FDI - Fire Damper for Circular Ducts - Halton

FDI - Fire Damper for Circular Ducts - Halton

FDI - Fire Damper for Circular Ducts - Halton

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

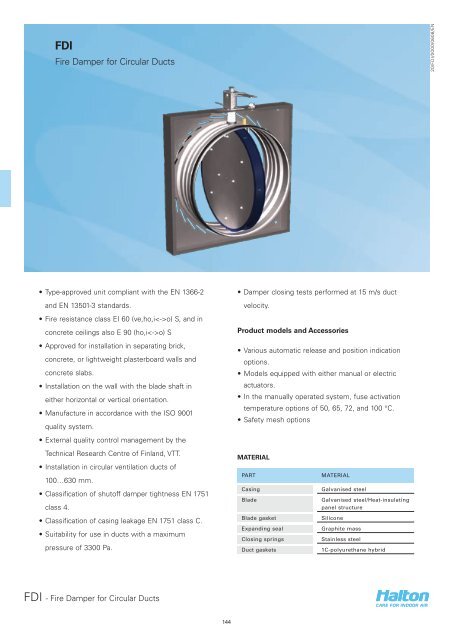

<strong>FDI</strong><br />

<strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

20/<strong>FDI</strong>/0000/0608/EN<br />

• Type-approved unit compliant with the EN 1366-2<br />

and EN 13501-3 standards.<br />

• <strong>Fire</strong> resistance class EI 60 (ve,ho,io) S, and in<br />

concrete ceilings also E 90 (ho,io) S<br />

• Approved <strong>for</strong> installation in separating brick,<br />

concrete, or lightweight plasterboard walls and<br />

concrete slabs.<br />

• Installation on the wall with the blade shaft in<br />

either horizontal or vertical orientation.<br />

• Manufacture in accordance with the ISO 9001<br />

quality system.<br />

• External quality control management by the<br />

Technical Research Centre of Finland, VTT.<br />

• Installation in circular ventilation ducts of<br />

100…630 mm.<br />

• Classification of shutoff damper tightness EN 1751<br />

class 4.<br />

• Classification of casing leakage EN 1751 class C.<br />

• Suitability <strong>for</strong> use in ducts with a maximum<br />

pressure of 3300 Pa.<br />

• <strong>Damper</strong> closing tests per<strong>for</strong>med at 15 m/s duct<br />

