Pneumatics Brand Partners - Eriks UK

Pneumatics Brand Partners - Eriks UK

Pneumatics Brand Partners - Eriks UK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

£<br />

Be<br />

Call Tech Direct!<br />

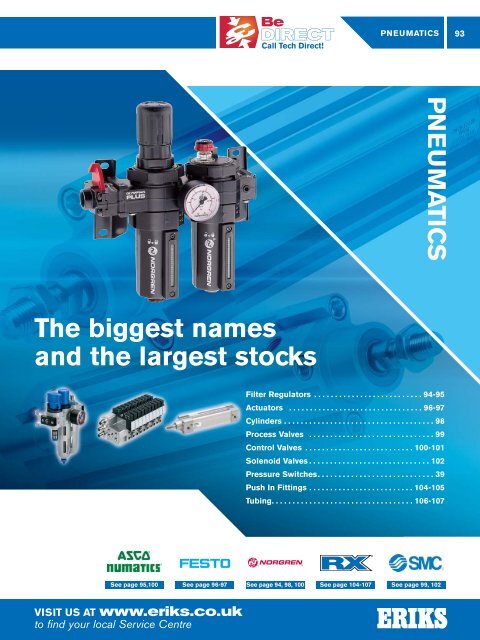

PNEUMATICS<br />

93<br />

2p<br />

PNEUMATICS<br />

The biggest names<br />

and the largest stocks<br />

Filter Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . 94-95<br />

Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96-97<br />

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98<br />

Process Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99<br />

Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . 100-101<br />

Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102<br />

Pressure Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39<br />

Push In Fittings . . . . . . . . . . . . . . . . . . . . . . . . . 104-105<br />

Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106-107<br />

See page 95,100 See page 96-97 See page 94, 98, 100 See page 104-107 See page 99, 102<br />

VISIT US AT www.eriks.co.uk<br />

to find your local Service Centre

94<br />

Filter Regulators<br />

Access<br />

Collection or delivered<br />

PNEUMATICS<br />

95<br />

Norgren has a worldwide reputation for quality and innovation.<br />

Offering excellent flow and regulation characteristics, the<br />

company’s filter/regulator units are extremely compact and<br />

efficient, and suitable for a wide range of applications.<br />

Olympian Boxed Sets<br />

Including filter/regulator and microfog lubricator complete<br />

with exhausting shut-off valve, pressure gauge and mounting<br />

brackets, these boxed sets offer outstanding value.<br />

2p<br />

Olympian Boxed Sets<br />

Part no Port Size Drain Type<br />

BL64-401 1/2" bsp Auto<br />

BL64-421 1/2" bsp Manual<br />

BL68-801 1" bsp Auto<br />

BL68-821 1" bsp Manual<br />

Featuring a double combination groove for most ‘T’ and ‘Semicircular’ switches, this new pneumatic cylinder can be used with most<br />

current magnetic sensors, making it a suitable replacement for any VDMA conforming profile cylinder with the same bore and stroke.<br />

With a hard chrome-plated piston rod (stainless steel available), it has a flush mounting magnetic switch in the cylinder and end-of-stroke<br />

pneumatic adjustable cushioning. ERIKS offers a comprehensive range of these superb products, with cylinder bores<br />

from 32mm–100mm (diameter) and all stroke lengths. The products below are just a small selection!<br />

Filter Regulators<br />

Part no Port Size Drain Type<br />

B64G-2GK-AD3-RMN 1/4" bsp Auto<br />

B64G-2GK-MD3-RMN 1/4" bsp Manual<br />

B64G-4GK-MD3-RMN 1/2" bsp Manual<br />

B68G-8GK-AR3-RLN 1" bsp Auto<br />

B68G-8GK-MR3-RLN 1" bsp Manual<br />

FRL Combinations<br />

Part no Port Size Drain Type<br />

BL64-208 1/4" bsp Auto<br />

BL64-228 1/4" bsp Manual<br />

BL64-408 1/2" bsp Auto<br />

BL64-428 1/2" bsp Manual<br />

BL68-808 1" bsp Auto<br />

BL68-828 1" bsp Manual<br />

Part no Bore (mm) Stroke (mm)<br />

GG032/0025/0000 032 0025<br />

GG032/0050/0000 032 0050<br />

GG032/0080/0000 032 0080<br />

GG032/0100/0000 032 0100<br />

GG032/0160/0000 032 0160<br />

GG040/0025/0000 040 0025<br />

GG040/0050/0000 040 0050<br />

GG040/0080/0000 040 0080<br />

GG040/0100/0000 040 0100<br />

GG040/0160/0000 040 0160<br />

GG050/0025/0000 050 0025<br />

GG050/0050/0000 050 0050<br />

GG050/0080/0000 050 0080<br />

GG050/0100/0000 050 0100<br />

GG050/0160/0000 050 0160<br />

Part no Bore (mm) Stroke (mm)<br />

GG063/0025/0000 063 0025<br />

GG063/0050/0000 063 0050<br />

GG063/0080/0000 063 0080<br />

GG063/0100/0000 063 0100<br />

GG063/0160/0000 063 0160<br />

GG080/0025/0000 080 0025<br />

GG080/0050/0000 080 0050<br />

GG080/0080/0000 080 0080<br />

GG080/0100/0000 080 0100<br />

GG080/0160/0000 080 0160<br />

GG100/0025/0000 100 0025<br />

GG100/0050/0000 100 0050<br />

GG100/0080/0000 100 0080<br />

GG100/0100/0000 100 0100<br />

GG100/0160/0000 100 0160<br />

Utilise your<br />

existing magnetic<br />

sensors when<br />

replacing with the<br />

VDMA Geometric<br />

Cylinder!<br />

4-hour cylinder build service available!<br />

When production has stopped, every second counts<br />

TECH TIPS<br />

Check your<br />

Air Preparation<br />

units regularly<br />

BS 6005 – 1997 standard for<br />

the Safety of Polycarbonate<br />

Bowls states:<br />

■ Bowls which show signs of<br />

damage, cracking or hazing<br />

■ Bowls which have been<br />

contaminated with paint<br />

■ Bowls which have been in<br />

service for 10 years, should<br />

Be Replaced!<br />

P64S + P74S SSDV<br />

Soft-start valves allow a controlled increase of pressure onto downstream<br />

cylinders/machines offering protection to personnel equipment. The positively<br />

driven micro-switch ensures a monitored dump function.<br />

■ Olympian Plus plug-in design or Excelon inline/modular installation<br />

■ Controlled increase of downstream pressure on start-up<br />

■ Monitored dump function<br />

■ High forward flow capacity<br />

■ High flow dump facility<br />

Technical Data<br />

Fluid: Compressed air<br />

Maximum Pressure: 16 bar (240 psig)<br />

Minimum Operating Pressure: 3 bar (45 psig)<br />

Operating Temperature: –20°C to 50°C (Solenoid rating max is 50°C whilst<br />

unit max is 80°C. Consult our technical service below +2°C)<br />

Gauge Ports: Rc1/8<br />

Exhaust Ports: ISO G1/2 with ISO G and Rc main ports, 1/2" PTF with PTF main ports<br />

Typical flow with 6.3 bar (90psig) inlet pressure andoutlet pressure drop of 0.5 var (7" psig)<br />

57dm 3 /s (120 scfm) (P1 to P2 = Cv 4.2) (P2 to P3 Cv = 5.6)<br />

Snap Pressure: Full flow when downstream pressure reaches 35% – 60% of inlet pressure<br />

Charge Time: For 2 litre downstream volume and inlet pressure of 6,3 bar (90 psig), 0,2s minimum,<br />

75 secs. maximum<br />

Solenoid Operator: 22mm, 24V DC, 2W only (no manual overide)<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55<br />

