May 2009 - Low Resolution - PAWPRINT PUBLISHING

May 2009 - Low Resolution - PAWPRINT PUBLISHING

May 2009 - Low Resolution - PAWPRINT PUBLISHING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CLASSICAL MACHINERY & EQUIPMENT<br />

Tudorwood Joinery selects Lamont<br />

TUDORWOOD Joinery Ltd offers<br />

a complete service for bespoke<br />

kitchens, including design,<br />

manufacture and fitting.<br />

Nothing is bought in: everything<br />

is manufactured to order.<br />

The kitchens are created to a<br />

high standard: “We pride ourselves<br />

on being at the top of the range,<br />

although our lower overheads<br />

allow us to offer competitive<br />

prices,” company owner, Rodney<br />

Lander, told PW&SS.<br />

Rodney finds that many of his<br />

customers come through personal<br />

recommendation: they have seen<br />

one of his kitchens in a friend’s<br />

home, and decide they would like<br />

one as well.<br />

In order to speed up the glue<br />

drying process, Tudorwood Joinery<br />

Ltd has recently invested in a<br />

refurbished gluesetter, purchased<br />

from Lamont.<br />

The need for the investment<br />

arose because it was taking half a<br />

day for the glue to dry, once the<br />

frames had been cramped onto<br />

the carcasses.<br />

“We had units sitting around in<br />

the workshop full of sash cramps!”<br />

Rodney said.<br />

With the gluesetter, a job which<br />

used to take three days per kitchen<br />

has been cut to one day per<br />

kitchen. “With the Lamont gluing<br />

system, we still cramp the frames<br />

onto the carcass, but the machine<br />

sets the glue very quickly: because<br />

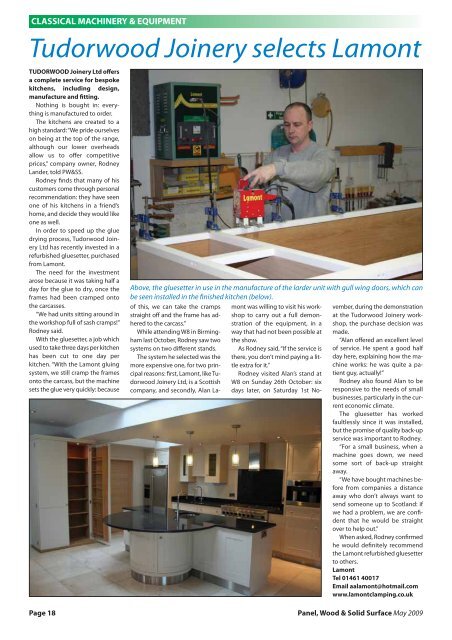

Above, the gluesetter in use in the manufacture of the larder unit with gull wing doors, which can<br />

be seen installed in the finished kitchen (below).<br />

of this, we can take the cramps<br />

straight off and the frame has adhered<br />

to the carcass.”<br />

While attending W8 in Birmingham<br />

last October, Rodney saw two<br />

systems on two different stands.<br />

The system he selected was the<br />

more expensive one, for two principal<br />

reasons: first, Lamont, like Tudorwood<br />

Joinery Ltd, is a Scottish<br />

company, and secondly, Alan Lamont<br />

was willing to visit his workshop<br />

to carry out a full demonstration<br />

of the equipment, in a<br />

way that had not been possible at<br />

the show.<br />

As Rodney said, “If the service is<br />

there, you don’t mind paying a little<br />

extra for it.”<br />

Rodney visited Alan’s stand at<br />

W8 on Sunday 26th October: six<br />

days later, on Saturday 1st November,<br />

during the demonstration<br />

at the Tudorwood Joinery workshop,<br />

the purchase decision was<br />

made.<br />

“Alan offered an excellent level<br />

of service. He spent a good half<br />

day here, explaining how the machine<br />

works: he was quite a patient<br />

guy, actually!”<br />

Rodney also found Alan to be<br />

responsive to the needs of small<br />

businesses, particularly in the current<br />

economic climate.<br />

The gluesetter has worked<br />

faultlessly since it was installed,<br />

but the promise of quality back-up<br />

service was important to Rodney.<br />

“For a small business, when a<br />

machine goes down, we need<br />

some sort of back-up straight<br />

away.<br />

“We have bought machines before<br />

from companies a distance<br />

away who don’t always want to<br />

send someone up to Scotland: if<br />

we had a problem, we are confident<br />

that he would be straight<br />

over to help out.”<br />

When asked, Rodney confirmed<br />

he would definitely recommend<br />

the Lamont refurbished gluesetter<br />

to others.<br />

Lamont<br />

Tel 01461 40017<br />

Email aalamont@hotmail.com<br />

www.lamontclamping.co.uk<br />

Page 18 Panel, Wood & Solid Surface <strong>May</strong> <strong>2009</strong>