Ecopaint Oven â Drying system for perfect surfaces

Ecopaint Oven â Drying system for perfect surfaces

Ecopaint Oven â Drying system for perfect surfaces

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

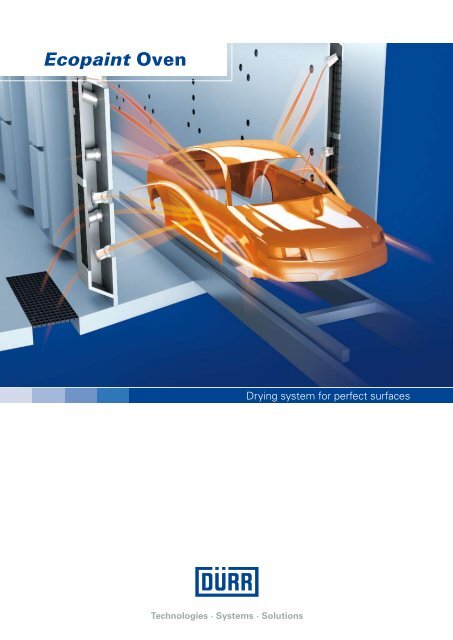

<strong>Ecopaint</strong> <strong>Oven</strong><br />

<strong>Drying</strong> <strong>system</strong> <strong>for</strong> <strong>perfect</strong> <strong>surfaces</strong>

<strong>Ecopaint</strong> <strong>Oven</strong><br />

Dürr delivers the key to optimal hardening of your<br />

<strong>surfaces</strong>:<br />

We plan, deliver and install turnkey paint shops. At the<br />

same time we work our way deep into your complex<br />

process environment to implement an individual<br />

solution. The <strong>Ecopaint</strong> brand name carried by our<br />

products and plants stands <strong>for</strong> innovation and maximum<br />

customer value. Dürr guarantees highest quality and<br />

lowest costs per unit throughout the entire process:<br />

from pretreatment and painting right through to curing.<br />

We are living in the age of the surface: increasingly<br />

scratch resistant finishes, harder paints, glossier<br />

<strong>surfaces</strong> are wrapped around products and vehicles<br />

protecting them and lending them status and appeal.<br />

Surface quality is indicative of the quality of the product<br />

as a whole enhancing the interior and adding value. It<br />

becomes synonymous with value, with value in and of<br />

itself. It defines the market and opens up markets, ever<br />

larger markets.<br />

For the drying process <strong>for</strong> your vehicle body:<br />

<strong>Ecopaint</strong> <strong>Oven</strong> is a modular drying <strong>system</strong>, ideally<br />

uniting all components and modules via integrative<br />

interfaces, to <strong>for</strong>m complete <strong>system</strong>s that assure:<br />

• highest quality<br />

• minimum costs per unit and<br />

• resource and energy conserving operation<br />

By using this product you gain much more than the<br />

product alone. As a leading technology developer we<br />

offer you:<br />

• in-depth process know-how<br />

• many years of experience and<br />

• a global presence<br />

Our drying <strong>system</strong>: <strong>Ecopaint</strong> <strong>Oven</strong>

<strong>Ecopaint</strong> <strong>Oven</strong> – <strong>Drying</strong> <strong>system</strong>s<br />

<strong>for</strong> curing and protection<br />

The drying process is used to cure coatings and to turn<br />

the paint finish into a <strong>perfect</strong> surface. Dürr delivers<br />

appropriate <strong>system</strong>s <strong>for</strong> each stage along the painting<br />

line: <strong>for</strong> gelling, intermediate drying and drying<br />

processes.<br />

Auslegung<br />

Planung der Anlage,<br />

Unterstützung<br />

Festlegung der Ziele,<br />

und schnelle<br />

gemeinsame<br />

Zuverlässige<br />

Simulation<br />

Prozessabsicherung zur<br />

Entscheidungen<br />

Optimierung des<br />

Energieeintrag in<br />

die Karosserie<br />

Wartungsarmer<br />

Betrieb & einfache<br />

Instandhaltung<br />

garantiert<br />

Gesamtkonzept<br />

Entwicklung einer<br />

Lösung anhand Ihrer<br />

Vorgaben und<br />

An<strong>for</strong>derungen<br />

Sicherer Transport<br />

schneller Aufbau<br />

Entwicklung, Berech-<br />

nung, Kontstruktion<br />

& Integration Ihrer<br />

Gesamtlösung<br />

nahme der Anlage<br />

Garantierte<br />

Qualität mit Kom-<br />

Fertigung<br />

& zeitnahe Inbetriebponenten<br />

aus eigener<br />

Engineering<br />

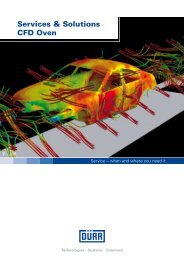

Take full advantage of Dürr‘s vast interdisciplinary<br />

competence and the support it offers from the planning<br />

phase right up to commissioning of your plant. Put your<br />

trust in proven drying processes, which we optimize in<br />

advance through extensive simulations to ensure their<br />

reliability and which we make available to you as a virtual<br />

planning basis in the <strong>for</strong>m, <strong>for</strong> example, of a simulated<br />

heating curve.<br />

Simulation of the drying process<br />

Simulation<br />

ung & Instandhaltung<br />

<strong>Ecopaint</strong> <strong>Oven</strong> modules <strong>for</strong> optimized total <strong>system</strong>s:<br />

• <strong>Oven</strong> tunnels with various heat transfer <strong>system</strong>s<br />

