Tender Document - Oil India Limited

Tender Document - Oil India Limited

Tender Document - Oil India Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Oil</strong> <strong>India</strong> <strong>Limited</strong><br />

(A Govt. of <strong>India</strong> Enterprise)<br />

P.O. Duliajan – 786602, Assam<br />

Telephone No. (91-374) 2800491<br />

Fax No: (91-374) 2800533<br />

Email: material@oilindia.in ; erp_mm@oilindia.in<br />

<strong>Tender</strong> No. : SDG2354P12/09 of 14.06.2011<br />

<strong>Tender</strong> Fee : INR 4,500.00 OR USD 100.00<br />

Bid Security Amount : INR 7,35,100.00.00 OR USD 15,980.00<br />

(or equivalent amount in any currency)<br />

Bidding Type<br />

: SINGLE STAGE TWO BID SYSTEM<br />

Date of Pre-Bid Conference : 6 th September 2011<br />

Bid closing date<br />

: As mentioned in Basic data of above –tender in the OIL’s e-portal<br />

Bid Opening date : -do -<br />

Venue of Pre-Bid Conference : Kolkata, West Bengal, <strong>India</strong><br />

Performance Guarantee<br />

: Applicable<br />

OIL INDIA LIMITED invites Global <strong>Tender</strong>s for items detailed below:<br />

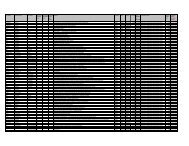

Item No. /<br />

Mat. Code<br />

10<br />

OC000242<br />

Material Description QTY. UOM<br />

Supply, Installation, Testing and Commissioning of 125 KVA Natural Gas<br />

Engine driven Generating sets with Acoustic Enclosure as per the<br />

following Annexure:<br />

a) Detailed specification – Annexure - I.<br />

b) Bid Rejection Criteria (BRC) and Bid Evaluation Criteria – Annexure- II.<br />

c) Technical & Commercial Check list vide Annexure - III.<br />

8 Nos.<br />

Notes:<br />

1.0 A Pre-Bid Conference with the Parties will be held in Kolkata (<strong>India</strong>) on 6 th September, 2011 to discuss on the<br />

technical specifications and other terms and conditions of the tender. Parties who are interested to participate in<br />

the Pre-Bid Conference / tender can purchase the tender document and intimate their contact details for<br />

informing exact venue and time of the Pre-Bid conference nearer the time.<br />

2.0 Clarification on the technical specifications and other terms & conditions of the Genset shall be provided to the<br />

parties during the Pre-bid Conference. Parties should come fully prepared to the Pre-bid Conference and submit<br />

their queries to OIL in the Pre-bid Conference for clarification. The set of queries may also be sent to OIL at<br />

least 7 (seven) days before the Pre-bid Conference for study by OIL.<br />

3.0 Any changes in the technical specifications and other terms & conditions of the Genset arising out of discussion<br />

in the Pre-bid Conference shall also form part of the tender document.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 1 of 28

4.0 Parties, immediately after the purchase of the <strong>Tender</strong> documents, shall inform OIL at the following address<br />

about their participation in the Pre-Bid Conference with details of the persons to enable OIL to make<br />

arrangement for the Pre-Bid Conference.<br />

HEAD – MATERIALS<br />

OIL INDIA LIMITED<br />

P.O DULIAJAN, PIN – 786 602<br />

DIST. DIBRUGARH (ASSAM) INDIA<br />

FAX NO. : 91 - 374 – 2800533<br />

E-Mail : mmfd1@oilindia.in / material@oilindia.in<br />

Special Notes :<br />

1.0 The tender will be governed by “General Terms & Conditions” for e-Procurement as per Booklet No.<br />

MM/GLOBAL/E-01/2005 for E-procurement (ICB <strong>Tender</strong>s) including Amendments & Addendum to<br />

“General Terms & Conditions” for e-Procurement.<br />

2.0 Technical Check list and Commercial Check list are furnished vide Annexure – III. Please ensure that<br />

both the check lists are properly filled up and uploaded along with Technical bid.<br />

3.0 The item qualifies for Nil duty / Deemed Export benefits. For Deemed Export benefits, please refer<br />

Addendum to the General terms and conditions for Global tender.<br />

4.0 Please note that all tender forms and supporting documents are to be submitted through OIL’s e-<br />

Procurement site only except following documents which are to be submitted manually in sealed envelope<br />

super scribed with tender no. and due date to The Head Materials, Materials Department, <strong>Oil</strong> <strong>India</strong><br />

<strong>Limited</strong>, Duliajan- 786602, Assam on or before the Bid Closing Date and Time mentioned in the <strong>Tender</strong>.<br />

a) Original Bid Security.<br />

b) Details Catalogue and any other document which have been specified to be submitted in<br />

original.<br />

5.0 The tender is invited under SINGLE STAGE-TWO BID SYSTEM. The bidders are<br />

required to submit both the “TECHNICAL” and “COMMERCIAL” bids through electronic<br />

form in the OIL’s e-<strong>Tender</strong> portal within the Bid Closing Date and Time stipulated in the e-<br />

<strong>Tender</strong>. Please ensure that Technical Bid / all technical related documents related to the tender<br />

are to be uploaded in the c-Folder link (collaboration link) under Un-priced Bid Tab Page only.<br />

Please note that no price details should be uploaded as c-Folder link (collaboration link) under<br />

Un-priced Bid Tab Page. Details of prices as per Bid format / Commercial bid can be uploaded<br />

as Attachment in the attachment link Search and Add under “Unpriced Bid” under<br />

“General Data”. A screen shot in this regard is given below. Offer not complying with above<br />

submission procedure will be rejected as per Bid Rejection Criteria mentioned in Annexure-II<br />

(Refer Clause 1.0 of (B) Commercial).<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 2 of 28

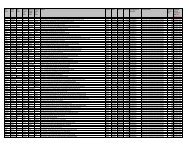

C-FOLDER LINK<br />

Details of prices as per Bid format /<br />

Commercial bid can be uploaded in<br />

this Attachment<br />

6.0 The Integrity Pact is applicable against this tender .OIL shall be entering into an Integrity Pact with<br />

the bidders as per format enclosed vide Annexure XII of the tender document. This Integrity Pact<br />

proforma has been duly signed digitally by OIL’s competent signatory. The proforma has to be<br />

returned by the bidder (along with the technical bid) duly signed (digitally) by the same signatory<br />

who signed the bid, i.e., who is duly authorized to sign the bid. Any bid not accompanied by Integrity<br />

Pact Proforma duly signed (digitally) by the bidder shall be rejected straightway. Uploading the<br />

Integrity Pact with digital signature will be construed that all pages of the Integrity Pact has been<br />

signed by the bidder’s authorized signatory who sign the Bid.<br />

OIL’s Independent External Monitors at present are as under:<br />

(I) SHRI N. GOPALASWAMI,I.A.S ( Retd) ,<br />

Former Chief Election Commissioner of <strong>India</strong><br />

E-mail Id : gopalaswamin@gmail.com<br />

(II) SHRI RAMESH CHANDRA AGARWAL , IPS( Retd)<br />

Former Director General of Police<br />

E-mail Id : rcagarwal@rediffmail.com<br />

7.0 Bidders are requested to examine all instructions, forms, terms and specifications in the bid. Failure<br />

to furnish all information required as per the bid or submission of offers not substantially responsive<br />

to the bid in every respect will be at the bidders risk and may result in the rejection of its offer<br />

without seeking any clarifications.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 3 of 28

Annexure – I<br />

SUPPLY, INSTALLATION, TESTING, COMMISSIONING AND HANDING OVER OF 2 Nos. 125 KVA GAS<br />

ENGINE DRIVEN GENERATING SET WITH ACOUSTIC ENCLOSURE.<br />

1.0 SCOPE OF SUPPLY:<br />

The scope of supply by the bidder shall be of 125 KVA, 415 Volts, 3 Phase, 50 Hz Industrial type,<br />

Natural Gas Engine driven Generating set with all accessories.<br />

The generating sets shall be the primary source of power for its application. The rating applies to<br />

supplying continuous power at variable load for unlimited annual hours. A 10% overload is allowed for<br />

up to 1 hour in every 12 hours.<br />

2.0 GAS ENGINE :<br />

The gas engine should be a four stroke, naturally aspirated / turbo charged, radiator cooled engine,<br />

rated for continuous power and capable of developing a net minimum of 145 HP at 1500 rpm with a<br />

maximum compression ratio of 10.5 : 1. The engine should comprise of the following sub systems<br />

2.1 ENGINE SUB SYSTEM<br />

a) Cooling System:<br />

The cooling system of water cooled engine should comprise of an engine mounted water pump, an<br />

industrial type heavy duty radiator/ heat exchanger suitable for operation in ambient temperature of 48<br />

