Midterm outline - Classes

Midterm outline - Classes

Midterm outline - Classes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

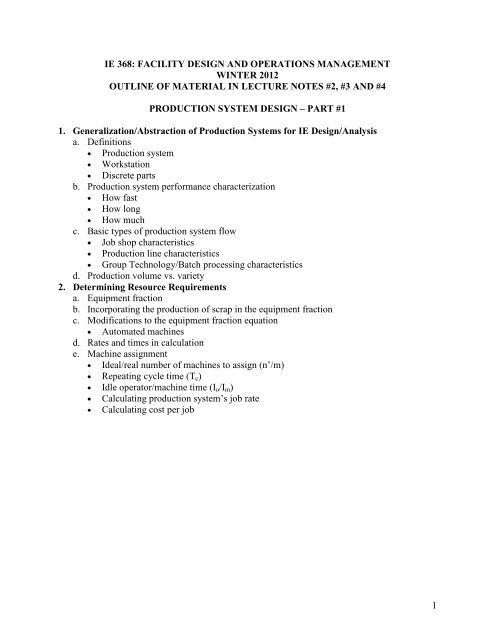

IE 368: FACILITY DESIGN AND OPERATIONS MANAGEMENT<br />

WINTER 2012<br />

OUTLINE OF MATERIAL IN LECTURE NOTES #2, #3 AND #4<br />

PRODUCTION SYSTEM DESIGN – PART #1<br />

1. Generalization/Abstraction of Production Systems for IE Design/Analysis<br />

a. Definitions<br />

• Production system<br />

• Workstation<br />

• Discrete parts<br />

b. Production system performance characterization<br />

• How fast<br />

• How long<br />

• How much<br />

c. Basic types of production system flow<br />

• Job shop characteristics<br />

• Production line characteristics<br />

• Group Technology/Batch processing characteristics<br />

d. Production volume vs. variety<br />

2. Determining Resource Requirements<br />

a. Equipment fraction<br />

b. Incorporating the production of scrap in the equipment fraction<br />

c. Modifications to the equipment fraction equation<br />

• Automated machines<br />

d. Rates and times in calculation<br />

e. Machine assignment<br />

• Ideal/real number of machines to assign (n’/m)<br />

• Repeating cycle time (T c )<br />

• Idle operator/machine time (I o /I m )<br />

• Calculating production system’s job rate<br />

• Calculating cost per job<br />

1

PRODUCTION SYSTEM DESIGN – PART #2<br />

1. Performance Evaluation<br />

a. Throughput<br />

b. System responsiveness (TIQ, TIS)<br />

c. WIP levels (WIP Q , WIP)<br />

2. Queuing theory<br />

a. Probability and statistics concepts<br />

• Random variable<br />

• Expected value<br />

• Variance<br />

• Coefficient of variation<br />

3. Utilization<br />

a. Needed to evaluate WS performance<br />

b. Need effective process time (t e ) and job interarrival time (t a )<br />

• Both given or calculated from data<br />

c. Classification of CVs<br />

4. Queuing models for performance evaluation<br />

a. WS m = 1 (simplest case)<br />

• Concept of throughput based on WS’s utilization (is u ≤ or equal to 1?)<br />

− See formulation for TIQ & TIS<br />

• Little’s law Throughput (TP) times either WIP Q or WIP<br />

• Examination of queuing model (relationships amongst parameters in queuing model)<br />

PRODUCTION SYSTEM DESIGN – PART #3<br />

1. Queuing models for performance evaluation (continued)<br />

a. Generalizations of queuing model<br />

• WS m = n (multiple parallel machines)<br />

− See formulation<br />

b. Generalizations of utilization formula<br />

• WS m = n (non-identical machines), 1 job type<br />

• WS m = n (identical machines), 2 job types<br />

• WS m = n (non-identical machines), n job types<br />

c. Multiple linked workstations<br />

• Coefficient of variation for the interdeparture times (CV d )<br />

• Formula to calculate CV d is different if:<br />

− WS m = 1<br />

− WS m = n<br />

d. Automated systems<br />

• Need to estimate t e and CV e<br />

• Comparison of t e and CV e vs. changes in MTTR and MTBF<br />

e. Batched arrivals and departures<br />

• Estimate t a and CV a<br />

• Selection of the queuing model to use depends on same conditions as before.<br />

2