Whirlybird Wind Turbine User Manual - Super Science Fair Projects

Whirlybird Wind Turbine User Manual - Super Science Fair Projects

Whirlybird Wind Turbine User Manual - Super Science Fair Projects

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

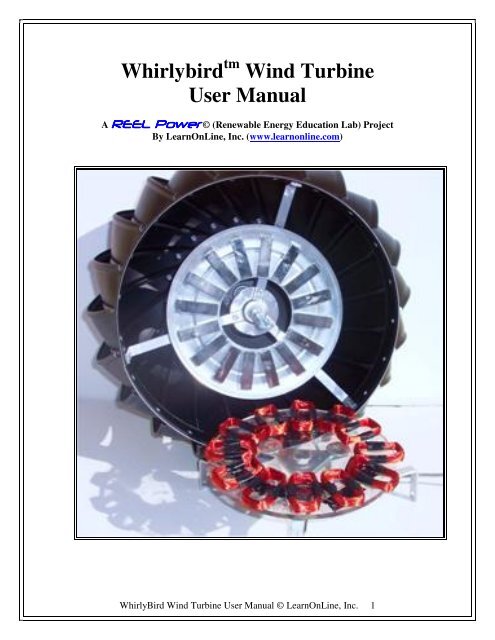

<strong>Whirlybird</strong> tm <strong>Wind</strong> <strong>Turbine</strong><br />

<strong>User</strong> <strong>Manual</strong><br />

A REEL Power © (Renewable Energy Education Lab) Project<br />

By LearnOnLine, Inc. (www.learnonline.com)<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 1

Contents<br />

1. Overview<br />

2. Intended Use<br />

3. General Safety Precautions<br />

4. Related Issues<br />

5. Assembling the <strong>Wind</strong> <strong>Turbine</strong><br />

6. Attaching to the 3-Phase Bar Graph Board<br />

<strong>Wind</strong> <strong>Turbine</strong> Design and <strong>User</strong> <strong>Manual</strong> by…<br />

LearnOnLine, Inc. – creator, sponsor and host of the REEL Power © Project<br />

567 W. Channel Islands Blvd. #101<br />

Port Hueneme, CA 93041<br />

e-mail information@learnonline.com<br />

website www.learnonline.com<br />

Caution<br />

This kit contains powerful magnets.<br />

People with pacemakers should not<br />

handle or go near strong magnets.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 2

1. Overview<br />

Imagine creating a 3-phase wind turbine from<br />

a common, everyday roof ventilator along<br />

with some magnets and coils of wire. That’s<br />

what we’ve created for your study of wind<br />

technology.<br />

We chose the <strong>Whirlybird</strong> tm<br />

several reasons.<br />

roof ventilator for<br />

First, it has great bearings that simply will not<br />

wear out under normal – and even severe –<br />

use. Without great bearings your wind<br />

turbine is always fighting friction that only<br />

serves to slow it down with the attendant loss<br />

of power.<br />

Second, it can be easily constructed<br />

with common tools and without<br />

soldering or drilling.<br />

Third, it can be used indoors and<br />

[especially] outdoors where your<br />

study of day-to-day and season-byseason<br />

wind never stops.<br />

Fourth, it produces 3-phase power<br />

just like the commercial wind<br />

turbines, which allows you to study<br />

this marvelous electrical principle first<br />

hand by using your computer and our<br />

3-phase Bar Graph Board.<br />

And, fifth, you will be able to modify it in order to study the effects of magnetism<br />

and how you can optimize the mechanical components to produce maximum power.<br />

Here is what is included in the <strong>Whirlybird</strong> tm <strong>Wind</strong> <strong>Turbine</strong> Kit:<br />

12 Wire Coils<br />

16 Bar magnets<br />

1 6-position terminal block<br />

1 8” diameter round metal rotor disk<br />

1 8” diameter round Plexiglas stator disk<br />

1 5/16”, 7/8” long threaded rod extender<br />

1 5/16”, 1 ½” long bolt<br />

10 5/16” flat washers<br />

3 1” flat washers<br />

Lomanco <strong>Whirlybird</strong> tm model B1B-12 roof ventilator purchased separately at Home<br />

