Cryogenic 3-Piece Ball Valves

Cryogenic 3-Piece Ball Valves

Cryogenic 3-Piece Ball Valves

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

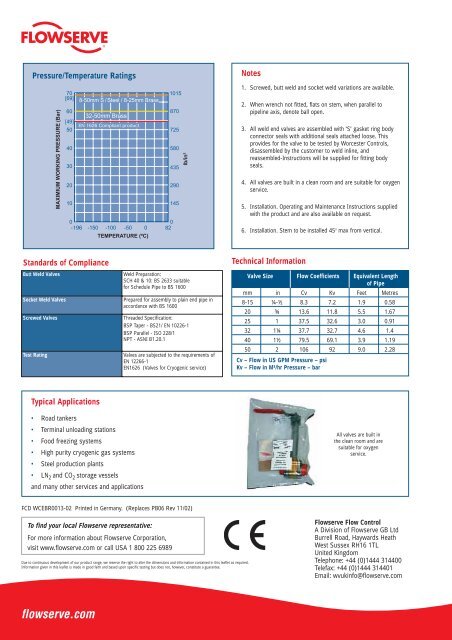

Pressure/Temperature Ratings<br />

Notes<br />

1. Screwed, butt weld and socket weld variations are available.<br />

[49]<br />

EN 1626 Compliant product<br />

2. When wrench not fitted, flats on stem, when parallel to<br />

pipeline axis, denote ball open.<br />

3. All weld end valves are assembled with ‘S’ gasket ring body<br />

connector seals with additional seals attached loose. This<br />

provides for the valve to be tested by Worcester Controls,<br />

disassembled by the customer to weld inline, and<br />

reassembled-Instructions will be supplied for fitting body<br />

seals.<br />

4. All valves are built in a clean room and are suitable for oxygen<br />

service.<br />

5. Installation. Operating and Maintenance Instructions supplied<br />

with the product and are also available on request.<br />

-196<br />

6. Installation. Stem to be installed 45 o max from vertical.<br />

Standards of Compliance<br />

Butt Weld <strong>Valves</strong><br />

Socket Weld <strong>Valves</strong><br />

Screwed <strong>Valves</strong><br />

Test Rating<br />

Weld Preparation:<br />

SCH 40 & 10: BS 2633 suitable<br />

for Schedule Pipe to BS 1600<br />

Prepared for assembly to plain end pipe in<br />

accordance with BS 1600<br />

Threaded Specification:<br />

BSP Taper - BS21/ EN 10226-1<br />

BSP Parallel - ISO 228/1<br />

NPT - ASNI B1.20.1<br />

<strong>Valves</strong> are subjected to the requirements of<br />

EN 12266-1<br />

EN1626 (<strong>Valves</strong> for <strong>Cryogenic</strong> service)<br />

Technical Information<br />

Valve Size Flow Coefficients Equivalent Length<br />

of Pipe<br />

mm in Cv Kv Feet Metres<br />

8-15 ¼-½ 8.3 7.2 1.9 0.58<br />

20 ¾ 13.6 11.8 5.5 1.67<br />

25 1 37.5 32.6 3.0 0.91<br />

32 1¼ 37.7 32.7 4.6 1.4<br />

40 1½ 79.5 69.1 3.9 1.19<br />

50 2 106 92 9.0 2.28<br />

Cv – Flow in US GPM Pressure – psi<br />

Kv – Flow in M³/hr Pressure – bar<br />

Typical Applications<br />

• Road tankers<br />

• Terminal unloading stations<br />

• Food freezing systems<br />

• High purity cryogenic gas systems<br />

• Steel production plants<br />

• LN 2 and CO 2 storage vessels<br />

and many other services and applications<br />

All valves are built in<br />

the clean room and are<br />

suitable for oxygen<br />

service.<br />

FCD WCEBR0013-02 Printed in Germany. (Replaces PB06 Rev 11/02)<br />

To find your local Flowserve representative:<br />

For more information about Flowserve Corporation,<br />

visit www.flowserve.com or call USA 1 800 225 6989<br />

Due to continuous development of our product range, we reserve the right to alter the dimensions and information contained in this leaflet as required.<br />

Information given in this leaflet is made in good faith and based upon specific testing but does not, however, constitute a guarantee.<br />

Flowserve Flow Control<br />

A Division of Flowserve GB Ltd<br />

Burrell Road, Haywards Heath<br />

West Sussex RH16 1TL<br />

United Kingdom<br />

Telephone: +44 (0)1444 314400<br />

Telefax: +44 (0)1444 314401<br />

Email: wvukinfo@flowserve.com