You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Central Heating Solutions<br />

<strong>Power</strong> <strong>flushing</strong> <strong>pump</strong>s for professionals<br />

NEW! MORE POWER,<br />

MORE CAPACITY<br />

Clearflow CF40<br />

Evolution<br />

Why buy from <strong>Kamco</strong>?<br />

1. We build our own <strong>pump</strong>s, and give<br />

first hand advice on selecting the<br />

right <strong>pump</strong> for your needs.<br />

2. We have full back-up facilities, with<br />

telephone help line, training, spares,<br />

and servicing.<br />

“My Clearflow<br />

<strong>pump</strong> is the best<br />

earning tool I’ve<br />

ever bought”<br />

PB, Harrow<br />

Telephone help line:<br />

+44 (0) 1727 875020<br />

The<br />

ultimate<br />

power <strong>flushing</strong><br />

<strong>pump</strong>!<br />

Clearflow CF90<br />

Quantum2<br />

3. The <strong>Kamco</strong> in-house training facility.<br />

Sessions include a power flush on a<br />

functioning heating system.<br />

4. We equip engineers with far more<br />

knowledge and insights than they<br />

could gain elsewhere.<br />

“My next power<br />

flush will be<br />

number 1274 so you<br />

really have a great<br />

product” RF, Kent<br />

<strong>Power</strong> <strong>flushing</strong> is the<br />

most effective method<br />

of cleaning existing heating<br />

systems, especially those<br />

containing a high level of black<br />

magnetite sludge. (Bs7593 : 2006.)<br />

f: +44 (0) 1727 875335<br />

www.kamco.co.uk<br />

With <strong>Kamco</strong> CLEARFLOW<br />

power <strong>flushing</strong> <strong>pump</strong>s<br />

you get:<br />

• Ultra high flow rates for<br />

maximum cleansing power.<br />

• Free training course with<br />

every <strong>pump</strong>.<br />

• <strong>Kamco</strong> help line support,<br />

service workshop.<br />

• Guaranteed future spares<br />

availability.<br />

• Instantaneous flow reverser.<br />

• Reversible dumping facility.<br />

• Acid proof - descales<br />

combination boilers, water<br />

heaters, and other equipment.<br />

• Hoses and fittings ready<br />

assembled.<br />

• Extreme portability -<br />

wheel, or carry.<br />

• Run dry capability;<br />

75°C operation.<br />

• Starter pack of chemicals<br />

for 2+ jobs.<br />

• Hose carry container.<br />

• Free mainland delivery.<br />

• Promotional leaflets.<br />

• Link to your website.<br />

5. Reassurance: from the original<br />

<strong>Power</strong> Flushing company, producing<br />

<strong>pump</strong>s since 1992.<br />

6. We don’t just sell you a box - you<br />

get technical support from well<br />

informed professionals.<br />

© <strong>Kamco</strong><br />

“Fast, personal<br />

service and great<br />

people within<br />

the company”<br />

Corgi customers<br />

Unit 9, Curo Park, Frogmore,<br />

St. Albans, Herts AL2 2DD UK<br />

e: info@kamco.co.uk

Telephone help line:<br />

+44 (0) 1727 875020<br />

Pumps for <strong>flushing</strong> domestic and small commercial systems<br />

Technical data<br />

and what’s<br />

included with a<br />

CLEARFLOW<br />

<strong>pump</strong>.<br />

CF40 EVOLUTION CF90 QUANTUM 2<br />

Flushing capability 20/25 radiators max; 2/3 storeys 40 radiators max; 3 storeys<br />

Tank 39 litre capacity translucent HDPE 57 litre capacity translucent HDPE<br />

Electric motor size 0.50 HP, IP54 rating, 230 or 110 volt 0.75 HP, IP54 rating, 230 or 110 volt<br />

Max.flow rate 90 lt/min 150+ lt/min<br />

Max. head 20 mt 24 mt<br />

Max. temperature 75 ° C 75 ° C<br />

Flow reverser type instantaneous instantaneous<br />

Control valves<br />

2 x 3-port combination valves for isolation and<br />

dumping<br />

2 x 3-port combination valves for isolation and<br />

dumping<br />

Flow and return hoses 2 x 5 metre hoses, 16 mm I.D. re-inforced PVC 2 x 5 metre hoses, 19 mm I.D. re-inforced PVC<br />

