REFINERY NEWS May 2012

REFINERY NEWS May 2012

REFINERY NEWS May 2012

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MAY <strong>2012</strong><br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 1

7 8 12<br />

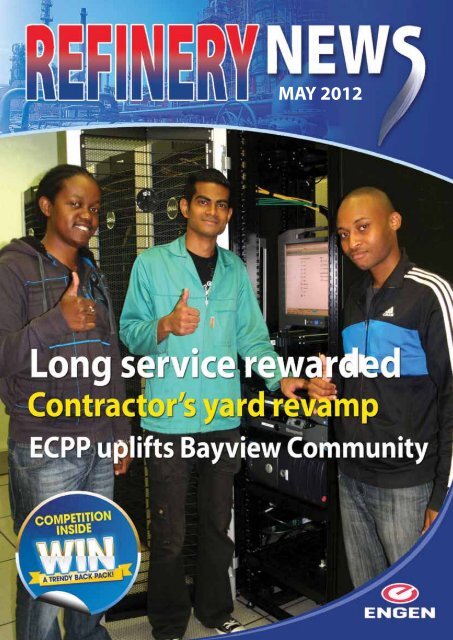

COVER: Control Systems Engineer, Neville Mshengu, Junior Process Control Technician, Ashlin Pillay and Process Control trainee, Andile<br />

Mthiyane were at the forefront of installing new equipment cabinets in the PCC. Read story on pg3<br />

