analiza naprezanja u ucvršcenju polova rotora generatora s ...

analiza naprezanja u ucvršcenju polova rotora generatora s ...

analiza naprezanja u ucvršcenju polova rotora generatora s ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

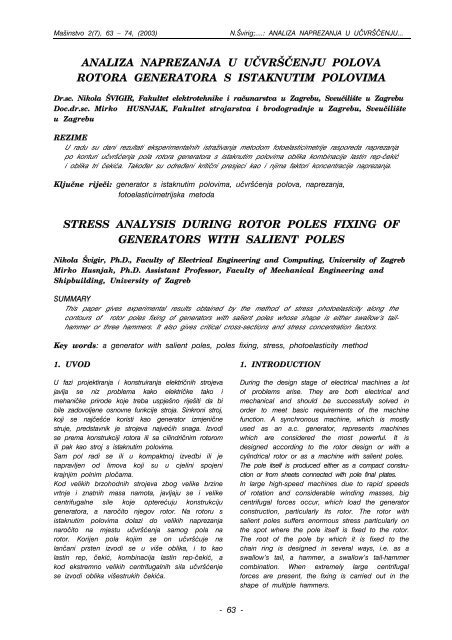

ANALIZA NAPREZANJA U U^VR[^ENJU POLOVA<br />

ROTORA GENERATORA S ISTAKNUTIM POLOVIMA<br />

Dr.sc. Nikola [VIGIR, Fakultet elektrotehnike i ra~unarstva u Zagrebu, Sveu~ili{te u Zagrebu<br />

Doc.dr.sc. Mirko HUSNJAK, Fakultet strojarstva i brodogradnje u Zagrebu, Sveu~ili{te<br />

u Zagrebu<br />

REZIME<br />

U radu su dani rezultati eksperimentalnih istra`ivanja metodom fotoelasticimetrije rasporeda <strong>naprezanja</strong><br />

po konturi u~vr{}enja pola <strong>rotora</strong> <strong>generatora</strong> s istaknutim polovima oblika kombinacije lastin rep-~eki}<br />

i oblika tri ~eki}a. Tako|er su odre|eni kriti~ni presjeci kao i njima faktori koncentracije <strong>naprezanja</strong>.<br />

Klju~ne rije~i: generator s istaknutim polovima, u~vr{}enja <strong>polova</strong>, <strong>naprezanja</strong>,<br />

fotoelasticimetrijska metoda<br />

STRESS ANALYSIS DURING ROTOR POLES FIXING OF<br />

GENERATORS WITH SALIENT POLES<br />

Nikola [vigir, Ph.D., Faculty of Electrical Engineering and Computing, University of Zagreb<br />

Mirko Husnjak, Ph.D. Assistant Professor, Faculty of Mechanical Engineering and<br />

Shipbuilding, University of Zagreb<br />

SUMMARY<br />

This paper gives experimental results obtained by the method of stress photoelasticity along the<br />

contours of rotor poles fixing of generators with salient poles whose shape is either swallow’s tailhammer<br />

or three hammers. It also gives critical cross-sections and stress concentration factors.<br />

Key words: a generator with salient poles, poles fixing, stress, photoelasticity method<br />