■ 250 million cycles<br />

■ No seal wear<br />

■ 5/2 single and double solenoid<br />

and all 5/3 variants<br />

Technical Data<br />

L1, L2 Series Valves<br />

5-ported, 2- or 3-position valves, solenoid pilot actuated<br />

Port size: L11 = 1/8 L22 = 1/4<br />

Flow capacity: L11 = 1000 Nl/min = CV 1.0 L22 = 1700 Nl/min = CV 1.7<br />

Operating pressure:<br />

Pilot pressure range:<br />

Vacuum to 10 bar, optional to 15 bar; with external pilot supply = vacuum to 21 bar<br />

1 to 10 bar (up to 15 bar upon request)<br />

Voltage: 24 VDC ± 10% 24V, - 110V, - 230V, 50-60 Hz ± 10%<br />

Power input: 3.35 W; optional 5.5 W (DC only) 10/7 VA<br />

Response Times [ms]<br />

Single actuated (5-port., 2-pos.) energise 10 de-energise 35 energise 7 de-energise 35<br />

Dual actuated (5-port., 2-pos.) energise 10 — energise 7 —<br />

Dual actuated (5-port., 3-pos.) energise 10 de-energise 35 energise 7 de-energise 35<br />

Material<br />

Body:<br />

Aluminium alloy<br />

Other Parts:<br />

Static Seals:<br />

Finish:<br />

Stainless steel, steel, aluminium<br />

NBR<br />

Anodised and varnished<br />

EMAIL: contact.direct@eriks.co.uk<br />

Remember to include your account code, part number and delivery address.

96<br />

Standard Industry <strong>Pneumatics</strong> – Actuators<br />

Choice<br />

Over 50,000 stock lines<br />

PNEUMATICS<br />

97<br />

DNCB Double Acting Actuators<br />

Ideal for all applications where technically and functionally advanced drives are used,<br />

these actuators feature a new piston system which delivers extremely smooth running<br />

