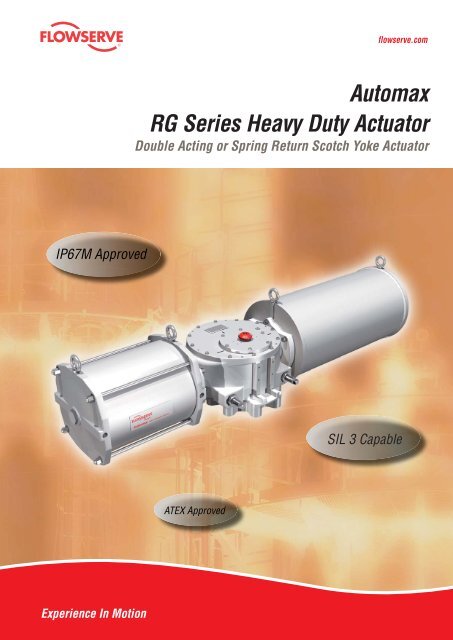

Automax RG Series Heavy Duty Actuator

Automax RG Series Heavy Duty Actuator

Automax RG Series Heavy Duty Actuator

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

flowserve.com<strong>RG</strong> <strong>Series</strong><strong>Heavy</strong>-<strong>Duty</strong> Scotch Yoke <strong>Actuator</strong>20% higher break torqueInterchangeable Yoke SystemSymmetrical YokeFeatures• Hard Chrome Plated Cylinder Walls• Symmetrical and Canted Yoke• Guide Bar Yoke Support• Dual DD Cylinder OptionCanted Yoke• Field Reversible Action• Overrides, Line Break and Special Controls• ESD Performance• Ductile iron casting• Totally enclosed yoke slot forincreased strength and cyclelife• Canted yoke results in approx.20% higher break torque• 2 keyway provision forflexibility of parallel orperpendicular mountingOverride OptionsSpring Module design facilitates field retrofittingof jackscrew or hydraulic overridesSlider BlockInduction hardened and hard chromeplated yoke pin with aluminum bronzeslider blocks minimize contact stressand ensure high cycle life.Steel Guide BarHard chrome plated alloysteel guide bar providesoptimal support of thetransverse loads.Spring ModulePull-to-compress, concentric-nesteddesign utilizes high strength alloyspring steel to maintain consistenttorque output (over time) and promotehigh cycle life performance.Pull RodSpring pull rod is over-sized to resist impactloads and hard chrome plated to providesuperior corrosion and wear resistance.Bidirectional Travel StopsAllow precise adjustment of open andclosed positions, ensuring valve shutoffand optimizing seat life.Torque ModuleModular with symmetrical flanges and female outputdrive. Provided with dual accessory mounting padsand compliant to international ISO/MSS and NAMURmounting specifications5