Depot and other home improvement outlets.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 3

2. Intended Use<br />

The hardware, software and experiments are developed exclusively for educational<br />

teaching and demonstration purposes. Any other use such as in life-critical applications is<br />

prohibited!<br />

3. Safety Precautions<br />

In order to avoid any risks, you must abide by the following Safety Precautions when<br />

working with the <strong>Whirlybird</strong> tm <strong>Wind</strong> <strong>Turbine</strong>.<br />

• The system may only be set up and operated by a competent person. Younger<br />

students require adult supervision at all times.<br />

• Read the assembly instructions and experiments before executing them.<br />

• The <strong>Whirlybird</strong> tm <strong>Wind</strong> <strong>Turbine</strong> is not a toy. Assemble and operate it<br />

responsibly. The use of safety glasses and protective gloves while assembling<br />

the wind turbine and performing experiments is highly recommended<br />

• READ AND UNDERSTAND EACH ASSEMBLY PROCEDURE BEFORE<br />

EXECUTING IT. This will help to understand what is to be done and, also,<br />

prevent inadvertent mistakes that could lead to incorrect results or possible injury.<br />

• LearnOnLine, its distributors or affiliates will not accept responsibility for injuries<br />

or damage sustained in the event that these Safety Precautions not followed<br />

completely.<br />

Caution<br />

This kit contains powerful magnets.<br />

People with pacemakers should not<br />

handle or go near strong magnets.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 4

4. Related Issues<br />

4.1 Reverse Engineering<br />

You are not entitled to reverse engineer, decompile or disassemble the software product<br />

in whole or in part.<br />

4.2 Errors and Omissions<br />

LearnOnLine has made every effort to supply the software and hardware without errors;<br />

however, we are not responsible for any unintentional errors or omissions in the design,<br />

construction or operation of the product. If you should notice undiscovered errors, please<br />

contact us.<br />

LearnOnLine, Inc.<br />

information@learnonline.com<br />

4.3 System Requirements<br />

<strong>Wind</strong>ows Pentium class computer with USB interface port. MACs with INTEL<br />

processors can use Parallels “Desktop 3.0 for Mac”.<br />

4.4 Software Installation<br />

You will need administrator rights for software installation under <strong>Wind</strong>ows 2000,<br />

<strong>Wind</strong>ows XP or <strong>Wind</strong>ows Vista.<br />

4.5 Warranty<br />

LearnOnLine, Inc. warrants its products against defects in materials and workmanship for<br />

a period of 90 days. If you discover a defect, LearnOnLine will, at its option, repair,<br />

replace or refund the purchase price. Simply contact us at information@learnonline.com.<br />

4.6 Disclaimer of Liability<br />

LearnOnLine, Inc. is not responsible for special, incidental or consequential damages<br />

resulting from any breach of warranty, or under any legal theory, including lost profits,<br />

downtime, goodwill, damage to or replacement of equipment or property, and any costs<br />

for recovering or reproducing any data stored in or used with LearnOnLine products.<br />

LearnOnLine is also not responsible for any personal damage, including that to life and<br />

health, resulting from use of any of our products. You take full responsibility for using<br />

LearnOnLine products and experiments no matter how life threatening it may be.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 5

5. Assembling the <strong>Wind</strong> <strong>Turbine</strong><br />

You are about to begin a worthwhile and engaging project by creating a 3-phase wind<br />

turbine from a common, everyday roof ventilator, some magnets and coils of wire.<br />

Before starting first check to see that you have the following component parts that came<br />

with your kit to begin assembly:<br />

1 Lomanco <strong>Whirlybird</strong> tm roof ventilator (purchased separately)<br />

12 Wire Coils<br />

16 Bar magnets<br />

1 6-position terminal block<br />

2 8” diameter round metal rotor disk<br />

2 8” diameter round Plexiglas stator disk<br />

1 5/16”, 7/8” long threaded rod coupler<br />

2 5/16”, 1 ½” long bolt<br />

3 1” flat washers<br />

10 5/16” flat washers<br />

You will also need the following tools and materials to complete the assembly:<br />

