ultrasound action on strength properties of polycrystalline metals

ultrasound action on strength properties of polycrystalline metals

ultrasound action on strength properties of polycrystalline metals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

74<br />

THE ANNALS OF UNIVERSITY “DUNĂREA DE JOS “ OF GALAŢI<br />

FASCICLE VIII, 2006 (XII), ISSN 1221-4590<br />

TRIBOLOGY<br />

and the nominal input power <strong>of</strong> 600 W. The acoustic<br />

power dissipated by ultras<strong>on</strong>ic probe in 1000mldei<strong>on</strong>ized<br />

water at ambient temperature and pressure<br />

as a functi<strong>on</strong> <strong>of</strong> electrical input power was determined<br />

by calorimetry. These data were used to allow<br />

selecti<strong>on</strong> <strong>of</strong> the appropriate input power to give<br />

c<strong>on</strong>stant transmitted power. After the completi<strong>on</strong> <strong>of</strong><br />

measurements, the ultras<strong>on</strong>ic horn was examined<br />

microscopically. No attack <strong>of</strong> the stainless steel by<br />

liquid metal samples was observed in either case, so<br />

there was no evidence <strong>of</strong> c<strong>on</strong>taminati<strong>on</strong> <strong>of</strong> the liquid<br />

metal by alloying.<br />

Table 1. Chemical compositi<strong>on</strong> <strong>of</strong> sample (ppm).<br />

Fe Si Cu Zn<br />

60 60 30 30<br />

The grain size <strong>of</strong> specimens was determined<br />

using the linear intercept method in c<strong>on</strong>juncti<strong>on</strong> with<br />

a logarithmic Gauss distributi<strong>on</strong>.<br />

To make individual hardness measurements for<br />

aluminium, Brinell hardness tests are widely used.<br />

3. RESULTS AND DISCUSSIONS<br />

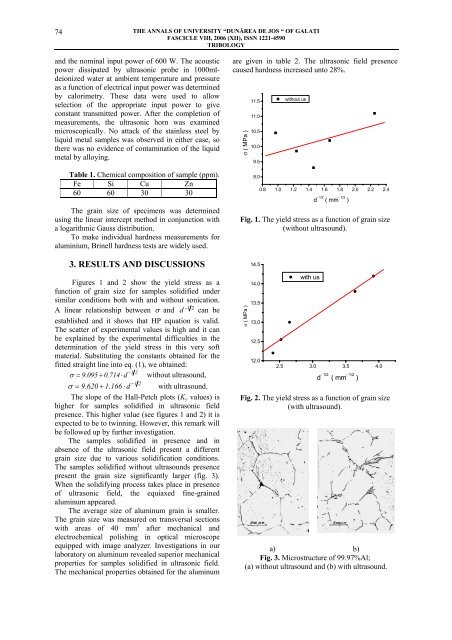

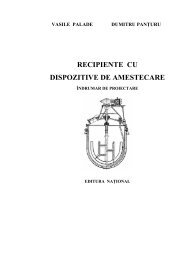

Figures 1 and 2 show the yield stress as a<br />

functi<strong>on</strong> <strong>of</strong> grain size for samples solidified under<br />

similar c<strong>on</strong>diti<strong>on</strong>s both with and without s<strong>on</strong>icati<strong>on</strong>.<br />

−1 2<br />

A linear relati<strong>on</strong>ship between σ and d can be<br />

established and it shows that HP equati<strong>on</strong> is valid.<br />

The scatter <strong>of</strong> experimental values is high and it can<br />

be explained by the experimental difficulties in the<br />

determinati<strong>on</strong> <strong>of</strong> the yield stress in this very s<strong>of</strong>t<br />

material. Substituting the c<strong>on</strong>stants obtained for the<br />

fitted straight line into eq. (1), we obtained:<br />

−12<br />

σ = 9.095 + 0.714 ⋅ d without <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g>,<br />

−12<br />

σ = 9.620 + 1.166 ⋅ d with <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g>.<br />

The slope <strong>of</strong> the Hall-Petch plots (K y values) is<br />

higher for samples solidified in ultras<strong>on</strong>ic field<br />

presence. This higher value (see figures 1 and 2) it is<br />

expected to be to twinning. However, this remark will<br />

be followed up by further investigati<strong>on</strong>.<br />

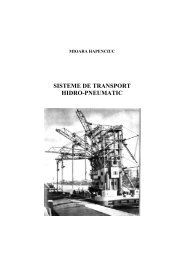

The samples solidified in presence and in<br />

absence <strong>of</strong> the ultras<strong>on</strong>ic field present a different<br />

grain size due to various solidificati<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s.<br />

The samples solidified without <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g>s presence<br />

present the grain size significantly larger (fig. 3).<br />

When the solidifying process takes place in presence<br />

<strong>of</strong> ultras<strong>on</strong>ic field, the equiaxed fine-grained<br />

aluminum appeared.<br />

The average size <strong>of</strong> aluminum grain is smaller.<br />

The grain size was measured <strong>on</strong> transversal secti<strong>on</strong>s<br />

with areas <strong>of</strong> 40 mm 2 after mechanical and<br />

electrochemical polishing in optical microscope<br />

equipped with image analyzer. Investigati<strong>on</strong>s in our<br />

laboratory <strong>on</strong> aluminum revealed superior mechanical<br />

<strong>properties</strong> for samples solidified in ultras<strong>on</strong>ic field.<br />

The mechanical <strong>properties</strong> obtained for the aluminum<br />

are given in table 2. The ultras<strong>on</strong>ic field presence<br />

caused hardness increased unto 28%.<br />

σ ( MPa )<br />

11.5<br />

11.0<br />

10.5<br />

10.0<br />

9.5<br />

9.0<br />

without us<br />

0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4<br />

d - 1/2 ( mm - 1/2 )<br />

Fig. 1. The yield stress as a functi<strong>on</strong> <strong>of</strong> grain size<br />

(without <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g>).<br />

σ ( MPa )<br />

14.5<br />

14.0<br />

13.5<br />

13.0<br />

12.5<br />

12.0<br />

with us<br />

2.5 3.0 3.5 4.0<br />

d - 1/2 ( mm - 1/2 )<br />

Fig. 2. The yield stress as a functi<strong>on</strong> <strong>of</strong> grain size<br />

(with <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g>).<br />

a) b)<br />

Fig. 3. Microstructure <strong>of</strong> 99.97%Al;<br />

(a) without <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g> and (b) with <str<strong>on</strong>g>ultrasound</str<strong>on</strong>g>.