Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

June 2009<br />

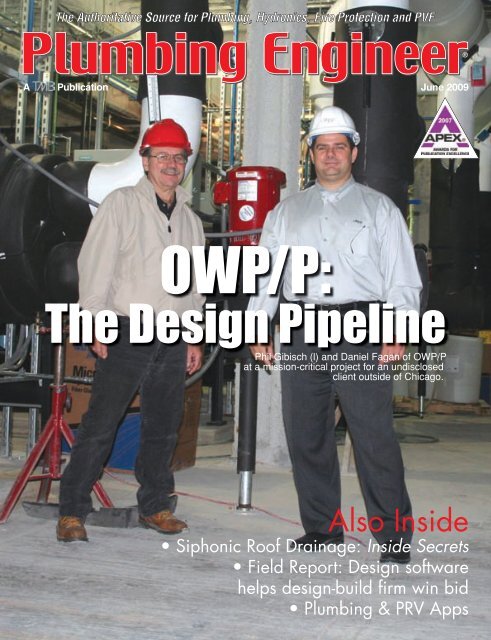

OWP/P:<br />

The Design Pipeline<br />

Phil Gibisch (l) and Daniel Fagan of OWP/P<br />

at a mission-critical project for an undisclosed<br />

client outside of Chicago.<br />

Also Inside<br />

• Siphonic Roof Drainage: Inside Secrets<br />

• Field Report: Design software<br />

helps design-build firm win bid<br />

• <strong>Plumbing</strong> & PRV Apps

Circle 1 on Reader Reply Form on page 61

Circle 2 on Reader Reply Form on page 61<br />

TM

INSIDE THIS ISSUE<br />

Volume 37, Number 6, June 2009<br />

FEATURES<br />

38 OWP/P: The Design Pipeline<br />

42 Siphonic Roof Drainage: Inside Secrets<br />

COLUMNS<br />

6 Editor’s Letter: The German diaries<br />

12 Designer’s Guide: Green Plumbers ®<br />

16 Code Update: Fuel gas safety<br />

21 Fire Protection: Protecting fire sprinklers from<br />

the human element<br />

26 Modern Hydronics: Doin’ the math<br />

32 Solar Solutions: Solar overheat protection<br />

36 Solar Cooling: Cool it, sunshine: Solar-powered A/C<br />

OWP/P:<br />

June 2009<br />

The Design Pipeline<br />

Phil Gibisch (l) and Daniel Fagan of OWP/P<br />

at a mission-critical project for an undisclosed<br />

client outside of Chicago.<br />

Also Inside<br />

• Siphonic Roof Drainage: Inside Secrets<br />

• Field Report: Design software<br />

helps design-build firm win bid<br />

• <strong>Plumbing</strong> & PRV Apps<br />

On the cover: OWP/P is a leader in<br />

providing integrated architecture,<br />

interior design, engineering and<br />

consulting services to clients worldwide.<br />

Read the article on page 38.<br />

INDUSTRY NEWS &<br />

OTHER DEPARTMENTS<br />

8 | WaterSense helps save $$$<br />

8 | AO Smith to offer Revit software<br />

8 | Ames Fire & WW revamps website<br />

10 | Uponor releases ’09 training<br />

30 | PLUMBING INNOVATION: CAROMA<br />

50 | FIELD REPORT: TACO<br />

52 | PRODUCT APP: AGF<br />

53 | LITERATURE NEWS<br />

54-55 | NEW PRODUCTS<br />

A Member of Our Family<br />

Since 2006<br />

www.siouxchief.com 1-800-821-3944<br />

56 | PRODUCT APP: JAY R. SMITH<br />

58 | LETTERS/INDUSTRY MOVERS<br />

59 | Hybrid piping offers flexibility<br />

60 | Classifieds<br />

61 | Ad Index<br />

Circle 3 on Reader Reply Card<br />

62 | CLSE adds PRV seminar<br />

Page 4/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Circle 4 on Reader Reply Form on page 61

Editor’s Letter<br />

John Mesenbrink, Editorial Director<br />

The German Diaries<br />

A first-hand account of traveling with Viega in Germany<br />

German coffee is a bit strong and it takes a little getting used to, but it’s 5:30 in the<br />

morning, and after an eight-hour flight, I need a pick-me-up. It is the beginning of a<br />

week-long trip to Germany, thanks to the generosity of Viega, an innovative global<br />

leader in plumbing and heating technology. (The powers that be had invited me to<br />

accompany 12-15 contractors, wholesalers, engineers and Viega employees to visit<br />

two Viega manufacturing and logistics facilities, attend ISH Messe Frankfurt and get<br />

a taste of the German culture. And that we did!)<br />

Tuesday, March 10, 2009 — At 5:30 a.m., I find myself navigating through the<br />

labyrinth of what is the Frankfurt airport. I am one of the first to arrive at our meeting<br />

point and I meet up with our Viega contact, Dave Garlow, vice president of sales<br />

for Viega North America. A very interesting guy, Dave reminds me of, well, me when<br />

I was single — never backing down from an adventure. During our early morning<br />

conversation, I learn that Dave loves to ride anything with wheels. He rides motorcycles<br />

to motorbikes, and he<br />

travels internationally any<br />

chance he gets. If you run into<br />

him, ask him about riding dirt<br />

bikes across the Mexican countryside.<br />

Cool stuff.<br />

Now we wait until our entire<br />

posse meets us at the airport,<br />

which spans the next three hours.<br />

One by one each personality<br />

makes his presence. Sean<br />

McGinnis, junior vice president,<br />

J.J.M. <strong>Plumbing</strong> Co. Inc.,<br />

The ISH Frankfurt Show had it all! The Viega<br />

booth captures it all: size, scale and attendance.<br />

Glendora, New Jersey — near<br />

Philly, actually — introduces<br />

himself. Sean is the most downto-earth,<br />

happy-go-lucky guy.<br />

After our tour of Germany, Sean is off to do some snowboarding at Innsbruck in<br />

Austria. Again, cool stuff.<br />

Next to the meeting point is Dan Schmierer, president of Viega North America.<br />

Normally I initially might get nervous sitting across the table from the “head honcho”<br />

of a major company, but Dan has an uncanny way of making everyone feel comfortable.<br />

I guess that’s because he likes to talk and he engages you in conversation.<br />

Running Viega North America for nearly 10 years, Dan should be proud of the fact<br />

that he is a main facilitator of the opening of a new 439,000,000-sq.-ft. manufacturing<br />

plant in McPherson, Kan.<br />

One of the bonuses of the trip is meeting people from across the country, and<br />

across borders. We have people on the trip who speak English, Spanish, French and,<br />

of course, German.<br />

The rest of this story can be found on page 46<br />

PLUMBING ENGINEER<br />

(USPS 567-950)<br />

ISSN 0192-1711<br />

PLUMBING ENGINEER (USPS 567-950) ISSN 0192-1711 is published monthly by TMB Publishing Inc., 1838 Techny<br />

Court, Northbrook, IL 60062. Phone (847) 564-1127, Fax (847) 564-1264. Magazine is free to those who design and specify<br />

plumbing/piping systems in commercial, industrial, institutional and governmental buildings; as well as government officials<br />

and plumbing inspectors. Subscription rates for U.S. and Canada: $50 for one year, $90 for two years. Other countries:<br />

$300 per year. Periodical postage paid at Northbrook, IL, and additional mailing offices. POSTMASTER: Change of<br />

address should be sent to <strong>Plumbing</strong> <strong>Engineer</strong>, 519 E. Briarcliff Rd, Bolingbrook, IL 60440. Material and opinions contained<br />

in contributed articles are the responsibility of the authors, not of TMB Publishing Inc., <strong>Plumbing</strong> <strong>Engineer</strong> magazine<br />

or its Editorial Advisory Board. The publisher cannot assume responsibility for any claims made by advertisers.<br />

Copyright © 2007 TMB Publishing Inc. All rights reserved. Volume 36, Number 6. <strong>Plumbing</strong> <strong>Engineer</strong> is microfilmed by<br />

University Microfilms, Ann Arbor, MI, and indexed by <strong>Engineer</strong>ing Index Inc. Publications Mail Agreement No. 41499518.<br />

Return Undeliverable Canadian Addresses to PO Box 503, RPO West Beaver Creek, Richmond Hill ON L4B 4R6<br />

