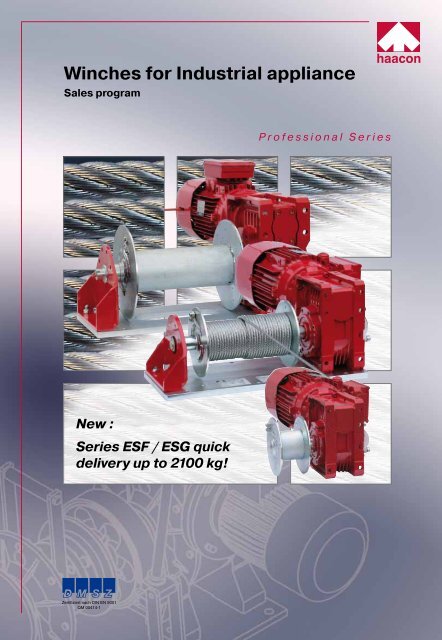

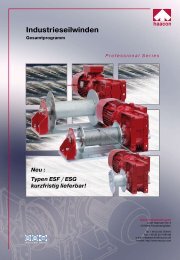

Winches for Industrial appliance

Winches for Industrial appliance

Winches for Industrial appliance

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Winches</strong> <strong>for</strong> <strong>Industrial</strong> <strong>appliance</strong><br />

Sales program<br />

P r o f e s s i o n a l S e r i e s<br />

New :<br />

Series ESF / ESG quick<br />

delivery up to 2100 kg!<br />

Zertifiziert nach DIN EN 9001<br />

QM 00414-1<br />

|1 |

P r o f e s s i o n a l S e r i e s<br />

1<br />

2<br />

3<br />

| 2 |<br />

4<br />

We reserve the right to amend specifications without notice<br />

or obligation

Welcome<br />

We are happy to welcome<br />

you in the new haacon<br />

catalogue and hope we<br />

can give you a clear view<br />

of our products. Winch<br />

engineering is constantly<br />

developing, so some products<br />

have been changed,<br />

some disappeared and<br />

others took their place.<br />

What remains the same<br />

is haacon's ingenuity and<br />

dedication.<br />

to our enlarged motorized winches<br />

sales program<br />

We took the opportunity to change the literature to be more a reference manual<br />

than an inventory list. Taking stock of our activities, we found that most<br />

winches we produced were "special" in one way or the other, be it a slightly<br />

modified standard winch or a winch that has no resemblance to anything in<br />

the catalogue other than the makers name. With this knowledge we decided<br />

that we would serve our customers better by providing them with a detailed<br />

background to winch selection and design, rather than providing them with<br />

a standard program only. In this catalogue you can find several diagrams<br />

that help to make a primary selection of type and size, type of motor and<br />

the required power. As always you are very welcome to ask us, or our local<br />

representative <strong>for</strong> advice on the final selection or possibilities not covered by<br />

this catalogue.<br />

Quick selection<br />

Winch types are now described in general terms, with a short list of non - options.<br />

Although our company philosophy is "nothing is impossible", we must<br />

be realistic too. The non-options are options or combina tions that cannot be<br />

made in that particular series. They will be covered by other series.<br />

We choose not to list all options and winch applica tions, so we have more<br />

space <strong>for</strong> technical in<strong>for</strong>mation and possibly you have found a use <strong>for</strong> the<br />

winch that we had never thought about.<br />

The options indicated by drawings at the bottom of each page are a small<br />

selection of special versions, not saying that these are the only versions<br />

available. The winch capacities listed in the tables refer to a FEM / ISO classification.<br />

The classification system is discussed in detail on page 21 of this<br />

catalogue. The loads and speeds are averages and with increasing demands<br />

the ultimate winch to select might differ from the data average given in this<br />

catalogue.<br />

We hope you will find this catalogue a useful guide that will lead to a successful,<br />

reliable and above all a safe use of haacon equipment.<br />

The long list of more or less boring data and compli cated calculations might<br />

suggest otherwise, but the true interaction between haacon and the customer<br />

lies in personal contact, so…… in case of doubt or questions do contact<br />

us. We are there <strong>for</strong> you, not the other way around.<br />

| 3 |

P r o f e s s i o n a l S e r i e s<br />

Content<br />

Welcome.....................................................................................................3<br />

Designs.......................................................................................................5<br />

ESF-Series..................................................................................................6<br />

ESG-Series..................................................................................................8<br />

HEB-series..................................................................................................10<br />

P-series......................................................................................................10<br />

VTF-series...................................................................................................11<br />

VP-series.....................................................................................................12<br />

CTF-series...................................................................................................13<br />

TN-series....................................................................................................14<br />

TME-series..................................................................................................14<br />

TMV-series..................................................................................................14<br />

Capstans <strong>for</strong> marine and industrial purposes........................................................15<br />

Winch options...............................................................................................16<br />

Motors........................................................................................................17<br />

Controls......................................................................................................18<br />

Power.........................................................................................................19<br />

Duty...........................................................................................................20<br />

Life-time......................................................................................................21<br />

Application sheet...........................................................................................22<br />

Application...................................................................................................23<br />