and significantly increased energy absorption. Compatible with accessories<br />

and mounting attachments from the DNC modular system, they are<br />

available with diameters from 32mm–100mm.<br />

■ ISO/VDMA<br />

■ New piston system<br />

■ Smooth and energy-efficient<br />

■ New precision adjustment with scale<br />

for end-position cushioning<br />

2p<br />

ADN Actuators<br />

Powerful, reliable and economical, these second-generation<br />

compact cylinders offer outstanding performance. With<br />

mounting accessories for practically any installation<br />

requirements, they feature a cylinder sensor on three sides<br />

and are available in a wide variety of variants and sizes.<br />

■ 12mm–125mm dia, 500mm stroke<br />

■ Cylinder sensor on three sides<br />

■ Mounting accessories for every requirement<br />

DNCB<br />

Double Acting<br />

Standard Cylinder<br />

– – – PPV –<br />

Bore Size<br />

32, 40, 50, 63,<br />

80, 100<br />

PPV<br />

Pneumatic Cushion,<br />

Adjustable both ends<br />

A<br />

A – Magnetic<br />

LOWER<br />

COST<br />

SELECTED<br />

FOR VALUE<br />

ADN<br />

– – – PPV –<br />

P<br />

–<br />

Reed Switches. Reed Switch. 24V dc<br />

Part no<br />

Description<br />

SME-8-K-7.5-LED-24 LED prewired 7.5m lead<br />

SME-8-S-LED-24 LED, 8mm in-line plug<br />

A<br />

Stroke (mm)<br />

25, 40, 50, 80, 100, 125, 160,<br />

200, 250, 320, 400, 500<br />

Max Stroke 2000<br />

Double Acting<br />

Standard Cylinder<br />

Bore Size<br />

12, 16, 20, 25, 32,<br />

40, 50, 63, 80, 100<br />

A– Male Piston Rod Thread<br />

I – Female Piston Rod Thread<br />

A – Magnetic<br />

Bore Size ø 32mm<br />

Part no Type Stroke (mm)<br />

532724 DNCB-32-25-PPV-A 25<br />

532725 DNCB-32-40-PPV-A 40<br />

532726 DNCB-32-50-PPV-A 50<br />

532727 DNCB-32-80-PPV-A 80<br />

532728 DNCB-32-100-PPV-A 100<br />

532729 DNCB-32-125-PPV-A 125<br />

532730 DNCB-32-160-PPV-A 160<br />

532731 DNCB-32-200-PPV-A 200<br />

532732 DNCB-32-250-PPV-A 250<br />

532733 DNCB-32-320-PPV-A 320<br />

532734 DNCB-32-400-PPV-A 400<br />

532735 DNCB-32-500-PPV-A 500<br />

Bore Size ø 40mm<br />

Part no Type Stroke (mm)<br />

532737 DNCB-40-25-PPV-A 25<br />

532738 DNCB-40-40-PPV-A 40<br />

532739 DNCB-40-50-PPV-A 50<br />

532740 DNCB-40-80-PPV-A 80<br />

532741 DNCB-40-100-PPV-A 100<br />

532742 DNCB-40-125-PPV-A 125<br />

532743 DNCB-40-160-PPV-A 160<br />

532744 DNCB-40-200-PPV-A 200<br />

532745 DNCB-40-250-PPV-A 250<br />

532746 DNCB-40-320-PPV-A 320<br />

532747 DNCB-40-400-PPV-A 400<br />

532748 DNCB-40-500-PPV-A 500<br />

Bore Size ø 50mm<br />

Part no Type Stroke (mm)<br />

532750 DNCB-50-25-PPV-A 25<br />

532751 DNCB-50-40-PPV-A 40<br />

532752 DNCB-50-50-PPV-A 50<br />

532753 DNCB-50-80-PPV-A 80<br />

532754 DNCB-50-100-PPV-A 100<br />

532755 DNCB-50-125-PPV-A 125<br />

532756 DNCB-50-160-PPV-A 160<br />

532757 DNCB-50-200-PPV-A 200<br />

532758 DNCB-50-250-PPV-A 250<br />

532759 DNCB-50-320-PPV-A 320<br />

532760 DNCB-50-400-PPV-A 400<br />

532761 DNCB-50-500-PPV-A 500<br />

Bore Size ø 20mm<br />

Part no Type Stroke (mm)<br />

536242 ADN-20-5-I-P-A 5<br />

536243 ADN-20-10-I-P-A 10<br />

536244 ADN-20-15-I-P-A 15<br />

536245 ADN-20-20-I-P-A 20<br />

536246 ADN-20-25-I-P-A 25<br />

536247 ADN-20-30-I-P-A 30<br />

536248 ADN-20-40-I-P-A 40<br />

536249 ADN-20-50-I-P-A 50<br />

Stroke (mm)<br />

5, 10, 15, 20, 25, 30, 40,<br />

50, 60, 80<br />

Max Stroke 500<br />

(Dependent on Bore Size)<br />

Bore Size ø 25mm<br />

P – Elastomer Cushion<br />

Part no Type Stroke (mm)<br />

536259 ADN-25-5-I-P-A 5<br />

536260 ADN-25-10-I-P-A 10<br />

536261 ADN-25-15-I-P-A 15<br />

536262 ADN-25-20-I-P-A 20<br />

536263 ADN-25-25-I-P-A 25<br />

536264 ADN-25-30-I-P-A 30<br />

536265 ADN-25-40-I-P-A 40<br />

536266 ADN-25-50-I-P-A 50<br />

Bore Size ø 32mm<br />

Part no Type Stroke (mm)<br />

536278 ADN-32-5-I-P-A 5<br />

536279 ADN-32-10-I-P-A 10<br />

536280 ADN-32-15-I-P-A 15<br />

536281 ADN-32-20-I-P-A 20<br />

536282 ADN-32-25-I-P-A 25<br />

536283 ADN-32-30-I-P-A 30<br />

536284 ADN-32-40-I-P-A 40<br />

536285 ADN-32-50-I-P-A 50<br />

Bore Size ø 63mm<br />

Part no Type Stroke (mm)<br />

532763 DNCB-63-25-PPV-A 25<br />

532764 DNCB-63-40-PPV-A 40<br />

532765 DNCB-63-50-PPV-A 50<br />

532766 DNCB-63-80-PPV-A 80<br />

532767 DNCB-63-100-PPV-A 100<br />

532768 DNCB-63-125-PPV-A 125<br />

532769 DNCB-63-160-PPV-A 160<br />

532770 DNCB-63-200-PPV-A 200<br />

532771 DNCB-63-250-PPV-A 250<br />

532772 DNCB-63-320-PPV-A 320<br />

532773 DNCB-63-400-PPV-A 400<br />

532774 DNCB-63-500-PPV-A 500<br />

Bore Size ø 80mm<br />

Part no Type Stroke (mm)<br />

532884 DNCB-80-25-PPV-A 25<br />

532885 DNCB-80-40-PPV-A 40<br />

532886 DNCB-80-50-PPV-A 50<br />

532887 DNCB-80-80-PPV-A 80<br />

532888 DNCB-80-100-PPV-A 100<br />

532889 DNCB-80-125-PPV-A 125<br />

532890 DNCB-80-160-PPV-A 160<br />

532891 DNCB-80-200-PPV-A 200<br />

532892 DNCB-80-250-PPV-A 250<br />

532893 DNCB-80-320-PPV-A 320<br />

532894 DNCB-80-400-PPV-A 400<br />

532895 DNCB-80-500-PPV-A 500<br />

Bore Size ø 100mm<br />

Part no Type Stroke (mm)<br />

532897 DNCB-100-25-PPV-A 25<br />

532898 DNCB-100-40-PPV-A 40<br />

532899 DNCB-100-50-PPV-A 50<br />

532900 DNCB-100-80-PPV-A 80<br />

532901 DNCB-100-100-PPV-A 100<br />

532902 DNCB-100-125-PPV-A 125<br />

532903 DNCB-100-160-PPV-A 160<br />

532904 DNCB-100-200-PPV-A 200<br />

532905 DNCB-100-250-PPV-A 250<br />

532906 DNCB-100-320-PPV-A 320<br />

532907 DNCB-100-400-PPV-A 400<br />

532908 DNCB-100-500-PPV-A 500<br />

536362 ADN-20-60-I-P-A 60<br />

Bore Size ø 40mm<br />

Part no Type Stroke (mm)<br />

536299 ADN-40-5-I-P-A 5<br />

536300 ADN-40-10-I-P-A 10<br />

536301 ADN-40-15-I-P-A 15<br />

536302 ADN-40-20-I-P-A 20<br />

536303 ADN-40-25-I-P-A 25<br />

536304 ADN-40-30-I-P-A 30<br />

536305 ADN-40-40-I-P-A 40<br />

536306 ADN-40-50-I-P-A 50<br />

536307 ADN-40-60-I-P-A 60<br />

536308 ADN-40-80-I-P-A 80<br />

536383 ADN-25-60-I-P-A 60<br />

Bore Size ø 50mm<br />

Part no Type Stroke (mm)<br />

536320 ADN-50-5-I-P-A 5<br />

536321 ADN-50-10-I-P-A 10<br />

536322 ADN-50-15-I-P-A 15<br />

536323 ADN-50-20-I-P-A 20<br />

536324 ADN-50-25-I-P-A 25<br />

536325 ADN-50-30-I-P-A 30<br />

536326 ADN-50-40-I-P-A 40<br />

536327 ADN-50-50-I-P-A 50<br />

536328 ADN-50-60-I-P-A 60<br />

536329 ADN-50-80-I-P-A 80<br />

536286 ADN-32-60-I-P-A 60<br />

536287 ADN-32-80-I-P-A 80<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55<br />

EMAIL: contact.direct@eriks.co.uk<br />

Remember to include your account code, part number and delivery address.

