High Performance Sealing for the Hydropower ... - James Walker

High Performance Sealing for the Hydropower ... - James Walker

High Performance Sealing for the Hydropower ... - James Walker

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

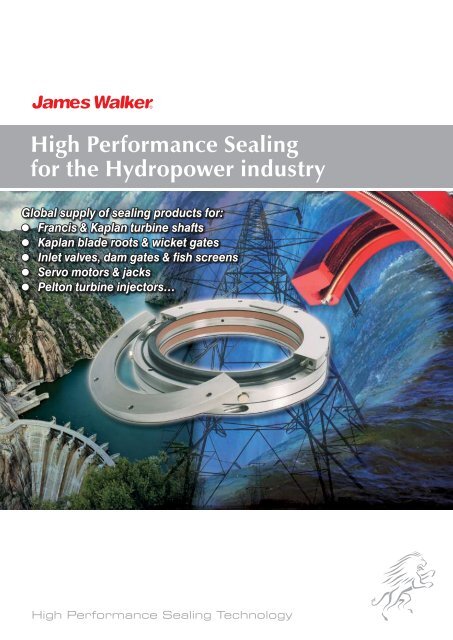

<strong>High</strong> <strong>Per<strong>for</strong>mance</strong> <strong>Sealing</strong><br />

<strong>for</strong> <strong>the</strong> <strong>Hydropower</strong> industry<br />

Global supply of sealing products <strong>for</strong>:<br />

● Francis & Kaplan turbine shafts<br />

● Kaplan blade roots & wicket gates<br />

● Inlet valves, dam gates & fish screens<br />

● Servo motors & jacks<br />

● Pelton turbine injectors…<br />

<strong>High</strong> <strong>Per<strong>for</strong>mance</strong> <strong>Sealing</strong> Technology

Main <strong>High</strong> per<strong>for</strong>mance Page Subject sealing Heading <strong>for</strong> hydropower<br />

Introduction<br />

<strong>James</strong> <strong>Walker</strong>’s vast ranges of fluid sealing products and<br />

services are widely used in hydropower applications around<br />

<strong>the</strong> globe. We back <strong>the</strong>se with top level technical expertise<br />

from dedicated specialists in our Power Generation Industry<br />

Support Team and highly efficient customer support<br />

operations.<br />

HydroSele ® — innovative cartridge seal<br />

Long life, low maintenance sealing <strong>for</strong> turbine shafts<br />

The quality and longevity of our products are well appreciated by<br />

original equipment manufacturers and hydropower operators,<br />

who rely on <strong>the</strong>ir efficiency to improve cost effectiveness and<br />

operational per<strong>for</strong>mance by helping to reduce plant downtime.<br />

Your global partner in sealing success<br />

<strong>James</strong> <strong>Walker</strong> is a global manufacturer and distributor that<br />

supplies standard ranges and custom-designed sealing products<br />

to virtually every industrial sector. These activities help to keep<br />

plant and equipment running safely, efficiently and with improved<br />

environmental per<strong>for</strong>mance, year-in and year-out.<br />

We have a worldwide family of companies with over 50<br />

production, engineering, distribution and customer support sites<br />

spread across Europe, Australasia, Asia Pacific, Africa and <strong>the</strong><br />

Americas.<br />

At a local level, a close-knit network of <strong>James</strong> <strong>Walker</strong> companies<br />

and official distributors supplies our products and services to<br />

well over 100 countries. Our worldwide IT systems and logistics<br />

operations give customers <strong>the</strong> surety of supply <strong>the</strong>y need.<br />

HydroSele ® is <strong>the</strong> result of over ten years of design, development<br />

and long-term field trials on operational Francis and Kaplan-type<br />

equipment working under a wide variety of conditions. This fully-split<br />

cartridge assembly has verified its ability to improve significantly a<br />

turbine’s cost efficiency and operational per<strong>for</strong>mance.<br />

Why fit HydroSele ® ?<br />

● Swift pay back on investment. At two years, HydroSele should<br />

have paid <strong>for</strong> itself in terms of maintenance costs, turbine<br />

downtime and power absorption. At four years, total investment<br />

in cash and downtime could be just one-quarter of that <strong>for</strong> an<br />

equivalent mechanical seal.<br />

● Long and reliable service life. Prototype HydroSeles are<br />

still running trouble-free after ten years’ operation. This<br />

reliability enables you to schedule maintenance with absolute<br />

confidence.<br />

● Simple to install and adjustment free. HydroSele is one of <strong>the</strong><br />

easiest arrangements to fit on a turbine shaft. Downtime is cut<br />

to a minimum and <strong>the</strong> seal is adjustment free once installed.<br />

