Customizing Accessories ( Excerpt)

Customizing Accessories ( Excerpt)

Customizing Accessories ( Excerpt)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Customizing</strong> <strong>Accessories</strong><br />

<strong>Customizing</strong> <strong>Accessories</strong> ( <strong>Excerpt</strong>)<br />

To enable your own customizing of INGU N Fixtures we supply the<br />

matching accessories. In the following is a choice of components<br />

from our extensive <strong>Accessories</strong> catalog. Ask for this catalog as well<br />

as our Test Probes and RF-Probes catalogs. Alternatively you can<br />

download the catalogs from our homepage.<br />

Marking Units<br />

The INGU N Marking Units excel themselves with their sturdiness,<br />

compact size, simple assembly and their long-life. We offer vari -<br />

ous types to support all Fixture designs and concepts.<br />

Electrical Marking Units for „Good Marking“<br />

Part No. 24447 Marking Unit with scratching Engraver<br />

Ø 12 x 60 mm (SW 14 mm); 12 V, Ø Circle<br />

2 mm, mounting in e.g. Probe Plate, Marking<br />

of FR4/C EM1 etc.<br />

Part No. 25251 Marking Unit with cutting Engraver<br />

Ø 12 x 60 mm (SW 14 mm); 12 V, Ø Circle 2<br />

mm, Marking of soft, sensitive surfaces (e.g.<br />

labels, stainless steel, hardwood etc.)<br />

Part No. 24456 Marking Unit extended version with scratch -<br />

ing Engraver; Ø 12 x 100.5 mm (SW 14 mm);<br />

12 V, Ø Circle 2 mm, mounting in narrow<br />

spacing, e.g. in the Pressure Frame Plate<br />

Pneumatic Marking Units for „Good Marking“<br />

Part No. 25241 Ø 16 mm (SW 15 mm) ; Ø Circle 2 mm,<br />

Mounting in e.g. Probe Plate, marking of FR4 /<br />

CEM1 etc.<br />

Screwing Units for Potentiometer Adjustment<br />

Automatic Screwing Unit<br />

The compact automatic Screwing Units enable potentiometer<br />

adjustment. The units are driven by means of a flexible shaft,<br />

which allows individual, compact mounting of the drive motor.<br />

The threaded section and the mounting holes in the housing<br />

enable multiple assembly possibilities in the Fixture.<br />

The Potentiometer Screwing Unit is designed modularly –<br />

offering problem-free adaption of the Unit in regard to the<br />

various Engraver tips and the special customer demands. The<br />

Engraver itself is spring-loaded.<br />

– Part No. 27791 Body of Potentiometer Screwing Unit<br />

– Part No. 27790 Replaceable Unit without insertable tip<br />

– I ndividual insertable tip on request<br />

Technical Data:<br />

Maximum Stroke: 4.0 mm, Applied<br />

Force by max. stroke: 1 N<br />

Further information can be found in our <strong>Accessories</strong> Catalog.<br />