Contents<br />

Process Control Network upgrade 3<br />

Rope Access services save Enref time and money 4<br />

Engen Computer School changing lives 5<br />

Long Service rewarded 6<br />

Durban EMSS Programmes produce excellent results 7<br />

Engen Relieves stationery burden 8<br />

Engen opens new supplementary education centre 8<br />

Contractor’s yard revamp 9<br />

Caring for the elderly 9<br />

New Switchgear for Refinery substations 10<br />

Lee-Ann tackles Midmar Challenge 11<br />

Competition 11<br />

ECPP uplifts Bayview Community 12<br />

6<br />

This newsletter is produced by the Public Affairs Department of<br />

The Engen Refinery.<br />

Send comments and feedback to:<br />

Thabisile Gumede<br />

Tel: 031 460 3617 OR<br />

E-mail: thabisile.gumede@engenoil.com<br />

Layout and Design by<br />

<strong>May</strong> Birthdays<br />

Sudesh Sarjoo<br />

1st Aniel Sahue<br />

Ntuthuko Mabaso<br />

1st Alistair Groom<br />

Siphamandla Chili<br />

1st Pule Molefe<br />

Anesh Sewduth<br />

1st Nelson Govender<br />

Ray Bhagwandin<br />

3rd Alfred Mhlongo<br />

Brian Lloyd<br />

4th Shabeer Mahomed<br />

Musa Ndwandwe<br />

4th Sandile Nzimakwe<br />

Melvin Jansen<br />

4th Zukisa <strong>May</strong>a<br />

Suren Ruthnum<br />

4th Michael Sharp<br />

Garry Pitman<br />

5th Strini Moodley<br />

Dhevan Naidoo<br />

5th Mellanie Chetty<br />

Rob Balfour<br />

6th Patrick Canham<br />

Links Govender<br />

6th Thokozani Langa<br />

Thabani Zondi<br />

6th Chad Van Der Merwe<br />

Steven Moodley<br />

7th Dave Moodley<br />

Learn Bhendane<br />

7th Romeo Sibiya<br />

Celeste Hudson<br />

8th Vikash Devraj<br />

Nokukhanya Dlamini 8th Vernon Mudaly<br />

Ceshan Hanuvanth<br />

9th Silindele Sithole<br />

Cyprian Shezi<br />

10th Jodie Peters<br />

Segren Govender<br />

10th Suren Naidoo<br />

Justin Gunkel<br />

10th Deveron Wagner<br />

Phindile Ngcobo<br />

11th Riaz Kajee<br />

Lizwe Dube<br />

11th Innocent Sekwaila<br />

Reginald Gasa<br />

12th Heather Seidle<br />

Kurt Seidle<br />

13th Cody Brauns<br />

Avir Ramkissoon<br />

13th Charles Koster<br />

Jeeten Jagadis<br />

14th Michele Padayachee<br />

Thobelani Boyana<br />

14th Famida Mohamed<br />

Burtie Dercksen<br />

15th Clairissa Padayachee<br />

Siyethaba Maphumulo 15th Charmaine Xaba<br />

Johnny Moodley<br />

Musa Ndwandwe<br />

Jerrold Lazarus<br />

Silindile Mathe<br />

Ronald Naidu<br />

Service anniversaries<br />

16th<br />

17th<br />

17th<br />

20th<br />

21st<br />

21st<br />

21st<br />

21st<br />

21st<br />

23rd<br />

23rd<br />

24th<br />

24th<br />

24th<br />

25th<br />

25th<br />

26th<br />

26th<br />

26th<br />

27th<br />

28th<br />

28th<br />

28th<br />

28th<br />

29th<br />

29th<br />

30th<br />

30th<br />

30th<br />

30th<br />

31st<br />

5 Years<br />

5 Years<br />

5 Years<br />

10 Years<br />

20 Years<br />

2 // engen Refinery news <strong>May</strong> <strong>2012</strong>

Process Control Network Upgrade<br />

Above: Before upgrade<br />

Above: After upgrade<br />

In with the new, out with the old. This is exactly what has happened in the PCC where five spanking new computer cabinets<br />

have replaced old cabinets that are no longer suitable for the Process Control computer equipment currently in use.<br />

The Process Control Network and<br />

Infrastructure Upgrade which is currently<br />

underway at the PCC was born of the<br />

need to improve the reliability of Process Control<br />

network systems. This not only meant upgrading<br />

the servers, but also introducing new cabinets<br />

to house and protect the computer equipment<br />

effectively and neatly.<br />

Control Systems Engineer, Neville Mshengu says<br />

the new cabinets provide better network cable<br />

management whereby cables are neatly tied and<br />

the cabinets provide better cooling for equipment<br />

and save space. Up to 42 units can now be installed<br />

in a cabinet whereas previously, only a maximum<br />

of five units could be installed per cabinet.<br />

“The three-phase project began with upgrading<br />

of the Historian (PHD) and Advanced Control<br />

old and smaller equipment cabinets have been<br />

upgraded with Dell D4220 cabinets to ensure<br />

security of the control network cables and higher<br />

reliability thereof,” he says.<br />

Subsequent to this will be the engineering of the<br />

Process Control Network domain and installation<br />

of the firewall between the Business Information<br />

Network and Process Control Network for better<br />

domain administration and management and<br />

Process Control network data security.<br />

Neville adds that although the project has not<br />

been without its fair share of challenges, it was<br />

well worth it. “The biggest challenge we have had<br />

is ensuring that while the project is underway that<br />

no disruptions occur to the control network as well<br />

as minimizing loss of data from the servers during<br />

upgrade.”<br />

(RMPCT) servers. Now in its second phase, the<br />

Above: Junior Process Control Technician, Ashlin Pillay says being part of<br />

this project was a great learning experience<br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 3

Rope Access Services save Enref<br />

time and money<br />

In these tough economic times every cent counts, which is why Enref is delighted to have saved more than<br />

R14m on scaffolding costs during the refurbishment of over 23 storage tanks.<br />

