rendon st. warehouse phase i and phase ii 950 south rendon street ...

rendon st. warehouse phase i and phase ii 950 south rendon street ...

rendon st. warehouse phase i and phase ii 950 south rendon street ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

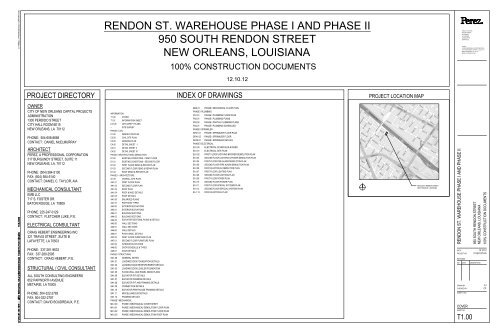

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

12.10.12<br />

PROJECT DIRECTORY<br />

INDEX OF DRAWINGS<br />

PROJECT LOCATION MAP<br />

OWNER<br />

CITY OF NEW ORLEANS CAPITAL PROJECTS<br />

ADMINISTRATION<br />

1300 PERDIDO STREET<br />

CITY HALL ROOM 6E15<br />

NEW ORLEANS, LA 70112<br />

PHONE: 504-658-8668<br />

CONTACT: DANIEL McELMURRAY<br />

ARCHITECT<br />

PEREZ, A PROFESSIONAL CORPORATION<br />

317 BURGUNDY STREET, SUITE 11<br />

NEW ORLEANS, LA. 70112<br />

PHONE: (504) 584-5100<br />

FAX: (504) 584-5140<br />

CONTACT: DANIEL C. TAYLOR, AIA<br />

MECHANICAL CONSULTANT<br />

EMB LLC<br />

717 S. FOSTER DR.<br />

BATON ROUGE, LA 70809<br />

PHONE: 225-247-0129<br />

CONTACT: FLETCHER LUKE, P.E.<br />

ELECTRICAL CONSULTANT<br />

CRAIG HEBERT ENGINEERING INC<br />

321 TRAVIS STREET, SUITE B<br />

LAFAYETTE, LA 70503<br />

PHONE: 337-261-9633<br />

FAX: 337-280-2595<br />

CONTACT: CRAIG HEBERT, P.E.<br />

STRUCTURAL / CIVIL CONSULTANT<br />

ALL SOUTH CONSULTING ENGINEERS<br />

652 PAPWORTH AVENUE<br />

METAIRIE, LA 70005<br />

PHONE: 504-322-2783<br />

FAX: 504-322-2787<br />

CONTACT: DAVID BOUDREAUX, P.E.<br />

INFORMATION<br />

T1.00 COVER<br />

T1.01 INFORMATION SHEET<br />

LS1.00 LIFE SAFETY PLANS<br />

-- SITE SURVEY<br />

PHASE I CIVIL<br />

C1.00 DEMOLITION PLAN<br />

C2.00 CIVIL SITE PLAN<br />

C3.00 GRADING PLAN<br />

C4.00 DETAIL SHEET - I<br />

C4.01 DETAIL SHEET II<br />

C4.02 DETAIL SHEET III<br />

PHASE I ARCHITECTURAL DEMOLITION<br />

D1.00 EXISTING CONDITIONS - FIRST FLOOR<br />

D1.01 EXISTING CONDITIONS - SECOND FLOOR<br />

D1.02 FIRST FLOOR DEMO & REPAIR PLAN<br />

D1.03 SECOND FLOOR DEMO & REPAIR PLAN<br />

D1.04 ROOF DEMO & REPAIR PLAN<br />

PHASE I - ARCHITECTURE<br />

G1.00 OVERALL SITE PLAN<br />

AA1.01 FIRST FLOOR PLAN<br />

AA1.02 SECOND FLOOR PLAN<br />

AA1.03 ROOF PLAN<br />

AA1.04 ROOF & MISC DETAILS<br />

AA1.05 ROOF DETAILS<br />

AA1.06 ENLARGED PLANS<br />

AA1.07 PARTITION TYPES<br />