Deg C and a blower fan.<br />

(i) The engine jacket water cooling system should be a closed circuit design with provision for filling,<br />

expansion, and de-aeration. The cooling pump should be driven by the engine. Auxiliary coolant pump<br />

required for heat exchanger or separate circuit after cooling should also be engine driven. Coolant<br />

temperature should be internally regulated to disconnect external cooling system until operating<br />

temperature is achieved.<br />

(ii) Radiator, Engine Mounted: Heat rejected to the engine jacket water shall be discharged to the<br />

atmosphere through a close coupled radiator. The radiator shall be sized to cool the engine<br />

continuously while operating at full rated load and at site conditions of 48 Deg C ambient.<br />

(iv) Blower Fan: The radiator cooling fan shall be a blower type driven from the engine. Air shall be drawn<br />

from the engine side and exhausted through the radiator core with no more than 12.7 mm (0.5 Inch) of<br />

water external restriction in addition to core restrictions.<br />

(v) Fan and Belt guarding: The fan, fan drive, and fan belts shall be covered with punched steel mesh<br />

guarding for personnel protection.<br />

b) Air Intake System:<br />

The air intake system should comprise of a heavy duty engine air cleaner mounted on the engine with a<br />

vacuum indicator and air intake manifold with dry element requiring replacement no more frequently<br />

than 500 hours or once each year.<br />

c) Electric Starting System:<br />

The engine should have an electric starting system comprising of a Maintenance Free Heavy Duty<br />

Battery pack of reputed make having a minimum capacity 180 ampere hours with a alternator mounted<br />

on the engine for a battery charging and a 12 or 24 Volt starter (preferably of LUCAS TVS/DELCO<br />

REMY make), starter relay, and automatic reset circuit breaker to protect against butt engagement.<br />

Batteries shall be maintenance free, lead acid type mounted near the alternator. Batteries should be<br />

housed in a hard rubber or polypropylene case with provision for venting. Required cables should be<br />

furnished and sized to satisfy circuit requirements.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 4 of 28

d) Battery Charger:<br />

The battery charger is to be a solid-state device with adjustable float voltage control. It is to be a<br />

constant voltage device with current limit, and it is to include an equalize switch which will allow the<br />

battery to be overcharged for maintenance purpose.<br />

e) Ignition System :<br />

The ignition system should be a shielded ignition comprising Altronic III/V Engine driven ignition timer,<br />

Ignition Coil, High Tension and Low Tension Wiring Harness, Transformer and Spark Plugs shall<br />

incorporate gold palladium electrodes for reliability and life ( Preferably STITT/ CHAMPION make)<br />

f) Exhaust System :<br />

(i)The exhaust system should comprise of water cooled exhaust manifold, stainless steel exhaust<br />

flexible connection, residential type exhaust silencer, spark arrestor and piping connections<br />

(ii) Heavy walled piping of schedule 40 with radii of 90° bend at least 1½ times the pipe diameter.<br />

Piping should be installed with appropriate insulation and shielding.<br />

(iii) Piping should be supported and braced to prevent weight or thermal growth being transferred to the<br />

engine and flexible expansion fittings provided to accommodate thermal growth.<br />

g) Fuel System :<br />

The fuel system should comprise of *Governor (Preferably WOODWARD make), carburetor (Preferably<br />

IMPCO make ), main line and secondary line gas pressure regulator ( Preferably VANAZ/FISHER<br />

make ) , gas filter and related linkages. The first stage regulator is to have an inlet pressure rating of<br />

20 psig and outlet pressure rating of 7 psig and outlet pressure rating.<br />

*Governor: The engine governor shall be Mechanical / Mechanical-Hydraulic / Electronic Speed Control<br />

with EG Electro-Hydraulic actuator or Barber Coleman Equal. Speed drop shall be extremely adjustable<br />

from 0 (isochronous) to 10% from no load to full rated load. Steady state frequency regulation shall be<br />

+ / - 0.5 percent.<br />

Fuel inlet line to the engine shall be having stainless steel flexible connection to take care of<br />

vibration/shock if any, in the system.<br />

h) Lubricating System:<br />

The lubricating system should comprise of lubricating oil pump, lubricating oil filter with a replaceable<br />

paper element, lubricating oil cooler, lubricating oil pan and crankcase breather.<br />

(i) The lubricating oil pump shall be a positive displacement type that is integral with the engine and<br />

gear driven from the engine gear train. The system shall incorporate full flow filtration with bypass valve<br />

to continue lubrication in the event of filter clogging.<br />

(ii) The bypass valve must be integral with the engine filter base of receptacle.<br />

i) Instrument Panel:<br />

The engine mounted instrument panel shall consist of a shock-mounted formed and welded enclosure.<br />

Provide Metric marked gauges as above.<br />

The instrument panel should include the following:<br />

a) Lubricating <strong>Oil</strong> pressure gauge<br />

b) Lubricating oil temperature gauge<br />

c) Water temperature gauge<br />

d) Starting Switch<br />

e) Ignition Switch<br />

f) Mechanical/Digital tachometer and hour meter<br />

g) Circuit Breaker<br />

h) Ampere meter<br />

i) Electric service meter<br />

j) Engine Safety Controls:<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 5 of 28

Engine mounted safety shut off/trip system for tripping the engine in the event of<br />

a) Low lubricating oil Pressure<br />

b) High cooling water temperature<br />

c) Engine over speed<br />

d) Over crank<br />

k) Other Features :<br />

a) flexible coupling / direct coupling<br />

b) AVM Pad.<br />

c) flywheel with housing<br />

d) lifting eyes<br />

e) coupling guard if applicable<br />

f) guards over belt drives ( blower fan, water pump drive pulley, timing pulley)<br />

g) standard painting<br />

h) suitable hand throttle control<br />

i) mechanical hour meter<br />

j) SAE standard rotation.<br />

k) Gas shut off valve for engine fuel gas line should close automatically when the engine is stopped.<br />

N.B: Provision of guards over belt drives and couplings has become mandatory as per<br />

recommendation of OISD (<strong>Oil</strong> Industry Safety Director) & DGMS ( Director General of Mines & Safety )<br />

2.2 GENERAL NOTES ON ENGINE :<br />

a) The engine shall conform to ISO : 3046 specifications and shall be rated for continuous power with<br />

an over load power rating of 110% of the continuous power corresponding to engine application for a<br />

period of 1 hr within a period of 12 hrs operation.<br />

b) The engine governing should be in accordance with Class A Governing specified in BS : 3109 : 1985<br />

( or latest)<br />

c) The bidder should submit the following information along with relevant performance rating Curves<br />

and engine product catalogue:<br />

i) Gross HP developed at rated RPM<br />

ii) Deduction for fan and other ancillary equipment.<br />

iii) Net HP developed at rated RPM<br />

iv) Specific fuel consumption at rated power as well as at 110%, 75%, 50% and 25% of rated load<br />

d) A suitable selected flexible coupling should be incorporated to transfer power from the engine to the<br />

alternator. A guard should be provided to cover the same to meet OISD norms<br />

e) The generating set should be suitable for operation at the following site condition:<br />

Maximum Temperature : 48 DEG C<br />

Minimum Temperature : 05 DEG C<br />

Maximum Humidity at 21 DEG C : 100 %<br />

at 35 DEG C : 95 %<br />

at 41 DEG C : 70 %<br />

Maximum Altitude above sea level : 150 Meter<br />

f) Composition of Fuel Gas:<br />

The engine should be capable of developing required BHP as detailed in para 2.0 above with fuel<br />

composition given below:<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 6 of 28

CONSTITUTION<br />

% VOLUME<br />

Methane 89.442<br />

Ethane 4.267<br />

Propane 2.083<br />

Butane- Pentane 6 - 3<br />

Nitrogen 1.5<br />

Carbon-dioxide 0.434<br />

Iso-Butane 0.641<br />

N-Butane 0.892<br />

Iso-Pentane 0.353<br />

N-Pentane 0.271<br />

Hexane 0.672<br />

Gravity 0.655<br />

Gross Calorific Value 1300- 1100 BTU/CFT<br />

Net Calorific Value 1200- 1045 BTU/CFT<br />

g) The fuel gas system shall consists of a minimum of following components but shall not be limited to<br />

these :<br />

a) Main line pressure regulator.<br />

b) Pressure relief safety valve.<br />

c) Gas scrubber tank.<br />

d) Gas fuel filter.<br />

e) Interconnecting gas piping from main line pressure regulator to engine.<br />

f) The gas conditioning & piping should be carried out in such a way as to prevent condensate carry<br />

over to engine.<br />

g) The make of the engine should be restricted to the following make only :<br />