The contracting company - Acumax (Pty)<br />

Ltd, supplied Engen with a comprehensive,<br />

cost-effective, safe and environmentallyfriendly<br />

solution for Ultra-high pressure Water<br />

Blasting, Grit blasting and protective coating<br />

utilizing Rope Access Services on above-ground<br />

storage tanks.<br />

To date, Acumax have UHP blasted/ grit blasted<br />

and painted a total of 41361m2 of tankage<br />

surfaces and used a total of 24817 Litres of paint<br />

with a total of 64 800 man hours at the refinery.<br />

Plant maintenance Deputy Manager, John<br />

Naidoo says the benefits of rope access include<br />

minimal impact on structures and surroundings,<br />

including traffic flow and pedestrian access,<br />

in comparison to the use of scaffolding, which<br />

makes substantial cost savings and minimal<br />

downtime possible. “Acumax has not only saved<br />

the Refinery money but during the year that they<br />

were contracted (between 2010 and 2011) they<br />

completed over 23 above-ground storage tanks<br />

utilizing Rope Access Services with zero lost-time<br />

incidents and zero near misses,” says John.<br />

Acumax was established in 2006 and is run<br />

by highly experienced, South African, expatriate<br />

management teams who have worked abroad<br />

providing maintenance and inspection services in<br />

the oil and gas industry.<br />

In 2011, Acumax was acquired by The SGS<br />

Group which is the largest inspection, verification,<br />

testing and certification organization in the world.<br />

Being part of the SGS Industrial Services global<br />

network has provided Acumax with massive<br />

growth and expansion opportunities and the<br />

prospect of supplying additional services to<br />

companies such as Engen and other significant<br />

industry participants in Southern Africa.<br />

4 // engen Refinery news <strong>May</strong> <strong>2012</strong>

Above: Eighty-two graduates were presented with certificates for successfully completing a basic computer course at the Engen Computer School<br />

Engen Computer School changing lives<br />

Refinery Call Centre Operator, Nokukhanya<br />

Dlamini thought she knew all she needed<br />

to know about computers until she heard<br />

about the Engen Computer School run by the<br />

Added Advantage Academy which is operated on<br />

the Refinery’s behalf.<br />

Enrolling in the course was easy; the challenge<br />

was finding time to attend the day course as<br />

Nokukhanya works shifts at the Call Centre.<br />

Determined to complete the course she chose to<br />

work night shifts for six months for the duration<br />

of the course.<br />

“It was not easy working night shifts every<br />

day but I knew that my sacrifice would lead to<br />

success. The course exceeded my expectations<br />

and I learnt many new skills. The facilitators are<br />

very knowledgeable and we all forged life-long<br />

relationships,” says Nokukhanya.<br />

She is one of 82 Engen Community Computer<br />

Training Centre graduates who received their<br />

certificates at a recent certification ceremony held<br />

at the Refinery.<br />

Five pensioners who also received their<br />

certificates proved that one is never too old to<br />

learn. Retired Wentworth Councillor, Derrick<br />

Parsons (75) says he was inspired to do the<br />

computer course when he saw people sitting<br />

at an internet café. “I looked at them and they<br />

seemed to be having fun and I thought this is an<br />

interesting challenge – I must learn how to use a<br />

computer.”<br />

More than 500 students have acquired new<br />

computer skills since Engen embarked on the<br />

partnership with Added Advantage in 2009. These<br />

have included added proficiency with a personal<br />

computer mouse, the keyboard and general<br />

competence at using Microsoft programmes like<br />

MS word, Excel and PowerPoint as well as emailing<br />

and logging onto the internet.<br />

Director of the Programme, Sheryll Cassalis says<br />

over 120 students who were unemployed before<br />

taking up the course are now employed. She<br />

believes that this can partly be attributed to the<br />

computer literacy as well as business skills they<br />

have learnt at the Training Centre.<br />

Above: Call Centre Supervisor, Brenda Ndlovu and Public Affairs Manager,<br />

Thandeka Cele congratulate Refinery Call Centre Operator, Nokukhanya<br />

Dlamini (centre) on her achievement<br />

Right: Refinery Fire Fighter, Jabulani Sithole (left) who also<br />

attended the course to enhance his computer skills, encourages<br />

other Refinery employees to attend the course<br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 5

Some of the long service award recipients for <strong>2012</strong><br />

Long Service rewarded<br />

In March the Refinery recognised and paid tribute to employees who have passed various long service<br />