Editorial, Advertising,<br />

Production, Accounting and<br />

Administrative Offices<br />

1838 Techny Ct.<br />

Northbrook, IL 60062<br />

(847) 564-1127 • Fax: (847) 564-1264<br />

E-mail: info@tmbpublishing.com<br />

Owner<br />

Tom M. Brown<br />

Editorial & Production Staff<br />

John Mesenbrink, Editorial Director<br />

Cate C. Brown, Production Manager<br />

Mark Bruno, Art Director/Prepress<br />

Contributors<br />

Timothy Allinson, P.E., Designer’s Guide<br />

Richard Schulte, Fire Protection<br />

Ron George, CIPE, CPD, Code Update<br />

Bob “Hot Rod” Rohr, Green Systems<br />

Paul Rohrs, Modern Hydronics<br />

Bristol Stickney, Solar Solutions<br />

Sales Staff<br />

Brad Burnside, Publisher<br />

East<br />

1838 Techny Court, Northbrook, IL<br />

60062 Phone: 847/564-1127<br />

Cell: 224/659-3984<br />

Fax: 847/564-1264<br />

E-mail: brad@tmbpublishing.com<br />

David Schulte<br />

Midwest, South and E. Canada<br />

1838 Techny Court, Northbrook, IL 60062<br />

Phone: 847/564-1127<br />

Cell: 847/420-4686<br />

Fax: 847/564-1264<br />

E-mail: dave@tmbpublishing.com<br />

Diane Spangler<br />

West, Texas and W. Canada<br />

PO Box 9802, Fountain Valley, CA<br />

92728 Phone: 714/839-6700<br />

Fax: 714/839-6777<br />

E-mail: diane@tmbpublishing.com<br />

Page 6/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

If you specify this:<br />

“Must meet ASSE<br />

1016 T/P...”<br />

All you need to know is:<br />

“Leonard<br />

Valve, 7600<br />

Showermaster ® ”<br />

NEW!<br />

The Showermaster ® 7600<br />

is certified to the stringent<br />

pressure and temperature<br />

requirements of ASSE 1016.<br />

It reduces water flow to<br />

prevent a continued spray of<br />

all hot or all cold water if a<br />

water supply should fail;<br />

therefore protecting bathers<br />

against scald conditions.<br />

Leonard’s new Showermaster ®<br />

7600 meets the needs of<br />

temperature and pressure<br />

control with technological<br />

advances raising the<br />

expectations for performance.<br />

Leonard meets the challenge<br />

by balancing time-proven<br />

technology with cutting-edge<br />

water control innovation.<br />

• Compensates for supply<br />

temperature and pressure<br />

fluctuations<br />

• Built-in shutoff, singlehandle<br />

operation<br />

• Highly responsive<br />

copper encapsulated<br />

thermostat<br />

• Bronze, brass<br />

and stainless steel<br />

construction<br />

Whether it’s shower<br />

valves or thermostatic<br />

master mixing valves,<br />

Leonard has the<br />

right mix for all of<br />

your requirements.<br />

Learn more about the<br />

Showermaster ® 7600 at<br />

www.leonardvalve.com,<br />

or call 888.797.4456.<br />

Adjustable High<br />

Temperature Limit Stop<br />

Set for (43° C) 110°F<br />

(No special modifications<br />

required for low temperature<br />

hot water supply)<br />

Highly responsive<br />

copper encapsulated<br />

thermostat<br />

In “OFF” position, Hot and Cold<br />

Water Entries are Shut Off,<br />

Eliminating the Possibility of<br />

Cross Connection<br />

Leonard...the right mix.<br />

Circle 5 on Reader Reply Form on page 61

Industry News<br />

WaterSense on pace to help builders save money<br />

WAshiNGtoN — the average newly built, single family home<br />

in the U.s. can waste 10,000 gallons of water annually. ePA’s<br />

Watersense program soon will make it easier for builders to<br />

construct and differentiate homes that use water about 20%<br />

more efficiently, once its draft specification is final.<br />

Watersense has refined its draft labeling specification<br />

(initially released in May 2008) for single-family new<br />

homes based on comments received from the public and<br />

additional research. the revised specification addresses<br />

efficient plumbing fixtures, hot water delivery systems,<br />

appliances, landscape design and irrigation.<br />

the revised specification will ensure that future<br />

Watersense labeled homes still use 20% less water than<br />

similar new homes, while reducing the burden and cost to<br />

the builders. the modifications to the previous draft specification<br />

have built in some additional flexibility; the<br />

changes include<br />

• hot water delivery systems — New performance standards<br />

no longer require specific types of hot water delivery<br />

systems or insulation of hot water pipes.<br />

• Landscaping — the revised landscaping criteria<br />

allow for a wider variety of landscaping options.<br />

• irrigation systems — Additional requirements for<br />

minimum distribution uniformity values and rain shutoff<br />

devices increase the efficiency of newly installed irrigation<br />

systems.<br />

• Water budget tool — An improved resource, the water<br />

budget tool, better reflects growing seasons and plant<br />

water requirements.<br />

• inspection guidelines- An optional sampling protocol<br />

adds flexibility and streamlines the inspection process for<br />

production builders.<br />

once the specification is finalized, homes built and<br />

inspected to the specification will bear the Watersense<br />

label. homeowners who invest in Watersense labeled<br />

homes will not only save water, but also money on utility<br />

bills. Watersense labeled new homes should be achievable<br />

by builders and affordable to consumers without compromising<br />

water savings. the Watersense new homes specification<br />

will also align with existing green building programs<br />

to ease the cost and obstacles to achieving other<br />

green labels.<br />

the updated specification for single-family new homes<br />

will be available for public comment through July 7,<br />

2009. ePA anticipates releasing the final Water-efficient<br />

single-Family New home specification in late 2009. ePA<br />

welcomes input on the revisions made to the specification,<br />

and encourages all interested parties to view the most<br />

recent documents and provide comments. in addition,<br />

ePA plans to hold at least one public meeting on the revisions<br />

in June 2009.<br />

For details on the specification, upcoming public meetings,<br />

and other program information, visit<br />

www.epa.gov/watersense.<br />

A.O. Smith to offer Revit software<br />

Ames Fire & Waterworks revamps website<br />

AshLANd City, teNN. — A. o. smith Water Products<br />

Company is the first in the water heater industry to offer<br />

specifying engineers and architects complete access to 3d<br />

building information modeling (BiM) of its commercial<br />

water heater and boiler products with Autodesk® revit®<br />

software. By visiting the company’s website, specifying<br />

engineers can download the 3d revit models to be inserted<br />

into their building model or drawings.<br />

each revit product family file allows the selection of the<br />

individual model and its associated database of critical installation<br />

information. Now, specifying engineers can easily<br />

integrate an A. o. smith product into their building designs.<br />

downloads are available at www.hotwater.com/lit/revit.html.<br />

Future plans include making the A. o. smith files available<br />

from the Autodesk “seek site” where product models can be<br />

directly accessed from within the revit program.<br />

“due to numerous requests from specifying engineers,<br />

we knew it was the right time to offer this service,” said<br />

howard holliman, product manager for A. o. smith<br />

Water Products Company.<br />

“We are proud that A. o. smith is the first water heater<br />

manufacturer to offer revit 3d product models to our engineers.<br />

it enables us to continue to build our brand message<br />

of innovation,” said david Chisolm, brand manager.<br />

revit models are currently available for the Cyclone® Xi<br />

(Bth), vF Boiler (vW / vB), Master-Fit® (Btr) and the<br />

Gold series (dre) product families.<br />

North ANdover, MAss. — Ames Fire & Waterworks<br />

announced the launch of its new revamped website:<br />

www.amesfirewater.com. the site’s<br />

new design makes finding<br />

information easy and<br />

fast. New detailed<br />

product pages<br />

include photos,<br />

descriptions, literature,<br />

approval information<br />

and warranty<br />

information. A new<br />

approval finder application<br />

lets users search Ames products<br />

by valve type and approval<br />

agency. Ames also has updated its<br />

site to include information on<br />

California and vermont Lead Free compliance. Lastly, Ames<br />

also is making available a mobile version of its website, available<br />

at www.amesfirewater.com.<br />

Ames Fire & Waterworks, A Watts Water technologies<br />

Company, is based in sacramento, Calif. Ames is focused<br />

upon and dedicated to the backflow prevention industry.<br />

the management team has more than 75 years of combined<br />

backflow industry experience and is committed to quality<br />

products and effective customer service.<br />

More Industry News on page 10<br />

Page 8/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Introducing Sloan’s<br />