Hose end fittings 3/4” x 16 mm tool-free brass hose couplings 3/4” x 19 mm tool-free brass hose couplings<br />

Dump hose 1 x 8 metre, 16 mm I.D. re-inforced PVC 1 x 8 metre, 19 mm I.D. re-inforced PVC<br />

Water inlet hose 1 x 8 metre ultra tough water hose pipe 1 x 8 metre ultra tough water hose pipe<br />

Overflow hose 1 x 3 metre, 16 mm I.D. re-inforced PVC 1 x 3 metre, 19 mm I.D. re-inforced PVC<br />

Other hoses supplied 2 x adaptor hoses for connection to 1.5”<br />

circulator <strong>pump</strong> fittings.<br />

2 x adaptor hoses for connection to 1.5”<br />

circulator <strong>pump</strong> fittings.<br />

Carrying / transport Integral handle; 75mm wheels Integral handle: large diameter 200mm wheels.<br />

Weight (without hoses) 17 kg 22.5 kg<br />

Chemical handling ability<br />

All commercially available acids,<br />

alkaline solutions, chlorine solutions.<br />

Dimensions (mm), w x d x h 390 x 440 x 690 390 x 590 x 890<br />

Also included<br />

Training<br />

All commercially available acids,<br />

alkaline solutions, chlorine solutions.<br />

Starter pack of <strong>flushing</strong> chemicals, inhibitor, and pH test strips, sufficient for 2+ power <strong>flushing</strong> jobs.<br />

10 part set of BSP adaptors.<br />

Comprehensive operations manual.<br />

Waterproof plastic hose set carry container.<br />

Pack of 50 promotional leaflets explaining the benefits of power <strong>flushing</strong> to householders.<br />

Other Clearflow models available are:<br />

The CLEARFLOW CF190, with 0.75 HP motor mounted on a<br />

100 litre tank, with flow rates up to 170 lt/min, and maximum head of 22<br />

metres. Suitable for power <strong>flushing</strong> commercial and industrial systems, and<br />

for descaling commercial boilers, calorifiers, chillers, and water heaters.<br />

CF40 wheels<br />

FREE proficiency training at St Albans Training Centre.<br />

© <strong>Kamco</strong>

Using a CLEARFLOW TM <strong>pump</strong> to power flush a heating system<br />

Attachment of the CLEARFLOW to a heating<br />

system may be made by several different<br />

methods, the choice of which will depend<br />

on accessibility and practicality:<br />

1. Across the system circulator <strong>pump</strong><br />

couplings, after removal of the <strong>pump</strong>.<br />

A set of adaptor leads is included with<br />

every CLEARFLOW <strong>pump</strong>.<br />

2. Using the CP2 adaptor (an optional extra)<br />

to connect onto the body of the system<br />

circulator <strong>pump</strong>, after removing the electric<br />

motor. This is the preferred method when<br />

<strong>flushing</strong> combi boiler systems, as the plate<br />

heat exchanger (primary water side) can<br />

also be power flushed without removal<br />

from the boiler.<br />

3. Across the flow and return connections at<br />

the boiler, effectively isolating the boiler<br />

itself, the preferred method when <strong>flushing</strong><br />

a system prior to replacing a boiler.<br />

4. Across the “tails” of one radiator, having<br />

drained and disconnected this radiator<br />

only. The standard CLEARFLOW hose<br />

Step-by-step guide<br />

to power <strong>flushing</strong><br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