1. UVOD<br />

U fazi projektiranja i konstruiranja elektri~nih strojeva<br />

javlja se niz problema kako elektri~ke tako i<br />

mehani~ke prirode koje treba uspje{no rije{iti da bi<br />

bile zadovoljene osnovne funkcije stroja. Sinkroni stroj,<br />

koji se naj~e{}e koristi kao generator izmjeni~ne<br />

struje, predstavnik je strojeva najve}ih snaga. Izvodi<br />

se prema konstrukciji <strong>rotora</strong> ili sa cilindri~nim rotorom<br />

ili pak kao stroj s istaknutim polovima.<br />

Sam pol radi se ili u kompaktnoj izvedbi ili je<br />

napravljen od limova koji su u cjelini spojeni<br />

krajnjim polnim plo~ama.<br />

Kod velikih brzohodnih strojeva zbog velike brzine<br />

vrtnje i znatnih masa namota, javljaju se i velike<br />

centrifugalne sile koje optere}uju konstrukciju<br />

<strong>generatora</strong>, a naro~ito njegov rotor. Na rotoru s<br />

istaknutim polovima dolazi do velikih <strong>naprezanja</strong><br />

naro~ito na mjestu u~vr{}enja samog pola na<br />

rotor. Korijen pola kojim se on u~vr{}uje na<br />

lan~ani prsten izvodi se u vi{e oblika, i to kao<br />

lastin rep, ~eki}, kombinacija lastin rep-~eki}, a<br />

kod ekstremno velikih centrifugalnih sila u~vr{}enje<br />

se izvodi oblika vi{estrukih ~eki}a.<br />

1. INTRODUCTION<br />

During the design stage of electrical machines a lot<br />

of problems arise. They are both electrical and<br />

mechanical and should be successfully solved in<br />

order to meet basic requirements of the machine<br />

function. A synchronous machine, which is mostly<br />

used as an a.c. generator, represents machines<br />

which are considered the most powerful. It is<br />

designed according to the rotor design or with a<br />

cylindrical rotor or as a machine with salient poles.<br />

The pole itself is produced either as a compact construction<br />

or from sheets connected with pole final plates.<br />

In large high-speed machines due to rapid speeds<br />

of rotation and considerable winding masses, big<br />

centrifugal forces occur, which load the generator<br />

construction, particularly its rotor. The rotor with<br />

salient poles suffers enormous stress particularly on<br />

the spot where the pole itself is fixed to the rotor.<br />

The root of the pole by which it is fixed to the<br />

chain ring is designed in several ways, i.e. as a<br />

swallow’s tail, a hammer, a swallow’s tail-hammer<br />

combination. When extremely large centrifugal<br />

forces are present, the fixing is carried out in the<br />

shape of multiple hammers.<br />

- 63 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

Kao {to je ve} nagla{eno najslo`eniji dijelovi ovih<br />

konstrukcija predstavljaju mjesta u~vr{}enja na<br />

kojima je distribucija kontaktnih <strong>naprezanja</strong> na<br />

dosjednim povr{inama nepoznata. ^est je slu~aj i<br />

stati~ke neodre|enosti sklopa {to ote`ava to~no<br />

definiranje optere}enja pojedinih sklopova i<br />

onemogu}ava jednostavno provo|enje izra~una<br />

metodama nauke o ~vrsto}i.<br />

Iz tog razloga provedena je u ovom radu<br />

eksperimentalna <strong>analiza</strong> <strong>naprezanja</strong> metodom<br />

