You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

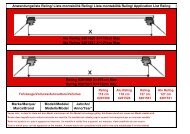

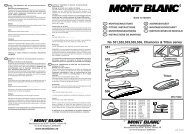

Assembly instruction for towbar<br />

Motor vehicle data<br />

Only to be used in motor vehicles with terminal chassis cross members and towing<br />

blocks with a 56 x 83 mm hole pattern.<br />

Towbar including bracket - data<br />

Type: 68-1 D-value up to <strong>24</strong>,8 kN<br />

EG No: e1 00-0157 Nose load up to 250 kg<br />

Art. No: 259 334<br />

General<br />

• THE TOWBAR INCLUDING BRACKET MUST ONLY BE USED FOR ITS<br />

INTENDED PURPOSE.<br />

• The nose load and towing capacity for the vehicle are stated in the vehicle<br />

documents. The D-value and the nose load of the tow bar must not be<br />

exceeded.<br />

• Modification of width across feat from DIN to ISO standart requires different tooles<br />

sizes for same nominal thread width.<br />

Attention is very important!<br />

• Prior to assembly a check should be made for transport damage and completeness of<br />

kit.<br />

• Remove underseal from vehicle where towbar will be fitted. Re-apply corrosion<br />

protection following fitment of tow bar assembly.<br />

• Any modifications to towbar / ball including the bracket will invalidate approval<br />

documents and warranty.<br />

• Any changes carried out on the vehicle necessary for towing must be checked with the<br />

car approval documents and the vehicle manufacturer.<br />

• Bolt torque:<br />

M 10 = 49 Nm<br />

• Bolt type: 8.8<br />

• The assembly diagram is shown on page 2.<br />

551542D_engl.DOC Blatt 1 von 3

Typenschild<br />

551542D_engl.DOC Blatt 2 von 3

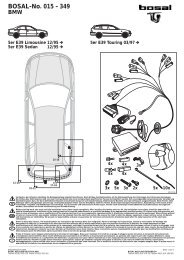

Assembly:<br />

1. The towing ball with mounting must be fastened with 4 x M10 ( 8.8) hexagonalheaded<br />

screws, spring washers and nuts to terminal chassis members or trailer<br />

blocks with a 56 x 83 mm hole pattern.<br />

2. Align towbar and tighten all bolts according to torque.<br />

3. Re-paint areas where you have removed underseal.<br />

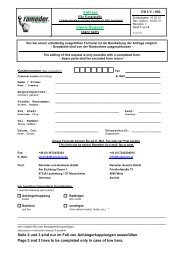

4. Attach the plate showing the nose load to the vehicle near to the towing bracket or<br />

on the inside of the boot in a clear and visible position.<br />

• The assembly and clearance measurements are according to EG 94/20.<br />

• Determined fixing points of vehicle manufacturer are used.<br />

• Electrical kit must be installed.<br />

• Tow ball must be kept clean and if necessary greased.<br />

• The assembly instructions should be kept with the car documentation.<br />

• After 1000km of towing trailers all the bolts and nuts of the towing bracket must be<br />

retighened with the relevant torque.<br />

Manufacturer:<br />

AL-KO Kober<br />

Ichenhauser Str. 14<br />

D-89359 Kötz<br />

551542D_engl.DOC Blatt 3 von 3