If system is vented, cap off the cold<br />

feed and expansion pipe.<br />

Connect Clearflow <strong>pump</strong> into heating<br />

system. Connect dump, water inlet,<br />

and overflow hoses to Clearflow<br />

<strong>pump</strong>.<br />

Open all radiator and lock-shield<br />

valves, and set zone valves to manual<br />

position, for full flow throughout<br />

system.<br />

Switch on Clearflow <strong>pump</strong>, and<br />

circulate for ten minutes, reversing<br />

flow regularly.<br />

Start dumping. Adjust inlet water to<br />

ensure tank water level remains<br />

constant. Allow to run until dump<br />

water is relatively clear.<br />

Set Clearflow into circulation mode,<br />

with full flow through the whole<br />

heating system (all radiator valves<br />

open).<br />

Boiler<br />

3<br />

Circulator<br />

<strong>pump</strong><br />

1<br />

2<br />

ZONE<br />

fittings will connect on to 3/4” radiator<br />

valves, and adaptors are supplied to fit<br />

1/2” radiator valves.<br />

5. Breaking into one ‘run’ of larger diameter<br />

pipework, using push-fit or compression<br />

connections adapted to 3/4” male BSP.<br />

It is necessary to make a heating system into<br />

a closed circuit, by capping off the cold feed<br />

and expansion pipes, or by looping them<br />

together (if they are not close-coupled).<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

Pour 2.5 litres POWER FLUSH FX2<br />

<strong>flushing</strong> chemical (or one litre of<br />

Hyper-Flush) into Clearflow tank.<br />

If possible, switch on boiler to<br />

heat water to 50 o C. It is not<br />

necessary to leave boiler firing<br />

continuously.<br />

Continue circulation through wide<br />

open system for fifteen minutes,<br />

to distribute chemical, whilst<br />

reversing flow regularly.<br />

Shut off all radiator valves except<br />

for one radiator. Allow full flow<br />

through this radiator for five<br />

minutes, reversing flow regularly.<br />

Shut off first radiator, and move<br />

to second. Work around system,<br />

putting full flow through each<br />

radiator in turn.<br />

After circulating through last<br />

radiator, switch to dumping on<br />

that one radiator, until water runs<br />

crystal clear.<br />

Operate flow reverser and appropriate<br />

valves to dump with water<br />

flow in opposite direction, until<br />

water again runs clear.<br />

f: +44 (0) 1727 875335<br />

www.kamco.co.uk<br />

5<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Removing the circulator <strong>pump</strong>, and connecting across<br />

the fittings, using the supplied extension adaptor hoses.<br />

Using aCP2 circulator <strong>pump</strong> head adaptor.<br />

Connecting across the flow and return pipe work after<br />

removing the boiler.<br />

Removing one radiator only, and connecting Clearflow<br />

flow and return hoses on to the valve bodies.<br />

Breaking in to arun of copper pipe and using push-fit<br />

connections.<br />

4<br />

Alternative Clearflow<br />

connection locations<br />

When using POWER FLUSH FX2 liquid, this<br />

method can also clear deposit accumulations<br />

at the lower end of the cold feed pipe, a<br />

problem frequently found in conventional<br />

open vent heating systems.<br />

Comprehensive instructions for use are<br />

included with every CLEARFLOW <strong>pump</strong>, and<br />

the telephone help line service ensures that<br />

<strong>pump</strong> users can get helpful and experienced<br />

advice on using both equipment and chemicals.<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

Unit 9, Curo Park, Frogmore,<br />

St. Albans, Herts AL2 2DD UK<br />

e: info@kamco.co.uk<br />

Open up previous radiator, and dump<br />

on that until water runs clear. Work<br />

around system in reverse, dumping<br />

through each radiator alone in turn.<br />

Restore circulation through<br />

Clearflow <strong>pump</strong> and complete heating<br />

system with all radiator valves wide<br />

open.<br />

Add contents of one tube Neutralising<br />

Crystals to tank, and circulate for ten<br />

minutes. Omit this stage if using Hyper-<br />

Flush, as it is a pH neutral product.<br />

Commence final dump procedure, with<br />

all radiators wide open. Allow to run<br />

until dump water is crystal clear.<br />

Test that dump water is neutral with<br />

pH meter or paper, and add Systemsafe-DM<br />

corrosion inhibitor to<br />

Clearflow tank.<br />

© <strong>Kamco</strong><br />

Circulate for ten minutes before<br />

disconnecting Clearflow <strong>pump</strong>,<br />

restoring system to normal operation,<br />

and bleeding radiators.