Solar Collection<br />

Combining environmentally sound technologies with<br />

leading-edge electronics, the Sloan SOLIS ® is designed<br />

to deliver continuous energy and water savings, while<br />

reducing operating and maintenance costs.<br />

Sloan SOLIS ®<br />

High-Efficiency<br />

Urinal<br />

Sloan SOLIS ®<br />

Dual-Flush<br />

High-Efficiency<br />

Toilet<br />

Sloan SOLIS ® Faucet<br />

The Sloan SOLIS ® solar-powered collection is<br />

a breakthrough in design and function that<br />

transforms light into power. The Sloan SOLIS ®<br />

Series of Flushometers and Faucets provides<br />

the ultimate in conservation and performance.<br />

Generating Efficiency Through Technology<br />

Patent Pending<br />

866-663-2289<br />

www.sloanvalve.com<br />

Circle 6 on Reader Reply Form on page 61

• sept. 10-11: radiant solutions Controls 101 Workshop<br />

• sept. 14-16: radiant solutions Fundamentals 101<br />

Workshop<br />

• sept. 17: radiant solutions Ads Workshop<br />

• sept. 21: AQUAsAFe Level 1<br />

• oct. 6-8: radiant solutions Fundamentals 101 Workshop<br />

• oct. 9: radiant solutions Ads Workshop<br />

• oct. 12: AQUAsAFe Level 1<br />

• oct. 14-16: radiant solutions Advanced 102 Workshop<br />

• oct. 26-27: radiant solutions Controls 101 Workshop<br />

• oct. 29-30: radiant solutions Controls 102 Workshop<br />

• Nov. 2-4: radiant solutions Fundamentals 101 Workshop<br />

• Nov. 5: radiant solutions Ads Workshop<br />

• Nov. 9: AQUAsAFe Level 1<br />

• Nov. 12-13: radiant solutions Controls 101 Workshop<br />

• dec. 7: AQUAsAFe Level 1<br />

• dec. 9-11: radiant solutions Fundamentals 101<br />

Workshop<br />

For additional information about all Uponor training<br />

programs, including online webinars, or to register online<br />

for factory training, visit the Uponor website at<br />

www.uponor-usa.com/training.<br />

Circle 7 on Reader Reply Form on page 61<br />

Industry News<br />

Continued from page 8<br />

Uponor releases 2009 training schedule<br />

APPLe vALLey, MiNN. — the June through december<br />

2009 dates for Uponor’s Factory training are available<br />

and ready for online registration by going to www.uponorusa.com/training.<br />

“this year we’re taking our factory training classes to<br />

the next level,” said Wes sisco, senior trainer, at Uponor.<br />

“We’ve enhanced our curriculum to include more in-depth<br />

education and training for our radiant and multi-purpose<br />

plumbing and fire sprinkler systems. With this new training<br />

program, we can ensure our professional partners in<br />

the industry are well-equipped to meet the demanding<br />

needs of today’s building market.”<br />

headed by sisco, and supported by customer trainer<br />

steve swanson, the Uponor Factory training program<br />

offers the following training classes for radiant and<br />

plumbing professionals:<br />

• June 11-13: radiant solutions Fundamentals 101<br />

Workshop<br />

• July 7: AQUAsAFe Level 1<br />

• July 20-22: radiant solutions Fundamentals 101<br />

Workshop<br />

• July 27-28: radiant solutions Controls 101 Workshop<br />

• Aug. 13: AQUAsAFe Level 1<br />

• Aug. 17-19: radiant solutions Fundamentals 101<br />

Workshop<br />

• Aug. 20: radiant solutions Ads Workshop<br />

Solar Usage Now launches new system<br />

hArLAN, iNd. — solar Usage Now, LLC will be releasing<br />

the s.U.N. equinox heating system, a technology that is<br />

new to the U.s. marketplace but has been a staple in the<br />

european and Australian markets for years. solar Usage<br />

Now is a renewable energy distributor and has the exclusive<br />

rights to the s.U.N. equinox heating system<br />

throughout the United states.<br />

the s.U.N. equinox heating system is a combination<br />

hot water storage tank and instantaneous water heater providing<br />

100% of domestic hot water and space heating<br />

needs while placing special emphasis on water hygiene.<br />

the system is solar ready and has both residential and<br />

commercial applications. the s.U.N. equinox heating<br />

system utilizes the unique rotex atmospheric tank. the<br />

system is capable of producing up to 18 gallons per minute<br />

of hot hygienic water with a heat loss of less than 3ºF per<br />

day in residential installs. Commercial models can be<br />

assembled to handle large heat loads for hotels, hospitals,<br />

nursing homes, restaurants, schools and factories.<br />

For more information about the s.U.N. equinox<br />

heating system, please visit www.solarusagenow.com.<br />

More Industry News on page 59<br />

Page 10/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

<strong>Engineer</strong>ing a<br />

Siphonic Roof<br />

Drainage System<br />

Shouldn’t Have<br />

You Looking in<br />

7 Different<br />

Directions...<br />

Your Single Source For a Complete<br />

Siphonic Roof Drainage System<br />

Loro-Josam offers the most complete siphonic roof drainage solution available to<br />

the U.S. market. The Loro-Josam wide range of balcony and roof drainage systems<br />

made of galvanized steel are combined with the Loro-Josam galvanized steel push-fit<br />

drainage system and are offered complete with siphonic system calculations to<br />

ensure excellent results for every installation.<br />

The Loro-Josam siphonic drainage system offers facility owners, plumbing engineers<br />

and mechanical contractors a proven and complete siphonic roof drainage solution<br />

with support and warranty pointing only in one direction.<br />

For more information contact your local representative or visit our website at www.josam.com<br />

JOSAM COMPANY 525 West Highway 20 Michigan City, IN 46360 | P 800.36.JOSAM | F 800.627.0008 | www.josam.com<br />