98<br />

Cylinders and Process Valves<br />

2p<br />

Value<br />

More flexibility, more value<br />

PNEUMATICS<br />

99<br />

Double Acting<br />

Roundline Cylinders<br />

■ Three different basic versions provide flexibility<br />

and wide range of application<br />

■ Magnetic piston as standard provides a wide<br />

range of control options<br />

■ Comprehensive range of standard stroke lengths<br />

■ International series available world-wide<br />

Cylinder ø (mm) Substitute<br />

8 08<br />

10 10<br />

12 12<br />

16 16<br />

20 20<br />

25 25<br />

32 32<br />

40 40<br />

50 50<br />

63 63<br />

RT/572 – – –<br />

Rodless Cylinders<br />

■ New lightweight design extrusion with universal<br />

mounting grooves<br />

■ Proved and patented sealing system<br />

■ Dust protection as standard (ø 25 to 63mm)<br />

■ Interchangeability with series M/46000<br />

Guiding System Substitute<br />

Internal 0<br />

External 1<br />

Roller 2<br />

Cylinder ø (mm) Substitute<br />

16 16<br />

20 20<br />

25 25<br />

32 32<br />

40 40<br />

50 50<br />

63 63<br />

80 80<br />

Cylinder variants<br />

Substitute<br />

Magnetic piston<br />

M<br />

Magnetic piston, central rear port, flat end MC<br />

Magnetic piston, side port, flat end<br />

MF<br />

Magnetic piston, double ended piston rod JM<br />

Stroke (mm)<br />

500 max.<br />

M/146 – – – –<br />

Varients (non-magnetic piston) Substitute<br />

Alternative ports<br />

IC<br />

Active brake<br />

L1<br />

Passive brake<br />

L2<br />

With added caged ball linear motion guide P<br />

Double carriages *1)<br />

ID<br />

M/146***/ID/****/****<br />

Distance between<br />

carriage centres (mm)<br />

Varients (magnetic piston)<br />

Substitute<br />

Alternative ports<br />

MC<br />

Active brake<br />

L3<br />

Passive brake<br />

L4<br />

With added caged ball linear motion guide PM<br />

With linear position sensor<br />

F1<br />

Double carriages *1)<br />

MD<br />

M/146***/ID/****/****<br />

Distance between<br />

carriage centres (mm)<br />

*1) For M/146100 & M/146200 only<br />

Strokes (mm)<br />

On request<br />

Compact Direct Operated<br />

2/3-Port Solenoid Valve<br />

Series VDW<br />

SMC’s smallest 2-port valve and<br />

simplest design gives a low cost yet<br />

versatile solution. Much smaller than<br />

the VX equivalent, it uses SMC low<br />

wattage coils to minimise running costs.<br />

Can be used for vacuum, air or water.<br />

Part no Flow (Cv) Max † P (MPa) Port<br />

VDW11-3G-1-M5-Q 1 0.04 0.9 M5<br />

VDW11-4G-1-M5-Q 0.04 0.9 M5<br />

VDW11-5G-1-M5-Q 0.04 0.9 M5<br />

VDW21-3G-1-01F-Q 0.09 0.7 G1/8<br />

VDW21-4G-1-01F-Q 0.09 0.7 G1/8<br />

VDW21-5G-1-01F-Q 0.09 0.7 G1/8<br />

Direct Operated<br />

3-Port Solenoid Valve<br />

Series VX31/32/33<br />

Using the same internal components,<br />

this is the 3-port version of our VX2<br />

range. The 3-port configuration means<br />

this valve is ideal for using as a diverter<br />

for air or water. Again, low wattage<br />

coils help keep running costs low.<br />

Part no Flow (Cv) Max † P (MPa) Port<br />

VX3114-01F-3DR1 0.08 0.7 G1/8<br />

VX3114-01F-JDR1 0.08 0.7 G1/8<br />

VX3114-01F-5D1 0.08 0.7 G1/8<br />

VX3224-02F-3DR1 0.17 0.7 G1/4<br />

VX3224-02F-JDR1 0.17 0.7 G1/4<br />

VX3224-02F-5D1 0.17 0.7 G1/4<br />

VX3334-03F-3DR1 0.27 0.6 G3/8<br />

VX3334-03F-JDR1 0.27 0.6 G3/8<br />

VX3334-03F-5D1 0.27 0.6 G3/8<br />

Direct Operated<br />

2-Port Solenoid Valve<br />

Series VCB20/30/40<br />

Designed specifically to handle<br />

heated water up to 99°C, this<br />

valve is direct operated and is<br />

widely used on heated<br />

temperature control circuits.<br />

Part no Flow (Cv) Max † P (MPa) Port<br />

VCB31-3T-4-03F-Q 0.54 0.8 G3/8<br />

VCB31-36T-4-03F-Q 0.54 0.8 G3/8<br />

Process Valves<br />

A complete selection of valves for a variety of fluids,<br />

these cover 80% of applications and are the most<br />

widely used process valves that make up our range.<br />

Direct Operated<br />

2-Port Solenoid Valve<br />

Series VX21/22/23<br />

SMC considers this our<br />

‘Workhorse’ valve range. The<br />

1/8" and 1/4" sizes are ideal<br />

for low-medium flow applications.<br />

Low wattage coils, typically 4.5W<br />

keep running costs down.<br />

Part no Flow (Cv) Max † P (MPa) Port<br />

VX2110-01F-3DR1 0.18 1.5 G1/8<br />

VX2110-01F-JDR1 0.18 1.5 G1/8<br />

VX2110-01F-5DZ1 0.18 1.5 G1/8<br />

VX2330-02F-3DR1 0.61 0.9 G1/4<br />

VX2330-02F-JDR1 0.61 0.9 G1/4<br />

VX2330-02F-5DZ1 0.61 0.9 G1/4<br />

Zero Differential Pressure Type<br />

Pilot Operated 2-Port Solenoid Valve<br />

Series VXZ22/23<br />

Reaching 1/2" thread size from<br />

stock, this valve caters for larger<br />

flow capacity applications. Available<br />

in all voltages, this valve is one of our<br />

most versatile. This range also features our low<br />

watt coils and has zero pressure differential.<br />

Part no Flow (Cv) Max † P (MPa) Port<br />

VXZ2230-03F-3DR1 2.8 1 G3/8<br />

VXZ2230-03F-JDR1 2.8 1 G3/8<br />

VXZ2230-03F-5D1 2.8 0.7 G3/8<br />

VXZ2240-04F-3DR1 6 1 G1/2<br />

VXZ2240-04F-JDR1 6 1 G1/2<br />

VXZ2240-04F-5D1 6 0.7 G1/2<br />

VXZ2240A-04F-3DR1 5.3 0.7 G1/2<br />

VXZ2240A-04F-JDR1 5.3 0.7 G1/2<br />

VXZ2240A-04F-5D1 5.3 0.7 G1/2<br />

Direct Operated<br />

2-Port Solenoid Valve<br />

Series VCL20/30/40<br />

The internal stem and armature<br />

components have been specifically<br />

designed to avoid lag in response<br />

time due to fluid adhesion<br />

(below 50st. viscosity).<br />

Part no Flow (Cv) Max † P (MPa) Port<br />

VCL21-3D-3-02F-Q 0.33 0.8 G1/4<br />

VCL21-36D-3-02F-Q 0.33 0.8 G1/4<br />

VCL21-5D-3-02F-Q 0.33 0.8 G1/4<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55<br />

EMAIL: contact.direct@eriks.co.uk<br />

Remember to include your account code, part number and delivery address.

100<br />

Control Valves<br />

Response<br />

We’re here to help, try us<br />

PNEUMATICS<br />

101<br />

Fluid Control Valves<br />

for all Applications<br />

With over 100 years of experience, ASCO NUMATICS is an industry-leader<br />

in fluid power and fluid control technology. Customers across the world, in<br />

sectors ranging from packaging to petrochemical, rely on ASCO NUMATICS<br />

fluid control solutions for the quality, performance and value they need.<br />

Air, Water, Steam<br />

A comprehensive range of robust valves for applications that require the transport<br />

of fluids such as air, water and steam.<br />

Aggressive Liquids and Gases<br />

Whether your application involves superheated water, acids, bases or analytical reagents,<br />

we can provide a control valve that meets your needs precisely. With hermetic separation<br />

of control mechanism and fluid, they are available in multiple flow configurations.<br />

Medical and Analytical<br />

Ideal for use in applications such as medical analysers, biotechnology and<br />

chromatography, these low power, direct acting valves provide sterile conditions through<br />

hermetic separation between the fluid and valve parts to prevent contamination.<br />

ATEX<br />

We offer a full range of ATEX certified products, designed for use in potentially<br />

explosive gaseous and dust laden atmospheres.<br />

Catalogues and other literature available on request<br />

Solenoid and Pressure Operated<br />

Valves for Fluid Control<br />

From industrial vacuums to saturated steam.<br />

Medical Analytical<br />

A full range of products for medical<br />

and analytical applications.<br />

Apparatus for Potentially<br />

Explosive Atmospheres<br />

Everything you need to know about<br />

hazardous atmospheres and the<br />

ATEX directive.<br />

Proportional Technology<br />

Valves with proportional control,<br />

including poppet valves, servo valves<br />

and solenoid valves.<br />

Pulse Valves for Dust Collector Systems<br />

From the single pulse valve to the<br />

complete tanks system, this catalogue<br />

offers a full product range.<br />

Pilot Valves for the Process Industry<br />

All the pilot valves used in the Process<br />

Industry are in this special catalogue,<br />

including ATEX and SIL-certified products.<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55<br />

V60–63 Series Inline Valves<br />

With optimised flow rates combined with low power consumption as<br />

standard, this range reduces installation space and cost.<br />

■ High flow rate (750–4200 l/min)<br />

■ Easily customised soft-seal cartridge system<br />

■ Flexible mounting systems<br />

■ Double pilot valve with ported pilot exhaust<br />

Override – Push and Lock<br />

Part no<br />

V60A313A-A213L<br />

V60A313A-A218L<br />

V60A513A-A213L<br />

V60A513A-A218L<br />

V60A523A-A213L<br />

V61B313A-A213L<br />

V61B413A-A213L<br />

V61B413A-A218L<br />

V61B423A-A213L<br />

V61B513A-A213L<br />

V61B513A-A218L<br />

V61B523A-A213L<br />

V61B611A-A213L<br />

V61B611A-A218L<br />

V62C413A-A213L<br />

V62C413A-A214L<br />

V62C413A-A218L<br />

V62C511A-A213L<br />

V62C513A-A213L<br />

V62C513A-A218L<br />

V62C523A-A213L<br />

VS Valves<br />

With a glandless spool and sleeve for millions of trouble-free cycles, a soft<br />