Just an example. Please find some<br />

more applications on page 23<br />

| 4 |

ESF Series Floating Designs<br />

Drum<br />

Electric<br />

ESG Series Supported Drum<br />

Electric<br />

HEB Series<br />

P Series Compact winch<br />

Electric Hydraulic Pneumatic<br />

VTF Series Floating Drum<br />

Electric Hydraulic Pneumatic<br />

TN/TME/TMV Series<br />

Only Hydraulic<br />

CTF Series<br />

Custom Made<br />

Electric Hydraulic Pneumatic<br />

| 5 |

P r o f e s s i o n a l S e r i e s<br />

ESF-Series<br />

Options:<br />

• Grooved drum<br />

• Devided drum<br />

• Pressure roller<br />

• Load limiter<br />

• Limit switch<br />

• Slack rope device<br />

• Special coating<br />

If a larger drum capacity<br />

is needed, please favor<br />

annother series<br />

Non-options<br />

• Clutch<br />

• Hydraulic drive<br />

• Pneumatic drive<br />

Motorized - Rope winch Type ESF<br />

Specifications<br />

Voltage 400 V 50 Hz/ 3-Phase 230V/ 50 Hz ≈<br />

1 st Layer W.L.L kg 150 250 500 200 400<br />

Storage m 3,4 2,8 3,2 3,4 3,2<br />

V Seil<br />

m/min 8,3 7,2 7,5 7,1 7,5<br />

3 rd Layer W.L.L kg 125 200 400 165 320<br />

Storage m 11,5 9,6 11,0 11,5 11,0<br />

V Seil<br />

m/min 10,2 9,1 9,4 8,6 9,4<br />

max. no. of Layers 3 6 5 6 6 6<br />

max. Storage m 26 17,8 25 26 25<br />

Rope Ø 5 mm Ordinary rope 4 1 5 1 6 1 4 1 6 1<br />

Rating 4 1 Am 1 Am 1 Bm 1 Am 1 Am<br />

Non twisting rope 4 1 5 2 6 2 4 2 6 2<br />

Rating 4 1 Am 1 Bm 1 Bm 1 Bm 1 Bm<br />

Power kW 0,37 0,55 1,1 0,55 1,1<br />

Current A 1,09 1,43 2,82 4,5 7,5<br />

Weight kg<br />

18 21,5 38 23 43,5<br />

w.o. rope<br />

Type ESF 150 250 500 200 400<br />

1)<br />

Single strain strength min. 1570 N/mm 2<br />

2)<br />

Single strain strength min. 1770 N/mm 2<br />

3)<br />

Regular No. of layers: 3<br />

4)<br />

Rating according to DIN 15020 resp. FEM 9.511<br />

5)<br />

suitable ropes, differing rope dimension on request, rope not included<br />

| 6 |<br />

For bigger, smaller, faster or slower units do contact haacon (request sheet page 22)

ESF-Series<br />

H<br />

B<br />

A<br />

Dimension sheets delivered on demand<br />

Dimensions in mm<br />

Type ESF A B H Center<br />

Drum Ø Flange Ø Drum Length<br />

150 94 145 72.5 70 140 61<br />

200 94 145 72.5 70 140 61<br />

250 94 145 72.5 70 140 61<br />

400 125 200 100 90 190 67<br />

500 125 200 100 90 190 67<br />

incl. Pressure roller and base<br />

150 225 200 84.5 70 140 61<br />

200 225 200 84.5 70 140 61<br />

250 225 200 84.5 70 140 61<br />

400 280 220 112 90 190 67<br />

500 280 220 112 90 190 67<br />

ESF winches are designed as modular rope winches <strong>for</strong> small and medium loads with flanged<br />

on wormgear. The simple design is suitable <strong>for</strong> many lifting tasks with lower load cycles and<br />

small load requirements. The winch can also be easily integrated into the given construction<br />

by the mounting holes provided on all sides of the gearbox casing. The wire can take off in any<br />

direction. It has a compact design, because the basic configuration only consists of gear, motor,<br />

and drum. The robust outward impression of the ESF winch is completed by practical corrosion<br />

protection and a combination of high-quality finishing and galvanised parts.<br />

The ESF winch is immediately available.<br />

Do you need winch accessories? We deliver rope pulleys, idling rollers in different executions,<br />

and confected ropes on request. (www.haacon.com/Products/Product selection/<strong>Industrial</strong><br />