CUMMINS/CATERPILLER/WAUKESHA<br />

3.0. ALTERNATOR:<br />

1. Make : Stamford/Kirloskar/Crompton/NGEF/Kato/Caterpillar<br />

2. Rated Output : 125 kVA<br />

3. Rated Voltage : 415 Volts ± 6%<br />

4. Phase : 3 phase - 4 wire<br />

5. Frequency : 50 Hz ± 3%<br />

6. No. of Poles : 4<br />

7. RPM : 1500<br />

8. Rated power factor : 0.8 lagging<br />

9. Conductor Material. : Copper<br />

10. Type : Industrial<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 7 of 28

11. Duty : Continuous base load duty<br />

12. Class of insulation : Class F / H<br />

13. Phase sequence : UVW (Phase sequence and direction of rotation shall be<br />

clearly marked on the alternator.)<br />

14. Connection : Y ( Star )<br />

15. Site Condition : Temp.= 5 - 40 deg C, RH = 95%, Alt = 150 Meter<br />

16. Alternators Internal Protection (Enclosure) : IP 23<br />

17. Alternators Terminal Box protection : IP 54<br />

18. Cooling : Air cooled by integral fan<br />

19. Excitation system : Brush less, self excited and self regulated.<br />

The brush less alternator shall be composed of 3-phase AC exciter with rotating diodes, pilot exciter<br />

and static voltage regulator with voltage adjuster potentiometer, main field windings and stator<br />

windings. At nominal speed the exciter must produce sufficient residual voltage in order to ensure<br />

perfect excitation.<br />

20. Automatic Voltage Regulation : The machine shall be voltage regulated & shall maintain a voltage<br />

accurate to ± 0.5% to ± 1.0% in any condition between no load & full load even if its speed fluctuates<br />

by ± 4%.<br />

AVR should be mounted in the control panel with rubber washers to arrest vibration. AVR should have<br />

under speed, over excitation protection features with LED display.<br />

21. Permissible voltage variation at rated : + 2 % speed, and power factor<br />

22. Voltage swing (transient response) : When rated load is suddenly switched ON voltage dip shall<br />

be limited to 5-10% and will be corrected within 0.2 to 0.7 sec.<br />

23. Permissible Engine Speed variation : When the speed of engine is 1.2 times for two minutes, the<br />

alternator should be capable of withstanding it without any damage.<br />

24. Permissible frequency variation at rated : + 2 % speed and power factor<br />

25. Period for taking load from start impulse : 5 sec<br />

26. Motor starting ability : 200 % for 20 sec.<br />

27. Overload capacity : Should be capable of sustaining a 10 % overload for one hour in any 12<br />

hours operation.<br />

28. Unbalanced current carrying capacity : 20 %<br />

29. Short circuit current withstand capacity: Alternator should be capable of sustaining short circuit<br />

current 3 to 4 times of full load current for 3 seconds.<br />

30. Over voltage : The alternator should be capable of operation over a range of 110 % of rated voltage<br />

31. Mounting : Foot mounted on anti vibration pads<br />

32. Amplitude of vibration at no load : 100 micron<br />

3.1 GENERAL NOTES ON ALTERNATOR:<br />

1. The alternator shall be of proven design.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 8 of 28

2. Alternator and AVR shall be suitable for humid and corrosive atmosphere.<br />

3. Alternator’s winding terminals shall be connected to 4 terminals of suitably rated tinned copper bars<br />

of appropriate length, mounted on sheet moulding compound (SMC) supports, in the cable terminal<br />

box.<br />

4. Cable entry arrangement: The alternator terminals & terminal box shall be suitable for terminating 2<br />

nos of 4 core , 120 sq.mm PVC insulated and PVC sheathed armoured copper cable. All cables from<br />

the alternator shall be terminated through suitably sized single compression glands on a detachable<br />

gland plate at the bottom of the reverse entry terminal box and connections will be made through<br />

properly rated tinned copper sweating sockets crimped rigidly to the copper conductors.<br />

5. Earthing system for the alternators (body and neutral) shall be as per the IS: 3043.<br />

6. 2 nos. of earth studs shall be provided on both sides of the alternator.<br />

7. Two nos. lifting hooks shall be provided for lifting the alternator.<br />

8. The following information shall be provided:<br />

i. Unbalanced current carrying capacity<br />

ii. Efficiency of the alternator at 25 %, 50 %, 70 % and 100 % load.<br />

iii. Power factor of the alternator at 25 %, 50 %, 70 % and 100 % load.<br />

iv. Motor starting capability.<br />

v. Dimensional drawings.<br />

9. Name plate (Rating plate): Nameplate shall be fixed on the Alternator frame containing the following<br />

minimum information in English language.<br />

Manufacturers name, Applicable standards, Serial no., Type, Frame reference, Rated output, Rated<br />

power factor, Duty, Rated frequency, Rated voltage, No. of phases, Type of connection, Rated stator<br />

current, Rated speed in rpm, Class of insulation, Excitation current and voltage at rated output, Phase<br />

rotation, Temperature rise, Year of manufacture.<br />

3.2 STANDARDS<br />

The alternator shall conform to the following standards:<br />

IS : 12065------ Noise limit<br />

IS : 12075------Vibration<br />

IS : 4722------- Governing Standards<br />

IS : 4691------- Enclosure<br />

IS : 6362------- Cooling<br />

IS : 2253------- Mounting<br />

3.3 TESTING OF ALTERNATOR AT MANUFACTURER’S WORKS:<br />

All the routine tests and load tests of the alternator (along with the control panel) shall be witnessed by<br />

OIL engineers at manufacturer’s works. The routine test of the alternator will include the following<br />

minimum tests/measurements: -<br />

1. Measurement of winding resistances for generator armature, field, exciter armature and exciter field.<br />

2. Measurement of insulation resistance tests (before and after HV tests) for generator armature and<br />

field, exciter armature and field.<br />

3. High voltage (HV) test.<br />

4. Phase sequence test.<br />

5. Voltage regulation test.<br />

6. Vibration measurement.<br />

7. Measurement of noise level.<br />

8. Overload test.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 9 of 28

3.4 DOCUMENTS :<br />

1. The following <strong>Document</strong>s / drawings shall be submitted with the offer<br />

# GA drawing<br />

# Technical literature of alternator<br />

# Catalogues of various components<br />

2. The successful bidder shall obtain approval for the drawings prior to manufacturing of alternator and<br />

ten sets of following documents shall be submitted along with the supply<br />

# GA drawing<br />

# Technical literature of alternator<br />

# O&M manual<br />

# Catalogues of various components<br />

# All test certificates<br />

# List of recommended spares for two years<br />

3. One set of the above <strong>Document</strong>s shall be furnished with the equipment.<br />

4.0 SWITCHGEAR & CONTROLS:<br />

Switchgear & Controls will consist of the following:<br />

1. Generator Control Panel<br />

2. Change Over Switch<br />

4.1 GENERATOR CONTROL PANEL:<br />

The generator control panel shall be sheet steel clad, self supporting, floor mounting with vibration<br />

dampers, cubicle type, dust and vermin proof made of 14G MS CR sheet and built upon rigid<br />

framework, having front and rear hinged doors with danger plate fitted on both sides, lifting lugs on top,<br />

ventilation louvers with perforated sheet on both sides, bottom detachable gland plates, double earthing<br />

studs on two sides, complete with suitably sized zinc plated & passivated double nuts and spring<br />

washers; as fully described below :<br />

It shall broadly have the following compartments / sections.<br />

1) Incomer / Bus bar Section.<br />

2) Generator Protection Section.<br />

3) Generator control section<br />

4) Engine control section<br />

A) Incomer / Bus bar Section: This section shall have:<br />

# 1 No. 250 A 4P, 415V, CFS unit, fused 400 A (Make: Siemens/GEPC/Havells/L&T)<br />

# 1 No. 250 A, 4 pole, 415V, Moulded Case Circuit Breaker, 50 kA, with adjustable overload so that<br />

overload can be set at full load current of the alternator, with remote tripping facility with 230 volt shunt<br />

tripping. (Make: Siemens/ /Merlin Gerin/ Legrand).<br />

# MCCB should trip on the following faults with indication<br />

i) Over current & Earth fault<br />

ii) Short circuit<br />

iii) Earth leakage<br />

iv) Over voltage<br />

v) Under voltage<br />

vi) Incorrect phase rotation<br />

# 1 set TP & N electrolytic grade, high conductivity, copper bus-bars, conforming to as per IS: 5082,<br />

rated 250 amps and supported at required intervals to withstand short circuit fault levels up to 50 KA.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 10 of 28