milestones ranging from five, to 40 years service.<br />

Refinery GM, Kamal Bahrin Ahmad,<br />

personally thanked each individual for<br />

their contributions and loyalty to the<br />

organisation often sacrificing time with families<br />

when the Refinery needed them.<br />

Certificates were handed out for five, ten, 15, 20,<br />

25, 30, 35 and 40 years. Most of the recipients were<br />

cheered and applauded as they went up to receive<br />

their certificates.<br />

At the top of the list was Clean Fuels Process<br />

Manager, Dave Laurence who has been with the<br />

Refinery for 40 years. Dave is one of the more<br />

jovial personalities at the Refinery, and has a knack<br />

of making people laugh with his entertaining<br />

anecdotes. Dave joined the refinery as a Junior<br />

Chemical Engineer and has seen the Refinery go<br />

through both good and bad times. He started<br />

working at Engen when it was still called Mobil<br />

and still considers Engen to be one of the best<br />

companies to work for. Now Dave is using all<br />

his acquired knowledge to give direction and<br />

guidance of how all fuel specifications will change<br />

into the future in his assignment to the Clean Fuels<br />

project.<br />

Others who have spent most or all of their<br />

working life at the Refinery for 30 years and above<br />

include HSEQ Manager, Lynne Hanekom who<br />

never shies away from a challenge regardless of<br />

how daunting the task. She started off as an agile<br />

engineer and has a vast knowledge of Refinery<br />

operations and is always willing to share her<br />

knowledge with others around her.<br />

Refinery Security manager, Nicholas Ngubo<br />

takes the safety and security of every individual<br />

at the Refinery very seriously and has a high level<br />

of commitment to his work. The same goes for<br />

Laboratory Supervisor Francis Mkize who started<br />

off at the lab as a junior technician and worked his<br />

way up to becoming a supervisor,<br />

a position he has now held for<br />

the past 12 years. He is a very<br />

knowledgeable and hands<br />

on person when it comes to<br />

his work. These two<br />

gentlemen are<br />

just two out<br />

of 16 refinery employees who received certificates<br />

for completing 30 years of service.<br />

Another familiar face around the Refinery is IS<br />

System Support Specialist, Roger Crawley who<br />

speaks fondly about the past and the people<br />

who joined the company at the same time as him<br />

35 years ago. Roger is also one of nine refinery<br />

colleagues who have completed 35 years at Engen.<br />

6 // engen Refinery news <strong>May</strong> <strong>2012</strong>

Durban EMSS Programmes<br />

produce excellent results<br />

For most learners being 35km from a<br />

classroom would be more than sufficient<br />

reason to skip lessons.<br />

Not for Nqobile Hlongwane. She was a pupil at<br />

Mqhawe High School in Inanda (about 35km<br />

North of Durban; on the extreme opposite side<br />

of the city to Umlazi). Nevertheless she went to<br />

great lengths to make sure she was able to attend<br />

the Engen supplementary education programme<br />

at Mangosuthu University of Technology (MUT),<br />

not just occasionally, but every day.<br />

Nqobile, with help from a caring and generous<br />

teacher made sure that distance was not an<br />

obstacle to attending the supplementary tutorials.<br />

Their efforts were handsomely rewarded when<br />

Nqobile passed all her matric subjects with<br />

distinctions. She was fortunate that a grade 11<br />

teacher at her school, Mrs Shabane recognised her<br />

potential and each day, used her own car to drive<br />

Nqobile from Inanda to Umlazi and back to attend<br />

the extra tuition. The reward for this extraordinary<br />

dedication and sacrifice: Nqobile romped home<br />

81% for English, 81% for Physical Science and 86%<br />

for Mathematics in her matric exams.<br />

Not only that. Nqobile was the only matriculant<br />

to achieve distinctions in all her subjects at Mqhawe<br />

including Zulu, Life Science and Accounting.<br />

That has left here well placed to fulfill her dream<br />

Above: Fairvale Saturday school programme learners and educators<br />

of becoming a chartered accountant. She is now in<br />

her first year of studies for a B.Com in Accounting<br />

at the University of the Western Cape. “I found<br />

Physical Science very challenging but the Engen<br />

programme, through its tutorials, provided the<br />

support that I needed.”<br />

Hard work and dedication has paid off for over<br />

100 learners who attended the Engen Maths<br />

and Science School (EMSS) Programme. An<br />

awards ceremony was held that the Refinery to<br />

recognise and reward these learners for passing<br />

their supplementary programme subjects with<br />

distinction. The successful students received<br />

vouchers for each relevant distinction. The<br />

