing system<br />

a. Copper Plate earthing station as per Drg. Enclosed 6 Nos<br />

b. G.I Pipe earthing station as per Drg. Enclosed 10 Nos<br />

c. Out door yard grid earthing as per Drg. Enclosed 4 + 16<br />

d. Supply & laying of Copper flat for earthing 40 x 6 mm 100 Mtrs<br />

e. Supply & laying of G.I flat for earthing 35 x 4 mm 500 Mtrs<br />

5. Monitoring & Control<br />

a. PLC for complete Sub - Station Automation 1 No<br />

1 No For Bus<br />

Coupler<br />

Page 8 of 23

(HT/LT & Captive system Analog , Digital input & out<br />

put to interface PC for remote monitoring & control) as<br />

per requirement.<br />

Required Software, hardware & interface cables<br />

A.R<br />

b. For SNMP/RS 485 interface to PC from individual<br />

equipment<br />

c. OFC cable 1KM<br />

d. End termination of the OFC cable 2 Nos<br />

Industrial PC (Server & Viewer) as per specification 2 Nos<br />

e. enclosed<br />

Preferred make: HP<br />

f. Colour laser printer : Preferred Make HP 1 No<br />

g.<br />

Stand alone Sub-station Mimic display of Poly- 1 No.<br />

membrane<br />

Supply, Installation, Testing & commissioning of Remote 2 Nos<br />

Annunciation & Operating console with necessary<br />

hardware interface apart from monitoring / control<br />

through PC. (Panel for Manual & Remote mode of<br />

h. Operation at local substation Control room) as per detail<br />

specification<br />

Size: 600mm x 600mm x 2100mm with accessories for<br />

housing complete<br />

Make: Elsteel, BCH or Rittal (PS)<br />

Supply, Installation, Testing & commissioning of PC 2 Nos<br />

Enclosure System for housing Industrial PCs<br />

i.<br />

Size: 600mm x 636(836)mm x 1600mm (Approx)<br />

With Base/plinth, stationary based on TS & Handle set<br />

and other accessories complete<br />

Make: Elsteel, BCH or Rittal (PS)<br />

j. Control cables for Sl.No. h 400 Mtrs.<br />

Supply, Installation, Testing & commissioning of Substation<br />

1 set<br />

6 battery bank of 30 volts, 150 AH.<br />

Each cell 2 V, 150 AH stationary<br />

Make; Exide Plante (YKP) cell along with battery<br />

charger & Non corrosive battery stand.<br />

7<br />

OPTIONAL<br />

Total Sub-station SCADA & Interfacing software 1 set<br />

2.2 Site Condition<br />

The equipment covered under this specification is for indoor & outdoor installation<br />

and should be suitable for use at the sites in CESC (Chamundeshwary Electricity<br />

Supply Co.) & MCF (Master Control Facility) jurisdiction for the prevailing climatic<br />

conditions.<br />

2.3 Temperature:<br />

The reference ambient temperature is to be taken as 43.3°C as per IS 9676.<br />

Maximum ambient temp = 38°C<br />

Page 9 of 23

2.4 Relative Humidity<br />

Maximum: 90%, Minimum: 30 %<br />

Average Annual rainfall: 750mm<br />

Average no of thunderstorm days/annum: 40<br />

Altitude: 1000 M above S/L<br />

Rainy months: June to November<br />

The atmosphere is normal, laden with mild dust suspension during the dry months<br />

and is subjected to fog in cold months Heavy lightening occurs in the area during<br />

rainy months.<br />

All equipments shall be designed to withstand seismic forces, corresponding to an<br />

acceleration of 0.1g.<br />

3.0 CODES AND STANDARDS TO BE FOLLOWED<br />

The equipment shall comply with the requirements of latest revision of following<br />

standards issued by BIS (Bureau of Indian Standards), unless otherwise specified.<br />