DimensionsLNFAABCJGEINPT Air PortsSpring ReturnGSide ViewBKANABAMNABDGYY1GNPT Air PortsZXDouble Acting Single CylinderDouble Acting Dual Cylinder<strong>Actuator</strong> Dimensions, mm (inch)SERIES A B C D E F I J K L M N X Y Y1<strong>RG</strong>1141 310 498 18,5 264 55 99 129 610,5 1090 902 282 68 60 30(5.55) (12.20) (19.61) (0.73) (10.39) (2.17) (3.90) (5.08) (24.04) (42.91) (35.51) (11.10) (2.68) (3.36) (1.18)<strong>RG</strong>2162 368 586 20 322 65 116 144 712 1278 1060 324 68 60 30(6.38) (14.49) (23.07) (0.79) (12.68) (2.56) (4.57) (5.67) (28.03) (50.31) (41.73) (12.76) (2.68) (3.36) (1.18)<strong>RG</strong>3175 444 706 23 380 75 111 151 817 1500 1238 350 95 52 13(6.98) (17.48) (27.80) (0.91) (14.96) (2.95) (4.37) (5.94) (32.17) (59.06) (48.74) (13.78) (3.74) (2.05) (0.51)<strong>RG</strong>4243 565 868 23 467 91 145 175 1074 1919 1616 486 95 60 30(9.57) (22.24) (34.17) (0.91) (18.39) (3.58) (5.71) (6.89) (42.28) (75.55) (63.62) (19.13) (3.74) (3.36) (1.18)<strong>RG</strong>5312 716 1008 26 568 145 175,5 189,5 1366 2348 2056 624 95 60 30(12.28) (28.19) (39.69) (1.02) (22.36) (5.71) (6.91) (7.46) (53.78) (92.44) (80.94) (24.57) (3.74) (3.36) (1.18)<strong>RG</strong>6394 756 1640 28 600 185 208 218 1572 3184 2300 788 95 60 30(15.51) (29.76) (64.57) (1.10) (23.62) (7.28) (8.19) (8.58) (61.89) (125.35) (90.55) (31.02) (3.74) (3.36) (1.18)<strong>RG</strong>7500 810 2030 50 615 220 265 310 1860 3840 2620 1000 95 100 30(19.69) (31.89) (79.92) (1.97) (24.21) (8.66) (10.43) (12.20) (73.23) (151.18) (103.18) (39.37) (3.74) (3.94) (1.18)<strong>RG</strong>8665 860 2600 55 680 280 306 360 2245 4790 3050 1330 95 100 30(26.18) (33.86) (102.36) (2.17) (26.77) (11.02) (12.05) (14.17) (88.39) (188.58) (120.08) 52.36) (3.74) (3.94) (1.18)Cylinder Size 5" 6" 7" 8" 9" 10" 12" 14" 16' 18" 20" 22" 24" 28" 32" 36" 40"G178(7.01)178(7.01)196(7.72)222(8.74)248(9.76)274(10.79)324(12.76)375(14.76)438(17.24)486(19.13)532(20.94)588(23.15)648(25.51)865(34.06)967(38.07)1069(42.09)Port Size NPT 3/8˝ 3/8˝ 3/8˝ 3/8˝ 3/8˝ 1/2˝ 3/4˝ 3/4˝ 3/4˝ 1˝ 1˝ 1˝ 1˝ 1½˝ 1½˝ 1½˝ 2˝1170(46.06)6

flowserve.comDimensionsISO BASE DETAILS(<strong>RG</strong>1, <strong>RG</strong>2)SIDE VIEWISO BASE DETAILS(<strong>RG</strong>3 3to <strong>RG</strong>6)SIDE VIEWISO BASE DETAILS(<strong>RG</strong>7)SIDE VIEWISO BASE DETAILS(<strong>RG</strong>8)SIDE VIEWMounting Base Details & Dimensions, mm (inch)SERIES ISO BASE SPIGOT Ø PCD BORE Ø BORE Tol W W Tol No of Bolt X Size T U U Tol<strong>RG</strong>1 F14100 140 48145 51,8H9+0.12/+0.05 4 X M16(3.94) (5.51) (1.89)(0.55)(0.20) (2.04)+0.2/+0.0<strong>RG</strong>2 F16130 165 60185 64,4H9+0.15/+0.07 4 X M20(5.12) (6.50) (2.36)(0.71)(0.20) (2.54)+0.2/+0.0<strong>RG</strong>3 F25200 254 72205 76,9H9+0.15/+0.07 8 X M16(7.87) (10.0) (2.83)(0.79)(0.20) (3.03)+0.2/+0.0<strong>RG</strong>4 F30230 298 98285 104,4H9+0.15/+0.07 8 X M20(9.06) (11.73) (3.86)(1.10)(0.20) (4.11)+0.2/+0.0<strong>RG</strong>5 F35260 356 160405 169,4H9+0.18/+0.08 8 X M30(10.24) (14.02) (6.30)(1.57)(0.20) (6.67)+0.2/+0.0<strong>RG</strong>6 F40300 406 180458 190,4H9+0.18/+0.08 8 X M36(11.81) (15.98) (7.09)(1.77)(0.20) (5.50)+0.2/+0.0<strong>RG</strong>7 F48370 483 220508 231,4H9+0.18/+0.08 12 X M36(14.57) (19.02) (8.66)(1.97)(0.20) (9.11)+0.3/+0.0<strong>RG</strong>8 F60470 603 280638 292,4H9+0.22/+0.10 20 X M36(18.5) (23.74) (11.02)(2.48)(0.20) (11.51)+0.3/+0.07

