Negative pressure in the oil film of journal bearing Dr

Negative pressure in the oil film of journal bearing Dr

Negative pressure in the oil film of journal bearing Dr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

216<br />

NATIONAL<br />

TRIBOLOGY<br />

CONFERENCE<br />

24-26 September 2003<br />

THE ANNALS OF UNIVERSITY<br />

“DUNĂREA DE JOS“ OF GALAŢI<br />

FASCICLE VIII, TRIBOLOGY<br />

2003 ISSN 1221-4590<br />

2. EXPERIMENTAL EVIDENCE OF<br />

NEGATIVE PRESSURE<br />

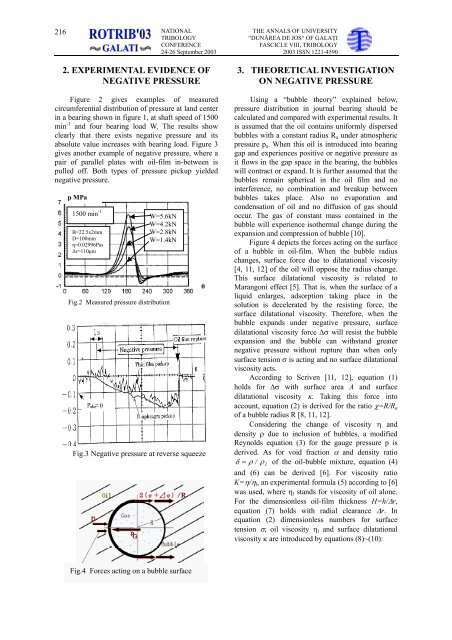

Figure 2 gives examples <strong>of</strong> measured<br />

circumferential distribution <strong>of</strong> <strong>pressure</strong> at land center<br />

<strong>in</strong> a bear<strong>in</strong>g shown <strong>in</strong> figure 1, at shaft speed <strong>of</strong> 1500<br />

m<strong>in</strong> -1 and four bear<strong>in</strong>g load W. The results show<br />

clearly that <strong>the</strong>re exists negative <strong>pressure</strong> and its<br />

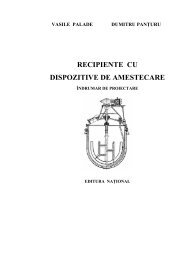

absolute value <strong>in</strong>creases with bear<strong>in</strong>g load. Figure 3<br />

gives ano<strong>the</strong>r example <strong>of</strong> negative <strong>pressure</strong>, where a<br />

pair <strong>of</strong> parallel plates with <strong>oil</strong>-<strong>film</strong> <strong>in</strong>-between is<br />

pulled <strong>of</strong>f. Both types <strong>of</strong> <strong>pressure</strong> pickup yielded<br />

negative <strong>pressure</strong>.<br />

p MPa<br />

1500 m<strong>in</strong> -1 W=5.6kN<br />

W=4.2kN<br />

B=22.5x2mm<br />

W=2.8kN<br />

D=100mm<br />

W=1.4kN<br />

η=0.02996Pas<br />

∆r=110µm<br />

Fig.2 Measured <strong>pressure</strong> distribution<br />

Fig.3 <strong>Negative</strong> <strong>pressure</strong> at reverse squeeze<br />

t<br />

θ<br />

3. THEORETICAL INVESTIGATION<br />

ON NEGATIVE PRESSURE<br />

Us<strong>in</strong>g a “bubble <strong>the</strong>ory” expla<strong>in</strong>ed below,<br />

<strong>pressure</strong> distribution <strong>in</strong> <strong>journal</strong> bear<strong>in</strong>g should be<br />

calculated and compared with experimental results. It<br />

is assumed that <strong>the</strong> <strong>oil</strong> conta<strong>in</strong>s uniformly dispersed<br />

bubbles with a constant radius R a under atmospheric<br />

<strong>pressure</strong> p a . When this <strong>oil</strong> is <strong>in</strong>troduced <strong>in</strong>to bear<strong>in</strong>g<br />

gap and experiences positive or negative <strong>pressure</strong> as<br />

it flows <strong>in</strong> <strong>the</strong> gap space <strong>in</strong> <strong>the</strong> bear<strong>in</strong>g, <strong>the</strong> bubbles<br />

will contract or expand. It is fur<strong>the</strong>r assumed that <strong>the</strong><br />

bubbles rema<strong>in</strong> spherical <strong>in</strong> <strong>the</strong> <strong>oil</strong> <strong>film</strong> and no<br />

