Negative pressure in the oil film of journal bearing Dr

Negative pressure in the oil film of journal bearing Dr

Negative pressure in the oil film of journal bearing Dr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

215<br />

NEGATIVE PRESSURE IN THE OIL-FILM OF JOURNAL BEARING<br />

Tsuneo Someya<br />

University <strong>of</strong> Tokyo, Faculty <strong>of</strong> Eng<strong>in</strong>eer<strong>in</strong>g, Tokyo, 112-0006, Japan,<br />

t-someya@tcn-catv.ne.jp<br />

ABSTRACT<br />

In <strong>the</strong> present paper, negative <strong>pressure</strong> developed <strong>in</strong> <strong>the</strong> <strong>oil</strong>-<strong>film</strong> <strong>of</strong> <strong>journal</strong><br />

bear<strong>in</strong>g is discussed. Assum<strong>in</strong>g dilatational surface viscosity, negative <strong>pressure</strong><br />

found experimentally could be reproduced. Parameter study has shown that, when<br />

negative <strong>pressure</strong> is developed: <strong>the</strong> load capacity <strong>in</strong>creases and <strong>the</strong> friction<br />

coefficient <strong>of</strong> bear<strong>in</strong>g decreases slightly near <strong>the</strong> eccentricity 0.6, but this effect<br />

reverses at larger eccentricity. Oil flow rate decreases under negative <strong>pressure</strong>. The<br />

locus <strong>of</strong> center <strong>of</strong> <strong>journal</strong> <strong>in</strong> <strong>the</strong> bear<strong>in</strong>g clearance is pushed outwards and<br />

horizontally under vertical static load. This means that <strong>the</strong> stability <strong>of</strong> a turbo-rotor<br />

can be reduced, when negative <strong>pressure</strong> is developed.<br />

KEYWORDS: negative <strong>pressure</strong>, dilatational surface viscosity, <strong>journal</strong> bear<strong>in</strong>g, <strong>oil</strong><strong>film</strong>,<br />

bubble <strong>the</strong>ory<br />

1. INTRODUCTION<br />

Characteristics <strong>of</strong> <strong>journal</strong> bear<strong>in</strong>g, such as load<br />

capacity, frictional power loss, <strong>oil</strong> flow rate etc, are<br />

determ<strong>in</strong>ed by <strong>pressure</strong> distribution <strong>in</strong> <strong>the</strong> <strong>oil</strong>- <strong>film</strong> <strong>of</strong><br />

<strong>the</strong> bear<strong>in</strong>g. Therefore, <strong>in</strong> order to get <strong>the</strong><br />

characteristics correctly, <strong>the</strong> <strong>pressure</strong> distribution has<br />

to be calculated under realistic boundary condition.<br />

In <strong>the</strong> literature, <strong>the</strong> <strong>oil</strong> <strong>film</strong> <strong>pressure</strong> has been<br />

usually calculated under <strong>the</strong> condition that <strong>the</strong> <strong>oil</strong><strong>film</strong><br />

can not susta<strong>in</strong> negative <strong>pressure</strong>. However,<br />

several experimental results with negative <strong>pressure</strong><br />

are also reported for <strong>the</strong> <strong>oil</strong> <strong>film</strong> <strong>of</strong> <strong>journal</strong> bear<strong>in</strong>g<br />

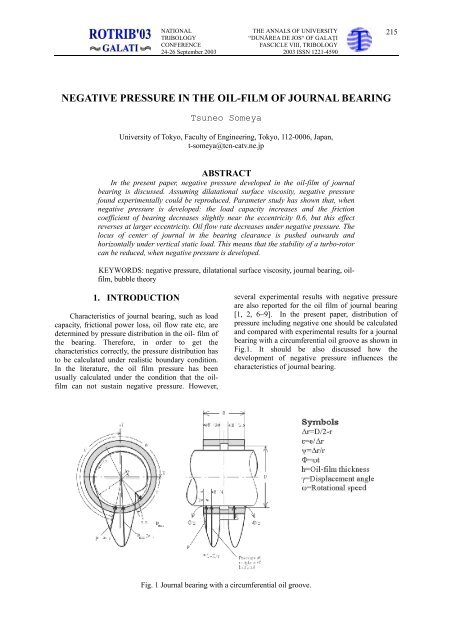

[1, 2, 6~9]. In <strong>the</strong> present paper, distribution <strong>of</strong><br />