DimensionsZDouble Acting Single CylinderDimension Z, mm (inch)SERIES 5" 6" 7" 8" 9" 10" 12" 14" 16' 18" 20' 22" 24" 28" 32" 36" 40"-10 -10 1 12 25 38 63<strong>RG</strong>1– – – – – – – – – –(-0.39) (-0.39) (0.04) (0.47) (0.98) (1.50) (2.48)5 8 21 46 71,5 103<strong>RG</strong>2 – – –– – – – – – – –(0.20) (0.31) (0.83) (1.81) (2.81) (4.06)26 51 76,5 108 132 155<strong>RG</strong>3 – – – – –– – – – – –(1.02) (2.01) (3.01) (4.25) (5.20) (6.10)42,5 74 98 121 149 179<strong>RG</strong>4 – – – – – – –– – – –(1.67) (2.91) (3,86) (4.76) (5.87) (7.05)43,5 67,5 90,5 118,5 148,5 257<strong>RG</strong>5 – – – – – – – –– – –(1.71) (2.66) (3.56) (4.67) (5.85) (10.12)35 58 86 116 224,5 275,5 326,5<strong>RG</strong>6 – – – – – – – – ––(1.38) (2.28) (3.39) (4.57) (8.84) (10.85) (12.85)59 167,5 218,5 269,5 320<strong>RG</strong>7 – – – – – – – – – – – –(2.32) (6.59) (8.6) (10.61) (12.60)177,5 228,5 279<strong>RG</strong>8 – – – – – – – – – – – – – –(6.99) (9.00) (10.98)LNBAACGEDouble Acting Tandem CylinderDimensions for Spring Return Tandem Cylinders, mm (inch)SERIES A B C E G N L<strong>RG</strong>8 32-3266517152600680117013305645(26.18)(67.52)(102.36)(26.77)(46.06)52.36)(222.24)<strong>RG</strong>836-3666517402600680117013305670(26.18)(68.50)102.36)(26.77)(46.06)52.36)(223.23)8

flowserve.comModule WeightsModel TorqueModule<strong>RG</strong>1<strong>RG</strong>2<strong>RG</strong>3<strong>RG</strong>4<strong>RG</strong>5<strong>RG</strong>6<strong>RG</strong>7<strong>RG</strong>831(68)45(99)65(143)134(295)231(510)423(933)853(1881)1686(3718)Module Weights, kg (Lbs)Pressure ModuleSpring Module5 6 7 8 9 10 12 14 16 18 20 22 24 28 32 36 40 1 2 3 4 5 6 7 814(31)16(35)22(47)– – –24(53)25(56)30(66)32(69)– – – – –43(94)45(99)45(100)63(139)65(143)64(142)– – – – – – –– – – – – – – – – –95(209)91(200)99(217)– – – – – – – –145(320)145(318)154(339)162(356)– – – – – – – –185(406)194(427)207(455)255(561)266(586)277(610)– – – – – –337(741)388(853)428(942)452(994)– – – –743(1634)– – –– – – – – – – – –224 280 391 478 787 1055 1384 583 790 760 787 937 907–(493) (616) (861) (1051)(1732)(2321)(3044)(1283)(1738)(1671)(1730) (2061)(1995)– – – – – – – – – – – – –829 1096 1435 1779 1038 1339 1383 1444 1650 1686(1824)(2411)(3156)(3913)(2283)(2946)(3043)(3177) (3630)(3709)– – – – – – – – – – – – –984 1282 1533 1891 2103 2367 2779 2830 3232 3374(2165)(2819)(3372)(4159)(4627)(5800)(6113)(6227) (7111) (7423)40(88)58(128)103(226)183(402)290(639)44(97)66(145)118(260)201(442)335(737)46(101)70(154)121(267)210(462)350(770)47(103)72(158)122(269)217(477)356(783)48(106)72(158)125(276)232(510)410(901)52(114)78(172)150(330)248(545)434(955)54(119)82(180)146(321)257(565)54(119)85(186)–254(581)– –– –– –– –NAMUR shaft height and bracket mounting detailsO8040SQ. 19Detail B15 30308X Ø 4.20 13.00M5 - 6H 10.00<strong>Series</strong> O<strong>RG</strong>1 -<strong>RG</strong>2 -<strong>RG</strong>3 -<strong>RG</strong>4 130<strong>RG</strong>5 130<strong>RG</strong>6 130<strong>RG</strong>7 130<strong>RG</strong>8 130Detail CAgency & Environmental Approvals• IP67M (1 meter depth for 30 minutes)• IEC 61508 SIL 3 Suitable• ATEX Certifi edStandard Paint SpecificationThe standard external surface treatment consists of a 2 pack primer and 2 pack epoxy coating. This international marine coating is suitablefor chemical, coastal and offshore environments providing superior corrosion resistance.Primer Coat: Akzo Nobel Intergard 251, anticorrosive zinc phosphate epoxy primer, 75 microns DFT, color: KGA902-Red.Top Coat: Akzo Nobel Intergard 740 epoxy finish, 2 mills DFTFinished Color: ECK724 – Storm Grey, High Gloss9