AA3.00 EXTERIOR ELEVATIONS<br />

AA3.01 EXTERIOR ELEVATIONS<br />

AA4.01 BUILDING SECTIONS<br />

AA4.02 BUILDING SECTIONS<br />

AA4.03 ELEVATOR SECTIONS, PLANS & DETAILS<br />

AA5.00 WALL SECTIONS<br />

AA5.01 WALL SECTIONS<br />

AA6.00 WALL DETAILS<br />

AA6.01 PLAN & MISC. DETAILS<br />

AA7.00 FIRST FLOOR FURNITURE PLAN<br />

AA7.01 SECOND FLOOR FURNITURE PLAN<br />

AA7.02 INTERIOR ELEVATIONS<br />

AA8.00 DOOR SCHEDULE & TYPES<br />

AA8.01 DOOR DETAILS<br />

PHASE I STRUCTURAL<br />

SA1.00 GENERAL NOTES<br />

SA1.01 LOADING DOCK FOUNDATION DETAILS<br />

SA1.02 LOADING DOCK REINFORCEMENT DETAILS<br />

SA1.03 LOADING DOCK LEVELER FOUNDATION<br />

SA1.05 FLOOD WALL AND PANEL DEMO PLANS<br />

SA1.06 ELEVATOR PIT DETAILS<br />

SA1.07 ELEVATOR FRAMING DETAILS<br />

SA1.08 ELEVATOR PIT AND FRAMING DETAILS<br />

SA1.09 CONNECTION DETAILS<br />

SA1.10 ELEVATOR PENTHOUSE FRAMING DETAILS<br />

SA1.11 MISCELLANEOUS DETAILS<br />

SA1.12 FRAMING DETAILS<br />

PHASE I MECHANICAL<br />

MA1.00 PHASE I MECHANICAL COVER SHEET<br />

MA1.01 PHASE I MECHANICAL DEMOLITION FLOOR PLAN<br />

MA1.02 PHASE I MECHANICAL DEMOLITION FLOOR PLAN<br />

MA1.03 PHASE I MECHANICAL DEMOLITION ROOF PLAN<br />

MA2.01 PHASE I MECHANICAL FLOOR PLAN<br />

PHASE I PLUMBING<br />

PA1.01 PHASE I PLUMBING FLOOR PLAN<br />

PA2.01 PHASE I PLUMBING PLANS<br />

PA2.02 PHASE I PARTIAL PLUMBING PLANS<br />

PA4.01 PHASE I PLUMBING SCHEDULES<br />

PHASE I SPRINKLER<br />

SPA1.01 PHASE I SPRINKLER FLOOR PLAN<br />

SPA1.02 PHASE I SPRINKLER FLOOR<br />

SPA2.01 PHASE I SPRINKLER DETAILS<br />

PHASE I ELECTRICAL<br />

EA1.00 ELECTRICAL SCHEDULES & RISER<br />

EA1.01 ELECTRICAL SITE PLAN<br />

EA1.02 FIRST FLOOR LIGTHING &POWER DEMOLITION PLAN<br />

EA1.03 SECOND FLOOR LIGHTING & POWER DEMOLITION PLAN<br />

EA1.04 FIRST FLOOR FIRE ALARM DEMOLITION PLAN<br />

EA1.05 SECOND FLOOR FIRE ALARM DEMOLITION PLAN<br />

EA1.06 ROOF ELECTRICAL DEMOLITION PLAN<br />

EA1.07 FIRST FLOOR LIGHTING PLAN<br />

EA1.08 SECOND FLOOR LIGTHING PLAN<br />

EA1.09 FIRST FLOOR POWER PLAN<br />

EA1.10 SECOND FLOOR POWER PLAN<br />

EA1.11 FIRST FLOOR SPECIAL SYSTEMS PLAN<br />

EA1.12 SECOND FLOOR SPECIAL SYSTEMS PLAN<br />

EA.1.13 ROOF ELECTRICAL PLAN<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO<br />