fotoelasticimetrije u korijenu pola <strong>generatora</strong> s<br />

istaknutim polovima i oblika kombinacije lastin rep-<br />

~eki} s varijacijom kuta nagiba lastinog repa i<br />

oblika tri ~eki}a kako bi se {to egzaktnije odredio<br />

raspored <strong>naprezanja</strong> du` istog i definirala vr{na<br />

<strong>naprezanja</strong> po mjestu i iznosu.<br />

As pointed out before, the most complex parts of<br />

these constructions are the spots of fixing. The<br />

contact stress distribution on contacting surfaces<br />

of these spots is unknown. Very often the<br />

assembly is not determined statically, which makes<br />

accurate definition of assembly loading rather<br />

difficult and it also prevents simple calculations by<br />

means of the science of strength.<br />

This was the reason to carry out an experimental<br />

stress analysis by means of photoelasticity method<br />

in the pole root of the generator with salient poles<br />

and in the shape of swallow’s tail-hammer with the<br />

swallow’s tail varying angle and three hammers in<br />

order to determine the stress scheme along it as<br />

accurately as possible and define peak stress<br />

according to the place and amount.<br />

2. MATERIJAL ZA IZRADU MODELA<br />

Materijal za izradu modela mora biti opti~ki osjetljiv<br />

sa {to manjim opti~kim i mehani~kim puzanjem a<br />

uz to providan i izotropan. Mora pokazivati linearnu<br />

ovisnost deformacije u naprezanju, te<br />

proporcionalnost izme|u <strong>naprezanja</strong> i reda<br />

izokroma. Budu}i se pri optere}enju manje<br />

deformiraju povoljniji su materijali ve}e krutosti.<br />

Fotoelasti~ni materijal uz to mora biti bez<br />

unutra{njih <strong>naprezanja</strong> sa svojstvom dobre<br />

obradivosti i {to manjeg vremenskog rubnog efekta.<br />

Postavljene zahtjeve najbolje ispunjavaju materijali<br />

na bazi epoksidnih smola i poliestera.<br />

U Europi se naj~e{}e koristi araldit-B s modulom<br />

elasti~nosti E = 3,1 – 3,7 GPa, fotoelasti~nom<br />

konstantom <strong>naprezanja</strong> f σ = 103 – 120 N/cm, te<br />

dopu{tenim naprezanjem σ d = 40 Mpa, kakav je<br />

kori{ten i za izradu modela u ovom radu.<br />

3. IZRADA MODELA<br />

Svi ispitivani modeli izra|eni su iz plo~e araldit-B s<br />

dopu{tenim naprezanjem σ d = 40 MPa.<br />

Budu}i da to~nost rezultata u mnogome zavisi o<br />

kvaliteti izrade modela, potrebno je model izraditi<br />

vrlo precizno i to~no. U tu svrhu najprije je (za<br />

svaki model posebno) izra|ena {ablona od pleksistakla.<br />

Obrada modela izvr{ena je tako da se {ablona<br />

nalijepi pomo}u dvostrano ljepljive trake na plo~u<br />

araldita, te zatim tra~nom pilom izre`e dio plo~e s<br />

dodatkom od nekoliko milimetara za finalnu obradu.<br />

Fina obrada izvr{ena je obodno protusmjernim<br />

glodanjem na brzohodnoj kopirnoj glodalici. Promjer<br />

prstastog glodala iznosi φ 5 mm, a broj okretaja<br />

radnog vretena n = 40000 o/min.<br />

2. MATERIAL FOR MODEL PRODUCTION<br />

The material for producing the model should be<br />

optically sensitive with as small optical and mechanical<br />

creeping as possible and at the same time it should be<br />

transparent and isotropic. It has to show linear<br />

dependence of deformity during the stress, as well as<br />

the proportionality between the stress and isochrome<br />

order. More rigid materials are more convenient since<br />

they are less prone to deformity during loading.<br />

Photoelastic material should be without internal stress<br />

and should have good treatment characteristics. It<br />

should also have as small time edge effect as possible.<br />

Materials based on epoxy resin and polyesters are<br />

considered the best for these purposes.<br />

The material mostly used in Europe is araldite-B with<br />

elasticity module E=3.1-3.7 Gpa, photoelastic stress<br />

constant f σ σ=103–120 N/cm and the permitted stress<br />

σ d = 40 MP, like the one used for producing the<br />

model described in this paper.<br />

3. MODEL PRODUCTION<br />

All the models produced are made of an araldite-B<br />

plate with the permitted stress of σσ d = 40 MP.<br />

Since the accuracy of the results depends highly<br />

on the quality of the model, the model should be<br />

produced very precisely and accurately. That is<br />

why a perspex pattern should be made for each<br />

model separately.<br />

While making the model, the pattern is first stuck by<br />

means of a two-sided sticky strip on the araldite<br />

plate and then, a part of the plate is cut by a band<br />

saw. A few millimeters should be left for further final<br />

treatment. Fine treatment is carried out by<br />

circumferential counter-directional milling on a highspeed<br />

copying milling machine. The diameter of the<br />

finger-like mill is φ5 mm, and the number of<br />

revolutions of the operating spindle n=40000 r/min.<br />

- 64 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

Za vrijeme glodanja {ablona se oslanja na centralni<br />

zatik na radnoj plo~i glodalice. Dubina se rezanja<br />

pak regulira postepenim smanjivanjem promjera<br />

zatika. Posmak se vr{i ru~no, te je nemogu}e<br />

posti}i potpunu ravnomjernost obrade. Zbog<br />

istro{enosti glodala i vibriranja vretena glodalice u<br />

modelu su se pojavila unutra{nja <strong>naprezanja</strong> te je<br />

bilo potrebno izvr{iti finu zavr{nu obradu<br />

dugotrajnim postupkom ru~nog bru{enja pomo}u<br />

finog brusnog papira, kako bi nestala zaostala<br />

<strong>naprezanja</strong> i rubni efekt.<br />

Nakon toga u modelima su simetri~no izbu{eni<br />

provrti za optere}ivanje. Provrti su izbu{eni dovoljno<br />

daleko od mjesto u~vr{}enja <strong>polova</strong>, kako ne bi<br />

do{lo do utjecaja St. Venantovog principa.<br />

3.1 Izrada modela pola <strong>generatora</strong> s<br />

korijenom u obliku ~eki}a, kombinacije<br />

lastin rep-~eki} i lastinog repa<br />

Modeli I - IV su izra|eni iz plo~a araldita-B<br />

debljine 8 mm, na kojima je mijenjan kut nagiba<br />

dosjednih povr{ina γ, kako je prikazano sl. 3.3. i<br />

tb.3.1. Iz iste plo~e izra|en je model V (sl. 3.2.)<br />

kod kojeg je korijen pola izveden u obliku lastinog<br />

repa.<br />

3.2 Izrada modela pola <strong>generatora</strong> s<br />

korijenom u obliku tri ~eki}a<br />

Na svim modelima do sada bio je izra|en korijen<br />

pol jednostrukog oblika. Me|utim, kod ve}ih masa<br />

namota ili ve}eg broja okretaja javljaju se i ve}e<br />

centrifugalne sile koje uzrokuju <strong>naprezanja</strong> ve}a od<br />

dozvoljenih te se zato pri{lo izradi stati~ki<br />

neodre|enih nosa~a namota. U tu svrhu izra|en je<br />

model korijena pola <strong>generatora</strong> s tri ~eki}a te se<br />

ukupna centrifugalna sila raspodjeljuje na tri ~eki}a<br />

i za o~ekivati je da }e se i <strong>naprezanja</strong> po jednom<br />

~eki}u bitno smanjiti.<br />

Dimenzije pola modela VI dane su na sl. 3.4.<br />

Model je tako|er izra|en iz plo~e araldita-B debljine<br />

8 mm s dopu{tenim naprezanjem σ dop =40 MPa.<br />

During the process of milling the pattern leans<br />

against the central pin on the working panel of the<br />

milling machine. The depth of cutting is regulated by<br />

gradual reduction of the pin’s diameter. Shift is<br />

regulated manually so it is impossible to achieve<br />

uniformity in treatment. Due to the worn milling<br />

machine and the vibration of milling machine spindle<br />

internal stresses have occurred in the model. It was,<br />

therefore necessary to apply final treatment which<br />

lasted for a long time. That is why manual polishing<br />

with fine abrasive paper was required in order to<br />

eliminate stresses and edge effect.<br />

After that symmetrical bores for loading were made<br />

on models. Bores were drilled far enough from the<br />

spot of pole fixing in order to avoid St. Venant<br />

principle.<br />

3.1 Generator pole model with hammer<br />

like root, swallow’s tail-hammer shape<br />

and swallow’s tail<br />

Models I – IV are made from an araldite-B plate,<br />

whose thickness is 8 mm, and whose contact<br />

surface angle γ was changed (Fig. 3.3. and Table<br />

3.1.). Model V was produced from the same plate,<br />

(Fig. 3.2.) whose pole root was made in the<br />

shape of the swallow’s tail.<br />

3.2 Manufacture of the generator pole<br />

root model with three hammers<br />

All models produced so far have had a pole with<br />

one root only. However, when either winding masses<br />

or the number of revolutions increase, the centrifugal<br />

forces increase and they cause bigger stresses than<br />

those allowed. That was the reason why statically<br />

undefined winding carriers were made. Therefore, a<br />

generator pole model was made (model V) having<br />

three hammer-like roots. The centrifugal force is<br />

divided into three, which should decrease the stress<br />

in each hammer considerably. Pole model dimensions<br />

VI, are given in Fig. 3.4.<br />

The model is also made from an araldite-B panel<br />

(8mm thick) with the permitted stress, σσ dop =40 MP.<br />

Tabela 3. 1. Promjenljive veli~ine za modele I – IV<br />

Table 3.<br />

1. Changing values for models I – IV<br />

Model I II III IV<br />

γ, o 0 15 30 45<br />

v, mm 0 2 4,5 8,25<br />

t, mm 20 18 15,5 11,75<br />

s 1 , mm 0 0,75 1,5 2,12<br />

- 65 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

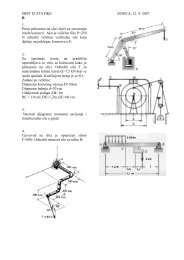

Slika 3.1. Dimenzije modela pola <strong>generatora</strong> oblika<br />

lastin rep-~eki} za modele I – IV<br />

Figure 3.1. The model size of the pole generator<br />

swallow’s tail-hammer shape for models I – IV<br />

Slika 3.2. Dimenzije modela pola <strong>generatora</strong> oblika lastin<br />

rep, model V<br />

Figure 3.2. The model size of the pole generator<br />

swallow’s tail, model V<br />

Slika 3.3. Prikaz promjenjivih veli~ina za modele I – IV, kombinacija lastin rep-~eki}<br />