Manual Screwing Unit<br />

Part No. 17049 Manual Screwing Unit for Potentiometer<br />

Adjustment ( Engraver: Cross-head with slot)<br />

Manual Key/Button activation<br />

Part No. 19637 Manual button/key activation<br />

Please note that the Engraver must be mounted vertical to the<br />

surface which is to be marked.<br />

The version with cutting Engraver has the identical design as the<br />

standard version (Part No. 24447).<br />

Short and long<br />

Marking Unit<br />

42<br />

Pneumatic Marking<br />

Unit<br />

Marking Unit with<br />

Cutting Engraver 35°<br />

Automatic and manual<br />

Potiometer Screwing Unit<br />

Part. No. 27791<br />

Manual Potiometer<br />

Screwing Unit<br />

Part. No. 17049

<strong>Customizing</strong> <strong>Accessories</strong><br />

Pylon Receiver<br />

The Pylon Receiver from INGU N can be loaded with all INGU N<br />

Interface Blocks.<br />

Interface Blocks<br />

Part No. 21329<br />

INGUN Receiver (Type Pylon) for<br />

PWB 170/INGUN (10 Contact<br />

Blocks) with extended contacting<br />

stroke (Handle can be assembled<br />

variably)<br />

Interface Blocks, loaded with INGU N Test Probes, guarantee best<br />

contacting quality and low contact resistance. Usage in Interface<br />

Blocks as e.g. Internal Intermediate Interface in the Fixture series<br />

MA 2111, 2112, 2113 as well as V IN 2040.<br />

High-current Pin Block max. 16<br />

A (34 pole), without photo (simi lar to<br />

High-current Pin Block 24 A)<br />

S-RC-034-16A<br />

Part No. 31011<br />

HSS-118 317 175 A 1502 M<br />

KS-112 30 M-R<br />

S-ATS-034-10<br />

Part No. 31009<br />

KT-254 L3 E02-30<br />

Optical Wave Guide Pin Block (45<br />

pole)<br />

S-RC-045-LWL<br />

Part No. 27618<br />

KS-004 35 G-K (without LWL)<br />

S-ATS-045-LWL<br />

Part No. 29448<br />

KS-004 35 G-K (without LWL)<br />

High-current Pin Block max. 50<br />

A (2 pole), without photo<br />

S-RC-002-50A<br />

Part No. 31549<br />

HSS-150 317 300 A 5002 M<br />

KS-150 M3 M3<br />

S-ATS-002-10<br />

Part No. 31550<br />

KT-150 L3 E02-M3<br />

Optical Wave Guide Pin Block<br />

(24 pole) (without loss, due to Spring<br />

Loaded wave<br />

guides (LWL)<br />

S-RC-024-LWL<br />

Part No. 30210<br />

KS inserted (without LWL)<br />

S-ATS-024-LWL<br />

Part No. 30211<br />

KS inserted (without LWL)<br />

Signal Pin Block (170 pole) Signal Pin Block max. 4 A (170<br />

pole) Low Ohm<br />

Radio-frequency Pin Block up to<br />

700 MHz (16 pole)<br />

Radio-frequency Pin Block up to<br />

2 GHz (15 pole)<br />

S-RC-170-4A<br />

Part No. 27616<br />

GKS-945 357 106 A 1100<br />

KS-945 47<br />

S-ATS-170-06<br />

Part No. 13515<br />

KT-158 06<br />

High-current Pin Block max. 16<br />

A (45 pole) Delivery status ( RC),<br />

unloaded, (Part No. 30962)<br />

S-RC-170-N-4A<br />

Part No. 31006<br />

HSS-118 317 175 A 1102<br />

KS-112 47<br />

S-ATS-170-06<br />

Part No. 13515<br />

KT-158 06<br />

High-current Pin Block max. 24<br />

A* (24 pole) (*24 A only possible<br />

when partly loaded)<br />

S-RC-016-700MHz*<br />

Part No. 31005<br />

HFS-110 307 100 A 3002 A<br />

KS-110 23 and SE-110 V<br />

S-ATS-016-2GHz*<br />

Part No. 31003<br />

KS-410<br />

SB-810 Z or<br />

SB-810 V<br />

(*unloaded, individually loaded)<br />

Pneumatic Pin Block (8 pole)<br />

S-RC-015-2GHz*<br />

Part No. 29444<br />

HFS-410 305 051 A 5006<br />

KS-410 and SE 810 V<br />

S-ATS-015-2GHz*<br />

Part No. 31489<br />

SB-810 Z or<br />

SB-810 V<br />

(*unloaded, individually loaded)<br />

S-RC-045-16A<br />

Part No. 30963<br />

HSS-120 317 300 A 1502 M<br />

KS-113 30 M2-R<br />

S-ATS-045-10<br />

Part No. 16900<br />

KT-120 L3 E02-30<br />

S-RC-024-24A<br />

Part No. 27628<br />

HSS-120 317 300 A 2202 M<br />

KS-113 30 M2-R<br />

S-ATS-024-10<br />

Part No. 27620<br />

KT-120 L3 E02-30<br />

S-RC-008-PK3<br />

Part No. 27630<br />

KSV-PK3<br />

S-ATS-008-PK3<br />

Part No. 27622<br />

KDV-PK3<br />

We will be pleased to provide<br />

individual Interface Blocks in<br />

accordance to your demands<br />

and requirements.<br />

43

<strong>Customizing</strong> <strong>Accessories</strong><br />

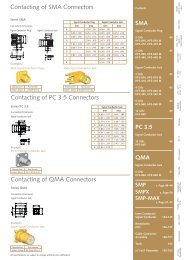

Contacting of Western Mini Plugs and USB Plugs<br />

For the wear-free contacting of Western Mini Plugs and USB<br />

Plugs INGU N offers especially manufactured mating parts, which<br />