• Flat head screwdriver<br />

Crescent wrench<br />

• Grease marking pen<br />

Multimeter<br />

• Pocket or Exacto tm knife<br />

2-part Epoxy Glue + stirring stick<br />

• Latex gloves & Safety Glasses Electrical tape<br />

• Length of 6-conductor wire (length to be determined by your setup)<br />

The <strong>Whirlybird</strong> tm <strong>Wind</strong> <strong>Turbine</strong> is designed to work with the 3-Phase Bar Graph<br />

Board. You are not required to have this board; however, the experiments towards the<br />

end of this <strong>User</strong> <strong>Manual</strong> use the 3-Phase Bar Graph Board along with your computer<br />

for graphic display.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 6

Part 1 – Preparing the <strong>Wind</strong> <strong>Turbine</strong> for Assembly<br />

1.1 The core part of the wind turbine assembly is the <strong>Whirlybird</strong> 12” diameter roof<br />

ventilator manufactured by Lomanco (part number B1B-12). You can find it in most<br />

Home Depots or other hardware stores in the roofing section. It looks like this all<br />

packaged up in its box (left). Carefully remove the staples, open the top and this is<br />

what you will see inside (right).<br />

1.2 Remove the wind turbine from the box and turn it over (left). You will see that<br />

the 3-leg triangular base is attached to the fan assembly by a single nut. Remove the<br />

nut and washer and save them for later use (right).<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 7

1.3 Next, remove the 3-leg base assembly by holding onto the fan struts with one<br />

hand and carefully wiggling off the leg assembly (left) with the other. Then screw on<br />

the 7/8” threaded rod coupler to the fan’s shaft (right). Finger tight is fine.<br />

1.4 With the 3-leg base sitting upright (below) place a 1” flat washer on each of the<br />

three rivets on the top triangular section. Mix a small portion of epoxy glue and dab<br />

the glue into the middle of each washer to hold the washer to the aluminum section.<br />

Use a plastic knife or a Popsicle stick to mix and dab the epoxy. BE VERY<br />

CAREFUL NOT TO INHALE THE FUMES AND, ALSO, WEAR<br />

PROTECTIVE GLOVES AND SAFTEY GLASSES. Allow the glue to dry for<br />

about 10 to 15 minutes.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 8

Part 2 – Assembling the Magnet Rotor<br />

Caution<br />

This kit contains powerful magnets.<br />

People with pacemakers should not<br />

handle or go near strong magnets.<br />

2.1 Starting with the 16 bar magnets, use a grease pen to mark each magnet’s side<br />

with an “N” and the opposite side with an “S” for North and South. It’s not important<br />

to know which side is actually North or South, only that they are marked as opposites.<br />

If you really want to know North from South, use a compass needle to indicate which<br />

is which. Do this with the remainder of the magnets. Be careful not to allow the<br />

magnets to crimp your fingers…they are very powerful!! Also, wear safety<br />

glasses since the magnets may shatter and fling sharp particles into your eyes.<br />

The magnets should look like this when finished (right).<br />

2.2 Next, place the 16 magnets around the edge of the 8” metal disk with the large<br />

hole in the middle. Make sure to alternate the magnets N-S-N-S…. as shown below.<br />

This is VERY IMPORTANT, which is why you marked them North and South in the<br />

first place. This may take some time since the magnets will want to snap together.<br />

Once in place, epoxy the each magnet to the metal disk by lifting up on the magnet<br />

and dabbing a bead of epoxy to the top and bottom ends. Use a plastic knife or a<br />

Popsicle stick to mix and to dab the epoxy. BE VERY CAREFUL NOT TO<br />

INHALE THE FUMES AND, ALSO, WEAR PROTECTIVE GLOVES AND<br />

SAFETY GLASSES. This epoxy sets very quickly so make sure you have the<br />

magnets correctly arranged before you start.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 9