velocity.<br />

Product models and Accessories<br />

• Various automatic release and position indication<br />

options.<br />

• Models equipped with either manual or electric<br />

actuators.<br />

• In the manually operated system, fuse activation<br />

temperature options of 50, 65, 72, and 100 °C.<br />

• Safety mesh options<br />

MATERIAL<br />

PART<br />

Casing<br />

Blade<br />

Blade gasket<br />

Expanding seal<br />

Closing springs<br />

Duct gaskets<br />

MATERIAL<br />

Galvanised steel<br />

Galvanised steel/Heat-insulating<br />

panel structure<br />

Silicone<br />

Graphite mass<br />

Stainless steel<br />

1C-polyurethane hybrid<br />

<strong>FDI</strong> - <strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

144

DIMENSIONS<br />

NS ØD L L1 L2 L3<br />

100 99 145 105 40 183<br />

125 124 145 105 40 208<br />

160 159 145 105 40 242<br />

200 199 145 105 40 283<br />

250 249 145 105 40 333<br />

315 314 145 105 40 398<br />

400 399 245 135 110 480<br />

500 499 245 135 110 580<br />

630 629 245 135 110 710<br />

Ø D<br />

D/2+30<br />

L1<br />

L<br />

D/2-30<br />

L2<br />

L3<br />

L3<br />

L3 + 65<br />

20/<strong>FDI</strong>/0000/0608/EN<br />

The size of the installation hole is ØD + 20 mm.<br />

Detailed installation instructions, as well as an<br />

installer’s installation certificate <strong>for</strong>m, are supplied<br />

with each product. See also the section ‘Documents’.<br />

ACCESSORIES AND PRODUCT MODELS<br />

ACCESSORY CODE DESCRIPTION<br />

Mesh on one side N1 galvanised steel<br />

Mesh on both sides N2 galvanised steel<br />

Fuse (manual) FU Thermal release at 50, 65,<br />

72, or 100 ºC<br />

Microswitch MS Closed position indication,<br />

enclosure class IP 65<br />

The manual fire damper can be equipped with a<br />

bipolar microswitch, MS, which indicates the closing<br />

of the shutoff blade. The microswitch has potentialfree<br />

points (no = normally open and nc = normally<br />

closed), which can be used to control other fire<br />

dampers equipped with an electric release, e.g.,<br />

triggering an alarm in the fire suppression system. The<br />

maximum operating voltage and current is 400 V, 10 A.<br />

Actuators<br />

Manual actuator, MA (spring return)<br />

BLF24-T HL, operating voltage AC/DC 24 V (72 ºC,<br />

contains a microswitch), B1<br />

BLF230-T HL, operating voltage AC 230 V (72 ºC,<br />

contains a microswitch), B2<br />

RELEASE TYPES (manual actuator)<br />

The manual fire damper has always a thermal release<br />

operation via a thermal a fuse. Additional release<br />

systems available:<br />

• Solenoid operation, providing a possibility <strong>for</strong><br />

electric signal release<br />

• Electromagnetic release<br />

• Pneumatic release with pressurised gas (e.g., CO2)<br />

Solenoid operation<br />

The manual fire damper can be released using<br />

solenoid, by switching on the solenoid operating<br />

voltage. The release can be initiated by e.g. a smoke<br />

detector, microswitch, pressure switch or similar,<br />

which connects the power supply via e.g. an auxiliary<br />

relay.<br />

Option S1 S2<br />

Operating voltage 24 VDC 230 VAC<br />

Power consumption (design 15 W 40 VA<br />

value)<br />

Enclosure class (minimum) IP20 IP20<br />

Operating Time Ratio ED 100% 100%<br />

<strong>FDI</strong> - <strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

145

Electromagnetic operation<br />

The fire damper stays open when the electrical circuit<br />

is closed. The fire damper is shut by opening the<br />

circuit.<br />

Note: Interruption of the power supply closes the<br />

damper. Uninterrupted power supply (e.g., a battery<br />

backup system) is recommended.<br />

Option<br />

EM<br />

Pneumatic release<br />

The manual fire damper can be released by<br />

a pneumatic release, connected to e.g. a fire<br />

suppression system. When the system is activated,<br />

pressure acting on the pneumatic cylinder releases<br />

the spring, closing the fire damper. The actuator is<br />

suitable <strong>for</strong> common pressure levels used in fire<br />

suppression systems. The lowest operating pressure<br />

of the actuator is 200 kPa.<br />

20/<strong>FDI</strong>/0000/0608/EN<br />

Operating voltage<br />

24 VDC<br />

Power consumption (design value)<br />

15 W<br />

Enclosure class (minimum)<br />

IP20<br />

Operating Time Ratio ED 100%<br />

Function<br />

The <strong>FDI</strong> is a circular fire damper, which prevents<br />

fire and smoke from spreading in the ductwork of<br />

ventilation and air conditioning systems.<br />

The <strong>FDI</strong> is approved <strong>for</strong> horizontal and vertical<br />