DATE<br />

DRAWN BY:<br />

CHECKED BY:<br />

SHEET TITLE<br />

COVER<br />

SHEET NO<br />

T1.00<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

100% CONSTRUCTION DOCUMENTS<br />

PJ<br />

CP

GRAPHICAL KEY:<br />

1 HOUR FIRE RATED WALL<br />

PATH OF TRAVEL<br />

3'-0"<br />

FE<br />

FIRE EXTINGUISHER<br />

RESTROOM<br />

122<br />

BREAKROOM<br />

123<br />

STORAGE<br />

124<br />

HALL<br />

121<br />

112' TRAVEL DISTANCE<br />

FE<br />

CR<br />

OPEN SERVICE AREA<br />

205<br />

MEETING ROOM<br />

126<br />

STORAGE<br />

128<br />

82' TRAVEL DISTANCE<br />

CR<br />

STAIR #2<br />

209<br />

FREIGHT<br />

ELEVATOR<br />

206<br />

176' TRAVEL DISTANCE<br />

HALLWAY<br />

204<br />

EX. EX. RESTROOM<br />

ELEVATOR 201<br />

213 EX. CLOSET<br />

202<br />

FE<br />

DN UP DN<br />

FE<br />

STAIR #1<br />

203<br />

DATA ROOM<br />

130<br />

2 SECOND FLOOR LIFE SAFETY PLAN<br />

SCALE: 1/16" = 1'-0"<br />

GRAPHICAL KEY:<br />

FE<br />

1 HOUR FIRE RATED WALL<br />

PATH OF TRAVEL<br />

FIRE EXTINGUISHER<br />

CR<br />

RESTROOM<br />

122<br />

MEETING ROOM<br />

126<br />

BREAKROOM<br />

123<br />

HALL<br />

121<br />

STORAGE<br />

128<br />

STORAGE<br />

124<br />

CR<br />

3<br />

LS1.00<br />

3 SECOND FLOOR LIFE SAFETY PLAN<br />

SCALE: 1/16" = 1'-0"<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

DATA ROOM<br />

130<br />

DATE:<br />

PROJECT NO:<br />

12.10.12<br />

01-08-1070-00<br />

REVISIONS:<br />

198' TRAVEL DISTANCE<br />

FE<br />

FE<br />

NO<br />

DATE<br />

DESCRIPTION<br />

FE<br />

FE<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

31' TRAVEL DISTANCE<br />

40' TRAVEL DISTANCE<br />

SHEET TITLE<br />

FE<br />

1 FIRST FLOOR LIFE SAFETY PLAN<br />

SCALE: 1/16" = 1'-0"<br />

FE<br />

LIFE SAFETY PLANS<br />

SHEET NO<br />

LS1.00

S. R E N D O N S T.<br />

S. S A L C E D O S T. ( S I D E )

PALMETTO ST.<br />

REMOVE EXIST.<br />

LIGHT POLE<br />

SAW CUT & REMOVE<br />

EXIST. PAVEMENT<br />

28'-6" 9' 6'<br />

EXIST.<br />

BUILDING<br />

HOWARD AVE.<br />

REMOVE EXIST.<br />

OVERHEAD LINE<br />

REMOVE EXIST.<br />

CONCRETE SLAB<br />

55'<br />

23'-3"<br />

6'-3"<br />

REMOVE EXIST.<br />

(3)- BOLLARDS<br />

REMOVE LOADING<br />

DOCK & STAIR<br />

REMOVE DOCK<br />

LEVELER & SIDEWALK<br />

WV<br />

DEMOLITION NOTES<br />

1. IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO<br />

FIELD VERIFY THE LOCATION AND DEPTH OF ALL<br />

UTILITIES BEFORE STARTING DEMOLITION.<br />

2. CONTRACTOR SHALL OBTAIN ALL REQUIRED PERMITS<br />