Product Specification• <strong>Actuator</strong> shall be designed in accordance with EN15714-3 to defi ne minimum cycle life performance and designed for on-off andmodulating service.• <strong>Actuator</strong> output shall meet ISO rated torque compliance to provide safe mounting interface and comply with ISO 5211/MSS SP-101mounting standards and NAMUR VDI/VDE standards for accessory mounting.• <strong>Actuator</strong> shall have a symmetrical torque module to simplify fi eld service and interchangeability of spring and air modules. Manualoverrides and mounting is consistent for both spring and torque module to simplify mounting.• The actuator torque module shall utilize an interchangeable yoke system to allow simple fi eld conversion of symmetrical and cantedyokes.• The spring module shall use a pull-to-compress motion with single or concentric-nested springs that are internally supported andguided and weld secured for safety.• The spring module shall be designed for minimum length and weight to improve the center of gravity, reduce material stress andassembly support requirements.• The actuator shall have hard chrome plated cylinder walls to provide superior corrosion and wear resistance.• The actuator piston sealing should use advanced Quad Seal technology to provide enhanced cycle life compared to conventionalO-Rings.• The internal support guide rods, spring rods and piston rods shall be hard chrome plated for superior corrosion and wear resistance.• The pneumatic cylinder shall use external retention rods to provide visual confi rmation and inspection of rod integrity for increasedsafety.<strong>Actuator</strong> Model DesignationHow to Order<strong>Series</strong>BodySizeCylinder SizeActionSpringModuleTorque Pattern(Yoke)Sealing/Temp Manual Override Material/ Coatings Options1 05 06 07 08 09 10 12 DA- Double Acting Single Cylinder 0 S- Symmetrical N- Nitrile, 0- None GE- Grey Epoxy (std) 00- None-20˚ F to 180˚ F2 08 09 10 12 14 16 DD- Double Acting Dual Cylinder 1 C- Canted G- Sandwich Declutch Gbox PO- Primer Only TC- Ext. Stopper -CW3 10 12 14 16 18 20 2 H- High Temp J- Jackscrew WE- White Epoxy TO- Ext. Stopper -CCW4 14 16 18 20 22 24 3(Viton),0˚ F to 300˚ F D- Bevel Gear Jackscrew SP- Specials TB- Ext. Stopper -Both Dir<strong>RG</strong>5 16 18 20 22 24 28 4 L- Low Temp, H- Hydraulic S xxx- Specials code(material)6 18 20 22 24 28 32 36 SR- Spring Return Fail CW 5-55˚ F to 180˚F7 24 28 32 36 40 SO- Spring Return Fail CCW 68 28 32 36 40 78Model Code Example:<strong>RG</strong> 5 22 SR 6 C N D GE TC10

flowserve.comManual Override OptionsJackscrewHydraulicSandwich GearBevel GearTorque DA SRModelISOMountingN-min-lbDirectOperationJackscrewBevelGearSandwichDeclutchableGearHydraulicDirectOperatorJackscrewBevelGearSandwichDeclutchableGearHydraulic<strong>RG</strong>1 F14 2000 17702 – – – –<strong>RG</strong>2 F16 4000 35404 – – – –<strong>RG</strong>3 F25 8001 70808 <strong>RG</strong>4 F30 16002 141616 – – <strong>RG</strong>5 F35 32005 283232 – – <strong>RG</strong>6 F40 63010 557613 – – – – – – <strong>RG</strong>7 F48 125020 1106375 – – – – – – <strong>RG</strong>8 F60 248600 2212750 – – – – – – 11