Figure 3.3. The presentation of changing values for models I – IV, swallow’s tail-hammer combination<br />

Slika 3.4. Dimenzije pola <strong>generatora</strong> s tri ~eki}a, model VI<br />

Figure 3.4. The model size of the pole generator with three hammers, model VI<br />

- 66 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

4. ISPITIVANJE MODELA<br />

4.1 Optere}ivanje modela<br />

Kona~no obra|en model spreman je da se optereti<br />

i da se izvr{e sva potrebna mjerenja. Polo`aj<br />

to~aka na modelu odre|en je pravokutnim<br />

koordinatama ~ija se jedna os poklapa sa osi<br />

simetrije modela. Urezivanje koordinatnih osi u<br />

povr{inu modela nije mogu}e zbog pojave<br />

unutra{njih <strong>naprezanja</strong> na modelu, koja bi imala<br />

negativnu posljedicu na ispitivanje.<br />

Optere}ivanje svih modela izvr{eno je u zatvorenom<br />

okvirnom nosa~u pomo}u vijka sa trapeznim<br />

navojem.<br />

Prijenos sile na modelima izveden je pomo}u<br />

posebnih ~eljusti koje se sa vijcima pri~vrste na<br />

model, a na drugoj strani ~eljusti nalazi se<br />

simetri~no izbu{ena rupa koja se spaja s<br />

prstenastim dinamometrom pomo}u zatika.<br />

Same ~eljusti su postavljene tako da budu<br />

simetri~ne sa modelom i da se sila prenosi<br />

podjednako na sve rupe modela<br />

Svi modeli optere}ivani su u dva me|usobno<br />

okomita smjera kako bi se {to vjernije simuliralo<br />

stvarno stanje <strong>naprezanja</strong> na mjestu u~vr{}enja<br />

pola.<br />

Omjer vertikalne i horizontalne sile kojom se<br />

optere}uje model odabran je tako kod svih<br />

modela, da se dobije odnos <strong>naprezanja</strong> koji<br />

odgovara stvarnom stanju <strong>naprezanja</strong> u realnim<br />

pogonskim uvjetima.<br />

Iznosi sila F V i F H kojima su optere}ivani modeli<br />

dani su u tablici 4.1. Odabran je uvijek onaj omjer<br />

sila F V / F H koji je za razmatranje pojava u modelu<br />

najpogodniji tj. za taj omjer u modelima se<br />

pojavljuje maksimalni red izokroma. Taj se red<br />

izokroma najlak{e snima u kriti~nom presjeku,<br />

budu}i bi se kod ve}ih iznosa optere}enja<br />

maksimalni red izokroma znatno pove}ao, te bi one<br />

postale toliko guste i nejasne da se ne bi mogle<br />

vi{e razlu~ivati (brojati).<br />

4. TESTING OF THE MODEL<br />

4.1. Loading of the model<br />

When the model is finished it is ready to be loaded<br />

and submitted to all the necessary measurements.<br />

The position of points on the model is defined by<br />

rectangular coordinates. One of their axes agrees<br />

with the model symmetry axes. Cutting in axis<br />

coordinates into the model surface is not possible<br />

because inner stresses occur in the model, which<br />

would have a negative effect on testing.<br />

The loading of all models was carried out in a<br />

closed frame carrier by means of trapeze thread<br />

screw.<br />

The transmission of force on models was carried<br />

out by means of special jaws fixed by screws to<br />

the model. On the other side of the jaw there is a<br />

symmetrically drilled hole which is connected to<br />

the ring dynamometer by means of a pin.<br />

The jaws are symmetrical with the model and the<br />

force is transmitted equally to all holes of the model.<br />

All the models are loaded in two vertical<br />

directions. In that way the simulation of the real<br />

stress on the spot where the pole is fixed is very<br />

reliable.<br />

The ratio between the vertical and horizontal force<br />

by which the model is loaded is chosen for all<br />

models, i.e. the stress ratio (σ v / σ h ) = 1, which<br />

corresponds to the real arrangement of the<br />

generator pole fixing.<br />

Values of the forces F V and F H by which the model<br />

was loaded can be seen in Table 4.1. The force<br />

ratio, F V and F H was chosen so that it would give<br />

the most convenient way of considering the<br />

phenomena in the model, i.e. for that ratio the<br />

maximum order of isochrome appears in the<br />

models. This isochrome order is recorded easily in<br />

the critical cross-section, since at higher loading the<br />

number of maximum isochrome order is increased<br />

considerably. They become so dense and unclear<br />

that they cannot be distinguished (counted).<br />

Tablica 4.1. Iznosi vertikalnih F V i horizontalnih F H sila optere}enja na modele<br />

Table 4.1. Amounts of vertical and horizontal (F V and F H ) loading forces on models<br />