Bus-bar support shall be non- hygroscope SMC / FRP and the bus-bar shall be insulated with heat<br />

shrinkable PVC sleeves.<br />

# Cable entry arrangement: All cables to the panel will enter through a detachable gland plate at the<br />

bottom of the panel. All cables will be terminated through suitably sized single compression glands and<br />

connections will be made through properly rated terminal strips and tinned copper sweating sockets<br />

crimped rigidly to the copper conductors.<br />

B) Generator Protection Section: This section shall have:<br />

# Earth leakage relay with CBCT, (Make: Merlin Gerin /Legrand/); ELR shall be adjustable (sensitivity:<br />

0-500 mA, time: 0-500 ms)<br />

# 1 No 3 phase Voltage Monitoring Relay for the following protections<br />

(Make: Telemecanique or eqv.)<br />

I. Over voltage - 110 %<br />

II. Under voltage - 85 % with 1- 10 seconds time setting<br />

III. Incorrect phase rotation<br />

# Suitably rated CTs, class 5P10 for above (Make: Kappa or Eqv.)<br />

All relays shall be mounted in front of the panel.<br />

C) Generator Control Section: This section shall have:<br />

i) Meters:<br />

# 1 - M.I. Voltmeter, 96 sq. mm, 0 - 500 V (Make: AE or eqv.)<br />

# 1 - Voltmeter selector switch (Make: Kaycee or eqv.)<br />

# 1 - M.I Ammeter, 96 sq. mm, 0-300 Amps, C.T. operated (Make: AE or eqv.)<br />

# 1 - Ammeter selector switch (Make: Kaycee or eqv.)<br />

# 1 - Digital frequency meter, 48 X 96 mm, scaled 0-100 Hz, suitable for 240 V AC operation, with a<br />

single pole ON / OFF switch (Make: AE or eqv.)<br />

# 1 - kW meter, Dynamometer type, 3ph, 3 ele, 96 sq.mm, 0 - 200 kW (Make: AE or eqv.)<br />

# Suitably rated CTs, class I for ammeter, kW meter and PF meter (Make: Kappa or eqv.)<br />

All meters shall be mounted in front of the panel.<br />

ii) Indications:<br />

Indications for the following are to be provided<br />

(a) Engine running<br />

(b) Power supply on<br />

(c) Power supply off<br />

(d) Over current and earth fault indication with reset push button<br />

(e) Over / under voltage indication with reset push button<br />

(f) Over / under frequency indication with reset push button<br />

(g) Engine fault<br />

(h) Indication for testing of healthiness of trip circuit<br />

All indication lamps shall be of LED type (Make: Vinay or eqv.) and shall be mounted in front of the<br />

panel.<br />

iii) Fuses:<br />

All meters, indication lamps shall be protected by adequate nos of HRC instrument fuses of suitable<br />

rating (Make: GEPC or eqv.).<br />

iv) Auxiliary relays:<br />

Auxiliary Relay / Contactors will be provided as per requirement of the control circuit. (Make:<br />

Siemens/Telemechanique/L&T)<br />

D) Engine control section: This section shall have:<br />

# Digital RPM meter - 1 No.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 11 of 28

# Engine trip indications: Engine should be stopped with the help of heavy-duty 24V D.C. fuel solenoid<br />

on following conditions.<br />

a) Engine over speed<br />

b) Low lube oil pressure<br />

c) High water temperature<br />

d) Over crank<br />

Indication of each of the trips shall be provided in the front door of the Engine control section. Suitable<br />

relay/ timer arrangement shall be provided wherever required.<br />

# Push buttons for<br />

(a) Accept<br />

(b) Reset<br />

(c) Engine stop<br />

(d) Lamp test<br />

# Hooter/alarm to indicate Engine trip on fault<br />

4.2 CHANGE OVER SWITCH (OFF LOAD):<br />

1 No. 250 Amp, 4-pole Change over switch (off load), (Siemens / Havells make), shall be mounted in a<br />

separate compartment inside the acoustic enclosure. One incoming will be connected to the alternator<br />

power from the MCCB with 2 Nos 4C ,120 sq mm PVC insulated and PVC sheathed armoured copper<br />

cable. The other incomer will be left for connecting other source of power. The outgoing of the<br />

changeover switch will be connected to the PMCC. All Terminations will be done through suitably sized<br />

single compression glands in detachable gland plates and connections will be made through properly<br />

rated terminal strips and tinned copper sweating sockets crimped rigidly to the copper conductors.<br />

Earthing arrangement will be provided with double earthing studs on two sides and will be connected to<br />

the earth bus with suitably sized zinc plated and passivated double nuts and spring washers.<br />

4.3 GENERAL NOTES ON SWITCH GEAR:<br />

1. The Control Panel shall be designed, manufactured and tested as per the latest applicable codes<br />

and standards and stringent quality control checks to be carried out at every stage.<br />

2. Copy of CPRI test certificate for type test of the panels will be furnished along with supply.<br />

3. The control wiring shall be done with PVC insulated flexible copper wires of 2.5 sq.mm and each<br />

wire shall have a ferrule numbers. The entire wiring will be properly dressed and tested.<br />

4. All control wires shall be brought to terminal strips and from there taken to different controls/devices.<br />

All connections shall be done through properly rated lugs.<br />

5. Suitable inscription plates should be provided for the indication lamps, push buttons, selector<br />

switches, terminal strips etc.<br />

6. The panels will be so placed in the enclosure that sufficient space shall be available in the front and<br />

rear of the panels for inspection & maintenance works on the panels.<br />

7. Neoprene gaskets to be provided wherever required.<br />

8. Earth Strips of 50 X 6 mm GI shall be provided as earth bus at the rear of the switchgear for the<br />

earth connections complete with adequate Nos of zinc plated and passivated studs, nuts, and spring<br />

washers.<br />

4.4 TESTING OF PANEL AT MANUFACTURER’S WORKS:<br />

All the routine tests and load tests of the panel (along with the genset) shall be witnessed by OIL<br />

engineers at manufacturer’s works. The routine test of the panels will include the following minimum<br />

tests/measurements: -<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 12 of 28

1. Physical checks & Operation check of all components<br />

2. HV tests<br />

3. Insulation tests (before and after HV tests).<br />

4.5 DOCUMENTS:<br />

A. The following drawings shall be submitted with the offer<br />

# GA drawing showing all details<br />

# Power and control circuit diagrams<br />

# Bill of materials with catalogues of various components<br />

# Copy of CPRI test certificate for type test of the panels<br />

B. The successful bidder shall obtain approval for the drawings prior to manufacturing of<br />

equipment/panel and four sets of the following documents shall be submitted with the supply<br />

# GA drawing showing all details<br />

# Bill of materials with catalogues of various components<br />

# Power and control circuit diagrams<br />

# List of recommended spares for two years<br />

# All test certificates including copy of CPRI test certificate for type test of the panels<br />

C. One set of Power and control circuit diagrams shall be furnished with the equipment.<br />

5.0 ACOUSTIC ENCLOSURE :<br />

The salient features of the acoustic enclosure shall be as follows:<br />

The generating set comprising of engine coupled with alternator, control panel etc for each set should<br />

be placed inside an acoustic enclosure having the following salient features :<br />

i. The acoustic enclosure should be of modular construction with the provision to assemble and<br />

disassemble easily at site. There should also be adequate provision of taking out the equipment for<br />

maintenance / repairing jobs and reinstalling the same after necessary corrective action<br />

ii. The engine generator shall be factory enclosed in not less than a 12 gauge cold rolled steel<br />

enclosure constructed with corner posts, uprights and headers. The roof shall aid in the runoff of water<br />

and include a drip edge. The weather- proof and corrosion resistant acoustic enclosure should be duly<br />

surface treated, phosphated and finally powder coated for long lasting finish. The sheet metal<br />

components should preferably be hot dip, seven tank pretreated before powder coating with special<br />

pure polyester based powder<br />

iii. The sound proofing of the enclosure should be done with self extinguishing high quality rock wool /<br />

mineral wool conforming to IS 8183. The rock wool should be further covered with fiber glass tissue<br />

and perforated sheet. The silencer must be such that sound level is 75 dbA at 1 meter from the<br />

enclosure surface.<br />

iv. Exhaust silencer shall be provided of the size as recommended by the manufacturer and shall<br />

attenuate the sound to the level noted above. It shall be supplied with a flexible , seamless, stainless<br />

steel exhaust connection as well as with all internal pipe work. A rain cap will be supplied to terminate<br />

the exhaust pipe. These components must be properly sized to assure operation with minimum back<br />

pressure and high sound when installed. The canopy should be finished in synthetic enamel paint<br />

incorporating rust inhibitors and aluminum sprayed silencers and spark arrestors to guarantee a<br />

superior and long lasting finish.<br />

v. There should be carefully designed inlet and outlet baffles / attenuators with corresponding weather<br />

louvers and bird mesh allowing sufficient air flow, for the set to operate even under the harshest<br />

ambient conditions whilst maintaining specified noise levels. Suitably sized blower should be<br />

incorporated to meet total air requirement.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 13 of 28

vi. The temperature inside the enclosure should be suitable for human comfort. The temperature of<br />

exhaust line should not exceed the self ignition temperature of fuel gas. A high temperature trip<br />

system ( to shut down the engine by cutting off fuel supply to the engine through the solenoid valve )<br />

with variable setting connected to a thermostatically controlled blower must be provided for eliminating<br />

excessive heat dissipated by the engine within the acoustic enclosure. Suitable continuous on line<br />