vouchers will help pay further education costs.<br />

The Fairvale group notched 22 As and 43 Bs<br />

while the Mangosuthu group achieved 62 As<br />

and 84 Bs. Learners in the programme from both<br />

the Mangosuthu and Fairvale Saturday school<br />

programmes have again done Engen proud by<br />

achieving top matric marks in Maths Physical<br />

Science and English subjects.<br />

The extra-curricular tutorials for learners<br />

attending schools in the Bluff, Wentworth and<br />

Merebank areas are hosted at the Fairvale<br />

Secondary school while lessons for learners in the<br />

Umlazi district are hosted at the MUT.<br />

Engen relieves stationery burden<br />

As ever there was widespread excitement<br />

when schools reopened for the <strong>2012</strong><br />

year. But some youngsters faced the<br />

new term with trepidation. They didn’t have, and<br />

could not afford, the exercise books, pens, rulers<br />

and other stationery necessary for their lessons.<br />

Their families cannot afford school fees let alone<br />

high-priced stationery for the children. As part of<br />

the CSI outreach programme, Engen has extended<br />

a helping hand to two schools in the neighbouring<br />

community - Settlers Primary School and Nizaam<br />

Road Primary by providing stationery for learners<br />

from indigent families. At Settlers ten learners<br />

are benefitting from the stationery and another<br />

ten at Ocean View Primary School. Settler’s<br />

Primary principal, I.Y Naidoo says he is extremely<br />

grateful to Engen for providing this much needed<br />

contribution. “It will go a long way to assist these<br />

learners to participate in everyday educational<br />

activities.” The Refinery has also donated stationery<br />

to the community through the local councilor,<br />

Aubrey Snyman who distributes it to a broader<br />

spectrum of the needy in the community.<br />

Top Right: The Refinery has also donated stationery to the community<br />

through the local councilor, Aubrey Snyman.<br />

Right: Refinery CSI Coordinator, Paul Makhanya with some of the learners who<br />

received stationery at Settlers primary school.<br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 7

Above: EMSS unveiling L-R Engen Corporate Affairs GM Natie Maphanga, DoE HOD Dr Nkosinathi Sishi, Cllr<br />

Speaker Logie Naidoo, Engen Refinery GM Kamal Ahmad, Refinery Public Affairs Manager Thandeka Cele<br />

Above: Principal of Ganges Secondary Deena Reddy, Lamontville Cllr Sthembiso Nzuza, Engen GM Corporate<br />

Affairs Natie Maphanga and Refinery GM Kamal Ahmad adress learners in the Saturday programme<br />

Engen opens new Supplementary<br />

Education Centre<br />

“Thank you Engen for playing and active role in the development of our youth in preparation for their future careers<br />

by making mathematics and science a priority thereby contributing to the future economy of our country”.<br />

This was the glowing commendation lauded<br />

upon Enref by HOD of the KZN Department<br />

of Education, Dr Nkosinathi Sish. Sishi<br />

made this statement during a keynote address at<br />

the opening, in the Durban<br />

South Basin (DSB),<br />

of the third Engen<br />

Maths and Science<br />

Supplementary (EMSS) education programme at<br />

Ganges Secondary School in Merebank. The other<br />

facilities are currently at Fairvale Secondary School<br />

on the Engen Refinery fence line and Mangosuthu<br />

University of Technology (MUT).<br />

Engen constantly strives to be at the forefront<br />

of the drive to enhance educational standards and<br />

bridge skills gaps, especially in our surrounding<br />

communities. Now the 232 learners enrolled at<br />

Merebank will no longer have to travel to Umlazi<br />

or Wentworth for special tuition in mathematics<br />

and physical science. Fairvale has 318 learners,<br />

whilst Mangosuthu has the highest enrollment of<br />

over 750 learners.<br />

The hugely successful EMSS offers learners in<br />

grades 10 to 12 three hours of mathematics and<br />

physical science on Saturdays (and daily in the case<br />

of MUT) throughout the year. A life-skills element<br />

is woven into the curriculum to help prepare<br />

youngsters for life after they have left school.<br />

The Ganges programme is facilitated by six<br />

educators and headed by Principal of Ganges<br />

Secondary, Deena Reddy, with the assistance of<br />

one administrator.<br />

Above: Ganges opening being addressed Dr Nkosinathi Sishi HOD KZN<br />

Department of Education<br />

Above: EMSS unveiling Education HOD, dignitaries, SDB Community stakeholders<br />

8 // engen Refinery news <strong>May</strong> <strong>2012</strong>

Contractor’s Yard revamp<br />

Enref is in the process of re-asserting its control of the contractor’s on-site fabrication yard and offices. That means<br />

that contractors doing business with Enref will have to operate from their own external bases.<br />