2.3 After the epoxy has had a chance to<br />

set, temporally place the magnet disk on the<br />

fan struts of the wind turbine. Holding the<br />

center shaft in one hand, carefully give the<br />

turbine fan a gentle spin to see if the rotor<br />

disk is centered on the shaft. Adjust the<br />

rotor disk until it is properly centered. With<br />

a grease pen mark the struts to indicate the<br />

disk’s outer edge. You can now epoxy the<br />

disk to the struts by placing a dab of epoxy<br />

both on each strut and the corresponding<br />

back of the metal disk. Before the epoxy has<br />

a chance to set, again make sure that the disk<br />

is centered. BE VERY CAREFUL NOT<br />

TO INHALE THE FUMES AND, ALSO,<br />

WEAR PROTECTIVE GLOVES AND SAFETY GLASSES.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 10

Part 3 – Assembling the Coil Stator<br />

3.1 There are twelve coils that form the 3-phase<br />

electrical coil assembly. With a pocket or Exacto tm<br />

knife carefully strip away about ½ inch of the<br />

enamel coating from both ends of each coil. Make<br />

sure all the enamel has been stripped away. Be<br />

careful not to cut your fingers in the process.<br />

3.2 You will need to add more length to the coil<br />

ends so “gently” pull one wire at a time towards you to find where it starts. Then pull<br />

the wire out from the electrical tape to make it longer.<br />

3.3 Strip the paper from the 8” Plexiglas disk.<br />

3.4 Place four coils around<br />

the disk in the 12, 3, 6 and 9<br />

o’clock positions as shown.<br />

Make sure that the coil wire<br />

ends face the outside of the<br />

plastic disk.<br />

Put a dab of epoxy on the<br />

bottoms of each coil and<br />

adhere it to the plastic disk.<br />

This will form Phase 1 of the<br />

three coil phases.<br />

3.5 Twist tie<br />

three of the coil<br />

wire ends<br />

together going<br />

from the left wire<br />

of one coil to the<br />

right wire of the<br />

next coil. There<br />

should be two<br />

free wires<br />

remaining from<br />

two of the coils.<br />

The free ends in<br />

the photo are on<br />

the coils in the 3<br />

and 6 o’clock<br />

positions.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 11

3.6 Turn the plastic disk<br />

over and fold over the<br />

twisted wire ends to the<br />

underside of the disk. Apply<br />

a piece of electrical tape to<br />

hold them to the disk.<br />

3.7 Place a dab of epoxy<br />

glue on the end of the 6<br />

position barrier strip and<br />

glue it to the underside of the<br />

disk as shown.<br />

3.8 With a grease pen label<br />

the screws as 1 through 6 as<br />

shown.<br />

3.9 Attach the left-most<br />

free wire to screw #1 and the<br />

right-most free wire to screw<br />

#2 and screw them in place.<br />

Make sure that these wires are attached to the screws nearest the outer edge of the<br />

disk, as the equivalent inner screws will eventually attach to a cable leading to the 3-<br />