Model I II III IV V VI<br />

F V , N 450 450 450 450 300 1500<br />

F H , N 460 460 460 460 310 500<br />

- 67 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

5. NAPREZANJA PO KONTURI<br />

MODELA I ODRE\IVANJE FAKTORA<br />

KONCENTRACIJE NAPREZANJA<br />

Fotoelasticimetrijska metoda je opti~ka metoda za<br />

odre|ivanje <strong>naprezanja</strong> i deformacija u tehni~kim<br />

konstrukcijama a zasniva se na piezo-opti~kom<br />

efektu tj. svojstvu materijala da u optere}enom<br />

stanju postaje opti~ki anizotropan. Fotoelasti~ni<br />

materijali su takvi materijali koji su u<br />

neoptere}enom stanju opti~ki izotropni, a kada se<br />

opterete postaju opti~ki anizotropni (dvolomni).<br />

Opti~ka anizotropnost ovisna je o veli~ini i<br />

rasporedu <strong>naprezanja</strong>, pa se mjerenjem dvoloma<br />

mo`e zaklju~iti o rasporedu <strong>naprezanja</strong> u modelu.<br />

Analiza anizotropnosti (dvoloma) vr{i se ure|ajima<br />

koji se nazivaju polariskopi. U njima koristimo<br />

polarizirano svjetlo tj. svjetlosni val ~ije titranje je<br />

na neki odre|eni na~in sre|eno i usmjereno.<br />

Sam eksperiment provodi se na slijede}i na~in. Iz<br />

ravne plo~e izre`e se model koji je geometrijski<br />

sli~an originalnom dijelu koji se ispituje.<br />

Model se postavi u polariskop a zatim se optereti i<br />

snima, ili promatra golim okom. U vidnom polju<br />

polariskopa pojavljuju se interferencijske svijetle i<br />

tamne pruge. Analizom ovih linija izokroma<br />

zaklju~uje se o rasporedu <strong>naprezanja</strong>, odnosno<br />

deformaciji modela.<br />

Opisani eksperiment odnosi se na jednostavne<br />

probleme stati~kog optere}enja racninskih modela<br />

u elasti~nom podru~ju.<br />

Snimanje izokroma vr{eno je u kru`no polariziranom<br />

svjetlu, u svjetlom i tamnom polju, uz parametre<br />

snimanja, otvor blende 11 i ekspoziciju 8 sekundi<br />

Nakon razvijanje filma i izrada fotografija na<br />

fotografskom dokument papiru, dobiveni su snimci<br />

izokroma u tamnom i svjetlom polju, za sve<br />

modele. Na slikama 5.1 .i 5.2. prikazani su snimci<br />

izokroma u svijetlom i tamnom polju za model I.<br />

Analizom snimaka izokroma za sve ispitane modele<br />

uo~ava se da se maksimalni red izokrome javlja na<br />

rubu modela gdje se glavna <strong>naprezanja</strong> pojavljuju<br />

u radijalnom i cirkularnom smjeru:<br />

Radijalno naprezanje jednako je nuli (σ 2 =0) te je<br />

cirkularno naprezanje jednako:<br />

σ<br />

N i<br />

⋅ f<br />

2<br />

= σ<br />

, N / mm (5.1)<br />

h<br />

Kako je f σ / h = konst. slijedi da }e se za<br />

maksimalni red izokrome N i max pojaviti maksimalno<br />

naprezanje:<br />

N i max<br />

⋅ fσ<br />

2<br />

σ<br />

max<br />

= , N / mm (5.2)<br />

h<br />

Nominalno naprezanje dano je relacijom (5.3):<br />

5. STRESSES ON MODEL CONTOUR<br />

AND STRESS CONCENTRATION<br />

FACTOR DEFINITION<br />

Photoelasticity method is an optical method for<br />

determining stresses and deformities in technical<br />

structures and is based on piezo-optical effect, i.e.<br />

it is based on the property of the material which,<br />

when loaded, becomes optically anisotropic.<br />

Photoelastic materials are materials which are optically<br />

isotropic when they are not loaded, and when they<br />

are loaded they become optically anisotropic (bidiffracted).<br />

Optical anisotropy depends on the size<br />

and arrangement of the stress. Therefore, by<br />

measuring bi-diffraction it is possible to conclude<br />

about stress arrangement in the model.<br />

The analysis of anisotropy (bi-diffraction) is carried<br />

out by means of devices called polariscopes. They<br />

use polarized light , i.e. light wave whose<br />

flickering is somehow stable and directed<br />

The experiment itself is carried out in the following way.<br />

A model is cut out of a flat plate and it is geometrically<br />

similar to the original part which is being tested.<br />

The model is put into the polariscope, it is loaded<br />

and then filmed or observed with the naked eye.<br />

Within the polariscope field of sight, interferential<br />

bright and dark lines appear. By analyzing these<br />

isochrome lines it is possible to conclude what the<br />

arrangement of the stresses is, i.e. what the<br />

deformity of the model is.<br />

The described experiment refers to simple<br />

problems of a plane stress in elastic area and for<br />

static loading.<br />

Recording of the isochromes was carried out in<br />

the circular polarized light, in the light and dark<br />

field, with the following parameters, i.e. diaphragm<br />

11 and exposition 11s.<br />

After that the film was developed, the photographs<br />

were made following regular photograph procedure,<br />

and the photos of isochromes were obtained in<br />

both dark and light field for all the models. Fig.<br />

5.1. and 5.2. give the isochrome photo in dark<br />

and light field for the model I.<br />

By analyzing isochrome photos for all the models<br />

examined, it can be noticed that the maximum isochrome<br />

order appears on the model edge where main stresses<br />

in radial and circular straight line are found:<br />

Radial stress equals zero (σ 2 = 0) so the circular<br />

stress is equal to:<br />

σ<br />

N i<br />

⋅ f σ<br />

2<br />

= N<br />

(5.1)<br />

h<br />