Circle 8 on Reader Reply Form on page 61<br />

JOSAM COMPANY 525 West Highway 20 Michigan City, IN 46360 P 800.36.JOSAM<br />

F 800.627.0008 www.josam.com

Designer’s Guide<br />

Timothy Allinson, P.E., Murray Co., Long Beach, Calif.<br />

GreenPlumbers ®<br />

Just when I thought I had heard all I could stand about<br />

everything green, I learned about GreenPlumbers and was<br />

pleasantly surprised. Something drew me to their ASPE<br />

presentation last April — call it morbid curiosity — but<br />

instead of being frustrated with the usual environmental bandwagon<br />

shtick, I heard creative ideas that promoted industry<br />

specific concepts that I have been harping on for years.<br />

GreenPlumbers was created in Australia in 2001 following<br />

a 10-year drought. The program has helped produce a 50%<br />

reduction in water use across that continent. In September<br />

2007 an alliance was established with the U.S. and since then<br />

the program has educated over 1,500 American plumbers in<br />

the arena of plumbing efficiency.<br />

The GreenPlumbers accreditation program includes five<br />

courses, namely Climate Care, Solar Hot Water, Caring For<br />

Our Water, Water Efficient Technology, and Inspection Report<br />

Services. They also offer five elective workshops in Natural<br />

Wastewater Treatment, Commercial Hot Water Systems,<br />

Principles in Pumps, Urban Irrigation Systems, and Cooling<br />

Tower Efficiency.<br />

What really opened my ears to GreenPlumbers was what<br />

you might call their vision statement: The ability to bring<br />

change to an industry that has remained relatively stagnant<br />

for over 30 years; improving public image, attracting the<br />

younger generation, and creating champions of conversation.<br />

Since the 1920s our industry has used the phrase, “The<br />

plumber protects the health of the nation.” For the 21st century<br />

this organization has rewritten that: “The GreenPlumber<br />

protects the resources of our planet.”<br />

While I take the green movement with a grain of salt,<br />

believing that global warming is part of a natural cycle that<br />

mankind has perhaps accelerated a bit - but nothing compared<br />

to what a really big, naturally occurring volcanic eruption can<br />

do — I have always embraced water as the most remarkable,<br />

valuable, and under appreciated gift on our planet. I like the<br />

fact that this program shares that value and also promotes the<br />

image of the plumbing industry in an effort to attract the<br />

younger generation while also promoting good communication<br />

skills for our trade.<br />

A more detailed breakdown of the GreenPlumbers curriculum<br />

is as follows.<br />

Climate Care<br />

• Hot Water Heating<br />

• Energy Consumption<br />

• Heating Appliances<br />

• Cooling Appliances<br />

• Greenhouse Gas Abatement<br />

Solar Hot Water<br />

• Solar Hot Water Technology<br />

• State Rebate Information<br />

• Sizing and Installation<br />

• Retro Fitting<br />

• New Technology<br />

Caring For Our Water<br />

• Water Efficient Products<br />

• New Technology<br />

The water display at the San Diego Museum of Natural<br />

History, which depicts the water system serving the entire<br />

Southwest.<br />

• Household Water Audits<br />

• Reducing Household Consumption<br />

• Stormwater<br />

Water Efficient Technology<br />

• Reuse/Recycled Water<br />

• Rainwater<br />

• Graywater<br />

• Wastewater Treatment Systems<br />

• Environmental, Public Health & Safety Regulations<br />

Inspection Report Services<br />

• Water and Energy Audits<br />

• Commercial, Industrial & Residential Buildings<br />

• Master Planning for Future Improvement<br />

While this program focuses on the trade plumber rather<br />

than the plumbing engineer, it is important for the latter to be<br />

familiar with the program and terminology in case it is raised<br />

in a meeting or addressed as a question by owner or architect.<br />

“What exactly is a green plumber,” you might be asked? It’s<br />

good to have the answer.<br />

I like anything that puts plumbing into the spotlight of<br />

importance for the American public. Take Joe the Plumber,<br />

made famous during John McCain’s presidential candidacy.<br />

Unfortunately Joe turned out to be less than the ideal poster<br />

boy for our trade, but I was still glad that McCain had select-<br />

Continued on page 14<br />

Page 12/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

He’s not only the reigning chess champ of Cedar Hills Village.<br />

He’s also our top product design consultant.<br />

At Moen Commercial, we spend many afternoons with folks like Karl. Because the better we know him, the better we’re able<br />

to design solutions that meet the unique needs of the elderly. Our faucets, flush valves and shower systems offer ergonomic<br />

handles for those with limited mobility or dexterity, temperature controls to prevent scalding, and innovative hands-free<br />

technology. Plus, these products comply with Universal Design principles and ADA standards, and are backed with a limited<br />

5-year warranty. All to ensure quality, safety and accessibility. You see, we understand that a tough chess opponent isn’t<br />

the only challenge Karl faces throughout the day.<br />

To learn more about how our products are built for the real world, visit www.moencommercial.com or call 800-BUY-MOEN.<br />

Circle 9 on Reader Reply Form on page 61<br />

©2009 Moen Incorporated Moen and the Crossed Water Drops device are registered trademarks of Moen Incorporated

Designer’s Guide<br />

Continued from page 12<br />

ed a plumber to stand as the American<br />

ideal. This is the person we are trying to<br />

embrace in our country. This is the person<br />

the system should work for — the<br />

hard working American, prepared to get<br />

his hands dirty for the benefit of others.<br />

There are many in this country who<br />

benefit from the system — perhaps<br />

more today than ever — who don’t hold<br />

a candle to the Plumber’s ethic. I know<br />

a bunch of plumbers in my company<br />

who would have been far better selections<br />

for John’s campaign. It’s too bad<br />

he didn’t consult with me — it would<br />

have saved him some embarrassment.<br />

In April, my son’s Cub Scout pack<br />

took a trip to the San Diego Museum of<br />

Natural History. There again I was<br />

pleased to see that they had an entire<br />

exhibit on water, emphasizing its<br />

importance, its remarkable history and<br />

its local scarcity. They created a wonderful<br />

display that I photographed (see<br />

page 12) depicting the water system<br />

serving the entire Southwest. They used<br />

copper pipe to represent the waterways,<br />

funnels to represent the areas of rainwater<br />

capture, copper ball floats to represent<br />

damned reservoirs, and hose bibbs<br />

to represent major areas of consumption.<br />

It was brilliant, simplistic, and<br />

artistic all at once. And it called attention<br />

to young and old of the importance<br />

of both water and plumbing.<br />

As I write this I just received email<br />

notification that my local water purveyor<br />

here in So Cal, the Moulton Niguel<br />

Water District (MNWD), is declaring a<br />

Level 2 Water Alert effective June 1st.<br />

This alert is intended to produce a 20%<br />

reduction in consumer demand. It limits<br />

residential irrigation to two weekdays<br />

and one weekend day, alternating days<br />

from city to city, and commercial irrigation<br />

to Monday, Wednesday, and Friday.<br />

Here’s a big one: no potable water is<br />

allowed for irrigating golf courses. Golf<br />

courses are required to convert to recycled<br />

water within 30 days. Now, I’m not<br />

sure how all the golf courses are going<br />

to do that. Do all of them have recycled<br />

water available? If not, a conversion<br />

would be nearly impossible. This could<br />

put some of the golf courses out of business.<br />

Other restrictions are relatively<br />

minor.<br />

The MNWD has four levels of water<br />

alerts. Level 4 requires irrigation only<br />

once a week, no car washing except at<br />

commercial recycled water facilities,<br />

and other measures relatively minor in<br />

nature. In actuality, even a Level 4<br />

emergency still does not represent a true<br />

hardship. Especially when you compare<br />

it to a country such as Jordan, where<br />

water mains are turned on only once a<br />

week, and people are required to collect<br />

all of their water for the week on that<br />

one day. I guess that’s what the MNWD<br />

might call a Level 10 emergency.<br />

If you are interested in more information<br />

on GreenPlumbers you can go<br />

to www.greenplumbersusa.com. ■<br />

Timothy Allinson is a senior professional<br />

engineer with Murray Co.,<br />

Mechanical Contractors, in Long<br />

Beach, Calif. He holds a BsMe from<br />

Tufts University and an MBa from New<br />

York University. He is a professional<br />

engineer licensed in both mechanical<br />

and fire protection engineering in various<br />

states, and is a Leed accredited<br />

professional. allinson is a past-president<br />

of asPe, both the New York and<br />

Orange County Chapters.<br />

Circle 10 on Reader Reply Form on page 61<br />

The views and opinions expressed in this<br />

column are those of the author and do not<br />

reflect those of <strong>Plumbing</strong> <strong>Engineer</strong> nor its<br />

publisher, TMB Publishing.<br />

Page 14/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Work Smart<br />

Get Current with 2009 American<br />

National Standard Uniform Codes<br />

The 2009 Illustrated Training Manuals now<br />

include complete code text and full color illustrations<br />

Developed by the industry for the industry,<br />

the UPC includes specific:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

The UMC includes specific:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Circle 11 on Reader Reply Form on page 61