are designed with robust copper-beryllium wires.<br />

Western-Mini Plugs<br />

Part No. 17824 Western-Mini Plug, 4-channels, FR 4 with<br />

CuBe Insert<br />

Part No. 17825 Western-Mini Plug, 6-channels<br />

Part No. 17826 Western-Mini Plug, 8-channels<br />

Part No. 17827 Western-Mini Plug, 10-channel s<br />

USB Test Plugs<br />

Part No. 17829<br />

USB Test Plug, 4-channels<br />

Mounting Shoes are available for the assembly of all Test<br />

Plugs.<br />

Spring-loaded Tooling Pins GFS-874<br />

To enable high-precision customizing INGU N also offers springloaded<br />

Tooling Pins. In this case the PC-Board sits on a conically<br />

shaped Tooling Pin Plunger. A Tooling Pin set is necessary for<br />

customizing. This set consists of one Tooling Pin with a conical-tip<br />

and one with a dagger-tip. More information can be found in our<br />

Fixture <strong>Accessories</strong> catalog.<br />

For Tooling Pin Holes:<br />

Ø 2.0 mm to Ø 3.5 mm<br />

Part No. 24481 conical-shaped<br />

Part No. 25214 dagger-shaped<br />

Tooling Pin Ø 3.98 mm<br />

For Tooling Pin Holes:<br />

Ø 3.5 to 5.5 mm<br />

Part No. 25215 conical-shaped<br />

Part No. 25217 dagger-shaped<br />

Tooling Pin Ø 5.98 mm<br />

Further special Tooling Pins are available such as e.g. with a disk<br />

or for In-line Systems (e.g. with optical safety check or springloaded).<br />

Further Plug variants available.<br />

Tooling Pins<br />

2 + 0.01<br />

3 -0.05<br />

7 7<br />

(14)<br />

Rigid Tooling Pins<br />

The Tooling Pins from INGU N<br />

register the PC-Board in the<br />

applicable Tooling Pin Holes<br />

and guarantee an exact place -<br />

ment of the PC-Board on the<br />

Fixture. Tooling Pin diameters<br />

from 1.9 to 5 mm in steps<br />

of 0.1mm are available. The<br />

Tooling Pins have a tolerance<br />

of 0/+ 0.05 mm.<br />

Pushrods<br />

A large range of Pushrods is available to support the listed<br />

Pressure Frame Units and Cover systems. Furthermore the<br />

range of Pushrods also takes the various PCB thicknesses into<br />

consideration.<br />

Pushrods for MA-Series<br />

Part No. 19813 Pushrods for Pressure- Frame Plate,<br />

L = 51 mm, Head Ø 2.5 mm (1)<br />

Part No. 19815 Pushrods for Pressure- Frame Plate,<br />

L = 51 mm, Head Ø 6.0 mm (1)<br />

Part No. 21615 Pushrods, L = 60 mm, Head Ø 2.5 mm (2)<br />

Part No. 23190 Pushrods, L = 60 mm, Head Ø 4.0 mm (2)<br />

Part No. 18870 Pushrods, L = 60 mm, Head Ø 6.0 mm (2)<br />

Pushrods for Vacuum Fixtures<br />

Part No. 17324 Pushrods 55,6 rigid, green, Ø 2.5;<br />

L = 55.6 mm<br />

Part No. 19419 Pushrods 55,6 rigid, green, Ø 6.0;<br />

L = 55.6 mm<br />

Numerous other types on request.<br />

(1)<br />

e.g. for MA 2130/2135/PA 2130/PAZ 215/200<br />

(2)<br />

e.g. for MA 2111/2112/2113/2113 T<br />

Western-Mini-Plugs<br />

44<br />

Spring-loaded Tooling Pin Set<br />

(Dagger / Conical)

<strong>Customizing</strong> <strong>Accessories</strong><br />

Vacuum-free Zone<br />

For customizing with Vacuum-free Zones INGUN offers tailormade<br />

sizes – both for single- and dual-stage customizing.<br />

Part No. 000512 Vacuum-free Zone made of silicone<br />

(single-stage); variable, manufacturing<br />

dimensions according to customer<br />

demands.<br />

Part No. 000513 Vacuum-free Zone made of silicone (dualstage);<br />

variable, manufacturing dimensions<br />

according to customer demands.<br />

Transfer Field<br />

The following contacting components are used in a Transfer Field.<br />

Note: The rigid Contact Terminals are normally mounted in the<br />

Pressure Frame Unit.<br />

Contact transfer: Transfer Field<br />

– Contact Terminal KT-254 W3 E12 with wire-wrap connection<br />

for Transfer Field (usage in upper Probe Plate)<br />

– Receptacle KS-100 47 with wire-wrap connection for Transfer<br />

Contact (usage in lower Probe Plate)<br />

– Test Probe GKS-100 307 150 A 1500 for Transfer Contact<br />

(assembly in Receptacle)<br />

– Contact Terminal KT-112 143 215 E02 variant with<br />

exchangeable KT: usage in Receptacle KS 112 47<br />

<strong>Customizing</strong> <strong>Accessories</strong> especially for Vacuum Fixtures<br />

Transfer Field<br />

KT-254 W3 E12 Contact Terminal with wire-wrap connection for Transfer Field (usage in upper Probe Plate)<br />

KS 100 47 Receptacle with wire-wrap connection. Receptacle for Transfer Contact (usage in lower Probe Plate)<br />