● Economical refurbishment. It takes just hours to refurbish<br />

HydroSele on site. Stand-by sealing units are no longer<br />

needed.<br />

● <strong>High</strong> efficiency sealing. HydroSele’s unique method of<br />

operation gives a very low and controlled level of water leakage.<br />

This greatly reduces <strong>the</strong> risk of flood damage to plant caused<br />

by uncontrolled leakage past sealing faces.<br />

General in<strong>for</strong>mation<br />

Health warning: If PTFE or fluoroelastomer (eg, FKM, FFKM, FEPM) products are<br />

heated to elevated temperatures, fumes will be produced which may give unpleasant<br />

effects, if inhaled. Whilst some fumes are emitted below 250°C from fluoroelastomers<br />

or below 300°C from PTFE, <strong>the</strong> effect at <strong>the</strong>se temperatures is negligible. Care should<br />

be taken to avoid contaminating tobacco with particles of PTFE or fluoroelastomer, or<br />

with PTFE dispersion, which may remain on hands or clothing. Material Safety Data<br />

Sheets (MSDS) are available on request.<br />

In<strong>for</strong>mation in this publication and o<strong>the</strong>rwise supplied to users is based on our<br />

general experience and is given in good faith, but because of factors which are<br />

outside our knowledge and control and affect <strong>the</strong> use of products, no warranty is<br />

given or is to be implied with respect to such in<strong>for</strong>mation. Specifications are subject<br />

to change without notice. Statements of operating limits quoted in this publication are<br />

not an indication that <strong>the</strong>se values can be applied simultaneously.<br />

Operating capabilities<br />

Shaft diameters: 250mm to 750mm (9.84-29.53 in). Please<br />

consult <strong>James</strong> <strong>Walker</strong> if shaft diameter exceeds 750mm.<br />

Maximum pressure at gland: 10bar gauge (145psi gauge).<br />

Maximum surface speed: 10m/s (1969fpm). Please consult<br />

<strong>James</strong> <strong>Walker</strong> when higher shaft speeds are involved.<br />

Maximum temperature: 50°C (122°F) at seal/flush interface.<br />

Flush water pressure: 2bar (29psi) above system pressure.<br />

How supplied<br />

Custom manufactured from modular components to suit specific<br />

applications. Service can include installation of HydroSele plus<br />

on-site cartridge refurbishment.<br />

<br />

To To order or or get fur<strong>the</strong>r details, please call your call local your contact shown on on rear cover or or listed at at www.jameswalker.biz

Solosele ® KB Hydro — special design<br />

<strong>High</strong> integrity sealing <strong>for</strong> Kaplan blade roots<br />

Chevron ® — multi-ring V packing<br />

For servo motors and valve trunnion<br />

housings<br />

Chevron ® (known as Shallex ® in some<br />

regions) is our universally proven multilip<br />

hydraulic packing. With its robust<br />

construction and long service life, it is<br />

ideal <strong>for</strong> safety critical operations and<br />

adverse mechanical conditions.<br />

This robust seal was developed specifically <strong>for</strong> <strong>the</strong> blade roots of<br />

Kaplan-type turbines. It operates with great success on turbine<br />

blades at hydropower schemes across <strong>the</strong> world — both as an<br />

OEM fit and as retrofit on older equipment — where it reduces<br />

significantly both turbine downtime and maintenance costs.<br />

Why fit Solosele ® KB Hydro?<br />

● Very cost effective. Solosele ® KB Hydro out-per<strong>for</strong>ms and runs<br />

significantly longer than many multi-lip seals and o<strong>the</strong>r seal<br />

types installed on Kaplan blade roots.<br />

● <strong>High</strong> per<strong>for</strong>mance sealing. Solosele KB Hydro has excellent<br />

low and high-pressure sealing capabilities under fluctuating<br />

conditions (including negative pressure).<br />

● Keeps oil in and water out. Two seals are installed back-toback<br />

in a housing to prevent hydraulic fluid leaking to <strong>the</strong> water<br />

course, and prevent water ingress to <strong>the</strong> blade adjustment<br />

mechanism.<br />

● Adverse mechanical conditions. Solosele KB Hydro will<br />

efficiently seal shafts that run eccentrically on worn bearings.<br />

● Suits OEM applications. Supplied as endless-type seals <strong>for</strong><br />

simple and highly effective OEM fitment on new turbines.<br />

● Easy to retrofit. Available as split-type seals <strong>for</strong> swift On-Site<br />