Temperature Monitoring and Control System with Alarm and Shut Down Mechanism should be<br />

provided.<br />

(a) When the concentration of gas inside the acoustic enclosure reaches 10 % of LEL of gas, audio<br />

visual alarm should activate and automatic preventive measure should activate to reduce the<br />

concentration of leakage gas. These preventive measures include switching on heavy duty exhaust fan<br />

to disperse leakage gas or stoppage of gas leakage itself.<br />

(b) When the concentration of gas inside the acoustic enclosure reaches 15 % of LEL of gas ( or any<br />

other suitable rating ), the alternator main circuit breaker should trip automatically and subsequently the<br />

engine should be shut down instantaneously by automatic device ( i.e., cutting off power supply to the<br />

fuel solenoid valve.)<br />

vii. A separate Blower of suitable size should be provided and it will be in operation even if the<br />

thermostatically controlled blower stops / fails.<br />

viii. There should be a provision of emergency shut down of the generating set ( Prime Mover ) from<br />

outside the enclosure .<br />

ix. The enclosure should be complete with power and control wiring between control panel and<br />

alternator and other components like blowers etc with proper size copper cable. The cables should be<br />

terminated using gland and tinned copper sweating sockets and run through guard pipe.<br />

x. The enclosure should have the sufficient space in and around the generating set to facilitate<br />

maintenance and operation of the set<br />

xi. Acoustic Enclosure’s base frame should incorporate necessary facilities for handling and inter<br />

location transfer through oil field trucks and its overall dimension should not exceed 9M x 2.5 M x 2.5M<br />

( Length x Width x Height).<br />

xii. The control panel for the Generating set should be installed separately on the same skid inside the<br />

same acoustic enclosure. The connection from the alternator and control panel should be carried out<br />

with 3.5 core 120 sq. mm PVC insulated, PVC sheathed armored copper cable and cable should be<br />

terminated with proper size of tinned copper sweating socket and cable glands at alternator and panel<br />

end.<br />

xiii. All the terminal boxes/Junction boxes etc, the battery and self starter connection terminals / and its<br />

components should be housed inside DGMS approved intrinsically safe enclosure.<br />

NOTE:SPECIFICATION OF CONTINUOUS ON LINE GAS MONITORING SYSTEM<br />

Detector / Gas Sensor : Actual Nos of Sensors to be decided based on locations where there is<br />

possibilities of gas leakage inside the acoustic enclosure.<br />

Type : IR (Infrared), suitable for detection of NATURAL GAS ( By Volume CH4 : 89.538 %, N2 : 1.004<br />

%, CO2 : 0.543 %, C2H6 : 4.132 %, C3H8 : 2.491 %, Others : 2.292 % )<br />

Range : 0 to 100 % LEL<br />

Operating Temperature : 0 to 50 Deg C<br />

Display : 4 digit LCD Display<br />

Alarm Setting : Variable<br />

Shut down setting : Variable<br />

Control system : Suitable control system to be provided for alarm and safety shut down of the engine<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 14 of 28

Sensor calibration : Adjustment of Zero & Span on-site Non Intrusive one man calibration, should have<br />

facility to calibrate the instrument on spot without disconnecting from power supply by using any<br />

portable hand held intrinsically safe calibrator.<br />

Detectors must be suitable for hazardous environment i.e., Zone 1 & Zone 2 hazardous area as per<br />

OMR, 1984.<br />

Approval for Detectors / Sensors : Valid DGMS approval certificate must be provided with the offer.<br />

5.1 ENCLOSURE ILLUMINATION:<br />

A separate circuit shall be provided for lighting of the acoustic part of the enclosure. There shall be only<br />

2 Nos DGMS approved intrinsically safe tube light fitting with control from non acoustic part of the<br />

enclosure. Armoured cable and FLP cable glands should be used for wiring purpose inside the acoustic<br />

enclosure.<br />

Make of Luminaire : Baliga / FCG / SUDHIR<br />

NOTE :<br />

1. Bidders should submit layout drawing of the acoustic enclosure indicating positions of engine,<br />

alternator, control panel etc along with the wiring diagram of the package and will have to be approved<br />

by OIL before execution of the order.<br />

2. Enclosure design should be such that for any major maintenance activities the enclosures from any<br />

side can be easily dismantled and re-erected.<br />

3. Generating set comprising of Engine, Alternator, Control Panel and other auxiliaries should be<br />

placed inside an acoustic enclosure ( approved by ARAI, Pune/ NPL, New Delhi/ NSTL, Visakapatnam/<br />

FCRI, Palghat / NAL, Bangalore) and the unit should be mounted to a common base frame. The set<br />

should have proper arrangement for easy loading /unloading to facilitate ease in transportation.<br />

4. A panel viewing window should be provided to facilitate visual monitoring of the equipment from<br />

outside.<br />

5.2 EARTHING ARRANGEMENT:<br />

1 ) The earthing scheme for the unit should be as per BIS-3043.<br />

2) Two nos. 50x6mm GI straps shall be suitably fixed on the floor of the unit skid as main earth bus.<br />

Alternator earth terminals, control panel earth terminals ,COS earth terminals ,enclosure and truck<br />

chassis shall each be connected through two nos. separate 25 x 5 mm GI straps to both the main<br />

straps with independent connections at separate points. All Galvanization thickness shall be min. 85<br />

micron as per BIS.<br />

3) The neutral of the alternator will be connected to the neutral bus thru the incomer cable. The neutral<br />

bus will be connected by two nos. of heavy duty PVC insulated ,PVC sheathed ,Flexible ,single core<br />

cables of 50 sqmm size to main earth straps at two independent points .The earth cables shall be<br />

suitably supported and protected to avoid any damage and shall be run in galvanized non-flexible<br />

conduits. Both ends of the cables shall be terminated with lugs and suitably protected against<br />

mechanical damage. Make of cables: Finolex / Havells.<br />

4) Both the main earth straps shall extend up to the back side of the enclosure and each strap will be<br />

provided with two nos of zinc coated terminal studs, 15 mm dia at the ends of the straps for connection<br />

to system earth. Two nos.of earthing cables of size & type mentioned in point no.3 above and of<br />

adequate length shall be provided and one end of each cable shall be connected with tinned copper<br />

lugs to the studs of the two straps for external earthing .The free ends of these cables shall be crimped<br />

with heavy duty, tinned copper tubular lugs.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 15 of 28

5) Six nos of 100 mm Ø,3 mtr. long earth electrodes designed as per BIS will be driven to earth and<br />

interconnection to each other shall be made thru 2 nos of 50X6mm GI straps. All connections will be<br />

made by using two nos of suitably sized zinc plated and passivated nuts and bolts.<br />

6) Brick work enclosure of internal dimensions and as instructed by Engineer in charge shall be<br />

constructed around each earth electrodes .L=600 mm, B = 600 mm ,depth= 400 mm<br />