Code Update<br />

By Ron George, CIPE, CPD<br />

President, Ron George Design & Consulting Services<br />

Fuel gas safety<br />

There are several codes and standards that can apply to<br />

a given fuel gas installation. Compliance with the<br />

applicable codes is mandatory, along with some<br />

common sense when dealing with safety for fuel gas systems.<br />

Fuel gas systems are covered by the Federal Energy<br />

Regulatory Commission and in the International Fuel Gas<br />

Code, The Uniform <strong>Plumbing</strong> Code, the National Fire<br />

Protection Association’s NFPA 54 National Fuel Gas Code,<br />

the Department of Transportation and state and local laws<br />

and ordinances. Fuel gases, like natural gas, propane or<br />

butane, can efficiently and inexpensively provide the fuel<br />

for common appliances like water heaters, furnaces, clothes<br />

dryers, ovens, stoves, fireplaces and other commercial and<br />

industrial equipment and appliances.<br />

Fuel gas piping must be installed to be leak free to prevent<br />

a dangerous build-up of explosive gases inside a building.<br />

Leak tests on fuel gas piping commonly are done by<br />

pressurizing the piping with air prior to filling it with fuel<br />

gas and using a spray bottle with a soap and water solution<br />

to spray each joint to check for leaks, which will show up<br />

as bubbles. Sometimes you will have people fill the system<br />

with gas and check for gas leaks with a cigarette lighter or<br />

a match. They usually only do that once until they find their<br />

first good leak. Once they have experienced a flash fire or<br />

explosion they learn quickly not to use an open flame to<br />

locate a gas leak. I call this the Darwin testing method or the<br />

explosive test method. If they don’t get burned, killed or<br />

blow up the building, they learn you should not test for<br />

leaks with an open flame. They usually learn to keep a spray<br />

bottle with some liquid soap in their toolbox to test for gas<br />

leaks by spraying each joint with soapy water.<br />

Odorant added<br />

Because fuel gases are odorless and flammable, there<br />

are federal regulations requiring an odorant to be added to<br />

fuel gases to help warn of leaks in the piping system; however,<br />

the specific type of odorant and amount is left up to<br />

the gas providers.<br />

To ensure that gas leaks are more easily detected, natural<br />

gas odorization with Mercaptan is mandated for public<br />

safety by the Department of Transportation (DOT).<br />

The DOT requires natural gas distribution companies to<br />

inject a harmless odorant into natural gas to give it an<br />

odor. Federal regulations, 49CFR, 192.625, “Odorization<br />

of Gas,” requires that gas transmitted interstate be odorized.<br />

The odorants most commonly used are mixtures of<br />

two general classes of organosulfur compounds — mercaptans<br />

and sulfides.<br />

The Code of Federal Regulations has the following text:<br />

Code of Federal Regulations 49 CFR - CHAPTER I<br />

S.192.625 Odorization of gas.<br />

(a) A combustible gas in a distribution line must contain<br />

a natural odorant or be odorized so that at a concentration<br />

in air of one-fifth of the lower explosive limit, the gas is<br />

readily detectable by a person with a normal sense of smell.<br />

The presence of natural gas at 1.26% in air must be<br />

detected by smell.<br />

The odorant is strong enough that it can usually be<br />

detected by smell at concentrations below the lower<br />

explosive or lower flammable limit. Since there is no way<br />

to tell if the lower flammable limit has been achieved, you<br />

should treat all incidences where gas is detected as a<br />

potential for an explosion or fire.<br />

Ethyl mercaptan is a common odorant used for this purpose<br />

and has the distinctive smell of rotten eggs. There are<br />

other types of odorants or thiols used to give fuel gases a<br />

distinctive odor. Ethyl mercaptan is commonly used for<br />

this purpose since it is chemically stable when mixed with<br />

natural gas or propane, and it has many of the same physical<br />

characteristics of propane. One can be reasonably<br />

assured: if ethyl mercaptan's distinctive rotten egg odor is<br />

detected, fuel gas vapors may also be present.<br />

The odorant was required in fuel gas shortly after a gas<br />

explosion in a New London, Texas school. The explosion<br />

occurred on March 18, 1937, when a natural gas leak<br />

caused an explosion, destroying the New London school.<br />

The disaster killed in excess of 295 students and teachers,<br />

making it the worst catastrophe to take place in a U.S.<br />

school building. Experts from the United States Bureau of<br />

Mines, which investigated the incident, concluded that a<br />

connection to a gas line was faulty. The connection had<br />

allowed gas to leak into the school, and since natural gas<br />

was invisible and at that time was odorless, the leak was<br />

unnoticed. To reduce the damage of future leaks, and aid in<br />

detection, the Texas legislature began mandating within<br />

weeks of the explosion that thiols or (mercaptans) be added<br />

to natural gas. Federal laws now require fuel gas to be<br />

odorized, but there is nothing mandating what the odorant<br />

should be. In Las Vegas, the Mirage Casino uses natural<br />

gas in large quantities to produce the volcanic eruption in<br />

the volcano in front of the casino. The facility engineers<br />

did not want to alarm the public because initially when<br />

there was a slight wind it was possible to smell the mercaptan<br />

or rotten egg smell prior to the eruption. The solution<br />

was to provide a scrubber to remove the mercaptan<br />

from the fuel gas followed by a resin tank filled with pina<br />

colada oil. Now the gas smells like pina colada so guests<br />

smell a tropical coconut smell prior to the eruption. The<br />

strong odor of many thiols or ethyl mercaptan makes leaks<br />

quickly detectable. The practice quickly spread worldwide.<br />

A lawsuit was brought against the school district and the<br />

Parade Gasoline Company, but the court ruled that neither<br />

could be held responsible because at that time odorants and<br />

gas detectors were not required. Natural gas now has an<br />

odor similar to rotten eggs, or ethyl mercaptan, so that even<br />

Continued on page 18<br />

Page 16/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Circle 12 on Reader Reply Form on page 57<br />

MADE IN<br />

USA

Code Update<br />

Continued from page 16<br />

the smallest leaks can be detected. If you ever smell gas you<br />

should not turn on any lights, use the telephone or do anything<br />

that could make a spark. You should open some windows<br />

and doors for ventilation and get everyone out of the<br />

building immediately and use a telephone away from the<br />

building to call the fire department and the gas company.<br />

Stay out of the building until you are told it is safe.<br />

Fuel gas odor fade<br />

Fuel gas odor fade is a serious, yet relatively unknown<br />

phenomenon. I have been a volunteer firefighter since<br />

1982 and I am a certified fire investigator. I also have<br />

investigated several fuel gas and propane explosions and<br />

in some cases the occupants have said they did not smell<br />

anything. There is a lot of data on the subject of fuel gas<br />

odor fade, but it does not seem to be widely known within<br />

the plumbing and pipe fitting industries. I would like to<br />

see the UA cover fuel gas odor fade in their plumbers and<br />

pipe fitters apprentice training programs.<br />

Natural gas or propane with odorant added has that distinctive<br />

smell. Natural gas or propane when in its natural<br />

state is typically colorless, tasteless and odorless. The natural<br />

gas or propane is often delivered through a high pressure<br />

transmission pipe to your local gas utility company<br />

with or without the odorant added where they meter it,<br />

reduce the pressure and distribute it in their local utility<br />

distribution system. The gas company also adds an odor-<br />

ant to the gas before distributing the gas.<br />

In new piping installations, all new gas-piping materials<br />

are porous and have the ability to absorb the odorant.<br />

Black iron pipe is the most likely to cause this phenomenon<br />

as the iron oxide and porous walls, if colder than the<br />

fuel gas, can condense the odorant and absorb the odorant<br />

in the dust, dirt, mud, iron oxide and pores of the pipe<br />

wall. Simply stated, the odor is absorbed into the walls of<br />

new pipe. The porosity of the pipe, the joining methods<br />

used and the temperature variations the fuel gas is piped<br />

through are three contributing factors to absorption of the<br />

odorant and odor fade. Oxidation or rust in the piping,<br />

along with cutting oils, water, dirt or any other foreign<br />

substances inside the piping system tend to absorb the<br />

odorant until they are saturated. Until the piping system<br />

has absorbed enough of the odorant to be saturated and<br />

essentially coat the inside walls of the pipe, the absorption<br />

process will continue and the odor fade will occur.<br />

All new piping systems absorb the odor. The larger the<br />

system, the longer it takes to “pickle” or coat the walls of<br />

the pipe with the odorant.<br />

Purging gas lines<br />

The proper procedure for purging a gas line should be<br />

to use a hose with a hose clamp of duct tape and route the<br />

hose to the outdoors so that flammable gases do not col-<br />

Continued on page 20<br />

Circle 13 on Reader Reply Form on page 61<br />

Page 18/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Discover the New Frontier in Scale Prevention<br />

The Intelligent Scale Solution<br />

Building owners, property managers and facility engineers have fought the battle against scale and its<br />

destructive byproducts for too long. Now there is a better solution that is environmentally friendly and<br />

virtually maintenance free. OneFlow prevents scale by transforming dissolved hardness minerals into harmless,<br />

inactive microscopic crystal particles. These particles make their way through plumbing systems without<br />

latching on to pipes, fixtures, valves or heating elements. Scientifically tested and certified for performance,<br />