Lifting Equipment/Motorized rope winches/Accessories1 .pdf)<br />

Remark: W.L.L. = Working Load Limit<br />

S.W.L. = Safe Working Load<br />

| 7 |

P r o f e s s i o n a l S e r i e s<br />

ESG-Series<br />

Options:<br />

• Grooved drum<br />

• Devided drum<br />

• Enlarged drum<br />

• Pressure roller<br />

• Load limiter<br />

• Limit switch<br />

• Slack rope device<br />

• Clutch<br />

• Special coating<br />

Non-options<br />

• Hydraulic drive<br />

• Pneumatic drive<br />

Motorized rope winch - Type ESG<br />

Specifications<br />

Voltage 400 V 50 Hz/ 3-Phasen 230V/ 50 Hz~<br />

1 st Layer W.L.L. kg<br />

150 250 500 750 990 /<br />

7<br />

1000<br />

1500 2100 200 400 650 1100<br />

Storage m 10 8 10,5 12,5 12 14 14 10 10,5 14 17<br />

Speed m/min 8,3 7,2 7,5 5,1 4,4 5 5 7,1 7,5 4,3 5<br />

3 rd Layer W.L.L. kg 125 200 400 590 775 1200 1650 165 325 520 910<br />

Storage m 34 28 35 43 43 45 45 34 35 48 56<br />

Speed m/min 10,2 9,1 9,4 6,5 5,5 6,1 6,1 8,6 9,4 5,3 5,9<br />

max. Layer 3 6 5 6 7 7 4 3 6 5 7 4<br />

Full storage m 79 53 82 126 126 45 45 79 82 138 76<br />

Rope Ø 5 mm Ordinary<br />

rope<br />

4 1 5 1 6 1 8 1 8 2 11 1 11 2 4 1 6 1 7 1 9 2<br />

Rating 4 1 Am 1 Am 1 Bm 1 Bm 1 Bm 1 Am 1 Cm 1 Am 1 Am 1 Bm 1 Am<br />

Non twisting<br />

rope<br />

4 1 5 2 6 2 8 2 8 2 11 2 11 3 4 1 6 1 7 2 9 2<br />

Rating 4 1 Am 1 Bm 1 Bm 1 Bm 1 Cm 1 Bm 1 Cm 1 Bm 1 Bm 1 Bm 1 Bm<br />

Power kW 0,37 0,55 1,1 1,5 1,5 1,5 2,2 0,55 1,1 1,1 1,1<br />

Current A 1,09 1,43 2,82 3,8 3,8 3,8 5,4 4,5 7,5 7,5 7,5<br />

Weight kg<br />

w.o. rope<br />

29 32,5 52,5 90 98 193 198 34 58 100 195<br />

Type ESG 150 250 500 750 990 1500 2100 200 400 650 1100<br />

1)<br />

Single strain strength min. 1570 N/mm 2<br />

2)<br />

Single strain strength min. 1770 N/mm 2<br />

3)<br />

Single strain strength min. 1960 N/mm 2<br />

4)<br />

Regular No. of layers: 3<br />

5)<br />

Rating according to DIN 15020 resp. FEM 9.511<br />

6)<br />

suitable ropes, differing rope dimension on request, rope not included<br />

7)<br />

From 1000 kg (10 kN) on a load monitoring system is mandatory<br />

| 8 |<br />

For bigger, smaller, faster or slower units do contact haacon (request sheet page 22)

ESG-Series<br />

H<br />

B<br />

A<br />

Dimension sheets delivered on demand<br />

Dimensions in mm<br />

Type ESG A B H Center<br />

Drum Ø Flange Ø Drum Length<br />

150 418 190 84.5 70 140 181<br />

200 418 190 84.5 70 140 181<br />

250 418 190 84.5 70 140 181<br />

400 485 220 112 90 190 211<br />

500 485 220 112 90 190 211<br />

650 581 260 140 110 248 282<br />

750 581 260 140 110 248 282<br />

990/1000 581 260 140 110 248 282<br />

1100 750 380 164 168 279 278<br />

1500 750 380 164 168 279 278<br />

2100 750 380 164 168 279 278<br />

ESG winches are modular rope winches <strong>for</strong> small and medium loads with flanged on wormgear.<br />

The drum is accommodated in a second support bearing.<br />

The ”workhorse“ in winch construction.<br />

Since winch and drum are always mounted on a base plate, which serves as a stand, all options<br />

<strong>for</strong> electrical rope winches can be realised. The ESG winch will be predominantly used <strong>for</strong><br />

medium loads and larger rope capacities than offered by the ESF... model. The robust outward<br />

impression of the ESG winch is completed by practical corrosion protection and a combination<br />

of high-quality finishing and galvanised parts.<br />

The ESG winch is immediately available.<br />

Do you need winch accessories? We deliver rope pulleys, idling rollers in different executions,<br />

and confected ropes on request. (www.haacon.com/Products/Product selection/<strong>Industrial</strong><br />

Lifting Equipment/Motorized rope winches/Accessories1 .pdf)<br />

Remark: W.L.L. = Working Load Limit<br />

S.W.L. = Safe Working Load<br />

| 9 |

P r o f e s s i o n a l S e r i e s<br />

H<br />

H<br />

HEB-Series<br />

A<br />

B<br />

P-Series<br />

A<br />

B<br />

HEB-series<br />

All options are possible on<br />

the HEB -series<br />

P-series<br />

Non-options<br />

All options are possible on<br />

the P-series, although the<br />

compact design with the<br />

gearbox shaft fixed to the<br />

winch frame, and the gearbox<br />

rotating at drumspeed.<br />

This makes options more<br />

expensive than in the other<br />

series<br />

Capacities<br />

Dimensionen in mm<br />

On a daily base we are asked to produce something new or special. In general manufacturers<br />

will be reluctant to even start when the lot to develop is smaller than 10 pieces, let alone when<br />

we speak about single units. haacon realizes that requests <strong>for</strong> single units or smaller series<br />

are to be taken serious. We know were and when we started, and what made us the company<br />

we are today. The HEB-series have the most basic design and are build in a modular way. All options<br />

are possible and can easily be adapted to the basic design. Development now is reduced<br />

to simply adding or combining existing options with the basic design. Consequently we treat<br />

your request <strong>for</strong> a single unit with the same enthusiasm as a bigger series.<br />

The P simply stands <strong>for</strong> planetary, because a planetary gearbox is mounted inside the winch<br />

drum. Having the gearbox inside the drum, means that the overall dimensions are reduced. The<br />

basic dimensions are shown in the tables on this page, but off course we can modify the design<br />