, / mm<br />

Since f σ /h = const it is evident that for maximum<br />

isochrome order N i max , maximum stress occurs:<br />

N i max<br />

fσ<br />

2<br />

σ<br />

max<br />

= , N / mm (5.2)<br />

h<br />

⋅<br />

Nominal stress is given by the relation (5.3):<br />

- 68 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

σ = F V<br />

2<br />

n<br />

, N / mm<br />

(5.3. )<br />

A<br />

gdje je:<br />

F V , N – vla~na sila na korijen pola<br />

A, mm 2 – povr{ina presjeka vrata korijena<br />

Poznavanjem maksimalnog i nominalnog <strong>naprezanja</strong><br />

mogu se odrediti faktori koncentracije <strong>naprezanja</strong><br />

α k u opasnom presjeku (I-I, II-II, sl. 5.3) pomo}u<br />

izraza (5.1.), (5.2.) i (5.3.):<br />

σ<br />

N<br />

=<br />

max i max<br />

α<br />

k<br />

=<br />

(5.4.)<br />

σn<br />

Ni<br />

n<br />

Na dijagramima danim na slikama 5.4. do 5.9. dan<br />

je prikaz raspodjela <strong>naprezanja</strong> po konturi za sve<br />

modele.<br />

F 2<br />

σ V<br />

n<br />

= , N / mm<br />

(5.3. )<br />

A<br />

where:<br />

F v , N – tensile force on the pole root<br />

A, mm 2 – neck root cross section surface<br />

When maximum and nominal stress is known, it is<br />

possible to determine the concentration stress factors α k<br />

in the dangerous cross section (I-I, II-II, Fig. 5.3) by<br />

means of the following expressions (5.1), (5.2) and<br />

(5.3):<br />

σ<br />

N<br />

=<br />

max i max<br />

α<br />

k<br />

=<br />

(5.4.)<br />

σn<br />

Ni<br />

n<br />

In the diagrams given in figures 5.4. to 5.9., stress<br />

distribution along the contour for all the models is<br />

presented.<br />

Slika 5.1. Snimak izokroma u tamnom polju za model I<br />

Figure 5.1. Isochrome photo in dark field for model I<br />

Slika 5.2. Snimak izokroma u svjetlom polju za model I<br />

Figure 5.2. Isochrome photo in light field for model I<br />

Slika 5.3. Prikaz opasnih presjeka modela V (a), i modela I-IV (b)<br />

Figure 5.3. Presentation of dangerous cross sections of models V (a) and model (I-IV (b)<br />

- 69 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

Dijagrami su crtani po konturi modela tako da<br />

normala na konturu predstavlja ordinatu <strong>naprezanja</strong><br />

odnosno reda izokrome.<br />

Svi dijagrami su crtani u mjerilu:<br />

- za red izokrome<br />

10 mm = 1 red izokrome<br />

- za naprezanje 10 mm = 2 ( N/mm 2 )<br />

Analiza je vr{ena za sve modele po konturi na<br />

radijusima zakrivljenja u presjecima I –I i II - II (sl.<br />

5.3).<br />

Za sve modele prema relaciji ( 5.3 ) i sl. 5.3. (<br />

presjek I – I odnosno presjek II – II),izra~unati su<br />

iznosi nominalnih <strong>naprezanja</strong> (tb. 5.1), a iznosi<br />

maksimalnih <strong>naprezanja</strong> o~itanih iz dijagrama sa sl.<br />

5.4. do 5.9. dani su u tablici 5.2.<br />

Faktori koncentracije <strong>naprezanja</strong> za modele I – VI<br />

izra~unati prema relaciji 5.4. dani su u tablici 5.3.<br />

Tablica 5.1. Iznosi nominalnih <strong>naprezanja</strong> σ n<br />

Table 5.1. Nominal stress values, σ n<br />

Diagrams have been drawn along the model<br />

contour so that the normal to the contour<br />

represents stress ordinate, i.e. isochrome order.<br />

All diagrams have been drawn in the following scale:<br />

- for isochrome order<br />

10mmm = 1 isochrome order<br />

- for 10mm stress = 2 (N/mm 2 )<br />

The analysis was carried out for all the models<br />

along the contour on roundness radius in crosssections<br />

I-I i II – II (Fig.5.3.).<br />

For all the models according to the relation (5.3) and<br />

Fig. 5.3. (cross section I – I and II – II), the amounts<br />

of nominal stresses have been calculated (Table 5.1.).<br />

The amounts of maximum stresses read from the<br />

diagram in Fig. 5.4. to 5.9. are given in the Table 5.2.<br />

Stress concentration factors for models I – VI have<br />

been calculated according to the relation 5.4. and<br />

are given in the Table 5.3.<br />

Model I II III IV V VI<br />

F V , N 450 450 450 450 300 1500<br />

A, mm 2 160 160 160 160 138 600<br />

σ n ,<br />

N/mm 2<br />

2,813 2,813 2,813 2,813 2,174 2,5<br />

Tablica 5.2. Iznosi maksimalnih <strong>naprezanja</strong> σ max<br />

Table 5.2. Maximum stress amounts, σ max<br />

Model I II III IV V VI Napomena<br />

σ max , N/mm 2 7,5 6,7 6,2 5,68 10,44 1,01 Presjek I-I<br />

11,24 8,92 8,8 8,16 - 4,95 Presjek II-II<br />

Slika 5.4. Raspored <strong>naprezanja</strong> i reda izokroma<br />

po konturi, za model I<br />

Figure 5.4. Stress arrangement and isochrome<br />

order along the contour for model I<br />

Slika 5.5. Raspored <strong>naprezanja</strong> i reda izokroma<br />

po konturi, za model II<br />

Figure 5.5. Stress arrangement and isochrome<br />

order along the contour for model II<br />

- 70 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

Slika. 5.6. Raspored <strong>naprezanja</strong> i reda izokroma<br />

po konturi, za model III<br />

Figure 5.6. Stress arrangement and isochrome<br />

order along the contour for model III<br />

Slika. 5.7. Raspored <strong>naprezanja</strong> i reda izokroma<br />

po konturi, za model IV<br />

Figure 5.7. Stress arrangement and isochrome<br />

order along the contour for model IV<br />

Slika 5.8. Raspored <strong>naprezanja</strong> i reda izokroma po konturi, za model V<br />