Telephone help line:<br />

+44 (0) 1727 875020<br />

The chemicals and accessories to use with Clearflow TM <strong>pump</strong>s<br />

POWER FLUSH FX2 and HYPER-FLUSH are formulated to<br />

penetrate, loosen and break down corrosion debris and<br />

sludge into small particles, which are then forcibly expelled<br />

from the system by the high water velocity generated by<br />

a Clearflow <strong>pump</strong>. Whilst high water velocity alone will<br />

remove some debris from heating systems, the smaller the<br />

particle size, the greater is the effect of the moving water,<br />

hence the dramatic increase in <strong>flushing</strong> efficiency when<br />

using POWER FLUSH FX2 and HYPER-FLUSH.<br />

<strong>Power</strong> Flushing<br />

Chemicals<br />

Performance<br />

tested!<br />

<strong>Power</strong> Flush FX2<br />

high performance <strong>flushing</strong><br />

chemical for maximum<br />

debris removal.<br />

Hyper-Flush<br />

non acidic mobiliser and<br />

solvent for sludge and<br />

iron oxides. Used when<br />

aluminium radiators or heat<br />

exchangers are present.<br />

Systemsafe-DM<br />

scale and corrosion inhibitor<br />

for all domestic heating<br />

systems. Systemsafe-DM<br />

carries the Buildcert /<br />

DWTA logo, proof that<br />

it has passed a tough<br />

performance test in a<br />

laboratory independently<br />

monitored by Buildcert.<br />

Neutralising<br />

Crystals<br />

used after power <strong>flushing</strong><br />

with FX2 to neutralise any<br />

residues.<br />

pH Paper<br />

to check that water<br />

within heating system is<br />

completely neutral.<br />

Foambreaker<br />

Antifoam<br />

Central Heating Solutions<br />

f: +44 (0) 1727 875335<br />

www.kamco.co.uk<br />

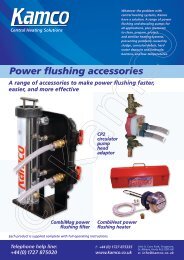

<strong>Power</strong> Flushing Accessories<br />

Stockist:<br />

Unit 9, Curo Park, Frogmore,<br />

St. Albans, Herts AL2 2DD UK<br />

e: info@kamco.co.uk<br />

FOR THE BEST RESULTS<br />

WHEN USING A CLEARFLOW<br />

PUMP, USE POWER FLUSH FX2<br />

OR HYPER-FLUSH.<br />

CP2 Circulator Pump<br />

Head Adaptor<br />

reduces set-up time and<br />

enables thorough <strong>flushing</strong> of<br />

combi systems.<br />

CombiMag <strong>Power</strong><br />

Flushing Filter<br />

reduces power <strong>flushing</strong> time,<br />

increases efficiency and saves<br />

water.<br />

CombiHeat <strong>Power</strong><br />

Flushing Heater<br />

heats system water to boost<br />

<strong>flushing</strong> chemical efficiency.<br />

Radhammer Vibrator<br />

Tool<br />

loosens compacted debris<br />

from radiators.<br />

Systemsure IK6<br />

Injector Unit<br />

enables chemicals to be<br />

added into sealed and vented<br />

systems through bleed valves.<br />

Plate Heat Exchanger<br />

Adaptor Set<br />

enables plate heat exchangers<br />

to be thoroughly flushed.<br />

Infra-Red Laser Spot<br />

Thermometer<br />

the engineer’s ‘eye’ inside a<br />

heating system.<br />

ecoTestr electronic<br />

TDS meter<br />

checks water purity after a<br />

power flush.<br />

ecoTestr electronic pH<br />

meter<br />

checks that system water has<br />

a neutral pH.<br />

Turbidity Tube<br />

checks clarity of water after a<br />

power flush.<br />

Water Analysis Kit<br />

enables system water to be<br />

checked for corrosion and<br />

contaminants.<br />

Pipestopper Plugs<br />

enables expansion and cold<br />

feed pipes to be quickly<br />

capped off.<br />

Electric Syphon Pump<br />

saves time and mess when<br />

emptying f&e tanks.<br />

Waterproof<br />

Maintenance Mat<br />

stops accidental water<br />

damage.<br />

© <strong>Kamco</strong>