according to your specific requirements.<br />

WINCH<br />

Nom.<br />

1 st layer 3 rd layer Full<br />

S2<br />

FEM<br />

HEB../..<br />

Torque<br />

Nm<br />

W.L.L.<br />

kN<br />

Speed<br />

m/min<br />

Storage<br />

m<br />

W.L.L.<br />

kN<br />

Speed<br />

m/min<br />

Storage<br />

m<br />

Storage<br />

m / Lay<br />

Power kW<br />

kW<br />

RATE<br />

0.0 1000 9 15 36 7 17 120 500 / 9 3 L4-T3<br />

10 1750 17 15 32 15 18 98 375 / 9 5,5 L4-T2<br />

20 2500 22 15 29 18,5 18 100 375 / 9 7,5 L4-T2<br />

45 5000 35 13,5 25 29 16 90 200 / 6 11 L4-T3<br />

65 7500 50 12 27 42 14 95 220 / 6 15 L4-T3<br />

90 14000 66 12 24 54 14 90 250 / 7 18,5 L4-T3<br />

…<br />

800 80000 250 5 21 207 6 85 250 / 7 30 L4-T6<br />

P../.. 1 st layer 3 rd layer Full S2 FEM<br />

20 2500 16 10 33 14 11 115 250 / 6 4 L3-T4<br />

…<br />

800 80000 300 5 48 250 6 170 250 / 4 30 L3-T4<br />

WINCH<br />

HEB../..<br />

Length A<br />

A<br />

Width B<br />

B<br />

C-Height H Center<br />

H<br />

Drum<br />

Ø<br />

Flange<br />

Ø<br />

Drum<br />

Length<br />

Recomm<br />

Rope Ø<br />

Weight<br />

± kg<br />

0.0 1400 500 315 195 410 500 8 245<br />

10 1500 500 315 195 410 500 10 260<br />

20 1500 600 360 244 500 500 12 340<br />

45 1600 600 360 298 500 500 16 400<br />

65 1900 700 410 355 600 500 20 620<br />

90 1900 800 480 406 700 500 22 790<br />

…<br />

…<br />

…<br />

800 2500 1500 820 660 1200 500 36 2450<br />

P../..<br />

20 646 500 580 326 480 450 12 325<br />

…<br />

800 1275 1030 1150 660 1000 960 36 1800<br />

…<br />

…<br />

| 10 |

VTF-series<br />

Options<br />

Drum dimensions can be<br />

modified within certain<br />

limits, but capacities will<br />

change accordingly<br />

H<br />

Non-options<br />

• De-clutch<br />

A<br />

B<br />

Manufacturing winches means making a clever combinations of existing components. The planetary<br />

gearbox is one of the most important component used in today's winches. A feature of<br />

the planetary gearbox is that it has a rein<strong>for</strong>ced shaft with a set of conical roller bearings, capable<br />

of taking very high radial loads. The drum is not sup ported by an end bearing, making it look<br />

as if it's floating. The advantages are obvious. Reduced cost price, because part of a frame and<br />

the end bearing can be saved and as a consequence the winch is very compact. The wire can<br />

take off in any direction. Another feature is the modular motor adaptor, giving us the possibility<br />

by simply selecting the right adaptor to mount any electric, hydraulic or pneumatic motor.<br />

Capacities<br />

Dimensionen in mm<br />

Typ Nom.<br />

1 st layer 3 rd layer Full S2 FEM<br />

VTF../.. Torque W.L.L. Speed Storage W.L.L. Speed Storage Storage Power<br />

Nm kN m/min m kN m/min m m / Lay kW<br />

RATE<br />

800 1000 8,5 11 13 7,5 12,5 50 150 / 8 2,2 L4-T2<br />

1400 1750 15 8 10 13 9 40 100 / 7 3 L4-T3<br />

1500 2500 20 8 10 17 9 40 95 / 6 4 L4-T3<br />

2500 5000 34 8 8 28 9,5 32 60 / 5 5,5 L4-T3<br />

3500 7500 40 8 14 35 9 50 75 / 4 7,5 L4-T5<br />

4500 9000 49 8 13 41 9,5 50 71 / 4 7,5 L4-T3<br />

6000 14000 60 9,5 15 50 11 57 105 / 5 11 L3-T3<br />

8500 17000 75 9,8 13 62 11,5 53 100 / 5 15 L3-T3<br />

With Pneumatic or Hydraulic drive the speed will change<br />

Typ<br />

VTF../..<br />

A B H Center<br />

Drum<br />

Ø<br />

Flange<br />

Ø<br />

Drum<br />

Length<br />

Recomm<br />

Rope Ø<br />

Weight<br />

± kg<br />

800/1400 310 440 215 244 380 176 8 \11 120/140<br />

1500/2500 350 500 235 272 410 191 12\14 200/240<br />

3500/4500 455 580 280 355 500 266 16\18 370/420<br />

6000/8500 510 750 355 406 625 310 20\22 590/650<br />

| 11 |

P r o f e s s i o n a l S e r i e s<br />

VP-series<br />

Options:<br />

All options are possible on<br />

the VP-series<br />

H<br />

B<br />

A<br />

Pulling a load is fundamentally different from lifting a load. A load pulled in a horizontal plane can<br />

not cause danger when released. This is the reason why regulations <strong>for</strong> pulling winches differ a<br />

lot from regulations <strong>for</strong> lifting. Pulling winches allow <strong>for</strong> a declutch possibility and the drum diameters<br />

are allowed to be smaller than with lifting tools. The main advantage is that with a smaller<br />

drum diameter, we can get a higher <strong>for</strong>ce (line pull) than with a bigger drum diameter, using<br />

the same size of gearbox. With a declutch we can spool off the steel wire freely and relieve the<br />

gearbox from high static loads (holding capacity) when the drum is held by a bandbra ke. With<br />

a de-clutched drum, we can also use the driving shaft running through the drum <strong>for</strong> another<br />

purpose. Often this almost free advantage is used to mount a warping head (horizontal capstan,<br />

bottom left drawing).<br />

Capacities<br />

WINCH Nom.<br />

1 st layer 3 rd layer Full S2<br />

VP../..<br />

FEM<br />

Torque W.L.L. Speed Storage W.L.L. Speed Storage Storage Power<br />

RATE<br />

Nm kN m/min m kN m/min m m / Lay kW<br />

65 8500 60 13 19 49 16 78 187 / 6 L2-T3<br />

150 18500 97 13 22 80 16 91 218 / 6 L2-T3<br />

400 35000 145 13 24 121 16 101 241 / 6 L2-T3<br />

600 50000 180 13 28 150 16 117 221 / 5 L2-T3<br />

With Pneumatic or Hydraulic drive the speed will be changed<br />

Dimensionen in mm<br />

WINCH<br />

VP../..<br />

A B H Center<br />

Drum<br />

Ø<br />

Flange<br />

Ø<br />

Drum<br />

Length<br />

Recomm<br />

Rope Ø<br />

Weight<br />

± kg<br />

65 930 600 350 270 600 500 16 495<br />

150 1085 700 400 360 700 550 20 750<br />

400 1205 900 500 460 880 600 24 1000<br />

600 1340 1000 510 533 950 700 28 1300<br />

| 12 |<br />

For bigger, smaller, faster or slower units do contact haacon (request sheet page 22)

