CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

CORROSION RESISTANCE OF HASTEllOY®AllOYS - Haynes ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

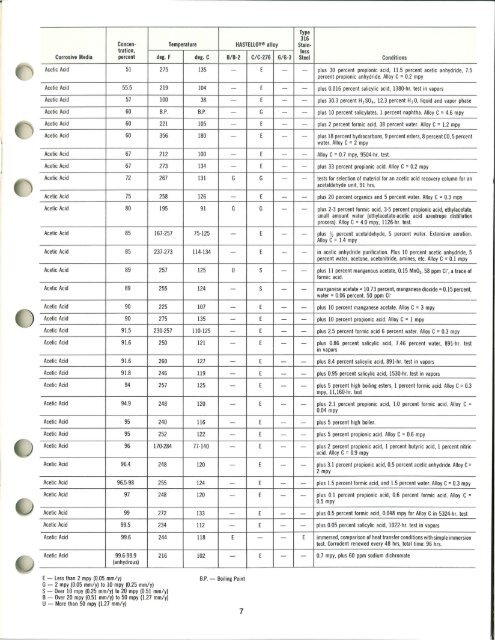

Type<br />

316<br />

Concen- Temperature HASTELlOY41> alloy Staintration,<br />

less<br />

Corrosive Media percent deg. F deg. C 8/8-2 C/C-276 G/G-3 Steel Conditions<br />

Acetic Acid 51 275 135 - E - - plus 30 percent propionic acid, 11.5 percent acetic anhydride, 7.5<br />

percent propionic anhydride. Alloy C=0.2 mpy<br />

Acetic Acid 55.5 219 104 - E - - plus 0.016 percent salicylic acid, 1380·hr. test in vapors<br />

Acetic Acid 57 100 38 - E - - plus 30.3 percent H 2 S0 4 , 12.3 percent H 2 0, liquid and vapor phase<br />

Acetic Acid 60 B.P. B.P. - G - - plus 10 percent salicylates, 1 percent naphtha. Alloy C=4.6 mpy<br />

Acetic Acid 60 221 105 - E - - plus 2 percent formic acid, 38 percent water. Alloy C=1.2 mpy<br />

Acetic Acid 60 356 180 - E - - plus 18 percent hydrocarbons, 9 percent esters, 8 percent CO, 5 percent<br />

water. Alloy C=2 mpy<br />

Acetic Acid 67 212 100 - E - - Alloy C=0.7 mpy, 9504·hr. test.<br />

Acetic Acid 67 273 134 - E - - plus 33 percent propionic acid. Alloy C=0.2 mpy<br />

Acetic Acid 72 267 131 G G - - tests for selection of material for an acetic acid recovery column for an<br />

acetaldehyde unit, 91 hrs.<br />

Acetic Acid 75 258 126 - E - - plus 20 percent organics and 5 percent water. Alloy C=0.3 mpy<br />

Acetic Acid 80 195 91 G G - - plus 2·3 percent formic acid, 3·5 percent propionic acid, ethylacetate,<br />

small amount water (ethylacetate·acetic acid azeotrope distillation<br />

process). Alloy C=4.0 mpy, 1126·hr. test.<br />

Acetic Acid 85 167·257 75·125 - E - - plus Ih percent acetaldehyde, 5 percent water. Extensive aeration.<br />

Alloy C=1.4 mpy<br />

Acetic Acid 85 237·273 114·134 - E - - in acetic anhydride purification. Plus 10 percent acetic anhydride, 5<br />

percent water, acetone, acetonitride, amines, etc. Alloy C=0.1 mpy<br />

Acetic Acid 89 257 125 U S - - plus 11 percent manganous acetate, 0.15 Mn02, 58 ppm CI', a trace of<br />

formic acid.<br />

Acetic Acid 89 255 124 - S - - manganese acetate =10.73 percent, manganese dioxide =0.15 percent,<br />

water =0.06 percent. 50 ppm CI'<br />

Acetic Acid 90 225 107 - E - - plus 10 percent manganese acetate. Alloy C=3 mpy<br />

Acetic Acid 90 275 135 - E - - plus 10 percent propionic acid. Alloy C=1 mpy<br />

Acetic Acid 91.5 230-257 110·125 - E - - plus 2.5 percent formic acid 6 percent water. Alloy C=0.3 mpy<br />

Acetic Acid 91.6 250 121 - E - - plus 0.86 percent salicylic acid, 7.46 percent water, 891-hr. test<br />

in vapors<br />

Acetic Acid 91.6 260 127 - E - - plus 8.4 percent salicylic acid, 891·hr. test in vapors<br />

Acetic Acid 91.8 246 119 - E - - plus 0.95 percent salicylic acid, 1530·hr. test in vapors<br />

Acetic Acid 94 257 125 - E - - plus 5 percent high boiling esters, 1 percent formic acid. Alloy C= 0.3<br />

mpy, 11,160-hr. test<br />

Acetic Acid 94.9 248 120 - E - - plus 2.1 percent propionic acid, 1.0 percent formic acid. Alloy C =<br />

0.04 mpy<br />

Acetic Acid 95 240 116 - E - - plus 5 percent high boiler.<br />

Acetic Acid 95 252 122 - E - - plus 5 percent propionic acid. Alloy C=0.6 mpy<br />

Acetic Acid 96 170·284 77-140 - E - - plus 2 percent propionic acid, 1 percent butyric acid, 1 percent nitric<br />

acid. Alloy C=0.9 mpy<br />

Acetic Acid 96.4 248 120 - E - - plus 3.1 percent propionic acid, 0.5 percent acetic anhydride. Alloy C=<br />

2 mpy<br />

Acetic Acid 96.5·98 255 124 - E - - plus 1.5 percent formic acid, and 1.5 percent water. Alloy C=0.3 mpy<br />

Acetic Acid 97 248 120 - E - - plus 0.1 percent propionic acid, 0.6 percent formic acid. Alloy C =<br />

0.5 mpy<br />

Acetic Acid 99 272 133 - E - - plus 0.5 percent formic acid, 0.048 mpy for Alloy C in 5324·hr. test<br />

Acetic Acid 99.5 234 112 - E - - plus 0.05 percent salicylic acid, 1022·hr. test in vapors<br />

Acetic Acid 99.6 244 118 E - - E immersed, comparison of heat transfer conditions with sim pie immersion<br />

test. Corrodent renewed every 48 hrs, total time: 96 hrs.<br />

Acetic Acid 99.6-99.9 216 102 - E - - 0.7 mpy, plus 60 ppm sodium dichromate<br />

(a nhyd rous)<br />

E- Less than 2 mpy (0.05 mm/YI<br />

G- 2 mpy (0.05 mm/y) to 10mpy (0.25 mm/y)<br />

S - Over 10 mpy (0.25 mm/y) to 20 mpy (0.51 mm/y)<br />

B - Over 20 mpy (0.51 mm/y) to 50 mpy (1.27 mm/y)<br />

U - More than 50 mpy (1.27 mm/y)<br />

B.P. -<br />

Boiling Point<br />

7