3/4 automatic screen printing machine, suitable for flat substrates up ...

3/4 automatic screen printing machine, suitable for flat substrates up ...

3/4 automatic screen printing machine, suitable for flat substrates up ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

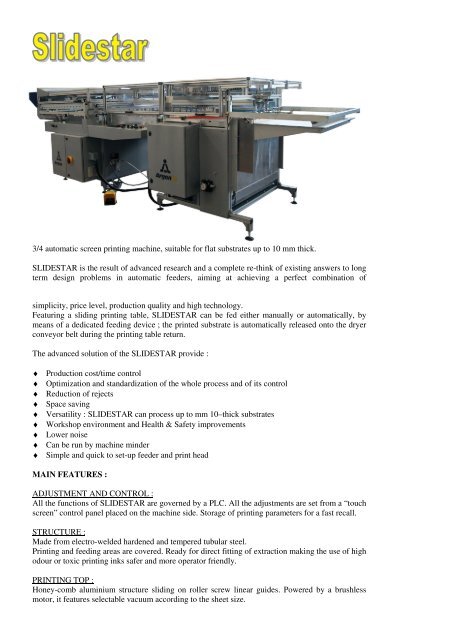

3/4 <strong>automatic</strong> <strong>screen</strong> <strong>printing</strong> <strong>machine</strong>, <strong>suitable</strong> <strong>for</strong> <strong>flat</strong> <strong>substrates</strong> <strong>up</strong> to 10 mm thick.<br />

SLIDESTAR is the result of advanced research and a complete re-think of existing answers to long<br />

term design problems in <strong>automatic</strong> feeders, aiming at achieving a perfect combination of<br />

simplicity, price level, production quality and high technology.<br />

Featuring a sliding <strong>printing</strong> table, SLIDESTAR can be fed either manually or <strong>automatic</strong>ally, by<br />

means of a dedicated feeding device ; the printed substrate is <strong>automatic</strong>ally released onto the dryer<br />

conveyor belt during the <strong>printing</strong> table return.<br />

The advanced solution of the SLIDESTAR provide :<br />

♦ Production cost/time control<br />

♦ Optimization and standardization of the whole process and of its control<br />

♦ Reduction of rejects<br />

♦ Space saving<br />

♦ Versatility : SLIDESTAR can process <strong>up</strong> to mm 10–thick <strong>substrates</strong><br />

♦ Workshop environment and Health & Safety improvements<br />

♦ Lower noise<br />

♦ Can be run by <strong>machine</strong> minder<br />

♦ Simple and quick to set-<strong>up</strong> feeder and print head<br />

MAIN FEATURES :<br />

ADJUSTMENT AND CONTROL :<br />

All the functions of SLIDESTAR are governed by a PLC. All the adjustments are set from a “touch<br />

<strong>screen</strong>” control panel placed on the <strong>machine</strong> side. Storage of <strong>printing</strong> parameters <strong>for</strong> a fast recall.<br />

STRUCTURE :<br />

Made from electro-welded hardened and tempered tubular steel.<br />

Printing and feeding areas are covered. Ready <strong>for</strong> direct fitting of extraction making the use of high<br />

odour or toxic <strong>printing</strong> inks safer and more operator friendly.<br />

PRINTING TOP :<br />

Honey-comb aluminium structure sliding on roller screw linear guides. Powered by a brushless<br />

motor, it features selectable vacuum according to the sheet size.

TAKE-OFF DEVICE :<br />

The patented system <strong>for</strong> the unloading of the printed substrate allows <strong>printing</strong> the whole substrate<br />

with no gripper margin ; the printed sheet is dropped directly onto the dryer conveyor belt.<br />

PRINTING HEAD AND PRINTING BRIDGE :<br />

The <strong>printing</strong> head is made <strong>up</strong> of two linear bars, where the <strong>printing</strong> carriage slides, and the frame holding bars.<br />

The <strong>printing</strong> head features a few mm lifting to allow <strong>printing</strong> table travel <strong>for</strong> sheet loading/unloading operations.<br />

For <strong>screen</strong> cleaning purposes the <strong>printing</strong> head features a 450 mm lift.<br />

♦ Printing top driven by a “brushless” motor, granting smooth operation<br />

♦ Independently adjustable <strong>printing</strong> stroke<br />

♦ Independently adjustable <strong>printing</strong> and flooding speeds<br />

♦ Squeegee and scraper pressure micro adjustable<br />

♦ Off-contact, peel-off and registration micro adjustable<br />

♦ Pneumatic control of squeegee/scraper inversion<br />

♦ Frame loading from both sides of the <strong>machine</strong><br />

♦ Movable hood above the <strong>printing</strong> head <strong>for</strong> the fitting of the exhaust system<br />

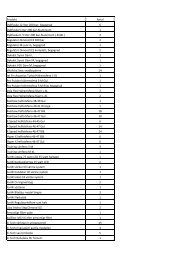

Technical data :<br />

Mod. 1 Mod. 2<br />

Max <strong>printing</strong> size mm 500 x 700 720 x 1020<br />

Max sheet size mm 510 x 710 750 x 1050<br />

Max <strong>screen</strong> size mm 780 x 980 1190 x 1380<br />

Max substrate thickness mm 10 10<br />

Mechanical speed Cycles/h 800<br />

Air consumption Lt/h 250 250<br />

Std. power s<strong>up</strong>ply<br />

400 V – 50 Hz 3-ph<br />

Air pressure BAR 6 6<br />

Installed power (with feeder) kW 4,5 4,5<br />

Installed power (without feeder) kW 3 3<br />

Weight (with feeder) Kg 700<br />

Weight (without feeder) Kg 500<br />

Length (with feeder) mm 3200<br />

Length (without feeder) mm 2000<br />

Width mm 1450<br />

Height mm 1400 1400<br />

Max pile height mm 470 470<br />

Max pile weight Kg 200<br />

Cmp Forni policy is aimed at continuous product improvement.<br />

The right is there<strong>for</strong>e reserved to amend specifications with no prior notice. CMP is not responsible <strong>for</strong> typographic errors.<br />

27013 CHIGNOLO PO (PV) ITALY LOCALITA’ CASOTTINA 36/B<br />

COD. FISC. E P.IVA 01811760188 –REA N. 223311 – R.I. (PV-1999-16207)<br />

TEL./FAX 0039 0382-766550 – www.cmp<strong>for</strong>ni.com – e.mail info@cmp<strong>for</strong>ni.com