CTF-series<br />

Options like press roller,<br />

upper and lower limit<br />

switch etc. are always to be<br />

discussed in cooperation<br />

with the customer, since<br />

there is no frame on which<br />

to fasten these options.<br />

Non-options<br />

• Electric motor<br />

• Air motor<br />

• Coupling/drum de-clutch<br />

Most winches can be considered stand alone units. If there is a solid foundation, the winch<br />

frame can be fastened to the foundation. But if the foundation is part of a machine, <strong>for</strong> example<br />

the jib of a crane, why not use it as the winch-frame. It saves space and money and it looks better.<br />

The CTF series are winches without a frame, developed <strong>for</strong> OEM crane-building. Cranes are<br />

very often production tools, think of harbors, offshore plat<strong>for</strong>ms, mining etc. So called power<br />

applications where speed is an important way to improve the results. The high speed in the CTF<br />

is obtained by hydraulic motors from Danfoss on the series 700 and 1500 and <strong>for</strong> the series<br />

1750 upto 30000 Rexroth motors are build on. Both the fail safe multi-disc brake and the "nose"<br />

of the motor are integrated in the gearbox, to build as compact as possible.<br />

Capacities<br />

WINCH<br />

1 st layer 3 rd layer Full<br />

Oil<br />

CTF..<br />

FEM<br />

W.L.L. Speed Storage W.L.L. Speed Storage Storage Pressure Flow<br />

Floating<br />

RATE<br />

kN m/min M kN m/min m m / Lay bar l/min<br />

700 7 50 6 6,2 6,2 20 29 \ 4 100 50<br />

1500 15 50 9 13 13 32 45 \ 4 175 60<br />

1750 17,5 50 9 15 15 32 45 \ 4 175 75<br />

3250 32,5 50 8 27 27 25 37 \ 4 200 90 L1-T5<br />

5750 57,5 35 10 48 48 35 50 \ 4 230 100<br />

9000 90 36 11 74 74 40 55 \ 4 230 140<br />

…<br />

25000 250 25 15 210 210 53 76 \ 4 220 300<br />

WINCH<br />

CTF..<br />

Bearing<br />

W.L.L.<br />

kN<br />

1 st layer<br />

Speed<br />

m/min<br />

Storage<br />

m<br />

W.L.L.<br />

kN<br />

3 rd layer<br />

Speed<br />

m/min<br />

Storage<br />

m<br />

Full<br />

Storage<br />

m / Lay<br />

Oil<br />

Pressure<br />

bar<br />

Flow<br />

l/min<br />

700 7 50<br />

6,2<br />

29 \ 4 100 50<br />

Depends on<br />

drumlegth<br />

Depends on<br />

drumlegth<br />

Depends on<br />

drumlegth<br />

FEM<br />

RATE<br />

1500 15 50 13 45 \ 4 175 60<br />

1750 17,5 50 15 45 \ 4 175 75<br />

3250 32,5 50 27 37 \ 4 200 90 L1-T5<br />

5750 57,5 35 48 50 \ 4 230 100<br />

9000 90 36 74 55 \ 4 230 140<br />

…<br />

…<br />

25000 250 25 210 76 \ 4 220 300<br />

…<br />

For bigger, smaller, faster or slower units do contact haacon (request sheet page 22)<br />

| 13 |

P r o f e s s i o n a l S e r i e s<br />

H<br />

A<br />

B<br />

Things other people do better. We think we can build you good, excellent value<br />

<strong>for</strong> money, winch, almost regardless of its specification. For some types of<br />

winches however other people simply do a better job than we. The notable exceptions<br />

are hand winches, and very compact hydraulic crane winches. Located<br />

in one particular region in the north of Italy a small number of companies are<br />

in fierce competition to make the best and most competitive hydraulic crane<br />

winches world wide. We represent the smallest but most dedicated manufacturer<br />

(TMA) which has three different series of winches. The TN type is the most<br />

compact type. It has been a long time favourite of the pile driving business as<br />

an auxiliary winch <strong>for</strong> lifting piles and general light lifting work. Also <strong>for</strong> use on compact marine<br />

cranes or indeed on truck mounted cranes. If you are looking <strong>for</strong> a very compact winch with<br />

amazing per<strong>for</strong>mance <strong>for</strong> its size, this is it.<br />

TN-series<br />

TME-series<br />

TMV-series<br />

Options:<br />

• Grooved drum<br />

• Pressure roller<br />

• Load limiter<br />

• Lower limit switch<br />

• Marine paints<br />

Capacities<br />

The heavy type TME covers what is effectively the middle field in the TMA programme, both<br />

in capacity as in weight. Swl’s from 1,5 tonne to 7,5 tonne, combined with speeds of around<br />

20 to 40 m/min. It is a competent per<strong>for</strong>mer <strong>for</strong> applications were a medium lifting capacity is<br />

required albeit not at the speed of the fast type but at a more competitive price.<br />

The fast type TMV covers a range of winches starting with a 3,5 tonne model, and ending<br />

with an impressive 16 tonne swl model. The speeds are between 40 and 60 m/min , but these<br />

are maximum speeds, and the winches can indeed run much slower <strong>for</strong> accurate lifting and<br />

lowering. These winches are not designed <strong>for</strong> compactness or lightness, in spite of the fact that<br />

there is a "heavy" type available, these are the fastest and biggest winches in the TMA line up.<br />