spool for enhanced flow rates, and easy integration with Fieldbus systems,<br />

they can be installed in seconds.<br />

■ Add up to four stations easily<br />

■ No need to disassemble the valve island<br />

VS 18 Manifold Valves<br />

Part no<br />

VS18G511DF313A<br />

VS18G527DF313A<br />

VS18G611DF313A<br />

VS18G711DF313A<br />

VS18S511DF313A<br />

VS18S517DF313A<br />

VS18S517DF513A<br />

VS18S527DF313A<br />

VS18S611DF313A<br />

VS18S711DF313A<br />

VS18SA11DF313A<br />

VS18SA11DF318A<br />

VS18SB11DF313A<br />

VS18SB11DF318A<br />

VS18SC11DF313A<br />

VS1872002-6FF0<br />

VS1872002-8FF0<br />

Description<br />

VS18 5/2 SOL/SOL VALVE<br />

VS18 5/2 SOL/SPRING VALVE<br />

VS18 5/3 SOL/SOL VALVE APB<br />

VS18 5/3 SOL/SOL VALVE COE<br />

VS18 5/2 SOL/SOL VALVE<br />

VS18 5/2 SOL/SPRING VALVE<br />

VS18 5/2 SOL/SPRING VALVE<br />

VS18 5/2 SOL/SPRING VALVE<br />

VS18 5/3 SOL/SOL VALVE APB<br />

VS18 5/3 SOL/SOL VALVE COE<br />

VS18 2X3/2 SOL/SPRING VALVE NC<br />

VS18 2X3/2 SOL/SPRING VALVE NC<br />

VS18 2X3/2 SOL/SPRING VALVE NO<br />

VS18 2X3/2 SOL/SPRING VALVE NO<br />

VS18 2X3/2 SOL VALVE NC/NO<br />

VS18 DOUBLE STATION BASE 6MM<br />

VS18 DOUBLE STATION BASE 8MM<br />

VS1872002-AFF0 VS18 DOUBLE STATION BASE G1/8<br />

VS1872003-1FF0<br />

VS1872003-6FF0<br />

VS1872003-8FF0<br />

VS18 SINGLE STATION BASE PF1/4<br />

VS18 SINGLE STATION BASE PF6MM<br />

VS18 SINGLE STATION BASE PF8MM<br />

VS1872003-AFF0 VS18 SINGLE STATION BASE G1/8<br />

VS1872004-6FF0<br />

VS1872004-8FF0<br />

Description<br />

3/2 G1/8 SOl VALVE N/O, 24V dc<br />

3/2 G1/8 SOl VALVE N/O, 110V ac<br />

5/2 G1/8 SOl VALVE, 24V dc<br />

5/2 G1/8 SOl VALVE, 110V ac<br />

5/2 G1/8 SOl VALVE, 24V dc<br />

3/2 G1/4 SOl VALVE, N/O, 24V dc<br />

3/2 G1/4 SOl VALVE, 24V dc<br />

3/2 G1/4 SOl VALVE, 110V ac<br />

3/2 G1/4 SOl VALVE, 24V dc<br />

5/2 G1/4 SOL/SPRING VALVE, 24V dc<br />

5/2 G1/4 SOL/SPRING VALVE, 110V ac<br />

5/2 G1/4 SOL/SPRING VALVE, 24V dc<br />

5/3 G1/4 SOL/SOL VALVE APB, 24V dc<br />

5/3 G1/4 SOL/SOL VALVE APB, 110V ac<br />

3/2 G3/8 SOL/SPRING VALVE, 24V dc<br />

3/2 G3/8 SOL/SPRING VALVE, 110V ac<br />

3/2 G3/8 SOL/SPRING VALVE, 110V ac<br />

5/2 G3/8 SOL/SOL VALVE, 24V dc<br />

5/2 G3/8 SOL/SPRING VALVE, 24V dc<br />

5/2 G3/8 SOL/SPRING VALVE, 110V ac<br />

5/2 G3/8 SOL/SPRING VALVE, 24V dc<br />

VS18 ONE STATION EXP KIT 6MM<br />

VS18 ONE STATION EXP KIT 8MM<br />

VS1872004-AFF0 VS18 ONE STATION EXP KIT G1/8<br />

VS1872010-AF00 VS18 SINGLE SUB BASE G1/4<br />

■ Double pilot valve for multi-pole manifolds and single valves<br />

■ Wide range for all voltages<br />

Override – Push only<br />

Part no<br />

V60A417A-A313L<br />

V60A417A-A318L<br />

V60A511A-A313L<br />

V60A511A-A318L<br />

V60A522A-A313L<br />

V60A611A-A313L<br />

V61B411A-A318L<br />

V61B511A-A313L<br />

V61B511A-A318L<br />

V61B522A-A313L<br />

V61B611A-A313L<br />

V62C422A-A318L<br />

V62C511A-A313L<br />

V62C511A-A318L<br />

V62C523A-A313L<br />

■ Field configurable and total reliability<br />

■ Correct connection guaranteed<br />

VS 26 Manifold Valves<br />

Part no<br />

VS26G511DF313A<br />

VS26G511DF318A<br />

VS26G517DF313A<br />

VS26G527DF313A<br />

VS26G611DF313A<br />

VS26G711DF313A<br />

VS26S511DF313A<br />

VS26S511DF318A<br />

VS26S517DF218A<br />

VS26S517DF313A<br />

VS26S517DF318A<br />

VS26S527DF313A<br />

VS26S611DF313A<br />

VS26S711DF218A<br />

VS26S711DF313A<br />

VS26SA11DF313A<br />

VS26SA11DF318A<br />

VS26SB11DF313A<br />

VS26SC11DF313A<br />

VS2672503-8GF0<br />

EMAIL: contact.direct@eriks.co.uk<br />

Remember to include your account code, part number and delivery address.<br />

Description<br />

3/2 G1/8 SOL VALVE N/C, 24Vdc<br />

3/2 G1/8 SOL VALVE N/C, 110V ac<br />

5/2 G1/8 SOL/SOL VALVE, 24V dc<br />

5/2 G1/8 SOL/SOL VALVE, 110V ac<br />

5/2 G1/8 SOL/SOL VALVE, 24V dc<br />

5/3 G1/8 SOL/SOL VALVE APB, 24V dc<br />

3/2 G1/4 SOl VALVE, 110V ac<br />

5/2 G1/4 SOL/SOL VALVE, 24V dc<br />

5/2 G1/4 SOL/SOL VALVE, 110V ac<br />

5/2 G1/4 SOL/SOL VALVE, 24V dc<br />

5/3 G1/4 SOL/SOL VALVE APB, 24V dc<br />

3/2 G3/8 SOL/SOL VALVE, 110V ac<br />

5/2 G3/8 SOL/SOL VALVE, 24V dc<br />

5/2 G3/8 SOL/SOL VALVE, 110V ac<br />

5/2 G3/8 SOL/SPRING VALVE, 24V dc<br />

Description<br />

VS26 5/2 SOL/SOL VALVE<br />

VS26 5/2 SOL/SOL VALVE<br />

VS26 5/2 SOL/SPRING VALVE<br />

VS26 5/2 SOL/SPRING VALVE<br />

VS26 5/3 SOL/SOL VALVE APB<br />

VS26 5/3 SOL/SOL VALVE COE<br />

VS26 5/2 SOL/SOL VALVE<br />

VS26 5/2 SOL/SOL VALVE<br />

VS26 5/2 SOL/SPRING VALVE<br />

VS26 5/2 SOL/SPRING VALVE<br />

VS26 5/2 SOL/SPRING VALVE<br />

VS26 5/2 SOL/SPRING VALVE<br />

VS26 5/3 SOL/SOL VALVE APB<br />

VS26 5/3 SOL/SOL VALVE COE<br />

VS26 5/3 SOL/SOL VALVE COE<br />

VS26 2X3/2 SOL/SPRING VALVE NC<br />

VS26 2 X 3/2 SOLENOID VALVE<br />

VS26 2X3/2 SOL/SPRING VALVE NO<br />

VS26 2X3/2 SOL VALVE NC/NO<br />

VS26 SINGLE SUB BASE 8MM<br />

VS2672503-BGF0 VS26 SINGLE STATION G1/4<br />