<strong>pressure</strong> <strong>in</strong>clud<strong>in</strong>g negative one should be calculated<br />

and compared with experimental results for a <strong>journal</strong><br />

bear<strong>in</strong>g with a circumferential <strong>oil</strong> groove as shown <strong>in</strong><br />

Fig.1. It should be also discussed how <strong>the</strong><br />

development <strong>of</strong> negative <strong>pressure</strong> <strong>in</strong>fluences <strong>the</strong><br />

characteristics <strong>of</strong> <strong>journal</strong> bear<strong>in</strong>g.<br />

Fig. 1 Journal bear<strong>in</strong>g with a circumferential <strong>oil</strong> groove.

216<br />

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

2. EXPERIMENTAL EVIDENCE OF<br />

NEGATIVE PRESSURE<br />

Figure 2 gives examples <strong>of</strong> measured<br />

circumferential distribution <strong>of</strong> <strong>pressure</strong> at land center<br />

<strong>in</strong> a bear<strong>in</strong>g shown <strong>in</strong> figure 1, at shaft speed <strong>of</strong> 1500<br />

m<strong>in</strong> -1 and four bear<strong>in</strong>g load W. The results show<br />

clearly that <strong>the</strong>re exists negative <strong>pressure</strong> and its<br />

absolute value <strong>in</strong>creases with bear<strong>in</strong>g load. Figure 3<br />

gives ano<strong>the</strong>r example <strong>of</strong> negative <strong>pressure</strong>, where a<br />

pair <strong>of</strong> parallel plates with <strong>oil</strong>-<strong>film</strong> <strong>in</strong>-between is<br />

pulled <strong>of</strong>f. Both types <strong>of</strong> <strong>pressure</strong> pickup yielded<br />

negative <strong>pressure</strong>.<br />

p MPa<br />

1500 m<strong>in</strong> -1 W=5.6kN<br />

W=4.2kN<br />

B=22.5x2mm<br />

W=2.8kN<br />

D=100mm<br />

W=1.4kN<br />

η=0.02996Pas<br />

∆r=110µm<br />

Fig.2 Measured <strong>pressure</strong> distribution<br />

Fig.3 <strong>Negative</strong> <strong>pressure</strong> at reverse squeeze<br />

t<br />

θ<br />

3. THEORETICAL INVESTIGATION<br />

ON NEGATIVE PRESSURE<br />

Us<strong>in</strong>g a “bubble <strong>the</strong>ory” expla<strong>in</strong>ed below,<br />

<strong>pressure</strong> distribution <strong>in</strong> <strong>journal</strong> bear<strong>in</strong>g should be<br />

calculated and compared with experimental results. It<br />

is assumed that <strong>the</strong> <strong>oil</strong> conta<strong>in</strong>s uniformly dispersed<br />

bubbles with a constant radius R a under atmospheric<br />

<strong>pressure</strong> p a . When this <strong>oil</strong> is <strong>in</strong>troduced <strong>in</strong>to bear<strong>in</strong>g<br />

gap and experiences positive or negative <strong>pressure</strong> as<br />

it flows <strong>in</strong> <strong>the</strong> gap space <strong>in</strong> <strong>the</strong> bear<strong>in</strong>g, <strong>the</strong> bubbles<br />

will contract or expand. It is fur<strong>the</strong>r assumed that <strong>the</strong><br />

bubbles rema<strong>in</strong> spherical <strong>in</strong> <strong>the</strong> <strong>oil</strong> <strong>film</strong> and no<br />

<strong>in</strong>terference, no comb<strong>in</strong>ation and breakup between<br />

bubbles takes place. Also no evaporation and<br />

condensation <strong>of</strong> <strong>oil</strong> and no diffusion <strong>of</strong> gas should<br />

occur. The gas <strong>of</strong> constant mass conta<strong>in</strong>ed <strong>in</strong> <strong>the</strong><br />

bubble will experience iso<strong>the</strong>rmal change dur<strong>in</strong>g <strong>the</strong><br />

expansion and compression <strong>of</strong> bubble [10].<br />

Figure 4 depicts <strong>the</strong> forces act<strong>in</strong>g on <strong>the</strong> surface<br />