Over the years the contractor’s yard has<br />

been used by both Enref and third party<br />

companies- some of the more than 14<br />

third party companies have had bases on site for<br />

over 15 years.<br />

However, after an extensive re-assessment<br />

of the pros and cons in terms of the business<br />

processes the engineering department decided<br />

that a change was needed.<br />

Deputy Engineering Manager, Sibusiso Zulu<br />

says the concept of removing contractors from<br />

the Refinery came about when Engen realised<br />

that having contractor’s on site was becoming an<br />

increasing HSE risk in terms of added responsibility<br />

for Engen controlling the yard.<br />

“We considered the cost involved in keeping<br />

the contractor’s on site as well as the image the<br />

yard was creating for Enref and weighed this<br />

against cost saving on these logistics.”<br />

As a refinery we were spending a lot of money<br />

on constant supervision, security (badging, theft,<br />

and confidential info), controlling traffic and<br />

personnel movement, property damage.<br />

“Our research showed substantial savings in the<br />

long term and we devised an engineering control<br />

plan,” says Sibusiso. This plan includes discussions<br />

with relevant contractors and revisiting our<br />

current workflow processes to manage risks.<br />

Relocating from site, however, does not<br />

excuse contractors from complying with Engen<br />

regulations as safety audits will still be conducted<br />

regularly by appointed Engen staff. If contractors<br />

do not comply with regulations they will be<br />

instructed to stop work until deviation is corrected.<br />

Above: The contractor’s yards in the process of demolition<br />

Caring for the elderly<br />

Recently, CSI Co-ordinator Paul Makhanya along with Refinery Events<br />

co-ordiantor Heather Seidle visited Old age homes in Lamontville,<br />

Wentworth, Bluff and UMlazi to show them love and appreciation in<br />

their respective communities.<br />

The elderly patrons of four old age homes could not contain their excitement<br />

when Paul arrived unexpectedly to give them a variety of clothing.<br />

Above: Refinery Social Investment continues to build a caring brand image and positive perceptions.<br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 9

Above: Some of the team members involved in the refurbishment L-R: Keith Charlton, Ravi Moodley, Donovan and Andrew. Other team members that made this project a huge success were Mohammed Ayoob,<br />

Francis Perry and Mike Hancock.<br />

New Switchgear for<br />

Refinery substations<br />

The Refinery has taken a giant step forward in terms of reducing the risk of<br />

trips triggered by power outages. The refurbishment of five substations in the<br />

Combo, South Complex and Alky units should go a long way towards ensuring<br />

uninterrupted power supplies to these sections of the plant.<br />

Project Manager, Steven Moodley says<br />

the refurbishment of the substations will<br />

ensure that we are better equipped to<br />

manage equipment failure, handle power outages<br />

and pin-point the failure causes earlier.<br />

The refurbishment which was completed in<br />

four weeks, involved the replacement of obsolete<br />

switchgear – some of which had been in the<br />

Refinery since the Refinery’s early days.<br />

These challenges should be a thing of the past<br />

as the new switchgear should be much more<br />

reliable and it incorporates a fast fault clearance<br />

time. This means that in the event of a fault the<br />

state-of-the-art features speed up detection and<br />

resolution of problems. The substation equipment<br />

is also protected from catastrophic damage.<br />

As part of this electrical infrastructure upgrade<br />

substation T, which supplies the majority of power<br />

to the Alkylation plant is now equipped with two<br />

sources of supply where it was a single source<br />

supply in the past. “This will increase the reliability<br />

and availability of Substation T substantially,” says<br />

Steven.<br />

Safety is our first priority and the teams involved<br />

must be commended for executing this high risk<br />

project without a Lost Time Injury or Medical<br />

treatment Case and just one First Aid injury.<br />

Over and above that, the strong technical<br />

support and team commitment resulted in the<br />

project being completed on schedule, with<br />

minimum deviations and a significant cost saving<br />

in excess of 40% achieved by utilizing in-house<br />

Engen personnel for the project.<br />

Senior Reliability Electrical Engineer, Ravi<br />

Moodley says the project was “a complex project<br />

involving a lot of hard work, but dedication and<br />

commitment from the team, made this project a<br />

success”.<br />

Above: The substations after refurbishment<br />

10 // engen Refinery news <strong>May</strong> <strong>2012</strong>

Lee-Ann tackles Midmar Challenge<br />

Above: It was a cold morning at Midmar and Lee-Ann and her friend Lara put on plastic bags<br />