OneFlow provides scale control results backed by years of successful field applications. Make the<br />

intelligent choice in scale prevention, OneFlow from Watts.<br />

For more information, visit our web site TheScaleSolution.com<br />

Available in<br />

at watts.com<br />

A Watts Water Technologies Company<br />

Circle 14 on Reader Reply Form on page 57

Code Update<br />

Continued from page 18<br />

lect inside of a building and create an explosion hazard. It<br />

only takes a very small percentage of gas in the volume of<br />

the room to reach the lower explosion limit (LEL).<br />

Natural gas can have a heat content or caloric value of<br />

950 to 1,100 British thermal units (Btus) per cubic foot<br />

(CF), and normally we calculate natural gas with the<br />

caloric value of 1,000 Btus/CF<br />

The specific gravity of natural gas is about 0.60 - .65<br />

(Air =1.00)<br />

Natural gas is lighter than air and it will eventually dissipate<br />

when released. The lower flammability limit for<br />

natural gas is 3.9 percent gas to air ratio and the upper<br />

flammability limit is 15 percent gas to air for the upper<br />

flammability limit. Below 3.9 percent gas to air mixture is<br />

too lean for combustion and above 15 percent gas to air<br />

mixture is too rich for combustion.<br />

This odor fade phenomenon is not a new issue, it has<br />

been known and recognized by the gas companies for<br />

many years. Most gas companies refer to it in their safety<br />

manuals and websites. Most gas companies are aware of<br />

the odor fade phenomenon and are required by law to do<br />

periodic testing of the odorant levels in the distribution<br />

piping and adjust the amount of additive as needed. The<br />

odorant must be detectable at a percentage well below the<br />

lower flammable limit.<br />

One-call utility location programs<br />

If someone is planning to dig a post hole for a fence,<br />

excavate to plant a tree, tear down a building or engage in<br />

any other underground earth trenching or moving activity,<br />

they should contact a utility one-call program. The onecall<br />

programs will typically send out people to locate<br />

underground utilities in the area of the proposed excavation.<br />

The one-call services are typically funded by the utility<br />

companies and they dispatch someone with ultrasound<br />

or metal detectors to locate underground utilities. They<br />

typically mark the utilities with paint or flags to show a<br />

contractor where gas, electric, phone, water and waste<br />

lines are located to help avoid construction accidents or<br />

problems. Some one-call programs simply contact each<br />

utility and they send their own people out to locate the<br />

underground utilities. Cutting a buried utility line can be<br />

dangerous, costly and inconvenient.<br />

When utility locaters respond to a utility location<br />

request, they usually mark where the underground facilities<br />

are in the area. If there are no underground facilities<br />

buried in the area, the locating personnel sometimes note<br />

this as well. This is often done by painting “OK” on the<br />

ground and placing a company flag to indicate which utility<br />

company has responded to the request. This does not<br />

mean it is OK to dig, it may mean that utility checked for<br />

their particular utility lines and did not have any underground<br />

utility lines in the area of the proposed excavation.<br />

The excavator must then correlate the responses with<br />

the list of notified companies to ensure that every company<br />

has responded before beginning the project and wait<br />

the required 48 hours. When excavating around underground<br />

utilities, the standard practice is to hand excavate<br />

until the utility line is located and then carefully expose it<br />

so the excavation work can continue.<br />

Color coding of piping systems<br />

The American Public Works Association (APWA) has<br />

Uniform Color Codes for temporary marking of underground<br />

utilities. The color for natural gas, oil, steam,<br />

petroleum or gaseous utilities such as propane or butane is<br />

yellow. The color codes are listed below:<br />

APWA Uniform Color Codes<br />

Red — Electric Power Lines, Cables, Conduit and<br />

Lighting Cables<br />

Yellow — Gas, Oil, Steam, Petroleum or Gaseous<br />

Material<br />

Gold — Communication, Alarm or Signal Lines,<br />

Cables or Conduit<br />

Blue — Potable Water<br />

Green — Sewers and Drain Lines<br />

White — Proposed Excavation Limits or Route<br />

Pink — Temporary Survey Markings, Unknown/<br />

Unidentified Facilities<br />

Purple — Reclaimed Water, Irrigation and Slurry Lines<br />

Carbon monoxide detectors<br />

Not too long ago there was a code battle to try to get<br />

smoke detectors mandated in residences, dormitories,<br />

hotels and motels. The idea was to put smoke detectors in<br />

areas where people were sleeping to wake them if there was<br />

a fire while they were sleeping. Recently, there have been<br />

code change proposals to mandate carbon monoxide detectors.<br />

Carbon monoxide detectors are not currently mandatory<br />

by code, but they are common on most mechanical<br />

rooms with fuel burning appliances to monitor for deadly<br />

carbon monoxide fumes. I suspect that within the next few<br />

years, carbon monoxide detectors will be required in buildings<br />

where people are sleeping, because it makes sense. The<br />

technology is getting better and they do save lives. As a<br />

volunteer firefighter, I have answered many alarms for carbon<br />

monoxide detector activations. In many cases, there<br />

were problems with the mechanical systems where the<br />

occupants were tired and nauseated and flushed, which are<br />

all signs of carbon monoxide poisoning. We had our fair<br />

share of false alarms from low batteries, as well.<br />

It is wise to have a working smoke detector and carbon<br />

monoxide detector on all levels of a residence; establish a<br />

home evacuation plan. Stay safe, and don’t use an open<br />

flame to look for a gas leak. ■<br />

Ron George is president of Ron George Design & Consulting<br />

Services. He is the former Chairman of the International<br />

Residential <strong>Plumbing</strong> & Mechanical Code Committee and he<br />

serves on the International Association of <strong>Plumbing</strong> & Mechanical<br />

Officials (IAPMO) Code interpretation Answers and Analysis<br />

Committee and the IAPMO Standards Council. He is active in<br />

<strong>Plumbing</strong> Code and <strong>Plumbing</strong> Product Standard development and<br />

consulting. His company specializes in plumbing, piping, fire protection<br />

and HVAC system design. He provides plumbing and<br />

mechanical code consulting, plumbing product standard consulting<br />

and forensic investigations and litigation support for plumbing<br />

and mechanical system failures. E-mail: rgdc@ronge<br />

orgedesign.com. Web site: www.rongeorgedesign.com.<br />

The views and opinions expressed in this column are those of<br />

the author and do not reflect those of <strong>Plumbing</strong> <strong>Engineer</strong> nor its<br />

publisher, TMB Publishing.<br />

Page 20/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Fire Protection<br />