<strong>of</strong> a bubble <strong>in</strong> <strong>oil</strong>-<strong>film</strong>. When <strong>the</strong> bubble radius<br />

changes, surface force due to dilatational viscosity<br />

[4, 11, 12] <strong>of</strong> <strong>the</strong> <strong>oil</strong> will oppose <strong>the</strong> radius change.<br />

This surface dilatational viscosity is related to<br />

Marangoni effect [5]. That is, when <strong>the</strong> surface <strong>of</strong> a<br />

liquid enlarges, adsorption tak<strong>in</strong>g place <strong>in</strong> <strong>the</strong><br />

solution is decelerated by <strong>the</strong> resist<strong>in</strong>g force, <strong>the</strong><br />

surface dilatational viscosity. Therefore, when <strong>the</strong><br />

bubble expands under negative <strong>pressure</strong>, surface<br />

dilatational viscosity force ∆σ will resist <strong>the</strong> bubble<br />

expansion and <strong>the</strong> bubble can withstand greater<br />

negative <strong>pressure</strong> without rupture than when only<br />

surface tension σ is act<strong>in</strong>g and no surface dilatational<br />

viscosity acts.<br />

Accord<strong>in</strong>g to Scriven [11, 12], equation (1)<br />

holds for ∆σ with surface area A and surface<br />

dilatational viscosity κ. Tak<strong>in</strong>g this force <strong>in</strong>to<br />

account, equation (2) is derived for <strong>the</strong> ratio χ=R/R a<br />

<strong>of</strong> a bubble radius R [8, 11, 12].<br />

Consider<strong>in</strong>g <strong>the</strong> change <strong>of</strong> viscosity η and<br />

density ρ due to <strong>in</strong>clusion <strong>of</strong> bubbles, a modified<br />

Reynolds equation (3) for <strong>the</strong> gauge <strong>pressure</strong> p is<br />

derived. As for void fraction α and density ratio<br />

δ = ρ / ρ 1 <strong>of</strong> <strong>the</strong> <strong>oil</strong>-bubble mixture, equation (4)<br />

and (6) can be derived [6]. For viscosity ratio<br />

K=η/η l , an experimental formula (5) accord<strong>in</strong>g to [6]<br />

was used, where η l stands for viscosity <strong>of</strong> <strong>oil</strong> alone.<br />

For <strong>the</strong> dimensionless <strong>oil</strong>-<strong>film</strong> thickness H=h/∆r,<br />

equation (7) holds with radial clearance ∆r. In<br />

equation (2) dimensionless numbers for surface<br />

tension σ, <strong>oil</strong> viscosity η l and surface dilatational<br />

viscosity κ are <strong>in</strong>troduced by equations (8)~(10):<br />

Fig.4 Forces act<strong>in</strong>g on a bubble surface

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

217<br />

1 dA<br />

∆ σ = κ<br />

(1)<br />

A dt<br />

(1 +<br />

p<br />

p<br />

a<br />

3<br />

) χ<br />

∧<br />

∧<br />

+ ( B+<br />

C<br />

dχ<br />

2<br />

) χ<br />

dφ<br />

∧<br />

dχ<br />

∧<br />

+ D χ − (1 + B)<br />

= 0<br />

dφ<br />

(2)<br />

∂ δH<br />

{ (<br />

∂ϕ<br />

K<br />

3<br />

∂p<br />

) +<br />

∂ϕ<br />

∂ δH<br />

(<br />

∂ς<br />

K<br />

3<br />

2<br />

∂p<br />

ψ<br />

)} = 6( H<br />

∂ς<br />

η ω<br />

l<br />

∂δ<br />

∂H<br />

+ δ )<br />

∂ς<br />

∂ϕ<br />

(3)<br />

3<br />

α<br />

a<br />

χ<br />

α =<br />

3<br />

1 − α + α χ<br />

a<br />

a<br />

(4)<br />

K<br />

= 1 + 0.5062 α + 9.044 α<br />

2<br />

3<br />

− 46 .83α<br />

+ 60 .13α<br />

4<br />

5<br />

− 23 .85α<br />

(5)<br />

δ = 1 − α<br />

(6)<br />

H<br />

= 1 − ε cos( ϕ − γ )<br />

(7)<br />

∧<br />

B<br />

=<br />

2 σ<br />

p R a a<br />

(8 )<br />

∧<br />

C<br />

=<br />

4η<br />

lω<br />

p<br />

a<br />

(9 )<br />

∧<br />

D<br />

=<br />

4κω<br />

p R a a<br />

(10 )<br />

Differential equations (2) for χ and (3) for p are<br />

<strong>in</strong>tegrated by Runge-Kutta method and by f<strong>in</strong>ite<br />

difference method, respectively, us<strong>in</strong>g periodic<br />

boundary condition with period 2π. This calculation<br />

should be called “bubble <strong>the</strong>ory”. Besides, <strong>pressure</strong><br />

distribution was calculated us<strong>in</strong>g Reynolds boundary<br />

condition, assum<strong>in</strong>g p=dp/dx=0 at <strong>the</strong> boundary <strong>of</strong><br />