6.0 GENERAL NOTES :<br />

a. The offer will not be acceptable if the party do not quote for all items of the tender and supply,<br />

installation, commissioning of all items and cables.<br />

b. In their offer the bidder must mention their detailed comments point-wise against each point of tender<br />

specifications. Any deviation from the tender specification shall be specifically mentioned. Specific type<br />

and make of equipment should be mentioned. All the information required as per tender specifications<br />

must be submitted.<br />

c. In the event of an order the bidder will submit to OIL within one month of placement of order all<br />

documents and drawings as required against each item.<br />

d. The manufacture of the equipment is to be started only after written approval of the drawings/<br />

documents by OIL as mentioned in tender against all equipment.<br />

e. Bidder will provide with the offer the list of tools and equipment available with the bidder to carryout<br />

the installation and commissioning work as per tender.<br />

f. The bidder will be responsible for safety of its personnel and safety of all the equipment. All the safety<br />

gadgets required for safely carrying out the job shall be provided by the bidder.<br />

g. Bidder will be responsible for safe custody of all the items before handing over to OIL.<br />

h. Handing over to OIL means supply, installation and commissioning of all items as per order and<br />

submission of all the documents and drawings as per order.<br />

i. The bidder to strictly ensure that all the cut ends of cables, packing materials, leftover items are<br />

removed from site after completion of work.<br />

j. No environmental damage shall be done while carrying out the job.<br />

k. All the test reports must be signed by licensed electricians, jointers and supervisors who have carried<br />

out the installation and commissioning work as per order.<br />

7.0 SKID :<br />

The skid should be of oilfield type and fabricated from sufficiently strong steel section for carrying the<br />

generating set from one place to another from time to time. The engine and alternator should be<br />

unitized and mounted on the skid before dispatch. The generator housing shall be one piece and<br />

mount directly to the engine flywheel housing without bolted adopter.<br />

8.0 PAINTING :<br />

All metal surface shall be thoroughly cleaned and degreased. The under surface shall be prepared by<br />

applying a coat of phosphate paint and a coat of yellow zinc chromate primer. After preparation of<br />

under surface, the panel shall be spray painted with two coats of epoxy based final paint. Panel finish<br />

shall be free from imperfections like pin holes orange peels, run off paint etc.<br />

9.0 SPARE PARTS :<br />

The bidder should provide a list of recommended spares for 2 years normal operation and maintenance<br />

of the Gen-sets / control panels / Coupling / Air Compressor / Cooling Towers and other accessories<br />

indicating item description, part number, quantity and price along with the quotation. The Prices of such<br />

spares should not change for next 2 years from the date quotation. However, the cost of these spares<br />

will not be considered for bid evaluation purpose.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 16 of 28

The bidders must submit a written undertaking that they would be able to supply all the requisite spares<br />

and consumables (including bought out items) for a minimum period of 10 (ten) years from the Certified<br />

date of completion / successful field commissioning of the unit. Original Equipment Manufacturer's<br />

undertaking must be forwarded for the items not manufactured by the bidder.<br />

10.0 PARTS LIST, INSTRUCTION MANUAL & DRAWING :<br />

A. The supplier should provide two sets each of the manuals and books listed below for each unit:<br />

1.OPERATING INSTRUCTIONS- with description and illustration of all switchgear controls and<br />

indicators and engine<br />

and generator controls.<br />

2. PARTS BOOKS- that illustrate and list all assemblies, subassemblies and components, except<br />

standard fastening hardware ( nuts, bolt, washers etc.).<br />

3. PREVENTIVE MAINTENANCE INSTRUCTIONS- on the complete system that cover daily, weekly,<br />

monthly, biannual, and annual maintenance requirements and include a complete lubrication chart.<br />

4. ROUTINE TEST PROCEDURES- for all electronic and electrical circuits and for the main AC<br />

generator.<br />

5. TROUBLESHOOTING CHART- covering the complete generator set showing description of trouble,<br />

probable cause and suggested remedy.<br />

6. RECOMMENDED SPARE PARTS LIST- showing all consumables anticipated to be required during<br />

routine maintenance and test.<br />

7. WIRING DIAGRAM AND SCHEMATICS- showing function of all electrical components.<br />

8. One set of drawing showing installation details of the generating set, oilfield type skid, wiring diagram<br />

for the control panel ( inclusive of float charger ) and wiring drawing between the alternator and control<br />

panel should be provided with each generating set. All control panel diagram and schematic diagram<br />

are to be sent to us before supply of order materials.<br />

9. The bidders should provide installation diagram of the set and performance data sheet along with the<br />

quotation.<br />

10.The supplier should provide along with the set<br />

i) Dynamic load<br />

ii) Static load<br />

iii) Any unbalanced load<br />

B. All manuals and books described above shall be contained in rigid plastic pouches and in digital<br />

form along with the genset.<br />

11.0 INSPECTION AND TEST :<br />

a) The plant and materials may be subjected for inspection during manufacture at the purchaser’s<br />

discretion but such inspection shall not relieve the supplier of his responsibility to ensure that the<br />

equipment supplied is free from al manufacturing and other defects and conform to correct<br />

specifications. The supplier will be notified in advance, if it is intended to inspect plant or material.<br />

b) Pre dispatch inspection of the sets shall be carried out by us at the works of manufacture. Load<br />

testing of the generator sets for output and performance shall be carried out in presence of the<br />

purchaser or his representative appointed for the purpose and to his satisfaction. If natural gas to run<br />

the engine for load testing is not available at manufacturer’s works, the generating set must be tested<br />

at purchaser’s premises and accordingly supplier to depute service engineer to commission the set at<br />

purchaser’s premise. The purchaser, in such case, will provide fuel gas and arrangement for loading<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 17 of 28

the generator. All other appliances, apparatus, labor etc. necessary for the tests shall have to be<br />

provided by the supplier at his cost.<br />

c) The generating set shall be acceptable to the purchaser only after satisfactory load test.<br />

Note:- Inspection/testing charges, if any, shall be quoted separately which shall be considered for<br />

evaluation of the offers. To and fro fares, boarding/ lodging and other en-route expenses of<br />

OIL’s Inspection team for carrying our inspection shall be borne by OIL.<br />

12.0 TEST CERTIFICATES :<br />

The supplier shall submit detailed records and certificates of the foregoing tests to the purchaser. The<br />

certificates/records shall be supplied in quadruplicate and those for electrical equipment shall be<br />

endorsed “suitable for use in the climatic conditions specified” . Supplier should also certify that spark<br />

plug cables are protected and possibility of spark is completely eliminated.<br />

13.0 PACKING :<br />

The packing shall be sufficiently robust to withstand rough handling. Boxes/packing cases containing<br />

electrical equipment shall be water proof lined. All the matters on the control panel should be packed<br />

separately for mounting at site or mounted in such a manner to prevent transit damage.<br />

14.0 INSTALLATION , COMMISSIONING, TESTING AND HANDING OVER :<br />

Installation and Commissioning of the generating set and control panels shall be carried out by the<br />

bidder in the presence of OIL representatives at its fields at Duliajan, Assam (<strong>India</strong>). Services of<br />

qualified and competent personnel from equipment manufacturer is essential during installation and<br />

commissioning of the generating sets. Persons engaged for installation, testing and commissioning of<br />

alternator and control panel should have valid electrical license issued by State Licensing Board.. A<br />

person who is authorized for supervision of all electrical works should have valid supervisory license.<br />

Materials such as line pipes, fittings necessary for fabricating fuel/ water lines, supports for engine<br />

exhaust shall be provided by OIL . However bidder has to arrange welding and cutting facilities that<br />

may be required during installation and commissioning the generating sets. OIL will provide necessary<br />

statutory permits for welding and cutting jobs in classified areas as and when required.<br />

Installation / commissioning charges should be quoted separately which shall be considered for<br />

evaluation of the offers. These charges should included amongst others to and from fares, boarding/<br />

lodging and other expenses of the commissioning engineers during their stay at Duliajan, Assam<br />

(<strong>India</strong>). All Personal, Income and Service Tax etc. towards the services provided by the supplier shall<br />

be borne by the supplier and will be deducted at source. Bidders should also confirm about installation/<br />

commissioning in the Technical Bid.<br />

Notes :<br />

a) Once commissioned at designated site the generating set will be subjected to a trial run<br />

(reliability run) on available load for a minimum period of 72 hrs continuously and on<br />

satisfactory performance shall be subsequently handed over to OIL.<br />

b) OIL will give 14 days advance notice prior to installation to the successful bidder.<br />

c) Installation / commissioning charges should be quoted separately which shall be considered for<br />

evaluation of the offers. These charges should included amongst others to and from fares,<br />

boarding/ lodging and other expenses of the commissioning engineers during their stay at Duliajan,<br />

Assam (<strong>India</strong>). Bidders should also confirm about installation/ commissioning in the Technical Bid.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 18 of 28

15.0 RESPONSIBILITY:<br />

The responsibility for performance to the specifications shall not be divided among individual<br />

component manufacturers, but must be assumed solely by the primary manufacturer. This includes<br />

generating system design, manufacture, test, and having a local supplier responsible for service, parts<br />

and warranty for the total system.<br />

16.0 AFTER SALES SERVICE :<br />

Bidder should indicate the availability of nearest after sales service centre along with the details of infra<br />

structural capabilities. The nature of after sales service, which can be provided by the supplier, during<br />

initial erection and commissioning as also subsequent operation should be clearly stated in the<br />

quotation.<br />

17.0 SERVICE AND WARRANTY:<br />

(i) The manufacturer shall have a local authorized dealer who can provide factory trained servicemen,<br />

the required stock of replacement parts, technical assistance, and warranty administration.<br />