BY Philip M. Awker,<br />

Futrell Fire Consult & Design, Inc., Osseo, Minn.<br />

Protecting fire sprinklers from the human element<br />

Fire sprinkler systems are<br />

designed and installed to protect<br />

life and property. Actuation<br />

of sprinkler heads in the event of a<br />

fire is desired, but actuation from<br />

damage or other causes is not. So<br />

what protects the sprinkler heads<br />

from us — the human element?<br />

Each year, some automatic sprinklers<br />

are damaged or compromised<br />

through accidents, vandalism or malicious<br />

mischief. This results in unintended<br />

discharge of as much as several<br />

hundreds of gallons of unwanted<br />

water that can damage property or<br />

could cause chaos for nearby occupants<br />

(ever been showered with cold,<br />

dirty, stale water?). Building operations<br />

can be shut down for extensive<br />

periods of time, and when the business<br />

interruption or temporary moving<br />

and housing costs are added to the<br />

costs of the building repairs, the loss<br />

can be significant.<br />

Although there have been improvements<br />

in recent years regarding protection<br />

of sprinklers during packaging,<br />

shipping, handling and installation<br />

(e.g., the protective plastic guards on<br />

sprinkler heads in the shipping box),<br />

some sprinklers fail each year due to<br />

damage caused by people.<br />

Currently, there are options to minimize<br />

the potential damage to sprinkler<br />

heads that have already been<br />

installed. The most common include<br />

the installation of the sprinkler at a<br />

location or height where damage will<br />

least likely occur, the use of the<br />

appropriate “Listed” head guard for<br />

the specific sprinkler, fully concealed<br />

sprinklers and institutional style<br />

sprinklers. Each option has its pros<br />

and cons. However, regardless of the<br />

options considered, the human element<br />

always enters the equation.<br />

Location & Height — Many<br />

installations can be designed where<br />

the proximity of the sprinkler head is<br />

unlikely to be damaged. For example,<br />

sprinklers can be located in normally<br />

occupied and/or supervised areas<br />

(offices, retail sales, etc.) with ceiling<br />

heights exceeding eight feet high, and<br />

in areas where equipment, storage or<br />

machinery are not an issue. Pendent,<br />

upright or horizontal sprinkler heads<br />

can be used if positioned correctly in<br />

areas where the potential for damage<br />

of any kind will be at a minimum.<br />

In most applications, sprinkler<br />

heads are installed in locations or at<br />

elevations where damage is unlikely.<br />

However, there are instances where<br />

protection of these devices must be<br />

considered and a few of these examples<br />

are as follows:<br />

• Warehouses & Mechanical/Service<br />

Rooms — Sprinklers installed below<br />

mechanical equipment or ductwork<br />

may be prone to accidental damage<br />

from occupants (“head-knockers”, if<br />

you will). Also, the use of forklifts or<br />

other equipment may subject sprinklers<br />

to damage. “Listed” sprinkler head<br />

guards are generally specified for these<br />

applications. A thorough review of<br />

building owner requirements and usage<br />

should be performed to determine<br />

where head guards should be recommended<br />

or installed.<br />

Sprinkler Head Guards — These<br />

devices are generally recommended<br />

where damage could occur to commercial<br />

sprinklers due to activities,<br />

operations, the use of equipment,<br />

ProBase TM<br />

Tile Ready Shower Base Kit<br />

Saves time and money<br />

- Pre-applied waterproofing membrane<br />

- No need to create a slope<br />

- 1-piece installation that is bonded in place<br />

- Flood test in 1 hour<br />

- Tile directly to ProBase<br />

Circle 15 on Reader Reply Form on page 61<br />

Continued on page 22<br />

Presloped, waterproof<br />

shower base<br />

- High compressive strength<br />

- UPC Listed: File #4339<br />

- Lightweight and durable<br />

Compatible with many<br />

shower layouts & sizes<br />

- Allows for 2” adjustment of drain<br />

- Use with most standard clamping<br />

ring drains<br />

- Easily cut to size<br />

- Available in 48” x 48” and 32” x 60”<br />

ProBase<br />

800.878.5788 www.noblecompany.com<br />

<strong>Plumbing</strong> <strong>Engineer</strong> June 2009/Page 21

Fire Protection<br />

Continued from page 21<br />

(warehouse forklifts, etc.) or machinery,<br />

where objects are hit, thrown,<br />

kicked or batted (school locker rooms<br />

& gymnasiums), where sprinklers are<br />

installed below eight feet above the<br />

floor, or in areas with limited or no<br />

supervision or where malicious mischief<br />

or vandalism could occur.<br />

Sprinkler head guards must be<br />

“Listed” for use with the automatic<br />

sprinkler they are used on. In many<br />

cases generic head guards should not<br />

be used because they could void the<br />

warranty of the sprinkler with the<br />

sprinkler manufacturer.<br />

Fully Concealed Sprinklers —<br />

“Out of sight — out of mind” is what<br />

generally comes to mind when using<br />

these sprinkler heads. The sprinkler<br />

assembly is located behind a plate<br />

that is generally flush with the ceiling.<br />

Most building occupants don’t<br />

realize that there is a sprinkler head<br />

behind the finish plate and won’t give<br />

it a second thought. The low profile<br />

of the concealed sprinkler may help<br />

prevent damage to the assembly as<br />

opposed to an automatic sprinkler<br />

that is protruding several inches<br />

down from the ceiling.<br />

• Schools, bathrooms, temporary<br />

residential and minimum security<br />

areas — Although fully concealed<br />

sprinkler heads are generally<br />

installed for aesthetic reasons, utilizing<br />

this type of sprinkler does not<br />

draw the attention to itself that a<br />

recessed or pendent sprinkler head<br />

might. Plus, the lower, almost flush<br />

profile of the sprinkler does not lend<br />

itself to as much accidental damage.<br />

Also, most people are not aware of<br />

the automatic sprinkler assembly<br />

behind the cover plate so there is less<br />

chance for vandalism or malicious<br />

mischief.<br />

Institutional Sprinklers — These<br />

may be the most misunderstood automatic<br />

sprinklers when considered for<br />

protection from the human element.<br />

When these devices were first introduced,<br />

manufacturers referred to<br />

them as “vandal-proof”. It was discovered,<br />

however, that there may not<br />

be an automatic sprinkler that is completely<br />

vandal-proof. Subsequently<br />

the terminology “vandal resistant”<br />

was applied to these sprinklers.<br />

Certain models, such as the old Star<br />

PH series, were standard response<br />

sprinklers that were popular for their<br />

construction features. But, when the<br />

Building operations can be<br />

shut down for extensive periods<br />

of time, and when the<br />

business interruption or temporary<br />

moving and housing<br />

costs are added to the costs<br />

of the building repairs, the<br />

loss can be significant.<br />

National Fire Protection Association<br />

Standard 13, Standard for the<br />

Installation of Sprinkler Systems,<br />

required quick response sprinklers in<br />

light hazard occupancies, manufacturers<br />

had to redesign their institutional<br />

sprinklers to meet quick<br />

response requirements. This resulted<br />

in a design change to the sprinklers<br />

that may not be as vandal resistant as<br />

their predecessors. Selection of these<br />

types of devices must take into<br />

account the usage of the building in<br />

each specific room or area and not the<br />

building as a whole.<br />

• Jails, Detention & Treatment<br />

Centers and Maximum Security<br />

Areas — Although designated as<br />

vandal resistant and not vandal proof<br />

by the manufacturers, institutional<br />

style sprinklers are still the choice to<br />

consider where individuals could<br />

vandalize or consider doing harm to<br />

themselves with the assist of an automatic<br />

sprinkler. The installation of<br />

these devices must adhere strictly to<br />

the manufacturers’ recommendations<br />

or they could fail. The suspended<br />

load (the link break-off weight) for<br />

the heat sensors must be taken into<br />

consideration, as it varies by manufacturer.<br />

A lower weight might be<br />

considered where juveniles are present.<br />

Also, the sprinkler assembly<br />

Continued on page 24<br />

Page 22/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

Visit us at AHR Expo Booth #2070<br />

All the hot water heaters in the world with PVC venting that are 98% efficient.<br />