Figure 5.8. Stress arrangement and isochrome order along the contour for model V<br />

Tablica 5.3. Faktori koncentracije <strong>naprezanja</strong><br />

Table 5.3. Stress concentration factors, α k<br />

Model I II III IV V VI Napomena<br />

α k<br />

2,67 2,38 2,2 2,02 4,8 0,40 Presjek I-I α kI<br />

4,00 3,17 3,13 2,90 - 1,98 Presjek II-II α kII<br />

- 71 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

Slika 5.9. Raspored <strong>naprezanja</strong> i reda izokroma po konturi, za model VI<br />

Figure 5.9. Stress arrangement and isochrome order along the contour for model VI<br />

6. ZAKLJU^AK<br />

Raspodjela <strong>naprezanja</strong> na kriti~nim mjestima<br />

u~vr{}enja pola <strong>generatora</strong>, bilo u obliku lastinog<br />

repa, ~eki}a ili pak njihove kombinacije, takova je<br />

iznosa da ih treba uzeti u obzir kod mehani~kih<br />

prora~una tih elemenata.<br />

Najve}i faktor koncentracije <strong>naprezanja</strong> javlja se pri<br />

modelima kod kojih je korijen pola izra|en u<br />

obliku lastinog repa ( model V ), budu}i je kod<br />

tog oblika najizra`eniji utjecaj radijusa zakrivljenosti<br />

na prijelazu tijela pola u korijen pola (sl. 5.8.).<br />

Na modelu I a posebno na modelima II – IV, faktor<br />

koncentracije <strong>naprezanja</strong> je upola manji u odnosu na<br />

model V (tablica 5.3.) {to je s jedne strane<br />

posljedica smanjenog utjecaja zareznog djelovanja<br />

(bla`i je prijelaz s tijela pola na njihov korijen), a s<br />

druge strane dosjedne povr{ine izme|u korijena pola<br />

i utora u lan~anom prstenu se pove~avaju s<br />

porastom kuta γ.<br />

Kod korijena <strong>polova</strong> u obliku ~eki}a i kombinacije<br />

~eki}-lastin rep dio <strong>naprezanja</strong> prenosio se du`<br />

vrata ~eki}a te se ukupno optere}enje ne<br />

koncentrira samo na presjek I-I (sl. 5.5.) kao pri<br />

modelu V, {to tako|er utje~e na znatno smanjenje<br />

koncentracije <strong>naprezanja</strong> na kriti~nim presjecima.<br />

Treba jo{ napomenuti da bi se dodatnim<br />

ispitivanjima trebao definirati optimalni kut nagiba γ.<br />

6. CONCLUSION<br />

Stress arrangement in critical points of the generator<br />

pole fixing, regardless of the type of fixing, i.e.<br />

swallow’s tail, hammer or their combination, are such<br />

that their values should be taken into consideration<br />

when the strength of these elements is calculated.<br />

The biggest stress concentration factor occurs with<br />

models whose pole root has the shape of the<br />

swallow’s tail (model V), since this shape shows<br />

the influence of radius roundness on the spot<br />

where pole body becomes pole root.<br />

On model I and particularly on models II – IV, stress<br />

concentration factor decreases considerably (Table<br />

5.3.) due to smaller influence of radius roundness<br />

(the transition from the body to the root is more<br />

temperate), whereas, on the other hand, the contact<br />

surface between the pole root and the groove in the<br />

chain ring increase as the angle γ increase.<br />

With pole roots in the shape of a hammer and the<br />

combination hammer-swallow’s tail, a portion of the<br />

stress is transmitted along the hammer neck and<br />

consequently, the total load is not concentrated on the<br />

cross section I – I only, (Fig. 5.5) as is the case with<br />

the model V. This also influences the stress<br />

concentration causing it to decrease at critical cross<br />

sections. It is also worth mentioning that additional<br />

tests should define optimal angle of the slope, γ.<br />

- 72 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

S porastom optere}enja (centrifugalne sile na<br />

originalima), treba izbjegavati izradu korijena pola u<br />

obliku lastinog repa i treba se orijentirati na<br />

korijene pola u obliku ~eki}a ili kombinacije lastin<br />

rep-~eki}, kod kojih je faktor koncentracije<br />

<strong>naprezanja</strong> manji i do 40% u odnosu na korijen<br />

oblika lastinog repa.<br />

Korijen pola s tri ~eki}a (model VI) treba se<br />

koristiti u onim slu~ajevima kada su optere}enja na<br />

korijen pola vrlo visoka tj. na korijen pola oblika<br />

jednostrukog ~eki}a izazivala bi <strong>naprezanja</strong> znatno<br />

iznad granica te~enja materijala koji se koriste za<br />

izradu polnih plo~a. Na taj na~in pove}ava se<br />

kriti~ni presjek tri puta pa se i <strong>naprezanja</strong><br />

smanjuju u tom omjeru.<br />

Kod modela VI, faktor koncentracije <strong>naprezanja</strong><br />

znatno se smanjuju (tablica 5.3.), u odnosu na<br />

ostale modele kod kojih je pol bio izra|en u<br />

obliku jednostrukog korijena, te se zato kod<br />

brzohodnih strojeva i velikih optere}enja uvijek<br />

mora i}i na izradu u~vr{}enja korijena pola oblika<br />

vi{estrukih ~eki}a.<br />

Rezultati ispitivanja nisu potpuno egzaktni budu}i je<br />

ispitivanje vr{eno uz aproksimaciju tj. polovi su na<br />