Joining using <strong>James</strong> <strong>Walker</strong>’s special OSJ ® technique that<br />

gives fully-moulded seal per<strong>for</strong>mance without removing <strong>the</strong><br />

blades.<br />

Recommended dimensions<br />

10mm housing section up to 575mm shaft diameter; 12.5mm<br />

section to 700mm diameter; 16mm section to 900mm diameter;<br />

19mm section to 1100mm diameter; 25mm section above<br />

1100mm diameter. (Please consult <strong>James</strong> <strong>Walker</strong> <strong>for</strong> maximum<br />

diameters and o<strong>the</strong>r section/diameter ratios).<br />

Why fit Chevron ® ?<br />

● Suitable <strong>for</strong> reciprocating (servo motors) and slow oscillating or<br />

rotary action.<br />

● Excellent resistance to extrusion and wear.<br />

● Low friction and low shaft wear <strong>for</strong> virtually zero maintenance.<br />

Operating capabilities<br />

Maximum pressure — reciprocating: 420bar (to ISO 5597)<br />

Temperature range: -20°C to +100°C<br />

Maximum surface speed — reciprocating: 0.5m/s<br />

How supplied<br />

As endless or split-type rings, in metric and inch sizes. Radial<br />

sections from 4mm upwards. Endless rings to 2.25m OD.<br />

Lofilm ® — versatile multi-lip seal<br />

For servo motors, valve trunnion<br />

housings and Pelton turbine<br />

injectors<br />

Lofilm ® operates reliably <strong>for</strong> very long<br />

periods with <strong>the</strong> minimum thickness of<br />

stable fluid film on <strong>the</strong> dynamic contact<br />

surfaces.<br />

Why fit Lofilm ® ?<br />

● Low pressure sealing capability on servo-motor applications.<br />

● Ideal <strong>for</strong> trunnion housings on butterfly valves.<br />

● Special sealing systems combining Lofilm and Solosele ® G on<br />

Pelton turbine injectors prove far superior to multi-lip packings.<br />

Operating capabilities<br />

Maximum pressure — reciprocating: 420bar (to ISO 5597)<br />

Temperature range: -20 to +120°C<br />

Maximum surface speed — reciprocating: 0.5m/s.<br />

How supplied<br />

As endless or split-type rings, in metric and inch sizes. Radial<br />

sections from 4mm upwards. Endless rings to 2.25m OD.<br />

How supplied<br />

Endless seals <strong>for</strong> OEM installation or split-type seals with OSJ<br />

(On-Site Joining) kits <strong>for</strong> retrofitting — in a range of sections to<br />

suit Kaplan-type blade root housings.<br />

To order or get fur<strong>the</strong>r details, call your local contact shown on rear cover or listed at www.jameswalker.biz

<strong>High</strong> per<strong>for</strong>mance sealing <strong>for</strong> hydropower<br />

Solosele ® G — single-element seal<br />

For servo-motors, wicket gates,<br />

fixed wheel gates, trunnion<br />

housings and Pelton turbine<br />

injectors<br />

Robust, compact seal that saves<br />

space without compromising high<br />

integrity sealing.<br />

Why fit Solosele ® G?<br />

● For servo-motors where housing space is restricted.<br />

● Modified version of Solosele ® G is <strong>the</strong> modern replacement <strong>for</strong><br />

‘O’ and ‘U’ rings on wicket gates.<br />

● Protects plastic and fabric bearings on fixed wheel gates.<br />

● Ideal <strong>for</strong> trunnion housings on butterfly and spherical valves.<br />