installation in heavy and light-weight structures<br />

fulfilling the fire resistance class EI 60 (ve,ho,io)<br />

S requirements. It is also approved <strong>for</strong> horizontal<br />

installation in concrete floors/ceilings to fulfill fire<br />

resistance class E 90 (ho,io) S requirements.<br />

The fire damper is equipped with either manual or<br />

electric actuators. All models are equipped with a<br />

thermal fuse and a visual position indicator. The fuse<br />

responds to a rise in temperature, closing the springreturn<br />

blade.<br />

Alternatively, the damper may be released by a<br />

system using an electric actuator or release systems<br />

that are available as accessories to the manual<br />

actuator (solenoid, electromagnetic, or pneumatic).<br />

If the power in the motorised actuator system is<br />

switched off, the blade is automatically closed by a<br />

springreturn actuator.<br />

A double-sealing solution closes the duct, effectively<br />

preventing the spreading of fire gases in the<br />

ventilation ductwork when the fire damper closes. The<br />

flexible seal of the double-sealing system operates<br />

at lower temperatures, while the graphite mass seal<br />

expands to insulate the system at temperatures above<br />

150 ºC.<br />

The nominal release temperature of the fuse with an<br />

electric actuator is 72 °C. Fuses with optional release<br />

temperatures 50, 65, 72 and 100 °C are available <strong>for</strong><br />

the manual actuator.<br />

The fire dampers equipped with electric actuators are<br />

released by switching off the power supply.<br />

The <strong>FDI</strong> fire damper is recommended to be connected<br />

to the MSH <strong>Fire</strong> <strong>Damper</strong> Management System. The<br />

MSH system enables the use of smoke detectors in<br />

ductwork or room spaces. The <strong>FDI</strong> fire damper can<br />

also be connected to other commonly used building<br />

automation systems.<br />

<strong>FDI</strong> - <strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

146

Installation<br />

The fire damper is installed on concrete or masonry<br />

walls and ceilings and on lightweight walls.<br />

An opening is always left in the separating element<br />

<strong>for</strong> the casing of the product to be led through the<br />

structure. The maximum diameter of the installation<br />

hole is the fire damper diameter D + 20 mm.<br />

Electric actuator wiring diagram<br />

-<br />

~<br />

+<br />

20/<strong>FDI</strong>/0000/0608/EN<br />

To make installation easier, all products come with an<br />

installation/casting frame, which is used to fasten the<br />

fire damper to the wall surface or the steel frame of<br />

the plasterboard wall.<br />

1 2<br />

S1 S2 S3 S4 S5 S6<br />

< 5 < 80<br />

Tf1 Tf2 Tf3 LED BAE72B-S<br />

The installation is finished by filling the casting frame<br />

from the front of the device with a gypsum-based<br />

firestop mastic that is tested <strong>for</strong> use <strong>for</strong> this purpose<br />