Condensing 98 Tankless Water Heater<br />

Where technology meets ecology.<br />

800.519.8794 NavienAmerica.com<br />

Circle 16 on Reader Reply Form on page 61

Fire Protection<br />

Continued from page 22<br />

needs to be securely attached in a<br />

manner where there is no movement.<br />

A review of the wall or ceiling assembly<br />

should be performed for adequacy<br />

of the support system and, if necessary,<br />

additional supports may need<br />

to be provided to comply with the<br />

manufacturers’ installation recommendations.<br />

Part of the challenge for designers<br />

is to select the appropriate automatic<br />

sprinkler for the specific application.<br />

This also extends to the protection of<br />

these devices that are not fragile, but<br />

need to be treated as if they are, so<br />

they are functional and can operate<br />

when you need them — not when you<br />

don’t.<br />

The building owner and/or occupants<br />

should be consulted when<br />

selecting the sprinklers and the proper<br />

method of protection prior to the<br />

design and installation of the sprinkler<br />

system.<br />

This only touches on types of protection<br />

and instances where protection<br />

of the automatic sprinklers<br />

should be considered. Each room or<br />

HOTBOX…®<br />

Accept no substitutes.<br />

Input from the building owner,<br />

occupants or users should be<br />

considered when evaluating<br />

how and where the human<br />

element will affect the sprinkler<br />

protection requirements.<br />

POLYEZ <br />

Lightweight, functional and<br />

low cost. This “drop over”<br />

irrigation product comes with<br />

or without insulation and heat<br />

and is available in either green<br />

or beige.<br />

POLYROK ®<br />

Lightweight, functional and<br />

aesthetically pleasing. With<br />

or without insulation and heat,<br />

the POLYROK hides and<br />

protects your valve while<br />

enhancing the landscape.<br />

DURAFOLD <br />

Arrives flat at the job site.<br />

Hinged walls, back, front and<br />

roof provide for quick installationrequiring<br />

only 4 machine bolts!<br />

The hinged front and roof provide<br />

instant unobstructed access for<br />

equipment testing and<br />

maintenance after installation.<br />

area of the building should be<br />

reviewed to help determine where<br />

and what type of protection could be<br />

utilized. Input from the building<br />

owner, occupants or users should be<br />

considered when evaluating how and<br />

where the human element will affect<br />

the sprinkler protection requirements.<br />

Although the final decisions may not<br />

be perfect (if someone really wants to<br />

damage a sprinkler head, they will),<br />

prudent choices will minimize accidental<br />

or intentional damage to these<br />

devices. ■<br />

The Industry Standard in Valve Protection<br />

HOT BOX ® complies with ASSE 1060 Certification for our entire<br />

product line. Included are all standard models of the HOT BOX,<br />

LOK BOX ® , VALVE GUARD ® , HOT ROK ® and EZ BOX ® lines. HOT BOX<br />

and LOK BOX are certified up through the dual 10" OS&Y enclosure<br />

for units with strainers - the HB10EDS. Contact our office with<br />

any questions about the ASSE 1060 Standards, or to request copies<br />

of our certifications.<br />

hot-box.com<br />

800.736.0238 • hotboxsales@hps.hubbell.com<br />

Circle 36 on Reader Reply Form on page 61<br />

Philip M. Awker, Jr., S.E.T., is the<br />

design director for Futrell Fire<br />

Consult & Design, Inc., in Osseo,<br />

Minn., and has more than 35 years<br />

experience in system design, sales,<br />

project management and negotiation<br />

of projects and issues. Awker is an<br />

alternate on the Minnesota<br />

Governor’s Council on Fire<br />

Prevention & Control, has served as<br />

chapter president of the<br />

SFPE/MFPC, and is a juvenile fire<br />

setter intervention education commissioner<br />

for the city of Maple<br />

Grove, Minn. Awker can be reached<br />

by email at phila@ffcdi.com; or by<br />

visiting www.ffcdi.com.<br />

The views and opinions expressed in this<br />

column are those of the author and do<br />

not reflect those of <strong>Plumbing</strong> <strong>Engineer</strong><br />

nor its publisher, TMB Publishing.<br />

Page 24/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

It’s time for the...<br />

NEW JERSEY STATE LEAGUE OF MASTER PLUMBERS<br />

<br />

<br />

Featuring Green Technology<br />

Friday, June 26, 2009<br />

Tropicana Casino & Resort<br />

Atlantic City, New Jersey<br />

Exhibits from 9 AM to 4 PM<br />

Admission is FREE<br />

The show is open to individuals in the<br />

construction industry – as well as the<br />

general public – so come and experience<br />

manufacturers showcasing the products<br />

and services you need to compete and<br />

be successful in today’s market!<br />

Exhibitors<br />

Reserve your booth space<br />

today! Call for a special<br />

TRADE SHOW RATE<br />

with a half-page ad<br />

and website link<br />

for 6 months!<br />

Don’t miss out on this<br />

great opportunity.<br />

For more info call<br />

609-296-2116<br />

WARREN<br />

HUNTERDON<br />

SUSSEX<br />

MORRIS<br />

SOMERSET<br />

9<br />

PASSAIC<br />

BERGEN<br />

ESSEX HUDSON<br />

UNION<br />

Circle 17 on Reader Reply Form on page 61<br />

1<br />

3<br />

New Jersey State League of Master Plumbers Inc<br />

791 Cedar Street, Tuckerton, NJ 08087<br />

Phone: 609-296-2116 • Fax: 609-296-5946 • Toll-free: 866-575-8623<br />

Web: www.njslmp.org • Email: LizMoritz@njslmp.org<br />

New Jersey Licensed Master Plumbers interested in becoming a member, please contact us<br />

BURLINGTON<br />

GLOUCESTER<br />

CAMDEN<br />

SALEM<br />

ATLANTIC<br />

CUMBERLAND<br />

CAPE MAY<br />

1<br />

OCEAN

Modern Hydronics<br />

By Paul Rohrs, Radiant Expert, Biggerstaff Radiant Solutions, Lincoln, Neb.<br />

Doin’ the math<br />

Ask me what my least favorite class was in school<br />

and without hesitation I would answer math! (Yet,<br />

here I am 25 years later doing math.) At the onset<br />

of any hydronic job I always do the math. I start with the<br />

heat loss, boiler sizing with minimum and maximum radiant<br />

loads, what my labor and materials costs are and what<br />

to charge for the project. Math, pure and simple. It would<br />

be hard to complete a successful boiler change out, let<br />

alone a new install without some form of math being successfully<br />

completed. Okay, let me modify that last statement<br />

a bit: It would be tough to be profitable without<br />

doing the math.<br />

So, what now Paul? I can hear the snickering, “That<br />

Rohrs guy is on his soapbox about math. Big whoop.” I<br />

couldn’t agree more; but what if we can add a couple of<br />

components that will save us time and money? Bear with<br />

me and let’s do the math together.<br />

I hate air in hydronic systems. My disdain for air-bound<br />

systems ranks right up there with, well, math. I know several<br />

articles from multiple authors have discussed airremoval<br />

and air-separators, but let’s talk about components<br />

that we can incorporate that will give us an immediate payback.<br />

Before I get to the math, let me pose a scenario to you.<br />

Have you ever been in an apartment complex with fintube<br />

baseboard heat-emitters? You finish the install, repipe,<br />

or change out and then need to bleed air from each<br />

apartment zone. You get your empty plastic Folgers coffee<br />

container and your radiator keys and head up to start the<br />

bleeding. With no apartment manager on-site, you knock<br />

on the first apartment door. Grandma Jones answers and<br />

welcomes you in and offers you cookies, tells you about<br />

her arthritic knees and tells you that her kids never call.<br />

Before she gets to the grandkid stories, you politely kneel<br />

down at the first fin-tube access cover to NOT find the<br />

radiator 90 with integral bleeder, or the radiator vent. On<br />

to the next room in search of the elusive bleeders. Right<br />

behind Grandma Jones’ stash of Elvis Presley albums, you<br />

find the first bleeder and you are well on your way to finishing<br />

the first apartment. Twenty minutes — not bad —<br />

and three more apartments to go.<br />

Apartment 2, I knock. “Who’s there?” comes from<br />

behind the door.<br />

“Orange,” I say.<br />

“Orange who?”<br />

“Orange you going to let me in so I can bleed your<br />

baseboard emitters and get you heat!” After exchanging<br />

pleasantries with the tenants, I knock out units 2 and 3.<br />

One more apartment to go. No one home in unit 4. Now<br />

what? Call the apartment owner/manager again to get<br />

access or come back later when they are home. You get<br />

the picture, and after one hour of bleeding apartments 1-<br />

3, you are unable to finish your task and get on to the<br />

next service call.<br />

I have spent an hour bleeding fin-tube and I am still not<br />

done. Why not consider changing the game plan? Let’s<br />

add some ball valves, fittings and boiler drains so that we<br />

will never again have to enter a tenants apartment and we<br />

can purge all air from the mechanical room. Figure 1<br />

shows some essential fittings that can be easily incorporated<br />

into most hydronic heating systems.<br />

NIBCO makes a C✕C✕FIP Tee that will make it very<br />

easy to solder in and then screw in a boiler drain. If you<br />

are a ProPress shop, Viega and others make a<br />

Press✕Press✕FIP tee that installs even quicker. We are not<br />

going to look at cost savings of ProPress versus sweat fittings<br />

in this article<br />

because that could<br />

be an article unto<br />

itself. So responsibly<br />

adding these fittings<br />

can enhance a<br />

system so that you<br />

can purge very easily.<br />

In a very basic<br />

zone valve system,<br />

with the zone valve<br />

on the supply and a<br />

drain and ball valve<br />

Figure 1. A few fittings can ultimately<br />

save time and money.<br />

on the return, you can purge each apartment from the<br />

mechanical room. Manually close the zone valve, close<br />

the ball valve on the return, and open the boiler drain to<br />

successfully purge each unit.<br />

Okay, let’s look at the math for our 4 unit apartment<br />

complex. For a baseline, I am going to use $100.00 an<br />

hour for labor. This was on a service call so we also bill<br />

for our trip charge.<br />

4- 3 /4" C✕C ball valves @ $7.00 each = $28.00<br />

4- 3 /4 ✕ 3 /4✕ 1 /2<br />

(NIBCO #712 Tee C✕C✕FIP) @$6.50 = $26.00<br />

4- 1 /2" boiler drains @ $4.90 = $19.60<br />

Material Total = $73.60<br />

Labor Total at 30 minutes<br />

($100.00 hr as rate)= $50.00<br />

Total for Labor & Materials = $123.60<br />

(add for trip charge)<br />

Now with three of the four units purged in one hour and<br />

still one more unit to go, this set up is starting to look more<br />

and more attractive. Now factor in the next service call at<br />

this location when a zone valve goes bad or we have an<br />

issue in an individual unit. This has now more than paid<br />

Continued on page 28<br />

Page 26/<strong>Plumbing</strong> <strong>Engineer</strong> June 2009

INSTALL GRATIFICATION<br />

TEMPRA© SERIES TANKLESS ELECTRIC WATER HEATERS<br />

• Unlimited Supply of Hot Water<br />

• Saves Energy and Reduces Your<br />

Electric Bills<br />

• Sleek Design Saves Space<br />

• Proven Reliability Backed by a Three<br />

Year Warranty<br />