<strong>oil</strong>-<strong>film</strong> rupture. This should be called “conventional<br />

<strong>the</strong>ory”. Figures 5a, b and c depict <strong>the</strong> <strong>pressure</strong><br />

distribution obta<strong>in</strong>ed by experiment, bubble <strong>the</strong>ory<br />

and conventional <strong>the</strong>ory, respectively. It can be found<br />

that <strong>the</strong> bubble <strong>the</strong>ory (b) can reproduce ra<strong>the</strong>r well<br />

<strong>the</strong> experimental <strong>pressure</strong> distribution <strong>in</strong>clud<strong>in</strong>g <strong>the</strong><br />

negative <strong>pressure</strong> (a). With <strong>in</strong>creas<strong>in</strong>g load <strong>the</strong><br />

absolute value <strong>of</strong> negative <strong>pressure</strong> <strong>in</strong>creases <strong>in</strong><br />

figures (a) and (b), whereas <strong>the</strong> conventional <strong>the</strong>ory<br />

(c), by assumption, can not reproduce negative<br />

<strong>pressure</strong>.<br />

4. INFLUENCE OF NEGATIVE<br />

PRESSURE ON BEARING<br />

CHARACTERISTICS<br />

Hav<strong>in</strong>g obta<strong>in</strong>ed <strong>the</strong> positive results from<br />

bubble <strong>the</strong>ory above, some parameter study should<br />

now be made to <strong>in</strong>vestigate how <strong>the</strong> bear<strong>in</strong>g<br />

characteristics will be <strong>in</strong>fluenced by <strong>the</strong> development<br />

<strong>of</strong> negative <strong>pressure</strong> [13~16].<br />

Figure 6 depicts <strong>the</strong> specific bear<strong>in</strong>g load p by<br />

bubble <strong>the</strong>ory and conventional <strong>the</strong>ory as function <strong>of</strong><br />

bear<strong>in</strong>g eccentricity ε. The curve for <strong>the</strong> ratio Z <strong>of</strong><br />

both p is also drawn. It can be seen from this figure<br />

that <strong>the</strong> load capacity <strong>in</strong>creases slightly near ε=0.6,<br />

when negative <strong>pressure</strong> is developed <strong>in</strong> <strong>the</strong> <strong>oil</strong>-<strong>film</strong>.<br />

At larger ε <strong>the</strong> effect reverses.

218<br />

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

Fig. 5 Pressure distribution <strong>in</strong> <strong>journal</strong> bear<strong>in</strong>g (1500m<strong>in</strong> -1 ).

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

219<br />

Figure 7 shows <strong>the</strong> reduced bear<strong>in</strong>g coefficient<br />

<strong>of</strong> friction µ’= µ/ψ by both <strong>the</strong>ories and <strong>the</strong>ir ratio Z.<br />

The curves show that <strong>the</strong> bear<strong>in</strong>g friction decreases<br />

slightly near ε=0.6, when negative <strong>pressure</strong> is<br />

developed. At larger ε <strong>the</strong> effect reverses.<br />

Figure 8 depicts <strong>the</strong> <strong>journal</strong> centre orbits<br />

calculated by both <strong>the</strong>ories under vertical load. The<br />

orbit is pushed horizontally and towards bear<strong>in</strong>g<br />

clearance circle when negative <strong>pressure</strong> is developed.<br />

This means that <strong>the</strong> <strong>oil</strong>-<strong>film</strong> force becomes more<br />

“unstable”, that is <strong>the</strong> equilibrium <strong>of</strong> a rotor carried<br />

by <strong>journal</strong> bear<strong>in</strong>gs can become more unstable due to<br />