GKS 100 307 150 A 1500<br />

Test Probe for Transfer Contact (assembly in Receptacle)<br />

KT 112 143 215 E02<br />

Variant with exchangeable KT: usage in Receptacle KS 112 47<br />

Pushrods/Vacuum-free zone<br />

Part No. 17324 Pushrods 55.6 rigid, green, Ø 2.5 Length: 55.6 mm long<br />

Part No. 19419 Pushrods 55.6 rigid, green, Ø 6.0 Length: 55.6 mm long<br />

Part No. 000512 Vacuum-free Zone (single-stage) variable, length according to customer requirements<br />

Part No. 000513 Vacuum-free Zone (dual-stage) variable, length according to customer requirements<br />

Pushrods Part No.<br />

19813, 19815 and<br />

21615<br />

Pushrods Part No.<br />

17324 and 19419<br />

Vacuum-free Zone<br />

<strong>Customizing</strong> example of Approach Mechanism<br />

45

<strong>Customizing</strong> <strong>Accessories</strong><br />

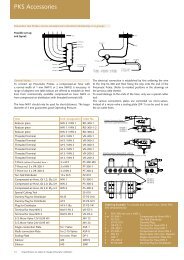

Connector Approach Mechanisms<br />

Approach Mechanisms offer the possibility to contact connectors<br />

from the side. They can be additionally built into a Fixture and are<br />

favoured for wear-free contacting of connectors. Mechanically or<br />

pneumatically driven versions are available.<br />

Further Approach mechanisms are available on request (e.g.<br />

mechanically driven via an inclined plane – see page 52).<br />

Part No. 12306 SAM- E (Contacting Stroke 14 mm) Outside<br />

Dimensions: 200 x 70 x approx. 70 mm<br />

(w x d x h)<br />

Part No. 12559 SAM- DE (Contacting Stroke 14 mm) Outside<br />

Dimensions: 270 x 70 x approx. 70 mm<br />

(w x d x h)<br />

Part No. 26239 SAM Pneumatic incl. Solenoid Valve 12 V<br />

Contact Cleaning Mats<br />

Part No. 3254<br />

Part No. 3255<br />

Part No. 3256<br />

Part No. 8460<br />

Part No. 21092<br />

KR M 01 Outside Dimensions: 250 x 100 mm<br />

KR M 02 Outside Dimensions: 250 x 200 mm<br />

KR M 03 Outside Dimensions: 250 x 300 mm<br />

KR M 04 Outside Dimensions: 700 x 500 mm<br />

KR M 08 Outside Dimensions: on request<br />

PC-Boards often show signs of flux deposits and oxide layers,<br />

which cause contamination of the contact surface and subse -<br />

quently provide an insulating coating. The longer the Test Probes<br />

are used the greater the danger that the deposits remain on the<br />

test probe tips. In this case INGU N recommends the cleaning of<br />

the probe tips by means of a Contact Cleaning Mat. This method<br />

can be used especially by tip-styles that have a self-cleaning char -<br />

acter, e.g. tip-styles 01, 09, 15, 31, 38, 77, 91, 93, 97, 98.<br />

Contact Cleaning Mats can be used on all INGU N Fixtures<br />

that don’t have a Pressure Frame Unit. The Mats are available in<br />

various sizes.<br />

Further details – also regarding probe cleaning brushes – can<br />

be found in our <strong>Accessories</strong> catalog.<br />

Counter-pressure Springs<br />

Part No. 2785 FED 10/80/15.0<br />

Part No. 23818 FED 10/85/21.5 dual-stage Fixtures<br />

Part No. 1571 FED 10/90/16 <strong>Customizing</strong> VA<br />

2030/2040<br />

Part No. 1572 FED 14/80/22 dual-stage Fixtures<br />

Part No. 1569 FED 14/90/17.5<br />

Part No. 1584 FED D-090 W-01 Counter-pressure Spring<br />

for spring-loaded Mounting Plate for<br />

Manual Fixtures MA<br />

Placement supports / Pre-registration Pins<br />

Part No. 13781<br />

PCB Support Disks<br />

Part No. 3161<br />

Stroke limiting Disks<br />

Part No. 2579<br />

Pre-registration / Placement Supports<br />

made of Delrin 22 mm (h)<br />

Antistatic PCB Support Disk<br />

5 x 3 mm (d x h)<br />

HBS-KTP for assembly on Probe Plate of<br />

Vacuum Fixture<br />

Cleaning Mat<br />

Counter-pressure Springs<br />

Pre-registration Pins<br />

Part No. 13781<br />

PCB Support Disks<br />

Part No. 3161<br />

Stroke limiting Disk<br />

Part No. 2579<br />

46