to keep warm before the race<br />

When Refinery Quality Systems<br />

Coordinator, Lee-Ann Olsen is not at<br />

the Refinery, you can be sure to find<br />

her in her bikini doing laps in a swimming pool<br />

or a local dam. No swimming challenge is too<br />

daunting for Lee-Ann and she proved it when<br />

she entered this year’s 39th Midmar Mile along<br />

with over 17 000 swimmers who participated in<br />

what has been hailed the world’s greatest open<br />

water swimming race. This being her first Midmar<br />

Mile, Lee-Ann says it was very challenging and<br />

she finished in 36 minutes<br />

and 44 seconds. “I would<br />

have liked to do better<br />

but it was very crowded in<br />

the water and the weather<br />

conditions were not good<br />

and as a result the water<br />

was choppy making the<br />

swim harder.” Despite these<br />

challenges, Lee-Ann says<br />

it was a great experience -<br />

enjoyable yet challenging<br />

and she is looking forward<br />

to next year’s Midmar race.<br />

Lee-Ann started swimming<br />

in September 2010 at the gym just to have fun<br />

and to keep her body fit. Seeing her growing<br />

passion for swimming, a friend suggested that<br />

she enter swimming competitions to challenge<br />

herself further. When she came<br />

across an advert in the paper<br />

encouraging swimmers to<br />

enter the 1Kilometre Capital ‘K’<br />

swim she rose to the challenge<br />

and completed the swim in 24<br />

minutes. She was then motivated<br />

to enter more swimming challenges and she<br />

entered the 1km challenge at Albert Falls and the<br />

Golden Mile. Seeking a greater challenge Lee-Ann<br />

then began entering 3km swim challenges.<br />

Now an avid swimmer, Lee-Ann trains four<br />

times a week to remain in tip-top shape. This year<br />

she is gearing up to enter 5km races and no doubt<br />

she will add to her collection of six medals she has<br />

clinched from all the races she has swum.<br />

If swimming is a bug, Lee-Ann has been infected<br />

as she says: “Every time I enter a swimming<br />

race I get excited about the next race and I am<br />

encouraged to enter another race.”<br />

Left: Lee-Ann proudly holds<br />

up her six medals<br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 11

ECPP Uplifts Bayview Community<br />

Above: The Bayview club runs successful school development programmes with a vision to build a drug free society. Pictured is the Bayview United<br />

FC Under 15 team which won the SAFA Chatsworth 2011 Knock-out Cup and the league with their trophy<br />

Uplifting the community is something that is close to the heart of the Refinery. This is why Engen has supported<br />

Refinery Laboratory Quality Chemist, Gary Moodley’s Bayview United Football Club through the Employee<br />

Community Partnership Programme (ECPP) for the past five years.<br />

The Bayview United Football Club founded<br />

11 years ago is committed to the upliftment<br />

of soccer and through the support of<br />

the ECPP funding; the club has managed to<br />

assist youngsters in the Bayview community by<br />

providing them with free soccer kit.<br />

As part of their community soccer development<br />

last year, the club gave away 15 sets of soccer kit<br />

to various underprivileged primary schools in the<br />

Bayview area. The club also runs successful schools<br />

soccer development programmes and a Bayview<br />

united schools Knockout Cup.<br />

Over the years, Gary says the club has<br />

recognised the need to focus more on community<br />

projects because strong, disciplined families<br />

build strong communities. The club has initiated<br />

a schools outreach programme and adopted<br />

eight underprivileged children from eight<br />

primary schools in the Bayview area and<br />

sponsored them with school uniforms.<br />

The programme has also been extended<br />

to three Secondary schools in the area.<br />

“We decided to extend the<br />

programme to learners in high schools<br />

because they are also experiencing<br />

many problems such as those related<br />

to drug and alcohol abuse, poverty,<br />

and lack of parental guidance. By<br />

providing them with food hampers,<br />

uniforms and introducing them to<br />

sport we believe we can make a<br />

difference in their lives,” says Gary.<br />

The Club completed a successful<br />

soccer season last year and continues to do what it<br />

can to turn its vision of a better future for Bayview<br />

community youngsters into a reality.<br />

Right: The Bayview United Football Club committee<br />

during a school outreach programme<br />

12 // engen Refinery news <strong>May</strong> <strong>2012</strong>