<strong>the</strong> <strong>oil</strong>-<strong>film</strong> force, when negative <strong>pressure</strong> is<br />

developed.<br />

Figure 9 depicts <strong>the</strong> <strong>oil</strong> flow rate Q out <strong>of</strong> both<br />

sides <strong>of</strong> <strong>the</strong> bear<strong>in</strong>g. The <strong>oil</strong> flow rate decreases by<br />

∆Q, when negative <strong>pressure</strong> is developed, because <strong>the</strong><br />

<strong>oil</strong> flowed out <strong>of</strong> <strong>the</strong> bear<strong>in</strong>g sides is sucked aga<strong>in</strong> by<br />

<strong>the</strong> negative <strong>pressure</strong>.<br />

0<br />

-0.2<br />

-0.4<br />

-0.6<br />

-0.8<br />

-1<br />

ε<br />

0 0.2 0.4 0.6 0.8 1<br />

Conventional<br />

<strong>the</strong>ory<br />

Fig.8 Journal orbit<br />

Bubble <strong>the</strong>ory<br />

(MPa)<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

p<br />

Z<br />

Conventional<strong>the</strong>ory<br />

× Bubble <strong>the</strong>ory<br />

Z=Bubble <strong>the</strong>ory/<br />

Conv.<strong>the</strong>ory<br />

ε<br />

0 0.5 1<br />

Fig.6 Load carry<strong>in</strong>g capacity<br />

p<br />

1<br />

Z<br />

0<br />

Q<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

Conventional <strong>the</strong>ory<br />

Bubble <strong>the</strong>ory<br />

0 0.5 1 ε<br />

Fig.9 Fig.9 Oil Oil flow flow rate rate Q<br />

∆Q<br />

µ’=µ/ψ<br />

Z<br />

150<br />

Z<br />

100<br />

1<br />

Convent. <strong>the</strong>ory<br />

50<br />

Bubble <strong>the</strong>ory<br />

0<br />

0<br />

0 0.5 ε 1<br />

Fig.7 Fig.7 Coefficient <strong>of</strong> <strong>of</strong> friction µ’<br />

CONCLUSIONS<br />

In this paper, existence and <strong>in</strong>fluences <strong>of</strong><br />

negative <strong>pressure</strong> are <strong>in</strong>vestigated for <strong>the</strong> <strong>oil</strong>-<strong>film</strong> <strong>of</strong><br />

<strong>journal</strong> bear<strong>in</strong>g with a circumferential <strong>oil</strong> groove. The<br />

results can be summarized as follows.<br />

(1) Existence <strong>of</strong> negative <strong>pressure</strong> could be<br />

verified experimentally <strong>in</strong> <strong>the</strong> <strong>oil</strong>-<strong>film</strong>.<br />

(2) Tak<strong>in</strong>g <strong>in</strong>to consideration <strong>the</strong> surface<br />

dilatational viscosity, <strong>the</strong> negative <strong>pressure</strong> could be<br />

reproduced.<br />

(3) When negative <strong>pressure</strong> is developed <strong>in</strong> <strong>oil</strong><strong>film</strong>,<br />

<strong>the</strong> bear<strong>in</strong>g load capacity <strong>in</strong>creases slightly and<br />

<strong>the</strong> frictional coefficient decreases near ε=0.6. At<br />

larger ε <strong>the</strong>se changes reverse.

220<br />

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

(4) When negative <strong>pressure</strong> is developed, <strong>the</strong><br />

static <strong>journal</strong> orbit is pushed horizontally and towards<br />

<strong>the</strong> bear<strong>in</strong>g clearance circle. Rotors runn<strong>in</strong>g <strong>in</strong> <strong>journal</strong><br />

bear<strong>in</strong>gs can become <strong>the</strong>n more unstable.<br />

(5) Oil flow is reduced by <strong>the</strong> amount <strong>of</strong> <strong>oil</strong><br />

sucked aga<strong>in</strong> by negative <strong>pressure</strong>, when it is<br />

developed.<br />

REFERENCES<br />

1. Dyer D., Reason B. R., 1976, “A study <strong>of</strong> tensile stress <strong>in</strong> a<br />

<strong>journal</strong>-bear<strong>in</strong>g <strong>oil</strong> <strong>film</strong>”, J. Mech. Eng. Sci., 18-1 , pp. 46-52.<br />