(ii) The manufacturer’s authorized dealer shall have a parts and service facility within 300 km of the<br />

jobsite.<br />

(iii) The generator set supplier shall have factory trained service representatives and tooling necessary<br />

to install and commission all provided equipment.<br />

The warranty period for the Gen set and ancillary equipment should be a minimum of 18 months from<br />

the date of dispatch/ shipment or 12 months from the date of commissioning of the equipment<br />

whichever is earlier. Any defects in the Engine or Alternator during warranty period shall be replaced by<br />

the supplier at his cost without any extra charge to OIL.<br />

iv)The bidder must undertake and confirm from OEMs that the equipment to be supplied are not going<br />

to become obsolete for the next 10 years and provisioning of spares can be continued.<br />

18.0 DATA SHEET FOR ENGINE :<br />

MAKE<br />

MODEL<br />

NUMBER OF CULINDER<br />

ASPIRATION<br />

COMPRESSION RATIO<br />

SIZE ( BORE & STROKE)<br />

DISPLACEMENT<br />

DUTY<br />

GROSS HP AT 1500 RPM<br />

DEDUCTION FOR FAN, ALD & TEMP.<br />

NETT HP AVAILABLE AT 1500 RPM<br />

SPECIFIC FUEL CONSUMPTION<br />

# 100% LOAD<br />

# 75% LOAD<br />

# 50% LOAD<br />

LUB OIL CONSUMPTION( LT/HR)<br />

ENGINE SUMP CAPACITY<br />

ENGINE RADIATOR/ HEAT EXCHANGER CAPACITY( LTS)<br />

MAKE & TYPE OF GOVERNOR<br />

LENGTHX WIDTH X HEIGHT<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 19 of 28

19.0 DATA SHEET FOR ALTERNATOR :<br />

Make :<br />

Rated Output :<br />

Phase :<br />

Frequency :<br />

No. of Poles :<br />

RPM<br />

Rated power factor :<br />

Conductor Material. :<br />

Type :<br />

Duty :<br />

Class of insulation : :<br />

Connection :<br />

Site Condition :<br />

Alternators Internal Protection (Enclosure) :<br />

Alternators Terminal Box protection :<br />

Cooling :<br />

Excitation system :<br />

Automatic Voltage Regulation :<br />

Permissible voltage variation at rated :<br />

speed, and power factor<br />

Voltage swing (transient response) :<br />

Permissible Engine Speed variation :<br />

Permissible frequency variation at rated :<br />

speed and power factor<br />

Period for taking load from start impulse :<br />

Motor starting ability :<br />

Overload capacity :<br />

Unbalanced current carrying capacity :<br />

Short circuit current withstand capacity :<br />

Over voltage :<br />

Mounting :<br />

Amplitude of vibration at no load :<br />

20.0 DATA SHEET OF PANEL AND INSTRUMENTS :<br />

1 MAIN SWITCH<br />

a) Make<br />

b) Rating<br />

c) Cat No/ Type<br />

2 MCCB<br />

a) Make<br />

b) Rating<br />

c) Cat No/Type<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 20 of 28

3 Earth Leakage Relay<br />

a) Make<br />

b) Range<br />

c) Cat No/Type<br />

4 Voltage Monitoring Relay<br />

a) Make<br />

b) Range<br />

c) Cat No/Type<br />

5) Digital RPM Meter<br />

a) Make<br />

b) Range<br />

c) Cat No.<br />

6)COS<br />

a) Make<br />

b) Rating<br />

c) Cat No<br />

All the components including CT, indicating meters, fuses, push buttons etc shall be as per NIT<br />

General Notes for Bidders :-<br />

(Bidders should confirm each & every point clearly. Deviations, if any, should be highlighted in the quotation.)<br />

1.0 Materials shall be brand new, unused & of prime quality.<br />

2.0 Pre-dispatch/Shipment Inspection & Testing charges, if any, must be quoted separately on lump sum basis<br />

which shall be considered for evaluation of the offers. To and fro fares, boarding/ lodging and other enroute<br />

expenses of OIL’s Inspection team for carrying our inspection shall be borne by OIL.<br />

3.0 Installation & Commissioning :<br />

3.1 The successful bidder will be required to install and commission the unit by their competent service engineer.<br />

3.2 Installation/ Commissioning charges must be quoted separately on lumpsum basis which shall be considered<br />

for evaluation of the offers. Total Nos. of days required for commissioning shall also be clearly indicated by the<br />

bidders.<br />

3.3 While quoting Installation/Commissioning above, bidder should take into account all charges including to and fro<br />

fares, boarding/lodging, local transport at Duliajan, Assam and other expenses of supplier's personnel during<br />

their stay at Duliajan. OIL may provide accommodation on Chargeable basis subject to availability. Bidder<br />

should confirm about providing all these services in their Bid. However, OIL reserves the right to avail such<br />

services at its own discretion.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 21 of 28

4.0 Tax & Duties:<br />

(i) All taxes, stamp duties and other levies imposed outside <strong>India</strong> shall be the responsibility of the<br />

Bidder/Seller and charges thereof shall be included in the offered rates.<br />

(ii) All Taxes & levies imposed in <strong>India</strong>, for the services including installation & commissioning, training,<br />

shall be to the Bidder/Seller's account.<br />

(iii) Income Tax on the value of the Services rendered by the Bidder /Seller in connection with installation,<br />

commissioning, training etc. shall be deducted at source from the invoices at the appropriate rate under<br />

the I.T. Act & Rules from time to time.<br />

5.0 The minimum FOB/FCA charges in case of partial order for reduced quantity/ items shall have to be indicated<br />

by the bidder. In case this is not indicated specifically, the charges quoted would be prorata calculated and the<br />

same will be binding on the bidder.<br />

6.0 Payment : Payment shall be released as follows:<br />

i) 80 % of the supply made by the supplier shall be paid against proof of despatch/shipment of the goods.<br />

ii) Remaining 20 % of the supply value along with commissioning charges shall be paid after successful<br />

commissioning and acceptance of the unit by OIL.<br />

iii) OIL may also consider making 100 % payment towards supply of the units against proof of despatch<br />

provided bidders agree to pay interest for 20 % of the order value and also submit Bank Guarantee for the<br />

amount equivalent to 20 % of the order value. This is in addition to the 10 % of the order value towards<br />

Performance Security as per the NIT requirement.<br />

Any offer not complying with the above shall be loaded at one percent above the prevailing Bank Rate (CC rate)<br />

of State Bank of <strong>India</strong> for evaluation purpose.<br />

7.0 <strong>Oil</strong> <strong>India</strong> Purchase Order No. must be engraved on the body of the item. Bidder must confirm the same<br />

categorically in their quotation.<br />

7.1 To ascertain the substantial reponsiveness of the bid OIL reserves the right to ask the bidder for<br />

clarification in respect of clauses covered under BRC also and such clarifications fulfilling the BRC clauses<br />

in toto must be received on or before the deadline given by the company, failing which the offer will be<br />

summarily rejected.<br />

7.2 The items covered by this enquiry shall be used by <strong>Oil</strong> <strong>India</strong> <strong>Limited</strong> in the PEL/ML areas which are<br />

issued/renewed after 01/04/99 and hence Nil Customs Duty during import will be applicable. Indigenous<br />

bidder shall be eligible for Deemed Export Benefit against this purchase. Details of Deemed Export are<br />

furnished vide Addendum to MM/GLOBAL/E-01/2005 attached.<br />

7.3 Other terms and conditions of the tender shall be as per “General Terms & Conditions” for e- Procurement<br />

as per Booklet No. MM/GLOBAL/E-01/2005 for E-procurement (ICB <strong>Tender</strong>s). However, if any of the<br />

Clauses of the Bid Rejection Criteria (BRC) / Bid Evaluation Criteria (BEC) mentioned here contradict the<br />

Clauses in the “General Terms & Conditions” for e-Procurement as per Booklet No. MM/GLOBAL/E-<br />

01/2005 for E-procurement (ICB <strong>Tender</strong>s) of the tender and/or elsewhere, those mentioned in this BEC /<br />

BRC shall prevail.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 22 of 28

Bid Rejection Criteria (BRC) & Bid Evaluation Criteria (BEC)<br />

Annexure – II<br />

(I)<br />

BID REJECTION CRITERIA (BRC)<br />

The bid must conform to the specifications and terms and conditions given in the enquiry. Bid will be<br />

rejected in case the items offered do not conform to all the required technical parameters stipulated in the<br />

technical specifications and to the respective international / national standards wherever stipulated.<br />

