OSTP â Outokumpu Stainless Tubular Products

OSTP â Outokumpu Stainless Tubular Products

OSTP â Outokumpu Stainless Tubular Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

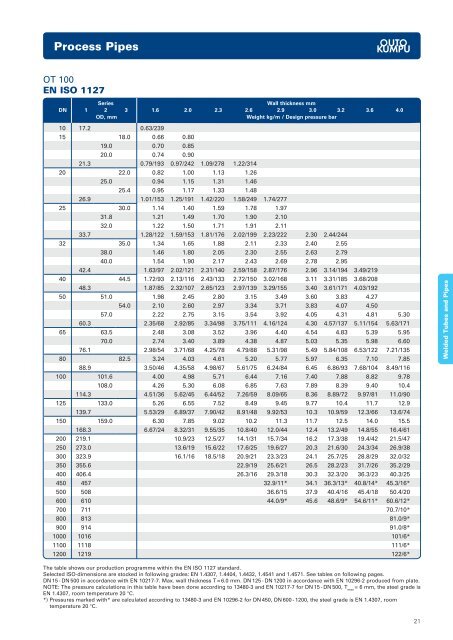

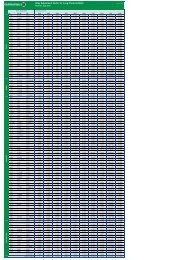

Process Pipes<br />

OT 100<br />

EN ISO 1127<br />

Series<br />

Wall thickness mm<br />

DN 1 2 3 1.6 2.0 2.3 2.6 2.9 3.0 3.2 3.6 4.0<br />

OD, mm<br />

Weight kg/m / Design pressure bar<br />

10 17.2 0.63/239<br />

15 18.0 0.66 0.80<br />

19.0 0.70 0.85<br />

20.0 0.74 0.90<br />

21.3 0.79/193 0.97/242 1.09/278 1.22/314<br />

20 22.0 0.82 1.00 1.13 1.26<br />

25.0 0.94 1.15 1.31 1.46<br />

25.4 0.95 1.17 1.33 1.48<br />

26.9 1.01/153 1.25/191 1.42/220 1.58/249 1.74/277<br />

25 30.0 1.14 1.40 1.59 1.78 1.97<br />

31.8 1.21 1.49 1.70 1.90 2.10<br />

32.0 1.22 1.50 1.71 1.91 2.11<br />

33.7 1.28/122 1.59/153 1.81/176 2.02/199 2.23/222 2.30 2.44/244<br />

32 35.0 1.34 1.65 1.88 2.11 2.33 2.40 2.55<br />

38.0 1.46 1.80 2.05 2.30 2.55 2.63 2.79<br />

40.0 1.54 1.90 2.17 2.43 2.69 2.78 2.95<br />

42.4 1.63/97 2.02/121 2.31/140 2.59/158 2.87/176 2.96 3.14/194 3.49/219<br />

40 44.5 1.72/93 2.13/116 2.43/133 2.72/150 3.02/168 3.11 3.31/185 3.68/208<br />

48.3 1.87/85 2.32/107 2.65/123 2.97/139 3.29/155 3.40 3.61/171 4.03/192<br />

50 51.0 1.98 2.45 2.80 3.15 3.49 3.60 3.83 4.27<br />

54.0 2.10 2.60 2.97 3.34 3.71 3.83 4.07 4.50<br />

57.0 2.22 2.75 3.15 3.54 3.92 4.05 4.31 4.81 5.30<br />

60.3 2.35/68 2.92/85 3.34/98 3.75/111 4.16/124 4.30 4.57/137 5.11/154 5.63/171<br />

65 63.5 2.48 3.08 3.52 3.96 4.40 4.54 4.83 5.39 5.95<br />

70.0 2.74 3.40 3.89 4.38 4.87 5.03 5.35 5.98 6.60<br />

76.1 2.98/54 3.71/68 4.25/78 4.79/88 5.31/98 5.49 5.84/108 6.53/122 7.21/135<br />

80 82.5 3.24 4.03 4.61 5.20 5.77 5.97 6.35 7.10 7.85<br />

88.9 3.50/46 4.35/58 4.98/67 5.61/75 6.24/84 6.45 6.86/93 7.68/104 8.49/116<br />

100 101.6 4.00 4.98 5.71 6.44 7.16 7.40 7.88 8.82 9.78<br />

108.0 4.26 5.30 6.08 6.85 7.63 7.89 8.39 9.40 10.4<br />

114.3 4.51/36 5.62/45 6.44/52 7.26/59 8.09/65 8.36 8.89/72 9.97/81 11.0/90<br />

125 133.0 5.26 6.55 7.52 8.49 9.45 9.77 10.4 11.7 12.9<br />

139.7 5.53/29 6.89/37 7.90/42 8.91/48 9.92/53 10.3 10.9/59 12.3/66 13.6/74<br />

150 159.0 6.30 7.85 9.02 10.2 11.3 11.7 12.5 14.0 15.5<br />

168.3 6.67/24 8.32/31 9.55/35 10.8/40 12.0/44 12.4 13.2/49 14.8/55 16.4/61<br />

200 219.1 10.9/23 12.5/27 14.1/31 15.7/34 16.2 17.3/38 19.4/42 21.5/47<br />

250 273.0 13.6/19 15.6/22 17.6/25 19.6/27 20.3 21.6/30 24.3/34 26.9/38<br />

300 323.9 16.1/16 18.5/18 20.9/21 23.3/23 24.1 25.7/25 28.8/29 32.0/32<br />

350 355.6 22.9/19 25.6/21 26.5 28.2/23 31.7/26 35.2/29<br />

400 406.4 26.3/16 29.3/18 30.3 32.3/20 36.3/23 40.3/25<br />

450 457 32.9/11* 34.1 36.3/13* 40.8/14* 45.3/16*<br />

500 508 36.6/15 37.9 40.4/16 45.4/18 50.4/20<br />

600 610 44.0/9* 45.6 48.6/9* 54.6/11* 60.6/12*<br />

700 711 70.7/10*<br />

800 813 81.0/9*<br />

900 914 91.0/8*<br />

1000 1016 101/6*<br />

1100 1118 111/6*<br />

1200 1219 122/6*<br />

Welded Tubes and Pipes<br />

The table shows our production programme within the EN ISO 1127 standard.<br />

Selected ISO-dimensions are stocked in following grades: EN 1.4307, 1.4404, 1.4432, 1.4541 and 1.4571. See tables on following pages.<br />

DN 15 - DN 500 in accordance with EN 10217-7. Max. wall thickness T = 6.0 mm. DN 125 - DN 1200 in accordance with EN 10296-2 produced from plate.<br />

NOTE: The pressure calculations in this table have been done according to 13480-3 and EN 10217-7 for DN 15 - DN 500, T max<br />

= 6 mm, the steel grade is<br />

EN 1.4307, room temperature 20 °C.<br />

*) Pressures marked with* are calculated according to 13480-3 and EN 10296-2 for DN 450, DN 600 - 1200, the steel grade is EN 1.4307, room<br />

temperature 20 °C.<br />

21