Phase Bar Graph Board.<br />

The wire attachments should<br />

look like this on the screw<br />

terminals.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 12

3.10 Repeat the<br />

procedure for the<br />

next four coils.<br />

3.11 Attach the<br />

left-most free wire<br />

to screw terminal #3<br />

and the right-most<br />

free wire to screw<br />

terminal #4.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 13

3.12 Repeat the<br />

procedure for the<br />

last four coils.<br />

3.13 Attach the<br />

left-most free wire<br />

to screw terminal<br />

#5 and the rightmost<br />

free wire to<br />

screw terminal #6.<br />

Tip<br />

If the coils get<br />

crowded<br />

together, squeeze<br />

the inner part of<br />

the coils so that<br />

they fit better<br />

side by side.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 14

3.14 Before going further it’s time to test the coil<br />

connections with a multimeter. Set the multimeter<br />

dial to resistance (sometimes indicated by the ohm<br />

symbol). Next, apply the probes to screw terminals<br />

#1 and #2. If all is correct, the reading should be<br />

between 25 and 30 ohms. This is the total resistance<br />

of the first four coils taken together (in series). If<br />

your reading is well above this value, you probably<br />

have an “open circuit” and need to re-check the coil<br />

connections as they most likely are not stripped of<br />

enable and are not making contact. Re strip the wires<br />

and re twist them together again. Then check the<br />

other two coil arrangements between screw terminals<br />

#3 and #4 as well as #5 and #6. Repeat the repair<br />

procedure if the coil resistance is not within limits.<br />

3.15 Add another dab<br />

of epoxy to the three 1”<br />

washers on the<br />

triangular leg assembly<br />

and “CAREFULLY”<br />

place the Plexiglas disk<br />

on top of the screws<br />

with the black terminal<br />

block on the underside<br />

of the disk facing down.<br />

Make sure that the hole<br />

in the disk is centered<br />

on the hole in the<br />

triangular leg assembly.<br />

THIS IS VERY<br />

IMPROTANT!!<br />

Keep the disk<br />

centered on the hole in<br />

the triangular<br />

assembly.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 15

Part 4– Putting It All Together<br />

Before putting the stator and rotor assemblies together take some time to examine the<br />

stator coils. They should be flat with no wires sticking up. One way to ensure this is to<br />

put a large telephone book on top of the coils to squash them down. If you take the time<br />

to do this and let it sit overnight, it will bring you a better working wind turbine. Even if<br />

you don’t flatten the coils now, you can take the wind turbine apart to do this at a later<br />

time. So, let’s get going on putting it all together….<br />

4.1 To finalize the<br />

connection between the<br />

rotor and stator assemblies,<br />

insert the 1.5”, 15/16” bolt<br />

through the bottom of the<br />

stator assembly with 1 or 2<br />

flat washers near the head<br />

of the bolt. Push the bolt<br />

through the center hole in<br />

the triangular base<br />

assembly then add about 4<br />

or 5 flat washers capped<br />

off with the nut that you<br />

saved from step 1.2. If<br />

you don’t have the nut<br />

anymore simply add a few more washers to the bolt. The nut just makes it easier to<br />

handle. Regardless, make sure that the free end of the bolt has about 1/2” of thread<br />

exposed.<br />

4.2 Now insert the<br />

triangular base through<br />

the threaded rod coupler,<br />

which is connected to the<br />

fan assembly. Screw the<br />

two assemblies together<br />

by rotating the threaded<br />

rod coupler in a counterclockwise<br />

direction with<br />

your thumb. Gently<br />

wiggle the triangular base<br />

assembly to make sure<br />

that the coils are not<br />

scraping the magnets. If<br />

they are, disassemble the<br />

two parts and flatten out the coils with a phone book as weight or add another washer.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 16

Part 5 – First Tests<br />

5.1 Before doing anything else, place the turbine base on a flat surface and give the<br />

turbine fan a GENTLE spin. If you hear any scraping noise this means that the coil<br />

wires are scraping against the magnets. Unbolt the base and fan assembly by<br />

unscrewing the threaded rod coupler and add another washer to the 1.5” 15/16” bolt.<br />

This should correct the problem. If it doesn’t, add yet another washer. Remember,<br />

however, that each additional washer will increase the space between the coils and<br />

magnets, thus producing less magnetic coupling and less voltage and current output.<br />

The whole idea is to reduce the gap between the coils and magnets to a minimum.<br />

Therefore, disassemble the two parts and check to see how best to reduce this gap.<br />