BEFORE DEMOLITION.<br />

3. DO NOT CLOSE, SHUT OFF OR DISRUPT EXISTING LIFE<br />

SAFETY SYSTEMS THAT ARE IN USE WITHOUT PRIOR<br />

NOTIFICATION TO THE OWNER.<br />

4. PROTECT EXISTING UTILITIES TO REMAIN FROM DAMAGE.<br />

DO NOT DISRUPT PUBLIC UTILITIES WITHOUT PERMIT<br />

FROM AUTHORITY HAVING JURISDICTION.<br />

5. PREPARE DEMOLITION AREAS BY DISCONNECTING AND<br />

CAPPING UTILITIES OUTSIDE THE DEMOLITION ZONE IF<br />

ANY. IDENTIFY AND MARK UTILITIES TO BE<br />

SUBSEQUENTLY RECONNECTED,<br />

6. CONTRACTOR SHALL PROVIDE PROTECTION TO<br />

EXISTING UTILITIES AND STRUCTURES THAT ARE TO<br />

REMAIN AND THE BUILDING. REPAIR CONTRACTOR<br />

CAUSED DAMAGES AT NO ADDITIONAL COST TO THE<br />

OWNER.<br />

7. ANY DISCREPANCIES SHALL BE IMMEDIATELY REPORTED<br />

TO THE ENGINEER.<br />

REMOVE<br />

EXIST. POLE<br />

169'-3"<br />

REMOVE EXIST.<br />

OVERHEAD LINE<br />

INTEGRITY OF STRUCTURES TO REMAIN.<br />

9. ALL DEMOLITION WORKS SHALL BE EXECUTED IN<br />

CONFORMANCE WITH ALL CODES AND ORDINANCES AS<br />

SET BY THE GOVERNING AUTHORITIES.<br />

10. SALVAGE IS DEFINED AS THE CAREFUL REMOVAL AND<br />

RETAINING OF ITEMS AS SHOWN IN DRAWINGS FOR<br />

POSSIBLE RE-USE OR DELIVERY TO OWNER.<br />

11. NO SOILS MAY BE REMOVED FROM THIS SITE WITHOUT<br />

PRIOR APPROVAL FROM LDEQ UNLESS THEY ARE<br />

REMOVED AND DISPOSED AT A PERMITTED DISPOSAL<br />

FACILITY.<br />

12. ANY CAVITIES LEFT BY STRUCTURE REMOVAL SHALL BE<br />

BACKFILLED AND COMPACTED TO THE SATISFACTION OF<br />

THE ENGINEER.<br />

13. ALL DEMOLISHED MATERIAL BECOMES THE PROPERTY<br />

OF THE CONTRACTOR UNLESS OTHERWISE DESIGNATED.<br />

DISPOSE OF ALL TRASH AND RUBBISH OFF THE OWNER'S<br />

PROPERTY.<br />

14. THE CONTRACTOR SHALL CONTROL DUST AND DIRT<br />

CAUSED BY THE DEMOLITION WORK.<br />

15. CONTRACTOR SHALL COORDINATE WITH ENTERGY<br />

WHILE REMOVING POWER/ LIGHT POLES AND<br />

OVERHEAD WIRES.<br />

RENDON ST.<br />

DEMOLITION PLAN<br />

(SCALE: 1"=20'-0")<br />

REMOVE<br />

EXIST. POLE<br />

REMOVE EXIST.<br />

OVERHEAD LINE<br />

X<br />

G<br />

WM<br />

WV<br />

S<br />

99'-2"<br />

LEGEND<br />

G<br />

W<br />

T<br />

D<br />

EXIST. FENCE<br />

PROPERTY LINE<br />

GAS LINE<br />

OVERHEAD UTILITY LINES<br />

GAS MANHOLE<br />

WATER MANHOLE<br />

WATER METER<br />

WATER VALVE<br />

FIRE HYDRANT<br />

DRAIN MANHOLE<br />

SEWER MANHOLE<br />

POWER POLE<br />

LIGHT POLE<br />

TELEPHONE MANHOLE<br />

EXIST. CATCH BASIN<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO DATE<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