(such as GBG, from Palokatkomiehet Oy; CB 637, from<br />

Hilti; and FIREBREAK COMPOUND, from Würth).<br />

BLF24-T HL<br />

BLF230-T HL<br />

Power supply 24 VAC/VDC, with fuse<br />

72ºC.<br />

Power supply 230 VAC, with fuse<br />

72ºC<br />

During installation, the fire damper and actuator must<br />

Manual actuator wiring diagram (microswitch, MS)<br />

be protected with, e.g., a plastic cover.<br />

The correct operation of the fire damper must be<br />

ensured both be<strong>for</strong>e and after grouting. Setting of the<br />

damper is per<strong>for</strong>med from outside the device.<br />

Detailed installation instructions, as well as an<br />

installer’s installation certificate <strong>for</strong>m, are supplied<br />

with each product. See also the section ‘Documents /<br />

Installation Instructions’.<br />

K1<br />

K1<br />

INSTALLATION OF MODULES<br />

Two fire dampers can be installed using the same<br />

screws on one side such that the lip of the installation<br />

frame of the lower damper is either flattened or<br />

removed, and the casting is spread uninterrupted<br />

from one outside end to the other. See the installation<br />

instructions.<br />

<strong>Fire</strong> damper open<br />

<strong>Fire</strong> damper closed<br />

K1: 13/14 closed K1: 13/14 open<br />

21/22 open 21/22 closed<br />

<strong>FDI</strong> - <strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

147

Servicing<br />

A manual fire damper can be reset after the fuse<br />

temperature has fallen below the release temperature.<br />

If the shutoff blade does not lock, the fuse is worn out<br />

and must be replaced. The fuse can be changed from<br />

outside the fire damper.<br />

The fuse of a fire damper equipped with an electric<br />

actuator must be replaced if the fuse has been<br />

released because of a rise in temperature.<br />

To ensure proper operation of fire dampers, they<br />

should be inspected regularly. The minimum<br />

recommended inspection period is one year or<br />

according to the building code It is recommended<br />

that the fire damper is connected to automatic fire<br />

damper management system MSH (operating voltage<br />

24-VAC).<br />

Upon failure during testing of the fire damper,<br />

maintenance service shall be ordered from an<br />

authorised <strong>Halton</strong> representative to ensure appropriate<br />

operation of the product.<br />

Suggested specifications<br />

The technical properties of the type-approved fire<br />

damper shall con<strong>for</strong>m to the EN 1366-2 and EN<br />

135013 standards.<br />

A fire damper of class EI 60 (ve,ho,io) S and in<br />

concrete ceilings also E 90 (ho,io) S, shall have a<br />

double-sealing solution that ensures fire-gas tightness<br />

and fire resistance both at room temperature and in<br />

high temperatures when the fire damper is closed.<br />

In motorised models, the fuse shall be activated at 72<br />

°C.<br />

In the manually operated model, the fuse activation<br />

temperature corresponds to the specifications (50, 65,<br />

72, or 100 °C).<br />

The fuse shall be located inside the damper, and it<br />

shall be possible to replace it from the outside.<br />

The fire damper shall have means <strong>for</strong> external opening<br />

/ triggering of the release and closing.<br />

The fire damper shall include a position indicator.<br />

Where indicated, the manually operated fire damper<br />

shall be supplied with the following release options:<br />

• Electric signal release by closing circuit (initiated<br />

by, e.g., a smoke detector or a microswitch or<br />

pressure switch); the enclosure class of the<br />

electric release arrangement shall be IP54 or better.<br />

• Electromagnetic release by opening circuit.<br />

• Pneumatic release.<br />

20/<strong>FDI</strong>/0000/0608/EN<br />

The fire damper casing complies with the tightness<br />

requirements <strong>for</strong> EN 1751 class C.<br />

The fire damper shall be suitable <strong>for</strong> vertical and<br />

horizontal installation in concrete and masonry walls<br />

and on ceilings and lightweight plasterboard walls<br />

between fire compartments.<br />

The blade shaft can be installed in either horizontal or<br />

vertical orientation, and the actuator can be installed in<br />

any direction.<br />

The fire damper can be installed from the installation<br />

frame side without separate sealing of the installation<br />

opening on the wall.<br />

The internal quality control of the fire damper<br />

manufacturer shall be based on the ISO 9001 quality<br />

system, and the operations of the manufacturer shall<br />

be subject to external third-party quality control.<br />

<strong>FDI</strong> - <strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

148

Product code<br />

<strong>FDI</strong>-D<br />

20/<strong>FDI</strong>/0000/0608/EN<br />

D = connection size<br />

100, 125, 160, 200, 250, 315, 400, 500, 630<br />

Specifics and accessories<br />

RE = release type<br />

MA Manual<br />

B1 BLF24-T-2 HL, fuse 72 °C<br />

B2 BLF230-T HL, fuse 72 °C<br />

S1 Solenoid, 24 VDC<br />

S2 Solenoid, 230 VAC<br />

EM Electromagnetic, 24 VDC<br />

PN Pneumatic<br />

FU = fuse release temperature (°C)<br />

72 72 °C<br />

50 50 °C<br />

65 65 °C<br />

100 100 °C<br />

AC = accessories<br />

N1 Safety mesh, 1 side, installed in<br />

actuator side<br />

N2 Safety mesh, 2 sides<br />

MS Microswitch<br />

Code example<br />

<strong>FDI</strong>-160, RE=MA, FU=72<br />

<strong>FDI</strong> - <strong>Fire</strong> <strong>Damper</strong> <strong>for</strong> <strong>Circular</strong> <strong>Ducts</strong><br />

149