<strong>in</strong>terference, no comb<strong>in</strong>ation and breakup between<br />

bubbles takes place. Also no evaporation and<br />

condensation <strong>of</strong> <strong>oil</strong> and no diffusion <strong>of</strong> gas should<br />

occur. The gas <strong>of</strong> constant mass conta<strong>in</strong>ed <strong>in</strong> <strong>the</strong><br />

bubble will experience iso<strong>the</strong>rmal change dur<strong>in</strong>g <strong>the</strong><br />

expansion and compression <strong>of</strong> bubble [10].<br />

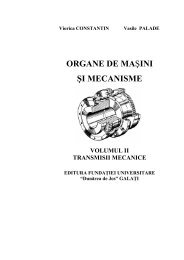

Figure 4 depicts <strong>the</strong> forces act<strong>in</strong>g on <strong>the</strong> surface<br />

<strong>of</strong> a bubble <strong>in</strong> <strong>oil</strong>-<strong>film</strong>. When <strong>the</strong> bubble radius<br />

changes, surface force due to dilatational viscosity<br />

[4, 11, 12] <strong>of</strong> <strong>the</strong> <strong>oil</strong> will oppose <strong>the</strong> radius change.<br />

This surface dilatational viscosity is related to<br />

Marangoni effect [5]. That is, when <strong>the</strong> surface <strong>of</strong> a<br />

liquid enlarges, adsorption tak<strong>in</strong>g place <strong>in</strong> <strong>the</strong><br />

solution is decelerated by <strong>the</strong> resist<strong>in</strong>g force, <strong>the</strong><br />

surface dilatational viscosity. Therefore, when <strong>the</strong><br />

bubble expands under negative <strong>pressure</strong>, surface<br />

dilatational viscosity force ∆σ will resist <strong>the</strong> bubble<br />

expansion and <strong>the</strong> bubble can withstand greater<br />

negative <strong>pressure</strong> without rupture than when only<br />

surface tension σ is act<strong>in</strong>g and no surface dilatational<br />

viscosity acts.<br />

Accord<strong>in</strong>g to Scriven [11, 12], equation (1)<br />

holds for ∆σ with surface area A and surface<br />

dilatational viscosity κ. Tak<strong>in</strong>g this force <strong>in</strong>to<br />

account, equation (2) is derived for <strong>the</strong> ratio χ=R/R a<br />

<strong>of</strong> a bubble radius R [8, 11, 12].<br />

Consider<strong>in</strong>g <strong>the</strong> change <strong>of</strong> viscosity η and<br />

density ρ due to <strong>in</strong>clusion <strong>of</strong> bubbles, a modified<br />

Reynolds equation (3) for <strong>the</strong> gauge <strong>pressure</strong> p is<br />

derived. As for void fraction α and density ratio<br />

δ = ρ / ρ 1 <strong>of</strong> <strong>the</strong> <strong>oil</strong>-bubble mixture, equation (4)<br />

and (6) can be derived [6]. For viscosity ratio<br />

K=η/η l , an experimental formula (5) accord<strong>in</strong>g to [6]<br />

was used, where η l stands for viscosity <strong>of</strong> <strong>oil</strong> alone.<br />

For <strong>the</strong> dimensionless <strong>oil</strong>-<strong>film</strong> thickness H=h/∆r,<br />

equation (7) holds with radial clearance ∆r. In<br />

equation (2) dimensionless numbers for surface<br />

tension σ, <strong>oil</strong> viscosity η l and surface dilatational<br />

viscosity κ are <strong>in</strong>troduced by equations (8)~(10):<br />

Fig.4 Forces act<strong>in</strong>g on a bubble surface