originalnoj konstrukciji optere}eni certifugalnim<br />

silama, dok su modeli bili optere}eni jednolikom<br />

vla~nom silom (ravninski model).<br />

Za daljnja istra`ivanja predvi|a se <strong>analiza</strong><br />

<strong>naprezanja</strong> na prostornom rotacionom modelu<br />

metodom zamrzavanja <strong>naprezanja</strong> uz simulaciju<br />

djelovanja centrifugalnih sila na u~vr{}enje pola<br />

<strong>rotora</strong> kako bi se uvjeti ispitivanju na modelu {to<br />

vi{e pribli`ili stvarnim pogonskim uvjetima.<br />

When the loading increases (centrifugal forces on<br />

the originals), the pole root in the shape of a<br />

swallow’s tail should be avoided. The design of<br />

the pole roots in the shape of a hammer or<br />

combinations of a swallow’s tail-hammer where the<br />

stress concentration factor is smaller than 40%<br />

compared to a swallow’s tail should be given<br />

priority.<br />

The pole root with three hammers (model VI) is<br />

used in the cases when the pole root loadings<br />

are very high, i.e. on a single hammer they would<br />

cause stresses far above the material limits, i.e.<br />

materials used for making pole root plates. In this<br />

way the critical cross section is increased three<br />

times. Consequently, stresses are reduced in that<br />

direction.<br />

With the model VI, stress concentration factor<br />

decreases considerably (Table 5.3.) compared to<br />

other models whose pole was made in the shape<br />

of a single root. Therefore, when fast speed<br />

machines and heavy loading are considered, it is<br />

always important to make poles with multiple<br />

hammers.<br />

Test results are not completely exact since tests<br />

were carried out with approximation, i.e. the poles<br />

on the original construction were loaded by<br />

centrifugal forces, whereas models were loaded by<br />

a uniform tensile strength (plane model).<br />

Further research should include the stress analysis<br />

on a rotary model using the freezing stress<br />

method along with centrifugal forces simulation on<br />

rotor poles fixing. In that, the way testing<br />

conditions on the model would be as close as<br />

possible to the real driving conditions.<br />

7. LITERATURA - REFERENCES:<br />

[1] I. Alfirevi}, S. Jeci}, Fotoelasticimetrija,<br />

Sveu~ili{na naklada Liber, Zagreb, 1983.<br />

[2] M.M. Filonenko-Borodi}, Teorija uprugosti,<br />

Gostehizdat, Moskva-Lenjingrad, 1947.<br />

[3] M.M. Frocht, Photoelasticity, I i II, John Wiley<br />

and Sons, New York, 1948.<br />

[4] V. Jari}, Naprezanja u elementima u~vr{~enja<br />

<strong>generatora</strong> s istaknutim polovima (lastin rep),<br />

Elaborat TG 66.0000, Tvornica <strong>generatora</strong> –<br />

''Rade Kon~ar'', Zagreb, 1978<br />

[5] V. Jari}, D. Pustaji}, B. Mila{in~i}, Mehani~ki<br />

prora~un <strong>generatora</strong> s istaknutim polovima,<br />

Tvornica <strong>generatora</strong> – ''Rade Kon~ar'', Zagreb,<br />

1979<br />

[6] S. Jeci}, Teorija elasti~nosti, Sveu~ili{na<br />

naknada Liber, Zagreb, 1981.<br />

[7] S.N. Nikiforov, Teorija uprugosti i plasti~nosti,<br />

Gosizdat, Moskva, 1955<br />

[8] D. Pustaji}, Prora~un i dimenzioniranje<br />

u~vr{~enja pola lastinim repom, Elaborat<br />

60.0001, Tvornica <strong>generatora</strong> – ''Rade Kon~ar'',<br />

Zagreb, 1978<br />

[9] D. Pustaji}, N. [vigir, Analiza <strong>naprezanja</strong> u<br />

lastinom repu <strong>generatora</strong> s istaknutim<br />

polovima, Referat na XVII savjetovanju<br />

elektroenergeti~ara Jugoslavije, Struga, 1985,<br />

str.19-29<br />

[10] N. [vigir, Izbor materijala <strong>polova</strong> <strong>rotora</strong> na<br />

temelju komparativna analize <strong>naprezanja</strong>,<br />

Magistarski rad, Zagreb, 1984.<br />

- 73 -

Ma{instvo 2(7), 63 – 74, (2003)<br />

N.[virig;....: ANALIZA NAPREZANJA U U^VR[^ENJU...<br />

[11] Lj. Kuterovac, Synchronous generator in<br />

unsymmetrical surge short circuits, Magistarski<br />

rad, FER, Zagreb 1995<br />

[12] E. Wiedemann,W. Kellenberger, Konstruktion<br />

elektrischer Maschinen, Springer-Verlag,<br />

Berlin/Heidelberg/New York, 1967<br />

[13] N. Dizdarevi}, Lj. Kuterovac, S. Te{njak, Z.<br />

Maljkovi}, Additional analysis of electric power<br />

system expected transient phenomena around<br />

HEPP «Vinodol» after reconstruction,<br />

Dissertation, Faculty of Electrical Engineering<br />

and Computing, Zagreb, 1996 (Croatian)<br />

[14] N. [vigir, Contibution to mechanical<br />

calculation of synchronous generator with<br />

salient poles regarding transient phenomena in<br />

electric power system, doctor's thesis, Faculty<br />

of Mechanical Engineering an Naval<br />

Architecture, Zagreb, 1999 (Croatian)<br />

- 74 -

![zavarivanje kao metod produ@enja @ivotnog vijeka ku]i[ta toplotnih ...](https://img.yumpu.com/36506092/1/184x260/zavarivanje-kao-metod-produenja-ivotnog-vijeka-kuita-toplotnih-.jpg?quality=85)