WINCH 1 st layer 3 rd layer Full<br />

Oil<br />

TN..<br />

FEM<br />

W.L.L. Speed Storage W.L.L. Speed Storage Storage Pressure Flow<br />

RATE<br />

kN m/min m kN m/min m m / Lay bar l/min<br />

TN 04 5 42 8 4,3 48 26 36 / 4 175 25<br />

TN 07 8 38 13 6,9 44 41 74 / 5 165 30<br />

TN 09 10 38 11 8,5 45 34 50 / 4 175 40<br />

TN 14 15 43 13 12,8 50 42 59 / 4 190 50 L1-T5<br />

TN 18 20 34 11 16,8 40 38 53 / 4 200 50<br />

…<br />

TN 51 57 27 22 47,7 33 72 101/ 4 205 100<br />

…<br />

Dimensionen in mm<br />

WINCH<br />

TN..<br />

A B H Center<br />

Drum Ø Drum<br />

Length<br />

Recomm<br />

Rope Ø<br />

Weight<br />

± kg<br />

TN 04 239 218 117 146 110 6 25<br />

TN 07 275 295 133 167 174 7 40<br />

TN 09 275 295 133 167 174 8 41<br />

TN 14 319 315 175 202 187 9 71<br />

TN 18 325 315 175 202 187 10 71<br />

…<br />

TN 51 570 630 292 353 360 18 296<br />

…<br />

| 14 |<br />

For bigger, smaller, faster or slower units do contact haacon (request sheet page 22)

Capstans<br />

<strong>for</strong> marine<br />

and industrial<br />

purposes<br />

This picture shows a brand<br />

new replica of an historic<br />

capstan.<br />

To respect the characteristic<br />

view of the ”Port de<br />

Marseille”. No other than<br />

the current capstans were<br />

allowed on site. Again a<br />

good example that we<br />

build what the customer<br />

asks <strong>for</strong>, rather than to sell<br />

what is available.<br />

Capstans have been part of ships equipment <strong>for</strong> centuries. The modern capstan is motor driven<br />

and can achieve high line pulls and high speeds thanks to powerful motors integrated with<br />

sturdy trans missions. Electric, hydraulic or pneumatic, the choice is yours. We do a wide range<br />

of capstans ranging from flush fitted deck capstans <strong>for</strong> a clean deck line to the classic console<br />

mounted capstan. Also very popular proved to be our horizontal capstans used in varying roles<br />

from pulling rolling stock on shunting yards in Belgium to moving cable ferry’s in deepest Africa.<br />

You want a standard electric capstan? we are happy to supply one. Or rather an exotic capstan<br />

no one can supply? we can help 100 kg line pull we have them, 10 tonne yes, those too.<br />

For bigger, smaller, faster or slower units do contact haacon (request sheet page 22)<br />