● Special sealing systems combining Lofilm ® and Solosele G on<br />

Pelton turbine injectors prove far superior to multi-lip packings.<br />

Operating capabilities<br />

Maximum pressure — reciprocating: 420bar (to ISO 5597)<br />

Temperature range: -20 to +120°C<br />

Maximum surface speed — reciprocating: 0.5m/s.<br />

How supplied<br />

As endless rings, in metric or inch sizes: 3mm ID to 2.3m OD.<br />

<strong>Walker</strong>sele ® — radial lip seal<br />

For fixed wheel gates, fish screen<br />

gearboxes and low head turbine<br />

shafts<br />

Our vast family of <strong>Walker</strong>sele ®<br />

radial lip seals is extensively proven<br />

worldwide <strong>for</strong> long-term bearing<br />

protection throughout <strong>the</strong> power<br />

generation industry.<br />

Why fit <strong>Walker</strong>sele ® ?<br />

● <strong>Walker</strong>sele ® D6 retains lubricant and/or prevents water ingress<br />

on runner bearings of fixed wheel gates.<br />

● <strong>Walker</strong>sele ® D7 will minimise river pollution from fish screen<br />

gearboxes at heads up to 4bar.<br />

● <strong>Walker</strong>sele D7 arrangements can be suitable <strong>for</strong> some low<br />

pressure turbine shafts.<br />

● Swift to fit with our patented OSJ ® (On-Site Joining) kit.<br />

Operating capabilities<br />

Maximum system pressures: 0.2bar <strong>for</strong> D6 design; 4bar <strong>for</strong> D7.<br />

Maximum surface speed: typically 15m/s <strong>for</strong> D6; 12m/s <strong>for</strong> D7.<br />

How supplied<br />

Metric and inch sizes, in over 10,000 size/material combinations.<br />

Duramid ® — aramid-based gland packing<br />

For small diameter turbine shafts,<br />

penstock expansion joints, pumps<br />

and valves<br />

A tough, high per<strong>for</strong>mance gland<br />

packing <strong>for</strong> sealing duties with<br />

abrasive and aggressive fluids.<br />

Why fit Duramid ® ?<br />

● Long life and minimal shaft wear on<br />

small diameter turbine shafts.<br />

● Extrusion resistance with large clearances <strong>for</strong> packed glands<br />

on penstock expansion joints.<br />

● Resilient and responsive in long-term service with pumps and<br />

valves handling chemically aggressive and abrasive media.<br />

Operating capabilities<br />

Maximum valve pressure: 150bar<br />

Maximum system pressure — rotary pumps: 25bar<br />

Maximum shaft speed — rotary pumps: 20m/s<br />

Maximum system pressure — reciprocating: 150bar<br />

Maximum surface speed — reciprocating: 1.5m/s<br />

Temperature range: -50°C to +250°C.<br />

How supplied<br />

All popular square sections from 3mm to 25mm, boxed in 8m<br />

lengths. Also available as split pre<strong>for</strong>med rings and sets.<br />

O<strong>the</strong>r recommended gland packings<br />

For pumps and valves across <strong>the</strong> hydropower industry<br />

Aluflon<br />

● White, con<strong>for</strong>mable packing <strong>for</strong> valves and rotary or<br />

reciprocating pumps handling media with suspended solids.<br />

● Long life and low maintenance.<br />

● Chemically compatible with media in pH range 0-14.<br />

Arasele<br />

● Soft and tough replacement <strong>for</strong> hard fibre aramid packings.<br />

● For valves and rotary or reciprocating pumps handling highly<br />

abrasive slurries or aggressive chemical media.<br />

● Kind to shafts — can eliminate unnecessary wear.<br />

Hornet<br />

● <strong>High</strong> per<strong>for</strong>mance packing that absorbs <strong>the</strong> eccentric action of<br />

worn shafts and bearings.<br />

● For valves and rotary or reciprocating pumps handling highly<br />

abrasive slurries or aggressive chemical media.<br />

Ramiex<br />

● Extremely durable packing with excellent extrusion resistance.<br />

● Used with great success on reciprocating pumps working at<br />

300bar with water containing highly abrasive particles.<br />

● Also suitable <strong>for</strong> valves and rotary pumps.<br />

To order or get fur<strong>the</strong>r details, please call your contact shown on rear cover or listed at www.jameswalker.biz

Main <strong>High</strong> per<strong>for</strong>mance Page Subject sealing Heading <strong>for</strong> hydropower<br />