VS2672503-YGF0<br />

VS2672504-8GF0<br />

VS2672504-BGF0<br />

VS2672504-YGF0<br />

VS26 SINGLE SUB BASE 10MM<br />

VS26 SINGLE STATION EXP 8MM<br />

VS26 TWO STATION MODULE<br />

VS26 SINGLE STATION EXP 10MM<br />

VS2672510-BG00 VS26 SINGLE SUB BASE G1/4

102<br />

Solenoid Valves<br />

SY Solenoid Valves<br />

Offering major advances in valve performance, these valves provide high<br />

flow with low power consumption in a compact design. Available in body<br />

ported or base mounted styles, they can be used individually or manifold<br />

mounted, and represent an extremely cost-effective solution. For complete<br />

manifold assemblies contact your local ERIKS Service Centre.<br />

SMC solenoid valves offer unsurpassed quality, performance and<br />

range, and are extensively in the semiconductor industry, as well as<br />

the automotive, packaging, medical, specialty machine and machine tool<br />

sectors. The company has a valve solution that will accommodate your<br />

most demanding application – if you don’t see what you need here, call us!<br />

Solenoid Valves for Prewired Manifolds<br />

SY3000<br />

Part no<br />

Description<br />

SY3140-5FU-Q<br />

5/2-Single Sol<br />

SY3245-5FU-Q<br />

SY3345-5FU-Q<br />

SY3445-5FU-Q<br />

SY3545-5FU-Q<br />

5/2-Double Sol<br />

5/3-Centre Closed<br />

5/3-Centre Exhaust<br />

5/3-Centre Pressurised<br />

Sub Base Mounted Valves<br />

SY3000<br />

Part no<br />

Description<br />

SY3140-5LOU-Q<br />

5/2-Single Sol<br />

SY3240-5LOU-Q<br />

SY3340-5LOU-Q<br />

SY3440-5LOU-Q<br />

SY3540-5LOU-Q<br />

5/2-Double Sol<br />

5/3-Centre Closed<br />

5/3-Centre Exhaust<br />

5/3-Centre Pressurised<br />

SY5000<br />

SY5000<br />

SY7000<br />

Part no<br />

Description<br />

Part no<br />

Description<br />

Part no<br />

Description<br />

SY5140-5FU-Q<br />

5/2-Single Sol<br />

SY5140-5LOU-Q<br />

5/2-Single Sol<br />

SY7140-5LOU-Q<br />

5/2-Single Sol<br />

SY5245-5FU-Q<br />

5/2-Double Sol<br />

SY5240-5LOU-Q<br />

5/2-Double Sol<br />

SY7240-5LOU-Q<br />

5/2-Double Sol<br />

SY5345-5FU-Q<br />

5/3-Centre Closed<br />

SY5340-5LOU-Q<br />

5/3-Centre Closed<br />

SY7340-5LOU-Q<br />

5/3-Centre Closed<br />

SY5445-5FU-Q<br />

5/3-Centre Exhaust<br />

SY5440-5LOU-Q<br />

5/3-Centre Exhaust<br />

SY7440-5LOU-Q<br />

5/3-Centre Exhaust<br />

SY5545-5FU-Q<br />

5/3-Centre Pressurised<br />

SY5540-5LOU-Q<br />

5/3-Centre Pressurised<br />

SY7540-5LOU-Q<br />

5/3-Centre Pressurised<br />

Body Ported Valves<br />

SY3000<br />

Part no Description Port Size<br />

SY3120-5LOU-C4-Q 5/2-Single Sol 4mm<br />

SY3220-5LOU-C4-Q 5/2-Double Sol 4mm<br />

SY3320-5LOU-C4-Q 5/3-Centre Closed 4mm<br />

SY3420-5LOU-C4-Q 5/3-Centre Exhaust 4mm<br />

SY3520-5LOU-C4-Q 5/3-Centre Pressurised 4mm<br />

SY5000<br />

Part no Description Port Size<br />

SY5120-5LOU-01F-Q 5/2-Single Sol 1/8"<br />

SY5120-5LOU-C8F-Q 5/2-Single Sol 8mm<br />

SY5220-5LOU-01F-Q 5/2-Double Sol 1/8"<br />

SY5220-5LOU-C8F-Q 5/2-Double Sol 8mm<br />

SY5320-5LOU-01F-Q 5/3-Centre Closed 1/8"<br />

SY5320-5LOU-C8F-Q 5/3-Centre Closed 8mm<br />

SY5420-5LOU-01F-Q 5/3-Centre Exhaust 1/8"<br />

SY5420-5LOU-C8F-Q 5/3-Centre Exhaust 8mm<br />

SY5520-5LOU-01F-Q 5/3-Centre Pressurised 1/8"<br />

SY7000<br />

Part no Description Port Size<br />

SY7120-5LOU-02F-Q 5/2-Single Sol 1/4"<br />

SY7120-5LOU-C10F-Q 5/2-Single Sol 10mm<br />

SY7120-5LOU-C8F-Q 5/2-Single Sol 8mm<br />

SY7120-5LOU-C8-Q 5/2-Double Sol 10mm<br />

SY7220-5LOU-02F-Q 5/2-Double Sol 1/4"<br />

SY7220-5LOU-C10F-Q 5/3-Centre Closed 10mm<br />

SY7320-5LOU-02F-Q 5/3-Centre Closed 1/4"<br />

SY7320-5LOU-C10F-Q 5/3-Centre Closed 10mm<br />

SY7420-5LOU-02F-Q 5/3-Centre Exhaust 1/4"<br />

SY7420-5LOU-C10F-Q 5/3-Centre Exhaust 10mm<br />

SY7420-5LOU-C8F-Q 5/3-Centre Exhaust 8mm<br />

SY7520-5LOU-02F-Q 5/3-Centre Pressurised 1/4"<br />

CP95 Cylinders<br />

■ Conform to ISO and VDMA<br />

■ Hard chromed steel piston rods<br />

■ Recessed cushion valves<br />

■ Enclosed tie-rods<br />

■ Six bore sizes<br />

■ Variety of mounting options<br />

CQ2 Compact Cylinders<br />

■ Front snap-ring design for<br />

easy access<br />

■ Single and double rod models<br />

■ 10 bore sizes up to 100mm<br />

■ Versatile mounting options<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55

104<br />

Push In Fittings<br />

Access<br />

Collection or delivered<br />

PNEUMATICS<br />

105<br />

Push-in Fittings<br />

High quality Push-in Fittings in composite materials or all nickel plated brass. 100% leak tested during production, these fittings<br />

are suitable for both pneumatic and vacuum applications. The composite fittings incorporate a wide range of sizes: All the popular<br />

variants, with an extended range of combinations of tube to thread size that reduce the requirement for adaptors, keeping cost<br />

and installation time down. All the straight fittings have an internal hex, allowing fitting into ports with limited access.<br />