Notwithstanding the general conformity of the bids to the stipulated specifications and terms and conditions,<br />

the following requirements shall have to be particularly met by the bidders, without which the offer will be<br />

considered as non-responsive and rejected.<br />

(B) TECHNICAL :<br />

1.0 The gas engine should be a four stroke , naturally aspirated , radiator cooled engine , conforming to<br />

ISO 3046 / BS 5514 / IS 10000 standards and capable of developing a net minimum of 145 BHP at<br />

1500 rpm with a maximum compression ratio of 10.5 : 1.<br />

2.0 The Alternator must be brushless type<br />

3.0 Bidders should have the experience of successfully completing at least 3(Three) orders in the last<br />

10(Ten) years preceding from the bid closing date of this tender against supply, installation,<br />

commissioning and testing of Gas Engine driven Generating sets of capacity 125 kVA or above for<br />

offered Genset along with the Control Panels and accessories in PSUs, Central Govt. or any other<br />

Public <strong>Limited</strong> Company. <strong>Document</strong>ary evidence in this regard must be provided along with the<br />

quotation failing which offer will be rejected.<br />

4.0 Bidder should be an OEM or authorized dealer of OEM for the engine or alternator or the complete<br />

generating set or an OEM approved assembler of generating sets or his authorized representative.<br />

(OR)<br />

If the bidder is an OEM of engine or their authorized dealer then he must purchase the Alternator from<br />

OEM of Alternator or their authorized dealer and vice versa and necessary documentary certificates<br />

from the OEM must be submitted along with the offer.<br />

(OR)<br />

If the bidder is an OEM approved assembler of generating sets, he must purchase the engine and the<br />

Alternator from OEM or their authorized dealers. <strong>Document</strong>ary evidence in this regard must be<br />

enclosed with the offer failing which offer will be rejected.<br />

5.0 The bidder must undertake and confirm from OEM’s that the equipment to be supplied are not going to<br />

become obsolete for the next 10 years and provisioning of spares can be continued.<br />

(B) COMMERCIAL :<br />

1.0 Bids are invited under Single Stage Two Bid System. Bidders shall quote accordingly under Single Stage<br />

Two Bid System. Any offer not complying with the above will be rejected straightaway.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 23 of 28

2.0 Bid security of US $ 15,980.00 or ` 7,35,100.00 shall be furnished as a part of the TECHNICAL BID (refer<br />

Clause Nos.9.0 & 12.0 (Section A) of “General Terms & Conditions” for e-Procurement as per Booklet No.<br />

MM/GLOBAL/E-01/2005 for E-procurement (ICB <strong>Tender</strong>s)). Any bid not accompanied by a proper bid<br />

security in ORIGINAL will be rejected without any further consideration. For exemption for submission<br />

of Bid Security, please refer Clause No. 9.8 (Section A) of “General Terms & Conditions” for e-Procurement<br />

as per Booklet No. MM/GLOBAL/E-01/2005 for E-procurement (ICB <strong>Tender</strong>s). The Bid Security shall be<br />

valid for 270 days from the date of bid opening.<br />

3.0 Validity of the bid shall be minimum 6 months (180 days) from Bid closing date. Bids with lesser validity will<br />

be rejected.<br />

4.0 Bidders must confirm that Goods, materials or plant(s) to be supplied shall be new of recent make and of<br />

the best quality and workmanship and shall be guaranteed for a period of eighteen months from the date of<br />

shipment/dispatch or twelve months from the date of commissioning whichever is earlier against any<br />

defects arising from faulty materials, workmanship or design. Defective goods/materials or parts rejected by<br />

OIL shall be replaced immediately by the supplier at the supplier’s expenses and no extra cost to OIL.<br />

5.0 Successful bidder will be required to furnish a Performance Bank Guarantee @10% of the order value. The<br />

Performance Bank Guarantee must be valid for one year from the date of receipt/acceptance of goods or<br />

18 months from the date of shipment whichever is earlier. Bidder must confirm the same in their Technical<br />

Bid. Offers not complying with this clause will be rejected.<br />

6.0 Bidders are required to submit the summary of the prices in their commercial bids as per bid format<br />

(Summary), given below:<br />

(i) Commercial Bid Format ( SUMMARY ) for Foreign Bidders :<br />

(A) Total Material value of the Gen set with Accessories<br />

(B) Cost of Commissioning spares, if any<br />

(C) Grand Total Material value, ( A + B )<br />

(D) Packing & FOB Charges up to port of shipment<br />

(E) Total FOB (Port of Shipment) value, ( C + D ) above<br />

(F) Ocean Freight Charges up to Kolkata, <strong>India</strong><br />

(G) Insurance Charges<br />

(H) Total CIF Kolkata value, ( E + F + G )<br />

(I) Pre-despatch Inspection & Testing ( by OIL personnel) charges, if any<br />

(J) Installation & Commissioning charges<br />

(K) Total Value, ( H + I + J ) above<br />

(L) Total value in words :<br />

(M) Gross Weight :<br />

(N) Gross Volume<br />

(ii) Commercial Bid Format ( SUMMARY ) for Indigenous Bidders :<br />

(A)<br />

(B)<br />

(C)<br />

(D)<br />

(E)<br />

Total Ex-factory Material value of Gen set with Accessories<br />

Cost of Commissioning spares, if any<br />

Grand Total Material value<br />

Packing and Forwarding Charges<br />

Total Ex-factory (packed) Material value<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 24 of 28

(F) Central Sales Tax, (Please indicate applicable rate of Tax)<br />

(G) Total FOR Despatching station price<br />

(H) Road Transportation charges to Duliajan<br />

(I) Insurance Charges<br />

(J) Assam Entry tax<br />

(K) Total FOR Duliajan* value<br />

(L) Pre-despatch Inspection & Testing ( by OIL) charges, if any<br />

(M) Installation & Commissioning charges<br />

(N) Total Value, ( K + L + M ) above<br />

(O) Total value in words :<br />

(P) Gross Weight :<br />

(Q) Gross Volume :<br />

NOTE :<br />

1. Cost of individual items must be quoted separately.<br />

2. The items covered under this enquiry shall be used by OIL in the PEL/ML areas issued/renewed<br />

after 01/04/99 and hence, applicable Customs Duty for import of goods shall be ZERO.<br />

Indigenous bidders must quote Deemed Export prices. Excise Duty under Deemed Export<br />

exempted.<br />

*(Transit Insurance will be borne by OIL in case of other than FOR destination orders and hence<br />

should not be included in offered rates. However, in case of FOR destination orders, the transit<br />

insurance shall be arranged and paid by successful bidder.)<br />

7.0 Pre-Despatch / Shipment Inspection & Testing charges, if any, shall be quoted on lumpsum basis separately<br />

which shall be considered for commercial evaluation of the offers. However, all to and fro fares,<br />

boarding/lodging and other expenses of OIL’s Inspection Engineer(s) shall be borne by OIL.<br />

Installation/Commissioning and Training charges must be quoted separately on lumpsum basis which shall be<br />

considered for evaluation of the offers. These charges should include amongst others to and fro fares,<br />

boarding/lodging, local transport at Duliajan and other expenses of supplier’s commissioning/training personnel<br />

during their stay at Duliajan, Assam(<strong>India</strong>).<br />

Bidders must categorically indicate the above charges in their commercial offers and must confirm the same in<br />

their Technical bids.<br />

8.0 OIL shall be entering into an Integrity Pact with the bidders as per format enclosed vide Annexure XII of the<br />

tender document. This Integrity Pact proforma has been duly signed digitally by OIL’s competent signatory. The<br />

proforma has to be returned by the bidder (along with the technical bid) duly signed (digitally) by the same<br />

signatory who signed the bid, i.e., who is duly authorized to sign the bid. Any bid not accompanied by<br />

Integrity Pact Proforma duly signed (digitally) by the bidder shall be rejected straightway. Uploading the<br />

Integrity Pact with digital signature will be construed that all pages of the Integrity Pact has been signed by the<br />

bidder’s authorized signatory who sign the Bid.<br />

(II) BID EVALUATION CRITERIA (BEC) :<br />

Bids conforming to the specifications, terms and conditions stipulated in the tender and considered to be<br />

responsive after subjecting to the Bid Rejection Criteria will be considered for further evaluation as per the<br />

Bid Evaluation Criteria mentioned in Section D of “General Terms & Conditions” for e- Procurement as per<br />

Booklet No. MM/GLOBAL/E-01/2005.<br />

<strong>Tender</strong> No. SDG2354P12/09 Page 25 of 28

CHECK LIST<br />

Annexure-III<br />

THE CHECK LIST MUST BE COMPLETED AND RETURNED WITH YOUR OFFER. PLEASE ENSURE THAT ALL THESE POINTS<br />

ARE COVERED IN YOUR OFFER. THESE WILL ENSURE THAT YOUR OFFER IS PROPERLY EVALUATED. PLEASE TICK<br />