2. Floberg L., 1968, “Sub-cavity <strong>pressure</strong>s and number <strong>of</strong> <strong>oil</strong><br />

streamers <strong>in</strong> cavitation regions with special reference to <strong>the</strong> <strong>in</strong>f<strong>in</strong>ite<br />

<strong>journal</strong> bear<strong>in</strong>g”, Acta Polyt. Scand., Mech. Eng. Ser., No.37, pp.1-<br />

35, Stockholm.<br />

3. Fukamatsu T., 1997, “A Study on <strong>the</strong> Oil-<strong>film</strong> Pressure<br />

Distribution <strong>in</strong> Journal Bear<strong>in</strong>g”, Master course paper <strong>of</strong> Musashi<br />

Inst. <strong>of</strong> Tech., pp.1-88 (<strong>in</strong> Japanese).<br />

4. Ida T., Sugiya T., 1979, “Motion <strong>of</strong> Bubbles <strong>in</strong> Oil under<br />

Chang<strong>in</strong>g Pressure”, Trans. JSME, 45-399, B, pp.1650-1658 (<strong>in</strong><br />

Japanese).<br />

5. Keii T. et al, 1973, Fundamentals <strong>of</strong> boundary phenomena,<br />

Asakura Shoten, Tokyo, pp.183-186 (<strong>in</strong> Japanese).<br />

6. Kawase T., Someya T., 1985, “A Study on Oil-Film Pressure<br />

Distribution <strong>in</strong> Dynamically Loaded Journal Bear<strong>in</strong>g”, T., Trans.<br />

JSME, 51-470, C , pp.2562-2570 (<strong>in</strong> Japanese).<br />

7. Nakai M., Ok<strong>in</strong>o N., 1976, “Tensile stress <strong>in</strong> <strong>journal</strong> bear<strong>in</strong>gs”,<br />

Wear, 39, pp.151-159.<br />

8. Natsumeda S., Someya T., 1987, “<strong>Negative</strong> <strong>pressure</strong>s <strong>in</strong><br />

statically and dynamically loaded <strong>journal</strong> bear<strong>in</strong>gs”, Proc. 13 th<br />

Leeds-Lyon Symposium on Tribology., pp.498-505.<br />

9. Patric J. K., 1967-68, “An experimental <strong>in</strong>vestigation <strong>in</strong>to <strong>the</strong><br />

performance <strong>of</strong> sleeve bear<strong>in</strong>gs subjected to a range <strong>of</strong> alternat<strong>in</strong>g<br />

loads”, Proc. Inst. Mech. Eng., 182-3N, pp.77-88.<br />

10. Plesset M. S., Hsieh D.-Y., 1960, “Theory <strong>of</strong> Gas Bubble<br />

Dynamics <strong>in</strong> Oscillat<strong>in</strong>g Pressure Fields”, Phys. Fluids, 3-6, pp.<br />

882-892.<br />

11. Scriven L. E., 1960, “Dynamics <strong>of</strong> a fluid <strong>in</strong>terface, Equation<br />

<strong>of</strong> motion for Newtonian surface fluids”, Chem. Eng. Sci., 12, pp.<br />

98-108.<br />

12. Scriven L. E., 1962, “On <strong>the</strong> dynamics <strong>of</strong> phase growth”,<br />

Chem. Eng. Sci., 17, pp.55-55.<br />

13. Someya T., 2000, “<strong>Negative</strong> Pressure <strong>in</strong> <strong>the</strong> Oil Film <strong>of</strong><br />

Journal Bear<strong>in</strong>g”, 1 st Report’, Trans. JSME, 66-650, C, pp.3489-<br />

3496 (<strong>in</strong> Japanese).<br />

14. Someya T., 2000, ‘ditto, 2 nd Report’, Trans. JSME, 66-650, C,<br />

pp.3497-3503 (<strong>in</strong> Japanese).<br />

15. Someya T., 2001, ‘ditto, 3 rd Report’, Trans. JSME, 67-655, C,<br />

pp.833-840 (<strong>in</strong> Japanese).<br />

16. Someya T., 2001, “On <strong>the</strong> Development <strong>of</strong> <strong>Negative</strong> Pressure<br />

<strong>in</strong> Oil Film and <strong>the</strong> Characteristics <strong>of</strong> Journal Bear<strong>in</strong>g”, Proc,,6 th<br />

Conference on Dynamical Systems-Theory and Applications, J.<br />

Awrejcewicz et al., Eds., Lodz, Poland, pp.79-110.