The premier one-touch tube joint system<br />

■ Simple and quick to install<br />

■ Flexible space-saving design<br />

■ Wide range to suit all applications<br />

■ Compatible with all other leading systems<br />

■ Tubing can be freely rotated, even after installation<br />

■ All taper threads are pre-coated with PTFE for<br />

improved seal performance<br />

■ Packaged in bags of 5<br />

2p<br />

Polymer Push-in Fittings Range<br />

Metal Adapters Range<br />

Straight Parallel<br />

Male<br />

Thread<br />

Tube size<br />

Size 4mm 6mm 8mm 10mm 12mm 16mm<br />

M5 W89A-10105 W89A-10106 – – – –<br />

1/8 W89A-10116 W89A-10117 W89A-10118 – – –<br />

1/4 W89A-10113 W89A-10114 W89A-10115 W89A-10111 W89A-10112 –<br />

3/8 – W89A-10121 W89A-10122 W89A-10119 W89A-10120 W89A-10781<br />

1/2 – W89A-10109 W89A-10110 W89A-10107 W89A-10108 W89A-10782<br />

Nipple Taper<br />

Thread size<br />

1/8 1/4 3/8 1/2 3/4 1<br />

W89A-12326 W89A-12328 W89A-12330 W89A-12332 W89A-12334 W89A-12336<br />

Elbow Parallel<br />

Male<br />

Thread<br />

Tube size<br />

Size 4mm 6mm 8mm 10mm 12mm 16mm<br />

M5 W89A-10157 W89A-10158 – – – –<br />

1/8 W89A-10168 W89A-10169 W89A-10170 – – –<br />

1/4 W89A-10165 W89A-10166 W89A-10167 W89A-10163 W89A-10164 –<br />

3/8 – W89A-10173 W89A-10174 W89A-10171 W89A-10172 W89A-10787<br />

1/2 – W89A-10161 W89A-10162 W89A-10159 W89A-10160 W89A-10788<br />

Reducer Taper<br />

Male/Female<br />

Thread Thread size 2<br />

Size 1 1/8F 1/4F 3/8F 1/2F<br />

1/4M W89A-12446 – – –<br />

3/8M W89A-12448 W89A-12450 – –<br />

1/2M W89A-12452 W89A-12454 W89A-12456 –<br />

3/4M – – W89A-12458 W89A-12460<br />

1M – – – W89A-12462<br />

Tee Parallel<br />

Male<br />

Elbow Union<br />

Thread<br />

Tube size<br />

Size 4mm 6mm 8mm 10mm 12mm 16mm<br />

M5 W89A-10259 W89A-10260 – – – –<br />

1/8 W89A-10270 W89A-10271 W89A-10272 – – –<br />

1/4 W89A-10267 W89A-10268 W89A-10269 W89A-10265 W89A-10266 –<br />

3/8 – W89A-10275 W89A-10276 W89A-10273 W89A-10274 –<br />

1/2 – W89A-10263 W89A-10264 W89A-10261 W89A-10262 –<br />

Tube size<br />

4mm 6mm 8mm 10mm 12mm 16mm<br />

W89A-10336 W89A-10337 W89A-10338 W89A-10339 W89A-10340 W89A-10754<br />

Elbow Adaptor<br />

Male/Male<br />

Elbow Adaptor<br />

Female/Female<br />

Thread size<br />

M5 1/8 1/4 1/4-1/8 3/8 1/2 3/4 1<br />

W89A-12110 W89A-12112 W89A-12114 W89A-12116 W89A-12118 W89A-12120 W89A-12122 W89A-12124<br />

Thread size<br />

M5 1/8 1/4 3/8 1/2 3/4 1<br />

W89A-12142 W89A-12144 W89A-12146 W89A-12148 W89A-12150 W89A-12152 W89A-12154<br />

Tee Union<br />

Tube size<br />

4mm 6mm 8mm 10mm 12mm 16mm<br />

W89A-10341 W89A-10342 W89A-10343 W89A-10344 W89A-10345 –<br />

Sleeve<br />

Thread size<br />

1/8 1/4 3/8 1/2 3/4 1<br />

W89A-12486 W89A-12488 W89A-12490 W89A-12492 W89A-12494 W89A-12496<br />

Y Union<br />

Tube size<br />

4mm 6mm 8mm 10mm 12mm 16mm<br />

W89A-10359 W89A-10360 W89A-10361 W89A-10362 W89A-10363 W89A-10752<br />

Cross Adaptor<br />

Female/Female/<br />

Female/Female<br />

Thread size<br />

1/8 1/4 3/8 1/2 3/4 1<br />

W89A-12258 W89A-12260 W89A-12262 W89A-12264 – –<br />

Speed Control Union<br />

Tube size<br />

4mm 6mm 8mm 10mm 12mm 16mm<br />

W89A-10359 W89A-10360 W89A-10361 W89A-10362 W89A-10363 W89A-10752<br />

Technical Details<br />

Speed Control Elbow Parallel Thread Tube size<br />

Size 4mm 6mm 8mm 10mm 12mm 16mm<br />

1/8 W89A-10706 W89A-10707 W89A-10708 – – –<br />

For the full range of push-in fittings,<br />

see the RX Catalogue.<br />

1/4 – W89A-10704 W89A-10705 W89A-10702 W89A-10703 –<br />

3/8 – – W89A-10711 W89A-10709 W89A-10710 –<br />

1/2 – – W89A-10701 W89A-10699 W89A-10700 –<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55<br />

■ All materials RoHS compliant<br />

■ Wide range of tube to thread size options<br />

■ 100% leak tested during production<br />

■ Life tested to > 3 million pressure switching cycles<br />

@ 0.8 MPa at 2 c.p.s. (cycles per second)<br />

■ Tube can be reinserted up to 5 times for a<br />

leak free seal<br />

■ After 5 operations the tube must be cut back<br />

to offer a clean gripping area<br />

EMAIL: contact.direct@eriks.co.uk<br />

Remember to include your account code, part number and delivery address.

106<br />

Tubing<br />

Choice<br />

Over 50,000 stock lines<br />

PNEUMATICS<br />

107<br />

Tubing<br />

Centre Back<br />

Bottom Entry<br />

2p<br />

Technical<br />

Details<br />

PA12 Nylon Tube<br />

(supplied in 30 metre coils)<br />

Part no Size (O/D I/D) Colour<br />

W89A-12880 4 x 2.5 Black<br />

W89A-12882 4 x 2.5 Blue<br />

W89A-12884 4 x 2.5 Green<br />

W89A-12886 4 x 2.5 Natural<br />

W89A-12888 4 x 2.5 Red<br />

W89A-12890 4 x 2.5 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-12944 10 x 7 Black<br />

W89A-12946 10 x 7 Blue<br />

W89A-12948 10 x 7 Green<br />

W89A-12950 10 x 7 Natural<br />

W89A-12952 10 x 7 Red<br />

W89A-12954 10 x 7 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-12980 16 x 12 Natural<br />

W89A-12982 16 x 12 Black<br />

SH98 Polyurethane Tube<br />

(supplied in 30 metre coils)<br />

Part no Size (O/D I/D) Colour<br />

W89A-12984 4 x 2.5 Black<br />

W89A-12986 4 x 2.5 Blue<br />

W89A-12988 4 x 2.5 Green<br />

W89A-12990 4 x 2.5 Natural<br />

W89A-12992 4 x 2.5 Red<br />

W89A-12994 4 x 2.5 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-13020 10 x 6.5 Black<br />

W89A-13022 10 x 6.5 Blue<br />

W89A-13024 10 x 6.5 Green<br />

W89A-13026 10 x 6.5 Natural<br />

W89A-13028 10 x 6.5 Red<br />

W89A-13030 10 x 6.5 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-12904 6 x 4 Black<br />

W89A-12906 6 x 4 Blue<br />

W89A-12908 6 x4 Green<br />

W89A-12910 6 x 4 Natural<br />

W89A-12912 6 x 4 Red<br />

W89A-12914 6 x 4 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-12956 10 x 8 Black<br />

W89A-12958 10 x 8 Blue<br />

W89A-12960 10 x 8 Green<br />

W89A-12962 10 x 8 Natural<br />

W89A-12964 10 x 8 Yellow<br />

W89A-12966 10 x 8 Red<br />

Part no Size (O/D I/D) Colour<br />

W89A-12996 6 x 4 Black<br />

W89A-12998 6 x 4 Blue<br />

W89A-13000 6 x 4 Green<br />

W89A-13002 6 x 4 Natural<br />

W89A-13004 6 x 4 Red<br />

W89A-13006 6 x 4 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-13032 12 x 8 Black<br />

W89A-13034 12 x 8 Blue<br />

W89A-13036 12 x 8 Green<br />

W89A-13038 12 x 8 Natural<br />

W89A-13040 12 x 8 Red<br />

W89A-13042 12 x 8 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-12928 8 x 6 Black<br />

W89A-12930 8 x 6 Blue<br />

W89A-12934 8 x 6 Green<br />

W89A-12936 8 x 6 Natural<br />

W89A-12940 8 x 6 Red<br />

W89A-12942 8 x 6 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-12968 12 x 9 Black<br />

