GL 22 - Jet Technologies

GL 22 - Jet Technologies

GL 22 - Jet Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

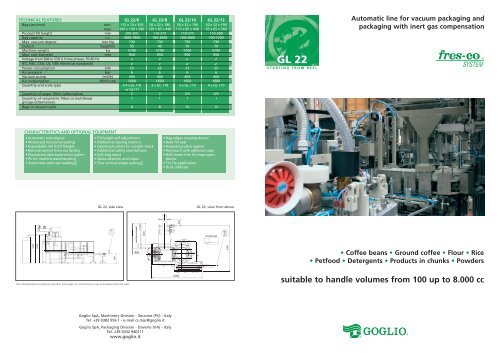

TECHNICAL FEATURES <strong>GL</strong> <strong>22</strong>/6 <strong>GL</strong> <strong>22</strong>/8 <strong>GL</strong> <strong>22</strong>/10 <strong>GL</strong> <strong>22</strong>/12<br />

Bag size (mm) min. 115 x 70 x 350 50 x 32 x 180 50 x 32 x 190 50 x 32 x 190<br />

max. 200 x 130 x 580 130 x 85 x 440 115 x 85 x 440 95 x 65 x 340<br />

Product fill height mm 200-300 110-275 110-275 110-200<br />

Bag capacity c.c. 1600-7800 100-3000 100-3000 100-1200<br />

Max. vacuum degree mm Hg 730 730 730 730<br />

Output bags/min 35 45 70 70<br />

Machine weight kg 5700 5700 5700 5700<br />

Max. reel diameter mm 950 950 950 950<br />

Voltage from 208 to 550 V, three phases, 50-60 Hz 3 3 3 3<br />

IEC, NEC, CSA, UL, VDE electrical standardsl 3 3 3 3<br />

Power consumption kW 25 25 25 25<br />

Air pressure bar 6 6 6 6<br />

Vacuum pump (m3/h) 400 400 400 400<br />

Air consumption Nl/minute 1600 1600 1600 1600<br />

Quantity and scale type 3-4 x <strong>GL</strong> 110 3 x <strong>GL</strong> 110 3 x <strong>GL</strong> 110 4 x <strong>GL</strong> 110<br />

or <strong>GL</strong>111<br />

Quantity of auger fillers (alternative) 2 2 2/3 2/3<br />

Quantity of volumetric fillers or multihead 1 1 1 1<br />

groups (alternative)<br />

Bags in vacuum cycle 6 8 10 12<br />

<strong>GL</strong> <strong>22</strong><br />

STARTING FROM REEL<br />

Automatic line for vacuum packaging and<br />

packaging with inert gas compensation<br />

CHARACTERISTICS AND OPTIONAL EQUIPMENT<br />

• Automatic web aligner<br />

• Motorized horizontal sealing<br />

• Expandable roll shaft flanges<br />

• Remote control from our factory<br />

• Production data supervision system<br />

• PC for machine data handling<br />

• Automatic web reel loading∑<br />

• Fill height self adjustment<br />

• Additional sealing stations<br />

• Opening buckets for weight check<br />

• Additional safety seal stations<br />

• Soft bag reject<br />

• Splice detector and reject<br />

• Four vertical edges sealing∑<br />

• Bag edges creasing device<br />

• Back fin seal<br />

• Degassing valve applier<br />

• Reclosure with adhesive tape<br />

• Half moon trim for easy-open<br />

device<br />

• Tin-Tie application<br />

• Dust collector<br />

<strong>GL</strong> <strong>22</strong>, side view<br />

<strong>GL</strong> <strong>22</strong>, view from above<br />

• Coffee beans • Ground coffee • Flour • Rice<br />

• Petfood • Detergents • Products in chunks • Powders<br />

The indicated technical data are indicative, and subject to confirmation in case of quotation and final order.<br />

suitable to handle volumes from 100 up to 8.000 cc<br />

Goglio SpA, Machinery Division - Zeccone (PV) - Italy<br />

Tel. +39 0382 956.1 - e-mail cs.mac@goglio.it<br />

Goglio SpA, Packaging Division - Daverio (VA) - Italy<br />

Tel. +39 0332 940111<br />

www.goglio.it

<strong>GL</strong> <strong>22</strong><br />

High speed Form &<br />

Fill Line for vacuum<br />

packaging<br />

• Vacuum packaging, with partial or total back gas flush.<br />

Reel unwinding with brake, film aligner<br />

and splice table. Automatic reel<br />

loading and unloading.<br />

Filling of the bags with various systems<br />

according to the type of product to be<br />

packed (electronic scales with load cells<br />

or multi-head scales or auger fillers).<br />

Vibration of the finished bags.<br />

Vacuum or gas flush packaging with<br />

oxygen residue of less than 1%.<br />

Bag top finishing on clearing conveyor.<br />

Finishing groups adjustment<br />

according to product density.<br />

• Wide range of finished packages: flat pouches, gusseted<br />

bags with square bottom, straight or folded upper<br />

bag flap, half moon shaped flap for easy opening,<br />

folded once or twice, fixed with adhesive tape, glued<br />

and fitted with reclosure tin-tie. Possible application of<br />

a degassing valve.<br />

Vertical forming of the bags by means<br />

of collar and mandrel of the desired<br />

section. Back and bottom sealing of<br />

the bags.<br />

• Wide selection of heat sealable packaging materials,<br />

transparent, paper coated, double wall, metallized, and<br />

easy open.<br />

• Memorized machine recipes for easy and quick change<br />

of bag size, style and material.<br />

• Complete integration between the forming machine<br />

and the valve application system. It is possible to apply<br />

many different valves, both in their inner and visible<br />

versions.<br />

Inner<br />

Thin<br />

High flow