AZ31 magnesium tube (made in Japan) Niobium steel tube (HT ...

AZ31 magnesium tube (made in Japan) Niobium steel tube (HT ...

AZ31 magnesium tube (made in Japan) Niobium steel tube (HT ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TOYO FRAME CO., Ltd.<br />

Company Profile<br />

Toyo Frame Co., Ltd. has 30 years of <strong>in</strong>dustry-lead<strong>in</strong>g expertise <strong>in</strong><br />

pipe weld<strong>in</strong>g/cutt<strong>in</strong>g/process<strong>in</strong>g and special th<strong>in</strong>-pipe process<strong>in</strong>g<br />

employ<strong>in</strong>g titanium, <strong>magnesium</strong>, alum<strong>in</strong>um and sta<strong>in</strong>less <strong>steel</strong><br />

materials.<br />

Now we take full advantage of this experience <strong>in</strong> our design,<br />

manufacture and supply of special frame products, for everyth<strong>in</strong>g<br />

from lightweight rac<strong>in</strong>g bicycles to mounta<strong>in</strong> bikes and tandem<br />

bicycles.<br />

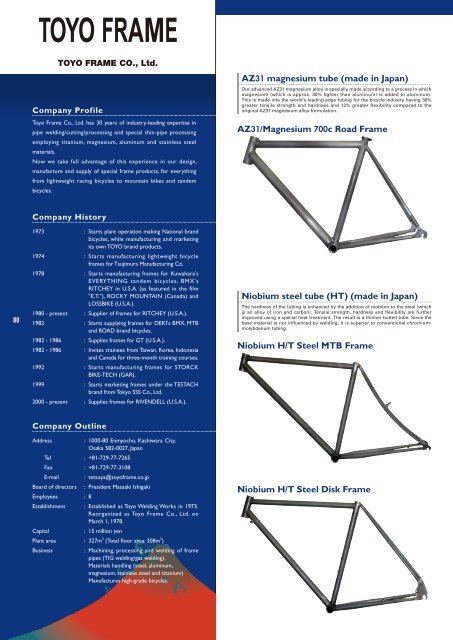

<strong>AZ31</strong> <strong>magnesium</strong> <strong>tube</strong> (<strong>made</strong> <strong>in</strong> <strong>Japan</strong>)<br />

Our advanced <strong>AZ31</strong> <strong>magnesium</strong> alloy is specially <strong>made</strong> accord<strong>in</strong>g to a process <strong>in</strong> which<br />

<strong>magnesium</strong> (which is approx. 30% lighter than alum<strong>in</strong>um) is added to alum<strong>in</strong>um.<br />

This is <strong>made</strong> <strong>in</strong>to the world's lead<strong>in</strong>g-edge tub<strong>in</strong>g for the bicycle <strong>in</strong>dustry hav<strong>in</strong>g 30%<br />

greater tensile strength and hardness and 12% greater flexibility compared to the<br />

orig<strong>in</strong>al <strong>AZ31</strong> <strong>magnesium</strong> alloy formulation.<br />

<strong>AZ31</strong>/Magnesium 700c Road Frame<br />

80<br />

Company History<br />

1973 : Starts plant operation mak<strong>in</strong>g National brand<br />

bicycles, while manufactur<strong>in</strong>g and market<strong>in</strong>g<br />

its own TOYO brand products.<br />

1974 : Starts manufactur<strong>in</strong>g lightweight bicycle<br />

frames for Tsujimura Manufactur<strong>in</strong>g Co.<br />

1978 : Starts manufactur<strong>in</strong>g frames for Kuwahara's<br />

EVERYTHING tandem bicycles, BMX's<br />

RITCHEY <strong>in</strong> U.S.A. (as featured <strong>in</strong> the film<br />

"E.T."), ROCKY MOUNTAIN (Canada) and<br />

LOSSBIKE (U.S.A.).<br />

1980 - present : Supplier of frames for RITCHEY (U.S.A.).<br />

1982 : Starts supply<strong>in</strong>g frames for DEKI's BMX, MTB<br />

and ROAD brand bicycles.<br />

1982 - 1986 : Supplies frames for GT (U.S.A.).<br />

1982 - 1986 : Invites tra<strong>in</strong>ees from Taiwan, Korea, Indonesia<br />

and Canada for three-month tra<strong>in</strong><strong>in</strong>g courses.<br />

1992 : Starts manufactur<strong>in</strong>g frames for STORCK<br />

BIKE-TECH (GAR).<br />

1999 : Starts market<strong>in</strong>g frames under the TESTACH<br />

brand from Tokyo SSS Co., Ltd.<br />

2000 - present : Supplies frames for RIVENDELL (U.S.A.).<br />

<strong>Niobium</strong> <strong>steel</strong> <strong>tube</strong> (<strong>HT</strong>) (<strong>made</strong> <strong>in</strong> <strong>Japan</strong>)<br />

The hardness of the tub<strong>in</strong>g is enhanced by the addition of niobium to the <strong>steel</strong> (which<br />

is an alloy of iron and carbon). Tensile strength, hardness and flexibility are further<br />

improved us<strong>in</strong>g a special heat treatment. The result is a th<strong>in</strong>ner butted <strong>tube</strong>. S<strong>in</strong>ce the<br />

base material is not <strong>in</strong>fluenced by weld<strong>in</strong>g, it is superior to conventional chromiummolybdenum<br />

tub<strong>in</strong>g.<br />

<strong>Niobium</strong> H/T Steel MTB Frame<br />

Company Outl<strong>in</strong>e<br />

Address<br />

: 1000-80 Enmyocho, Kashiwara City,<br />

Osaka 582-0027, <strong>Japan</strong><br />

Tel : +81-729-77-7265<br />

Fax : +81-729-77-3108<br />

E-mail : tetsuya@toyoframe.co.jp<br />

Board of directors : President Masaaki Ishigaki<br />

Employees : 8<br />

Establishment : Established as Toyo Weld<strong>in</strong>g Works <strong>in</strong> 1973.<br />

Reorganized as Toyo Frame Co., Ltd. on<br />

March 1, 1978.<br />

Capital<br />

: 15 million yen<br />

Plant area : 327m 2 (Total floor area: 308m 2 )<br />

Bus<strong>in</strong>ess<br />

: Mach<strong>in</strong><strong>in</strong>g, process<strong>in</strong>g and weld<strong>in</strong>g of frame<br />

pipes (TIG weld<strong>in</strong>g/gas weld<strong>in</strong>g).<br />

Materials handl<strong>in</strong>g (<strong>steel</strong>, alum<strong>in</strong>um,<br />

<strong>magnesium</strong>, sta<strong>in</strong>less <strong>steel</strong> and titanium)<br />

Manufactures high-grade bicycles.<br />

<strong>Niobium</strong> H/T Steel Disk Frame

TY RoadRacer<br />

TY CycloCross<br />

81<br />

TY Sportiv