Nebar ® — cork-elastomer jointings<br />

Flange gaskets on trans<strong>for</strong>mers<br />

and switchgear<br />

Seven grades of our Nebar ® corkelastomer<br />

jointings are exceptionally<br />

well proven <strong>for</strong> long-term flange<br />

sealing duties with heavy electrical<br />

plant.<br />

Nebar ® Black —<br />

Hi-<strong>Per<strong>for</strong>mance</strong> Electrical<br />

● For hydrogen coolers or where SF6 gas is present.<br />

Nebar ® Red — <strong>High</strong> Pressure<br />

● For high pressure applications in switchgear and trans<strong>for</strong>mers.<br />

Nebar ® White — Premium Neoprene Electrical<br />

● Top grade product <strong>for</strong> trans<strong>for</strong>mers and switchgear. Offers long<br />

operational life in contact with mineral oils.<br />

Nebar ® Grey — Premium Nitrile Electrical<br />

● Premium quality, medium hardness grade that meets ABB<br />

specifications <strong>for</strong> trans<strong>for</strong>mers and switchgear.<br />

Nebar ® Orange — Neoprene Electrical<br />

● Economical high-quality grade <strong>for</strong> switchgear and trans<strong>for</strong>mers.<br />

Nebar ® Purple — Nitrile Electrical<br />

● Recommended <strong>for</strong> trans<strong>for</strong>mer lids where mating faces are out<br />

of parallel. Resistant to vapour phase drying.<br />

How supplied<br />

Cut gaskets to any shape, size or quantity. Also in sheet <strong>for</strong>m to<br />

all popular thicknesses.<br />

Elastomer mouldings and extrusions<br />

Inlet valve seals, dam gate seals…<br />

Our plants <strong>for</strong> <strong>the</strong> production of<br />

elastomeric components are<br />

amongst <strong>the</strong> most advanced in <strong>the</strong><br />

world. Custom-designed<br />

components <strong>for</strong> <strong>the</strong> hydropower<br />

sector include:<br />

● Seals <strong>for</strong> butterfly and spherical<br />

inlet valves, with a wide selection to<br />

fit Boving types.<br />

Flange gaskets and sheet jointings<br />

General services, including oxygen<br />

and potable water<br />

Our wide range of sheet jointings<br />

includes: non-asbestos fibre grades<br />

<strong>for</strong> <strong>the</strong> majority of flange duties,<br />

Supagraf ® expanded graphite types<br />

<strong>for</strong> high temperatures, and Fluolion ®<br />

Integra White and Blue stabilised PTFE<br />

<strong>for</strong> use where hygiene and chemical<br />

resistance are top priority. Also ePTFE gasket products by WL<br />

Gore & Associates.<br />

How supplied<br />

Precision cut gaskets to any shape, size or quantity. In sheet or<br />

roll <strong>for</strong>m; sizes and thicknesses dependent on material grade.<br />

Hydraulic sealing<br />

For virtually every hydraulic duty<br />

We have a family of rod/gland seals,<br />

piston seals, wipers and bearing<br />

strips that suits <strong>the</strong> heaviest jacks and<br />

cylinders, down to <strong>the</strong> most accurate<br />

control actuators and instruments.<br />

How supplied<br />

Standard or non-standard sizes.<br />

RotaBolt ® — tension control fasteners<br />

Assured tension across bolted joints<br />

Our RotaBolt ® tension control fasteners<br />

provide reliable bolted connections in<br />

applications where cost, health and<br />

safety or environmental consequences<br />

are of paramount importance on<br />

structural assemblies and flange joints.<br />

How supplied<br />

Standard range: M12 to M125 bolts or M18 to M125 studs in most<br />

materials, with o<strong>the</strong>r sizes available. Customer-supplied fasteners<br />

can be modified.<br />

● Vertical lift sliding gate seals — as solid elastomer extrusions,<br />

fabric-rein<strong>for</strong>ced elastomer, or elastomer with a bonded<br />

cladding of wear-resistant PTFE.<br />

<br />

To To order or or get fur<strong>the</strong>r details, please call your call local your contact shown on on rear cover or or listed at at www.jameswalker.biz

<strong>James</strong> <strong>Walker</strong> companies worldwide<br />

<strong>James</strong> <strong>Walker</strong> & Co<br />

Tel: +44 (0)1270 536000<br />

Fax: +44 (0)1270 536100<br />

Email: csc@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> Australia<br />