Now to see how well the wind turbine generates voltage.<br />

5.2 With the multimeter set to AC<br />

voltage on a range between 0 and 5<br />

volts place the meter probes on screw<br />

terminals #1 and #2 then give the<br />

turbine a good spin. You should<br />

experience a voltage reading between<br />

1 and 4 volts AC depending on how<br />

fast you spin the turbine. Repeat the<br />

test for screw terminals 3 & 4 and 5 &<br />

6. If you get the same general voltage<br />

reading on all three screw terminal<br />

pairs this indicates that the turbine is<br />

working correctly.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 17

5.3 It’s now time to hookup a multi-wire cable to the terminal block. You will need<br />

to get a length of 6 conductor stranded or solid wire for this next step. It should be<br />

long enough to reach from where you will eventually place the wind turbine to where<br />

your computer is located. You can go to Home Depot and get a length of any size<br />

CAT-5 cable, which is normally used for Ethernet cables. It comes as 8 conductor<br />

solid wire, so there are two extra wires in the cable. Or if you search around you can<br />

find 6 conductor cables at Home Depot or at distributors like Digikey, Mouser or<br />

Jameco. Whatever you do, don’t pay extra for expensive cables – this project does<br />

not require them. Hookup the cable as in the photo below and make sure to note<br />

which colors are connected to which screw terminals. Then use a tie wrap to secure<br />

the cable to one of the aluminum struts to relieve any strain on the connection to the<br />

screw terminals.<br />

Congratulations!!!<br />

If the voltage tests worked you have successfully completed the wind turbine assembly<br />

portion of the project. However if you’re still experiencing problems, review the<br />

previous steps to see if you have done all the things correctly. Sometimes haste makes<br />

for mistakes.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 18

Part 6 - Attaching to the 3-phase Bar Graph Board<br />

6.1 Attach the<br />

wire cable from the<br />

<strong>Whirlybird</strong> tm <strong>Wind</strong><br />

<strong>Turbine</strong>’s 6-screw<br />

terminal block to<br />

the equivalent pin<br />

numbers on the 3-<br />

Phase Bar Graph<br />

Board. These<br />

numbers are<br />

clearly marked on<br />

the side of the<br />

board. Simply<br />

strip the wire cable<br />

ends, push down<br />

on the springloaded<br />

terminals<br />

and insert the<br />

wires. Gently pull<br />

on each one to<br />

make sure that a<br />

good connection is<br />

made.<br />

P1 P2 P3 DC<br />

3-Phase Bar Graph Board<br />

Battery<br />

X2<br />

X1<br />

Power<br />

USB<br />

USB<br />

LOAD<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

1 2 3 4 5 6<br />

6.2 If you are at your computer attach the USB cable between the 3-Phase Bar Graph Board<br />

and the computer’s USB port. If you’re not at the computer, insert a fresh 9-volt battery into the<br />

3-Phase Bar Graph Board. Set the toggle switch on the bottom-center of bhe board to the left<br />

for battery operation and to the right for USB operation. In either case you should see the four bar<br />

graph LEDs illuminate simultaneously three times; this is a test to make sure that all the LEDs are<br />

working.<br />

6.3 Set the Voltage Scale switch to the X1 position (down). The Voltage Scale switch is to the<br />

right of the USB connector. This means that each LED represents 1 volt. Setting the switch to<br />

the X2 postion simply doubles the voltage of each LED from 1 volt to 2 volts. You can change the<br />

X1 – X2 setting at anytime.<br />

6.4 Now give the turbine a spin. The Phase 1, Phase 2 and Phase 3 LED bar graphs should<br />

illuminate in order with Phase 1 then Phase 2 then Phase 3. The fourth vertical set of LEDs<br />

indicate the DC voltage being generated. If you don’t see this happening, go back and recheck<br />

the wire hookup between the wind turbine and the 3-Phase Bar Graph Board. It’s probably a<br />

loose wire or one that is not stripped of insulation that’s causing the problem.<br />

If you have come this far please refer to the 3-Phase Bar Graph <strong>User</strong> <strong>Manual</strong> for detailed<br />

installation and operating insturctions plus interesting computer experiments.<br />

WhirlyBird <strong>Wind</strong> <strong>Turbine</strong> <strong>User</strong> <strong>Manual</strong> © LearnOnLine, Inc. 19