Sales and service facilitiesare strategically located inindustrial centers throughoutthe world.Controls & AccessoriesThe actuator is the heart of anautomation system, but control accessoriesare important in creating acomplete system to meet increasinglysophisticated customer requirements.Solenoid valves and related accessorieswith NAMUR interfaces provide direct,modular mounting on actuator.Switches, Positioners, Gear Overridesand Lockout Modules can also beintegrated into the assembly. Automationmounting brackets, “AutoBrakit” withmounting hardware are engineered toassure consistency and properalignmentTo Access Literature OnlineEvery item in this catalog has a brochure containinga great deal of technical product detail. It’s easy tofind… it’s free… and you do not need a password.Do This:1 Go to www.flowserve.com2 Click in the box thatsays “Literature”3 Enter keyword orliterature number4 Click on “Search"The most recent version of each product bulletin will beavailable on this site.Once you have the PDF, you can: • read it• print it• download it• even e-mail itFlowserve Flow Control (UK) Ltd.Burrell RoadHaywards HeathWest Sussex United KingdomRH16 1TLPhone: +44 1444 314400Fax: +44 1444 314401Flowserve Flow Control Benelux BVRechtzaad 174703 RC Roosendaal NBNetherlandsPhone: +31 165 598 800Fax: +31 165 555 670Flowserve CorporationFlow Control Division1978 Foreman DriveCookeville, Tennessee 38501 USAPhone: +931 432 4021Fax: +931 432 5518www.flowserve.comFlowserve Flow Control GmbHRudolf Plank Str. 2D-76275 EttlingenGermanyPhone +49 (0)7243 103 0Fax +49 (0)7243 103 222Flowserve Flow Control GmbH<strong>Automax</strong> Valve AutomationIm grossen Rohr 2D-65549 LimburgGermanyPhone: +49 (0)6431 96610Fax: +49 (0)6431 966130Flowserve S.R.LVia Prealpi 30Cormano MI Italy I - 20032Phone: +39 02 663251Fax: +39 02 6151863Flowserve Ahaus GmbHvon-Braun-Str. 19a48683 AhausPhone: +49 2561 686-119Fax: +49 2561 686-109Flowserve CorporationFlow Control Division1350 North Mountain Springs ParkwaySpringville, Utah 84663-0913 USAPhone: +801 373 3028Fax: +801 489 2228Flowserve CorporationNo. 35, Baiyu RoadSuzhou Industrial ParkSuzhou 215021, Jiangsu Province, PRCPhone: +86-512-6288-1688Fax: +86-512-6288-8737Flowserve Australia Pty LtdFlow Control Division14 Dalmore DriveScoresby, Victoria 3179AustrialiaPhone: +61 3 9759 3300Fax: +61 3 9759 3301Flowserve Pte LtdNo. 12 Tuas Avenue 20Singapore 638824Phone: +65 6879 8900Fax: +65 6862 4940Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected this Flowserve product is designed to perform itsintended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applicationsunder a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possibleapplications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products.The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safeuse of Flowserve products in connection with the specific application.While the information and specifications contained in this literature are believed to be accurate they are supplied for informative purposes only and should not be considered certifiedor as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, expressed or implied, regarding any matter withrespect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject tochange without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.Unit 01\02\06\07 9FChina Fortune TowerNo. 1568, Century Avenue, PudongShanghai China 200122Phone: +86 21 38654800Fax: +86 21 50811781Flowserve do Brasil LtdaRua Tocantins, 128 - Bairro Nova GertiSão Caetano do Sul,São Paulo 09580-130 BrazilPhone: +5511 4231 6300Fax: +5511 4231 6329 - 423FCD AXEBR1002-03© Flowserve Corporation12