| 15 |

P r o f e s s i o n a l S e r i e s<br />

Winch options<br />

Pressure Roller<br />

Pushes slack wire to drum,<br />

helps to spool the wire better<br />

on the drum.<br />

Band brake<br />

Extra brake fitted on the drum,<br />

manual or automatic.<br />

Slack rope device<br />

Detects slack wire. Stops the winch or gives<br />

a warning signal.<br />

Limit switch<br />

Counts the number drum revolutions.<br />

Limits upper and lower stroke.<br />

Drum guard<br />

Covers rotating parts,<br />

protects user.<br />

Clutch<br />

Manual clutch<br />

to release the drum.<br />

On pulling winches<br />

only.<br />

Spooler<br />

Guides wire on to drum,<br />

helps to spool the wire better<br />

on the drum.<br />

Brake release pump<br />

Releases the brake <strong>for</strong> emergency<br />

operation<br />

For example on "man riding"<br />

winches.<br />

| 16 |<br />

For all other options please contact haacon

Motors<br />

What motor is the best motor to use <strong>for</strong> a<br />

winch, and why?<br />

The choice <strong>for</strong> the right motor depends<br />

mainly on the available power source.<br />

Mobile applications like earth moving<br />

machines, piling equipment and mobile<br />

cranes normally have a hydraulic power<br />

source, they don't carry high power compressors<br />

or generators. For these applications<br />

a hydraulic motor is selected.<br />

Stationary applications, most of the time<br />

can obtain power from the main grid,<br />

also on ships the electric power sources<br />

become more and more power ful, so an<br />

electric motor would be the right choice.<br />

Than we have the so called hazardous environments,<br />

where explosions might occur,<br />

think of exploitation of natural sources,<br />

mining on and off-shore oil and gas.<br />

Air motors are very common in these fields.<br />

Advantages and disadvantages:<br />

Electric motors<br />

economical and efficient<br />

clean and simple<br />

Energy mostly available<br />

Hydraulic motors<br />

small size<br />

Speed control easy<br />

Pneumatic motors<br />

Speed control expensive<br />

Explosion proofing expensive<br />

difficult to protect from<br />

extreme environment<br />

Power pack needed<br />

Pipes and hoses needed<br />

Abstract Protection Class<br />

Electric<br />

Hydraulic<br />

Wheel Fan Brake Electric motor<br />

Dust proofing (1) Water proofing (2)<br />

Protection max. Ø. of object Protection protect against<br />

class that can penetrate<br />

the protection<br />

class<br />

0 everything 0 nothing<br />

1 under 52,5 mm 1 Tripping from straight top<br />

2 under 12,5 mm 2 Tripping from at angle 0 bis15°<br />

3 under 2,5 mm 3 Spray at max. 60° (rain proof)<br />

4 under 1 mm 4 Water from all directions no pressure<br />

5 semi-dustproof 5 All directions, low pressure<br />

6 dustproof 6 All directions, medium pressure<br />

7 Immersion at 1m <strong>for</strong> 30 min.<br />

8 Immersion no limit<br />

Brake valve Valve Hydraulic motor Brake<br />

small size<br />

small size<br />

Speed control easy<br />

suitable <strong>for</strong> harsh environments<br />

Compressor needed<br />

Pipes and hoses needed<br />

noisy<br />

Torque drops with speed<br />

Each winch motor needs a control, after<br />

all motors are machines and they don't<br />

start moving unless they are told to do so<br />

(or to stop <strong>for</strong> that matter). The manner<br />

to control the winch depends on its task.<br />

Is it a stand alone lifting tool or a part of<br />

a complete automated process, to name<br />

just two extremes. There are no "standard"<br />

controls. You can express exactly what is<br />

needed. This can vary from the cheapest<br />

basic control, to a completely computerized<br />

control system. Some control options<br />

are shown on page 18.<br />

Air vane motor<br />

Air piston motor<br />

Valve Air vane motor<br />

Remote valve Hand valve Air piston motor Brake<br />

| 17 |

P r o f e s s i o n a l S e r i e s<br />

Controls<br />

Electric Hydraulic Pneumatic<br />

Push Button Up / Down /<br />

Emergency<br />

P<br />

P<br />

P<br />

Hydraulic<br />

P<br />

P<br />

P<br />

Aluminium Valve<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

Pendant Control Pendant Control Cast Iron Valve<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

Radio Control Foot Control Remote Control<br />

Variable Speed Function Valves Pendant Control<br />

| 18 |<br />

For all other options please contact haacon

Power<br />

40<br />

75 150 225 300<br />

L/Min<br />

Oil Flow<br />

Power is the ability to deliver<br />

a certain per<strong>for</strong>mance<br />

in a certain time.<br />

Speed (V) and load (F)<br />

combined, can be expressed<br />

in power (P in kW)<br />

by a mathematical <strong>for</strong>mula:<br />

P = (V x F) : 6120<br />

P in kW, V in meters/min.,<br />

F in kg (1 kg ~ 10 Newton),<br />

6120 is constant.<br />

The theoretical value can<br />

easily be calculated, but in<br />

practice we need to install<br />

sufficient power to overcome<br />

efficiency losses.<br />

Cable on sheaves, cable<br />

on drum, gearbox, motor<br />

electric or hydraulic and<br />

the supply lines all create<br />

losses.<br />

To overcome these losses<br />

we need to install extra<br />

power. In the power chart<br />

we already accounted <strong>for</strong><br />

an average loss,<br />

so the power you find in the<br />

graph is roughly the installed<br />

power.<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

LINE SPEED M/min.<br />

5.5Kw<br />

3Kw<br />

2.2Kw<br />

1.1Kw<br />

22Kw<br />

18.5Kw<br />

15Kw<br />

11Kw<br />

7.5Kw<br />

55Kw<br />

45Kw<br />

37Kw<br />

30Kw<br />

Planetary winch total efficiency 80%<br />

75Kw<br />

90Kw<br />

Example:<br />

Load (F) 27 Ton, speed (V) 16 meter/min, give 88 kW by calculation. Installed electric motor will<br />

be 90 kW<br />

Hydraulic required, with available 300 liter/min, a pressure of 190 bar is needed. Or; When we<br />

only have 150 liter/min. available oil flow, we need to go to a pressure over 360 Bar. Please<br />

check the available pressure and flow in hydraulic applications and make sure it suits the power<br />