IS Code Description<br />

IS 3427: Metal enclosed Switchgear and Control gear for voltages above<br />

1000 v but not exceeding 11000 v.<br />

IS 9046 Ac conductors of voltage above 1000V up to and including<br />

11000V.<br />

IEC:466:1987<br />

:IS:14659<br />

AC Insulator –enclosed Switch gear Control gear for rated<br />

voltages above 1KV and up to and including 38KV.<br />

IEC:694,1980:<br />

IS:12729<br />

Common clauses for high voltage Switch gear and Control gear<br />

standards.<br />

IEC: 529:1989: Degree of protection provided by enclosures(IP code).<br />

IS: 12063<br />

IS 722: Integrating meters.<br />

IS 1248: Electrical indicating instruments.<br />

IS 2071: Methods of high voltage testing.<br />

IEC:129 AC Switches and Earthing Switches.<br />

IEC:801 Monitoring and Control.<br />

IS:13118 / High voltage AC circuits breakers.<br />

BS 5311<br />

IS/BS:5463: High Voltage Switches.<br />

IS/BS:5227 Metal enclosed AC Switch gear.<br />

IS/BS 5463 High Voltage switches<br />

IEC 298 BS MV metal-enclosed / Switchgear<br />

5311<br />

IEC 265 MV switches,<br />

IEC 56 MV AC circuit breakers,<br />

IEC 801 Monitoring and control<br />

SECONDARY WIRING<br />

Specification : HFFR unilay, pre twisted single core multi strand electrolyte<br />

grade, annealed copper cable,<br />

Page 10 of 23

Confirming to IS: 694 / 1990<br />

Size & Rating 1.5 sq-mm, 1.1 Kv grade shall be used for all control / interlock<br />

wiring.<br />

2.5 sq-mm, 1.1 Kv grade shall be used for all CT related wiring.<br />

Power cable of suitable size for SDFUs / MCBs of rating up to<br />

63 A. Color of the cable shall be Gray for control wiring.<br />

Connectors : Mating type male-female connectors and holders shall be used<br />

between each transportable section for control wiring.<br />

Cage clamps : Din rail mounting, cage clamp terminal connectors shall be<br />

used for all control and power wiring up to 63A.<br />

Ferruling : Standard ferruling concept shall be followed for clear<br />

identification of control circuit wiring as per IS 375 mentioned<br />

below.<br />

Letter ‘A’ – CT for primary protection excluding O/C<br />

Letter ‘B’ –CT for busbar protection<br />

Letter ‘C’ –CT for O/C including E/F & instantaneous<br />

Letter ‘D’ –CT for metering & voltage control.<br />

Letter ‘E’ –Reference voltage for instrument metering &<br />

protection<br />

Letter ‘F’ – Reference voltage for voltage control<br />

Letter ‘G’ – Reference voltage for synchronizing<br />

Letter ‘H’ –AC & AC/DC supplies Numbers –1 to 69 for<br />

S’gears & Gen.<br />

Letter ‘J’ – DC supply<br />

-70 to 99 for<br />

Transformers<br />

Letter ‘K’ – Closing & tripping control circuit – Any no. 1<br />

upward<br />

Letter ‘L’ – Alarm & indication – Any no. 1 upward<br />

Letter ‘M’ – Auxiliary & motor control devices –1 to 19 for<br />

Switchgears, 20 to 69 for Generators & 70 to 99 for<br />

Transformers<br />

Numbers 10 to 29 – R phase<br />

Numbers 30 to 49 – Y phase<br />

Numbers 50 to 69 – B phase<br />

Numbers 70 to 89 – Residual & Neutral CT &<br />

Numbers 90 –Earth wire directly connected to earth bar.<br />

For DC bus<br />

Positive –Red, -Negative –Blue<br />

3.1 Incase of imported equipment standards of the country of origin shall be applicable if<br />

these standards are equivalent or stringent than the applicable Indian standards.<br />

3.2 The equipment shall also conform to the provisions of Indian electricity rules and<br />

other statutory regulations currently in force in the country.<br />

4.0 SYSTEM:<br />

The system network is 11000 Volts, 3 phase 3 wires 50 cycles which is stepped down<br />

to 433 volts through distribution transformer with neutral solidly grounded. The<br />

Page 11 of 23

voltage and frequency are subject to variation as per statutory limits governed by<br />