W89A-12970 12 x 9 Blue<br />

W89A-12972 12 x 9 Green<br />

W89A-12974 12 x 9 Natural<br />

W89A-12976 12 x 9 Red<br />

W89A-12978 12 x 9 Yellow<br />

Part no Size (O/D I/D) Colour<br />

W89A-13008 8 x 5.5 Black<br />

W89A-13010 8 x 5.5 Blue<br />

W89A-13012 8 x 5.5 Green<br />

W89A-13014 8 x 5.5 Natural<br />

W89A-13016 8 x 5.5 Red<br />

W89A-13018 8 x 5.5 Yellow<br />

Part no Thread Diameter Range<br />

size<br />

bar<br />

W89A-12712 1/8 40 -1 – 0<br />

W89A-12714 1/8 40 0 – 2<br />

W89A-12716 1/8 40 0 – 4<br />

W89A-12718 1/8 40 0 – 6<br />

W89A-12720 1/8 40 0 – 10<br />

W89A-12724 1/8 40 0 – 20<br />

W89A-12726 1/8 50 -1 – 0<br />

W89A-12728 1/8 50 0 – 2<br />

W89A-12730 1/8 50 0 – 4<br />

W89A-12732 1/8 50 0 – 6<br />

W89A-12734 1/8 50 0 – 10<br />

W89A-12738 1/8 50 0 – 20<br />

W89A-12742 1/4 63 0 – 2<br />

W89A-12744 1/4 63 0 – 4<br />

W89A-12746 1/4 63 0 – 6<br />

W89A-12748 1/4 63 0 – 10<br />

W89A-12752 1/4 63 0 – 20<br />

Centre Back,<br />

Panel Mount<br />

Part no Thread Diameter Range<br />

size<br />

bar<br />

W89A-12756 1/8 40 0 – 2<br />

W89A-12758 1/8 40 0 – 4<br />

W89A-12760 1/8 40 0 – 6<br />

W89A-12762 1/8 40 0 – 10<br />

W89A-12766 1/8 50 0 – 2<br />

W89A-12768 1/8 50 0 – 4<br />

W89A-12770 1/8 50 0 – 6<br />

W89A-12772 1/8 50 0 – 10<br />

Part no Thread Diameter Range<br />

size<br />

bar<br />

W89A-12774 1/8 50 -1 – 0<br />

W89A-12776 1/8 50 0 – 2<br />

W89A-12778 1/8 50 0 – 6<br />

W89A-12780 1/8 50 0 – 10<br />

W89A-12782 1/8 50 0 – 16<br />

W89A-12784 1/8 50 0 – 20<br />

W89A-12786 1/4 63 -1 – 0<br />

W89A-12788 1/4 63 0 – 2<br />

W89A-12790 1/4 63 0 – 6<br />

W89A-12792 1/4 63 0 – 10<br />

W89A-12794 1/4 63 0 – 16<br />

W89A-12796 1/4 63 0 – 20<br />

W89A-12798 3/8 BSPP 100 -1 – 0<br />

W89A-12800 3/8 BSPP 100 0 – 2<br />

W89A-12802 3/8 BSPP 100 0 – 6<br />

W89A-12804 3/8 BSPP 100 0 – 10<br />

W89A-12806 3/8 BSPP 100 0 – 16<br />

W89A-12808 3/8 BSPP 100 0 – 20<br />

All Stainless<br />

Steel Process<br />

Gauge<br />

Part no Thread Diameter Range<br />

size<br />

bar<br />

W89A-12810 1/2 BSPP 100 -1 – 0<br />

W89A-12812 1/2 BSPP 100 0 – 2<br />

W89A-12814 1/2 BSPP 100 0 – 6<br />

W89A-12816 1/2 BSPP 100 0 – 10<br />

Glycerine Bottle<br />

Part no<br />

W89A-12818<br />

Size<br />

Single fill 100ml<br />

General Purpose<br />

Pressure gauges for use in non-corrosive environments,<br />

typically used for pnuematic applications.<br />

■ Ranges 40mm to 100mm<br />

■ Dial -1 to 20 Bar<br />

■ Dual Scale – Bar/p.s.i.<br />

■ 40, 50 & 63mm snap on window<br />

■ 100mm and all panel mount sizes chromed bezel<br />

■ Accuracy 40, 50 & 63mm<br />

■ ASME B40.1-1991 B GRADE (± 3% of span)<br />

■ 100 ASME B40.1-1991 A GRADE (± 1% of span)<br />

Materials:<br />

Case<br />

Window<br />

Internal parts<br />

Mounting threads<br />

Specifications:<br />

Temperature rating:<br />

Process Gauges<br />

Black painted steel<br />

Polycarbonate<br />

Brass, bourdon tube<br />

BSPT (unless otherwise stated)<br />

-25°C to +60°C<br />

Stainless steel gauges for fluid and gaseous media,<br />

compatible to the wetted parts (SUS 316).<br />

■ Ranges 100mm<br />

■ Dial -1 to 10 Bar<br />

■ Gauges supplied dry, but have a fillable case<br />

■ Suitable glycerine available in single fill bottles<br />

■ Dual Scale – Bar/p.s.i.<br />

■ Protection ratings IP65<br />

■ Accuracy EN 873-1 (1% of scale)<br />

Materials:<br />

Case Stainless steel 304<br />

Window<br />

Laminated safety glass<br />

Internal parts Stainless steel 316, bourdon tube<br />

Mounting threads 1/2" BSPP<br />

Specifications:<br />

Pressure Limitation: Constant pressure 100%<br />

Cyclic pressure 90%<br />

Over pressure 130%<br />

Temperature rating: -25°C to +60°C<br />

For the full range of RX Fittings,<br />

Adaptors and Accessories,<br />

call 0845 006 6000 or visit us<br />

at www.eriks.co.uk and request<br />

your copy of the RX Catalogue<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55<br />

EMAIL: contact.direct@eriks.co.uk<br />

Remember to include your account code, part number and delivery address.

108<br />

<strong>Pneumatics</strong> EngineerÕs Know-how<br />

KNOW-HOW<br />

Cutting the cost of compressed air<br />

Minimising leakage<br />

The largest component of cost in a compressed air system is energy with heat and air leaks being the most<br />

common ways that energy is lost. Using a range of tools, including ultrasonic detectors, flow metering and data<br />

logging, leaks can be easily detected and quantified, even in noisy plant areas – saving you considerable cost. After<br />

completing the site survey ERIKS can help you plan and implement a programme of preventative and reactive<br />

maintenance, designed to identify problem areas, so that leakage – and therefore energy loss – is minimised.<br />

How do we know..?<br />

Ultrasound<br />

Thermography<br />

Compressed air follows a straight, direct path from<br />

the high-pressure source to a low-pressure outlet.<br />

This may be anything from air tools to actuators.<br />

When the compressed air passes into the<br />

atmosphere it changes from a pressurised laminar<br />

flow into a low-pressure turbulent flow. This<br />

turbulence creates “white noise” which contains<br />

ultrasound. Like all forms of sound, ultrasound will<br />

lose its energy over distance. We can use this to<br />

pinpoint where the leak is, by locating the highest<br />

level of ultrasound.<br />

Datalogging<br />

Recording usage of compressed air over production<br />

cycles provides the level of information required to<br />

maximize the efficiency of the compressors, and<br />

the use of the compressed air energy provided.<br />

Armed with the right information it is possible to<br />

make significant savings by ensuring the<br />

compressors are running when they need to, and the<br />

highest air consumption times are when you expect<br />

them. How many companies are running a compressor<br />

just to service their air leaks? Are you….?<br />

ERIKS have been carrying out thermographic surveys<br />

since these cameras became ‘portable’ in the late<br />

seventies. Traditionally, engineers have used<br />

thermography as a tool to detect defects within control<br />

gear and electrical distribution. The same technology<br />

can also detect defects with compressed air systems<br />

generating cold spots through leaks or heat from failing<br />

equipment and valves.<br />

The technology is capable of finding<br />

defects in real-time meaning an<br />

immediate condition can be given.<br />

Savings for clients have been in<br />

excess of £100,000 for a three-day<br />

survey. With energy prices rising,<br />

there is greater need and potential for<br />

the savings we can offer.<br />

This is just a part of a broad range of services and<br />

advice we can contribute to reducing your overall<br />

system costs. This is available as part of a full service<br />

package which includes supplying replacement parts<br />

and installing optimised solutions.<br />

We have identified over £1m of savings for clients in 2008 using our vast experience and know-how.<br />

Know-How makes a difference<br />

LOCAL SERVICE 0845 006 6000<br />

DIRECT SERVICE 08000 55 66 55