• Heater units (hotboxes) operated with recirculated<br />

Gesamtkonzept<br />

air and recirculated gas<br />

• Fresh air supply and heating <strong>system</strong>s<br />

• Exhaust air purification <strong>system</strong>s<br />

Transport<br />

Engineering<br />

• Cooling zones<br />

• Integrated conveyor <strong>system</strong>s<br />

• Air seals<br />

Fertigung<br />

Customer Service<br />

Assembly<br />

Maintenance & Commissioning<br />

Transport<br />

Quality <strong>for</strong> <strong>perfect</strong> <strong>surfaces</strong>

Modularity means flexible planning and<br />

optimum conditions<br />

We plan and implement new installations and extend or<br />

modernize existing <strong>system</strong>s according to your requirements<br />

and using the latest technology.<br />

In doing so we supply modular build<br />

<strong>system</strong>s which are based on<br />

standardized individual<br />

components and are<br />

delivered as completely<br />

pre-assembled modules.<br />

In this way we speed up<br />

installation and<br />

commissioning.<br />

Modularity also has its<br />

advantages when the<br />

<strong>system</strong> is in production<br />

operation: these innovative, modular<br />

solutions with e.g. fewer filters, optimized nozzles<br />

and asymmetrical holding zones provide the basis<br />

<strong>for</strong> high quality standards coupled with lower unit costs.<br />

In this way we guarantee minimized cleaning and maintenance<br />

ef<strong>for</strong>ts through easy accessibility.

Cleanliness Creates Quality<br />

With Dürr you opt <strong>for</strong> quality: as in all other stages of the<br />

painting process, the drying process is all about avoiding<br />

dirt coming into contact with the vehicle body so as to<br />

attain high value levels. Our plants, with their precise air<br />

nozzle and air directing <strong>system</strong>s, protect the car bodies<br />

by preventing dirt particles from being blown onto them<br />

and thus assure optimum application quality.<br />

<strong>Ecopaint</strong> <strong>Oven</strong> <strong>system</strong>s, with their fast and carefully<br />

managed energy input, also ensure uni<strong>for</strong>m heating of<br />

the vehicle body and create ideal drying conditions. Controlled<br />

heating up of the entire vehicle body is guaranteed<br />

– matched to the shape and material thickness so<br />

that thinner body parts are not overheated.<br />

<strong>Drying</strong> <strong>system</strong> heating zone with skid conveyor technology<br />

Modular and tailor-made

Air <strong>system</strong>s are environmentally<br />

sound<br />

Our <strong>Ecopaint</strong> <strong>Oven</strong> <strong>system</strong>s work with integrated air<br />

management <strong>system</strong>s. Thermal exhaust air purification<br />

also includes heat recovery <strong>system</strong>s to ensure that<br />

energy is used efficiently. Ecopure ® TAR cleans<br />

the exhaust air by incineration and the purified gas<br />

arising from this process generates energy <strong>for</strong> the<br />

EcoHeaterBox.<br />

With the EcoHeaterBox we offer a standard module <strong>for</strong><br />

the economical heating and filtration of air <strong>for</strong> the drying<br />

process. Your vehicle body is thus heated up optimally<br />

with an efficiently managed supply of energy yet with<br />

the minimum influx of dirt particles.<br />

Cooling zone with IMC (Inverted Monorail Conveyor)<br />

The EcoHeaterBox is adapted to handle the air volume<br />

throughput appropriate to the design of the oven.<br />

Dürr plants are energy efficient and meet the strictest<br />

environmental requirements. Continuing further<br />

development and improvement of our products enables<br />

us to equip your plant with the latest technologies<br />

and to ensure environmentally compatible processes.<br />

The EcoCoolingBox ensures an adequate supply of air<br />

to the cooling zones and handles filtration, heating and<br />

cooling.<br />

Systems <strong>for</strong> burner, steam and hot water heating are also<br />

included in Dürr’s extended product portfolio.<br />

<br />

The EcoCoolingBox supplies<br />

air <strong>for</strong> the cool zones

Interface and process competence <strong>for</strong><br />

individually designed <strong>system</strong>s<br />

The design of every oven <strong>system</strong> is individual and<br />

dependent on your plant layout as well as on the<br />

requested or existing conveyor <strong>system</strong>s. We have the<br />

necessary interface and process competence to develop<br />

the solution to suit your specific needs.<br />

Straight-through ovens: a high standard with a<br />

minimum footprint<br />

Dürr straight-through ovens with classic skid conveyor<br />

technology stand out because of their compact design,<br />

offer high standards with a minimum footprint and are<br />

energy efficient. The efficiency of the air seals not only<br />

prevents hot air from escaping out of the oven but<br />

also keeps the amount of dirt carried into the oven to a<br />

minimum.<br />

A-type and U-turn ovens with IMC equipment<br />

Optional – according to layout conditions – we deliver<br />

bottom entry and u-turn ovens. This way we can provide<br />

a flexible solution <strong>for</strong> every requirement.<br />

Straight-through oven (side view)<br />

A-type oven (side view)<br />

U-turn oven (top view)<br />

Drive station<br />

Air seals<br />

<strong>Oven</strong><br />

Roller bed<br />

Chain floor conveyor<br />

Cooling zone<br />

Lift unit<br />

(<strong>for</strong> A-type oven)<br />

Innovations which prove themselves

<strong>Ecopaint</strong> <strong>Oven</strong><br />

Your competitive edge with Dürr:<br />

• Modularity <strong>for</strong> flexibility and fast installation of your plant<br />

• Quality through carefully thought through processes<br />

• Resource conserving technologies <strong>for</strong> energy efficiency<br />

and environmental compatibility<br />

• Individual integration through interface and process<br />

competence<br />

• Technological edge thanks to innovative processes and<br />

equipment<br />

With each and every unit produced you save on cost per unit!<br />

Paint and Final Assembly Systems • www.durr.com