Welcome to the Next Generation of Sealing ... - CE Franklin Ltd.

Welcome to the Next Generation of Sealing ... - CE Franklin Ltd.

Welcome to the Next Generation of Sealing ... - CE Franklin Ltd.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MRG Gaskets<br />

An MRG (Metal Reinforced Gasket) is a laminated gasket consisting <strong>of</strong> a metal core, covered with s<strong>of</strong>t conformable sealing materials<br />

on each face <strong>of</strong> <strong>the</strong> core.<br />

While <strong>the</strong> solid metal core prevents gasket blowout, it provides high strength and rigidity; and <strong>the</strong> s<strong>of</strong>t facings provide for an exceptional<br />

seal.<br />

The metal core material is selected <strong>to</strong> suit <strong>the</strong> media <strong>to</strong> be sealed. A wide range <strong>of</strong> core materials is available. For chemical resistance<br />

and temperature stability purposes, <strong>the</strong> correct core material must always be selected.<br />

Standard core material is ei<strong>the</strong>r 304 or 316L stainless steel, and standard core thickness is 1/8".<br />

The s<strong>of</strong>t gasket facings can be Flexicarb, PTFE, Sigma, Thermiculite, or compressed fiber gasket material. However, Flexicarb is <strong>the</strong><br />

standard and most widely used facing material supplied with <strong>the</strong> MRG gasket.<br />

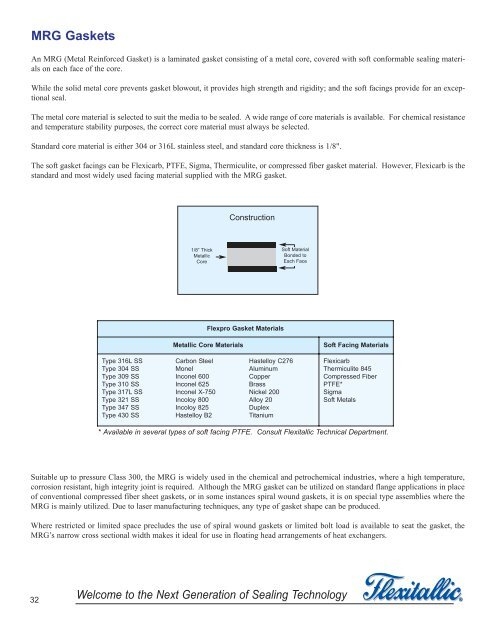

Construction<br />

1/8” Thick<br />

Metallic<br />

Core<br />

S<strong>of</strong>t Material<br />

Bonded <strong>to</strong><br />

Each Face<br />

Flexpro Gasket Materials<br />

Metallic Core Materials<br />

S<strong>of</strong>t Facing Materials<br />

Type 316L SS<br />

Type 304 SS<br />

Type 309 SS<br />

Type 310 SS<br />

Type 317L SS<br />

Type 321 SS<br />

Type 347 SS<br />

Type 430 SS<br />

Carbon Steel<br />

Monel<br />

Inconel 600<br />

Inconel 625<br />

Inconel X-750<br />

Incoloy 800<br />

Incoloy 825<br />

Hastelloy B2<br />

Hastelloy C276<br />

Aluminum<br />

Copper<br />

Brass<br />

Nickel 200<br />

Alloy 20<br />

Duplex<br />

Titanium<br />

Flexicarb<br />

Thermiculite 845<br />

Compressed Fiber<br />

PTFE*<br />

Sigma<br />

S<strong>of</strong>t Metals<br />

* Available in several types <strong>of</strong> s<strong>of</strong>t facing PTFE. Consult Flexitallic Technical Department.<br />

Suitable up <strong>to</strong> pressure Class 300, <strong>the</strong> MRG is widely used in <strong>the</strong> chemical and petrochemical industries, where a high temperature,<br />

corrosion resistant, high integrity joint is required. Although <strong>the</strong> MRG gasket can be utilized on standard flange applications in place<br />

<strong>of</strong> conventional compressed fiber sheet gaskets, or in some instances spiral wound gaskets, it is on special type assemblies where <strong>the</strong><br />

MRG is mainly utilized. Due <strong>to</strong> laser manufacturing techniques, any type <strong>of</strong> gasket shape can be produced.<br />

Where restricted or limited space precludes <strong>the</strong> use <strong>of</strong> spiral wound gaskets or limited bolt load is available <strong>to</strong> seat <strong>the</strong> gasket, <strong>the</strong><br />

MRG’s narrow cross sectional width makes it ideal for use in floating head arrangements <strong>of</strong> heat exchangers.<br />

32<br />

<strong>Welcome</strong> <strong>to</strong> <strong>the</strong> <strong>Next</strong> <strong>Generation</strong> <strong>of</strong> <strong>Sealing</strong> Technology<br />

®