Tel: +61 (0)2 9644 9755<br />

Fax: +61 (0)2 9645 2009<br />

Email: jwadmin@jameswalker.com.au<br />

<strong>James</strong> <strong>Walker</strong> Benelux<br />

(Belgium)<br />

Tel: +32 3 820 7900<br />

Fax: +32 3 828 5484<br />

Email: sales.be@jameswalker.biz<br />

(Ne<strong>the</strong>rlands)<br />

Tel: +31 (0)186 633111<br />

Fax: +31 (0)186 633110<br />

Email: sales.nl@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> China<br />

Tel: +86 21 5117 5802<br />

Fax: +86 21 5116 6899<br />

Email: info.cn@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> Deutschland<br />

Tel: +49 (0)40 386 0810<br />

Fax: +49 (0)40 389 3230<br />

Email: info@jameswalker.de<br />

<strong>James</strong> <strong>Walker</strong> France<br />

Tel: +33 (0)437 497 480<br />

Fax: +33 (0)437 497 483<br />

Email: headoffice.fr@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> Iberica<br />

Tel: +34 94 447 0099<br />

Fax: +34 94 447 1077<br />

Email: iberica@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> Ireland<br />

Tel: +353 (0)21 432 3626<br />

Fax: +353 (0)21 432 3623<br />

Email: sales.ie@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> Italiana<br />

Tel: +39 02 257 8308<br />

Fax: +39 02 263 00487<br />

Email: jameswalker@jameswalker.it<br />

<strong>James</strong> <strong>Walker</strong> Mfg (USA)<br />

Tel: +1 708 754 4020<br />

Fax: +1 708 754 4058<br />

Email: helpdesk1@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> New Zealand<br />

Tel: +64 (0)9 272 1599<br />

Fax: +64 (0)9 272 3061<br />

Email: sales@jameswalker.co.nz<br />

<strong>James</strong> <strong>Walker</strong> Norge<br />

Tel: +47 22 706800<br />

Fax: +47 22 706801<br />

Email: firmapost@jameswalker.no<br />

<strong>James</strong> <strong>Walker</strong> Oil & Gas (USA)<br />

Tel: +1 281 875 0002<br />

Fax: +1 281 875 0188<br />

Email: oilandgas@jameswalker.biz<br />

<strong>James</strong> <strong>Walker</strong> Singapore<br />

Tel: +65 6777 9896<br />

Fax: +65 6777 6102<br />

Email: sales@jameswalker.com.sg<br />

<strong>James</strong> <strong>Walker</strong> South Africa<br />

Tel: +27 (0)31 205 6251/2/3<br />

Fax: +27 (0)31 205 6266<br />

Email: info.za@jameswalker.biz<br />

Solosele ® KB Hydro __ <strong>for</strong><br />

Kaplan turbine blade roots<br />

Cost effective, long-term sealing<br />

Endless or On-Site Joining (OSJ)<br />

Efficient sealing on highly eccentric shafts<br />

Greatly reduces turbine downtime<br />

Compression Packings<br />

The comprehensive guide<br />

to compression packing<br />

products <strong>for</strong> all pumps,<br />

valves, lids and gland<br />

sealing duties<br />

<strong>High</strong> <strong>Per<strong>for</strong>mance</strong> <strong>Sealing</strong> Technology<br />

<strong>High</strong> <strong>Per<strong>for</strong>mance</strong> <strong>Sealing</strong> Technology<br />

Hydrosele ® Solosele ® KB Hydro Compression packings Gaskets & jointings<br />

RotaBolt ®<br />

<strong>Walker</strong>sele ®<br />

<strong>James</strong> <strong>Walker</strong> & Co Ltd<br />

Power Generation Industry Support Team<br />

1 Millennium Gate, Westmere Drive<br />

Crewe, Cheshire CW1 6AY, UK<br />

Tel: +44 (0)1270 536000<br />

Fax: +44 (0)1270 536100<br />

Email: powergen.jwc.uk@jameswalker.biz<br />

CERTIFICATE No. FM 01269<br />

BS EN ISO 9001:2000<br />

BP4322 1007/2m<br />

CPN000094509<br />

Registered Office: Lion House, Oriental Road, Woking, Surrey GU22 8AP, United Kingdom. Reg No. 2432592 England<br />

© <strong>James</strong> <strong>Walker</strong> 2007