chart's requirements.<br />

110Kw<br />

132Kw<br />

160Kw<br />

LINE PULL<br />

Tonne<br />

0 5 10 15 20 25 30 35 40<br />

PLANETARY WINCH<br />

Example:<br />

27 tonne pull at 16 m/min speed give 90 kW<br />

90 kW at 186 bar give min. 300 l/min<br />

Pressure<br />

Bar<br />

Air winches<br />

Air pressure 7 bar<br />

Air consumsion 21 l/s per kW<br />

420<br />

360<br />

300<br />

240<br />

180<br />

120<br />

60<br />

| 19 |

P r o f e s s i o n a l S e r i e s<br />

Duty<br />

Winch selection<br />

The basic winch-data in this catalogue, are based<br />

on the international FEM classification. Note that<br />

some local regulations might differ from these<br />

standards. This will help you to select the proper<br />

winch <strong>for</strong> the required application, and to understand<br />

the philo so phy behind the data in this<br />

catalogue.<br />

Some winches are seldom used, others quite<br />

often and some have to work all day. A basic 500<br />

kg winch, lifting the 500 kg once or twice in it’s<br />

lifetime, will have an unlimited life, whereas the<br />

same winch working 24 hours a day might not last<br />

<strong>for</strong> a year.<br />

Linespeed and drumtorque<br />

The linespeed of the winch is an important issue,<br />

because there is a direct link between linespeed<br />

and life-time. Basically the life-time is based on<br />

the drumtorque and total number of drumcycles.<br />

Any linespeed value in the catalogue can be<br />

changed according to customers request. Increasing<br />

the linespeed, with the same drumtorque,<br />

reduces the amount of time to reach the total<br />

number of drumcycles, thus reduces the life-time.<br />

Increasing or decreasing the drumtorque by altering<br />

linepull or drumdiametre, has an even more<br />

dramatic (exponential) effect on the winches<br />

life-time. (time is considered to be working time,<br />

standing still does not matter) For this reason it’s<br />

important to know how and how often the winch<br />

will be used, rather than just to select a winch that<br />

according the catalogue "seems" to have the right<br />

capacity. The haacon catalogue roughly guides<br />

you to select a winchtype, with linepull linespeed,<br />

drumtorque and FEM rating.<br />

FEM rating<br />

Once we know;<br />

•What has to be lifted, the load in kg or in Newton<br />

(1 kg = 9,81 N.)<br />

•Is the load always the same, or does it vary?<br />

If the load changes we need to know the percentage<br />

off load in relation to the percentage<br />

in time.<br />

For example:<br />

Max load 500 kg, use 20% off the time.<br />

Average load 400 kg, use 70% off the time.<br />

Minimum load 200 kg, use 10% off the time. With<br />

this "load spectrum" you can work out the Spectrum<br />

factor Km.<br />

Once we have worked out the average daily use<br />

and load, we can "FEM- rate" the winch. In general<br />

the haacon wormgear winches are rated FEM<br />

M3/M4. The planetairy winches are rated FEM<br />

M6/M7. If a lower FEM rating is allowed, because<br />

the winch will be seldom used or the max. load is<br />

seldom lifted, we could select a smaller transmission,<br />

or up-rate the winch capacity. Should the<br />

winch be <strong>for</strong> heavy-duty and work very often, we<br />

need to select a bigger transmission, or de-rate<br />

the winch capacity.<br />

| 20 |

Life-time<br />

Table 1 - Winch „FEM“ classification<br />

Winch Class<br />

Load spectrum<br />

Effective use<br />

T0 T1 T2 T3 T4 T5 T6 T7 T8 T9<br />

L1 M1 M1 M1 M2 M3 M4 M5 M6 M7 M8<br />

L2 M1 M1 M2 M3 M4 M5 M6 M7 M8 M8<br />

L3 M1 M2 M3 M4 M5 M6 M7 M8 M8 M8<br />

L4 M2 M3 M4 M4 M6 M7 M8 M8 M8 M8<br />

The <strong>for</strong>mula<br />

Km = ((F1/Fmax) 3 x (t1/T)) + ((F2/Fmax) 3 x (t2/T)) + ((F3/Fmax) 3 x (t3/T)) etc.<br />

Example:<br />

Winch max load 2000 kg (20 kN)<br />

Winch life request 1000 hours<br />

Winch use 1 hour/day – 10 % time at 1800 kg, 30 % time at 1200 kg, 60% time at 1000 kg<br />

In this example the Km factor (winch use) will be;<br />

Km = ((1800/2000) 3 x 0,1) + ((1200/2000) 3 x 0,3) + ((1000/2000) 3 x 0,6) = 0,21<br />

Km = 0,21 (table 3)<br />

leads to symbol L2<br />

The use and life-expectancy (table 2) leads to symbol T3<br />

The FEM classification (table 1) leads to symbol M3<br />

The FEM rating <strong>for</strong> this application is T3-L2 – M3<br />

Table 2 - Effective use and lifetime<br />

Symbol<br />

Total effictive use<br />

(lifetime in hours) „T“<br />

Daily use<br />

hours<br />

T0 T< 200 < 0,12<br />

T1 200

P r o f e s s i o n a l S e r i e s<br />

Fax to 0049 (0) 9375- 8486<br />

via email to hebetechnik@haacon.de<br />

Application sheet<br />

Company ..................................................... Date ............................................................<br />

Street............................................................<br />

Phone..........................................................<br />

PO Box......................................................... Fax ............................................................<br />

Official in charge..........................................<br />

Email...........................................................<br />

Pieces...........................<br />

REQUIREMENTS:<br />

Hoisting (vertical) ............kg<br />

Pulling (horizontal) ............kg<br />

Rope capacity<br />

............m<br />

Line speed<br />

............m/min<br />

BGV D8 1 BGV C1 2<br />

Temperature<br />

............°C<br />

MOTOR:<br />

Electric<br />

400 V - AC 230 V - AC 24 V - DC<br />

Protection IP......... duty ratio..............<br />

Indoor use<br />

Outdoor use<br />

Hydraulic<br />

Pressure................ bar<br />

Flow rate................l/min.<br />

Pneumatic<br />

Air pressure........... bar<br />

Air capacity............l/s<br />

OPTION:<br />

Limit switch<br />

Slack wire switch<br />

Load limiter<br />

Disengager / clutch (applicable <strong>for</strong> pulling<br />

winches only)<br />

Pressure roller<br />

Grooved drum<br />

Devided drum<br />

others......................................................<br />

CONTROLS:<br />

Pendant remote control<br />

Control box with push-buttons<br />

others......................................................<br />

PAINTING:<br />

Standard RAL 5010 gentian blue<br />

Special RAL-N°.:<br />

Documentation / Type plate<br />

english<br />

german<br />

french<br />

other<br />

Application:<br />

.............................................................................................................................................<br />

.............................................................................................................................................<br />

.............................................................................................................................................<br />

.............................................................................................................................................<br />

1<br />

German Accident Prevention Regulations (BG) <strong>for</strong> winches, lifting- and pulling equipment<br />

2<br />

German Accident Prevention Regulations (BG) <strong>for</strong> event areas, studios and scenes<br />

| 22 |

Application<br />

5<br />

8<br />

6<br />

9<br />

7<br />

10<br />

| 23 |

P r o f e s s i o n a l S e r i e s<br />

haacon hebetechnik gmbh<br />

Josef-Haamann-Str. 6<br />

D-97896 Freudenberg/Main<br />

Tel. + 49 (0) 93 75/84-0<br />

Fax + 49 (0) 93 75/84-86<br />

hebetechnik@haacon.de<br />

Regional Sales<br />

represented by<br />

haacon France Sàrl<br />

3 D, rue du Fort<br />

F - 67118 Strasbourg<br />

Tel. + 33 (0)3 90 / 40 30 10<br />

Fax + 33 (0)3 90 / 40 30 14<br />

haaconfrance@haacon.com<br />

haacon hebetechnik austria gmbh<br />

Ing. Johannes Haller<br />

Hauptplatz 44<br />

A-2293 Marchegg<br />

Tel. + 43 (0) 2285 6 48 39<br />

Fax + 43 (0) 2285 6 48 3922<br />

j.haller@haacon.com<br />

All sales partner adresses are available on<br />

www.haacon.com/contact/Sales partner/<br />

| 24 |<br />

© haacon hebetechnik gmbh edition_en / Copy 1000 / 01 2009 Article No. 098 251