100% CONSTRUCTION DOCUMENTS<br />

8. CONTRACTOR IS RESPONSIBLE FOR ALL SHORING AND<br />

BRACING NECESSARY TO MAINTAIN STRUCTURAL<br />

INTEGRITY OF STRUCTURES TO REMAIN.<br />

ALL DEMOLITION WORKS SHALL BE EXECUTED IN<br />

16. ALL EXISTING EXTERIOR SIGNAGE SHALL BE REMOVED.<br />

17. CONTRACTOR SHALL SAW CUT EXIST. PAVEMENT TO THE<br />

AREA SHOWN.<br />

N<br />

DRAWN BY:<br />

CHECKED BY:<br />

SHEET TITLE<br />

RKR<br />

DFB<br />

DEMOLITION PLAN<br />

SHEET NO<br />

CA1.00

HOWARD AVE.<br />

WV<br />

1'-6"<br />

15' (TYP.)<br />

50'<br />

REPAIR APPROX. 500 L.F. OF<br />

EXIST. FENCE w/ LIKE IN KIND.<br />

REPLACE ALL RAZOR WIRE IN KIND<br />

ASPHALT PAVEMENT REPAIR @<br />

LOCATION OF POLE REMOVAL<br />

9'<br />

1'-6" 6' 1'-6"<br />

WHEEL STOP<br />

PARKING<br />

STRIPING<br />

PAINT PARKING STRIPES<br />

AND BOLLARDS (YELLOW)<br />

TYP. PARKING SPOT PLAN<br />

WITH WHEEL STOP<br />

PATCH & RESEAL EXIST.<br />

ASPHALT PAVING AS REQ'D<br />

STRIPING AREA<br />

(YELLOW) OVER NEW<br />

ASPHALT PAVEMENT<br />

MODIFY EXIST. GATE<br />

TO INCORPORATE 30'<br />

OPENING<br />

REQUIRED ASPHALT PAVING<br />

AFTER WIDENING OF THE GATE<br />

15'<br />

STRIPING LETTERS<br />

(YELLOW)<br />

3'-6"<br />

8'<br />

3'-6"<br />

14'<br />

55'<br />

1'-6"<br />

28'-6"<br />

23'-3"<br />

NO PARKING<br />

43'-5"<br />

EXIST.<br />

STOOP<br />

6" BOLLARD (SEE<br />

DET. ON SHT. CA4.02)<br />

(TYP.)<br />

TYP. PARKING SPOT PLAN<br />

WITH BOLLARDS<br />

NEW CONCRETE<br />

FILLED BOLLARDS<br />

43'-5"<br />

PARKING<br />

STRIPING<br />

168'-11"<br />

(FLOOR LEVEL: 22.7')<br />

LOADING DOCK ADDITION<br />

(FLOOR LEVEL: 26.7')<br />

CLEAR ALL VEGETATION & DEBRIS; SPREAD 4"<br />

CRUSHED STONE OVER FABRIC LINER (NOTIFY<br />

ARCHITECT/OWNER BEFORE PROCEEDING)<br />

EXIST.<br />

BUILDING<br />

RENDON ST.<br />

CIVIL SITE PLAN<br />

(SCALE: 1"=20'-0")<br />

GENERAL NOTES:<br />

NEW DUMPSTER PAD<br />

(SEE SHT. CA4.00)<br />

REPAIR ASPHALT<br />

PAVEMENT (SEE<br />

SHT. CA3.00)<br />

REQUIRED ASPHALT<br />

PAVEMENT(SEE SHT.<br />

CA3.00)<br />

REPAIR EXIST.<br />

GATE<br />

REPAINT EXIST.<br />

BOLLARDS<br />

(SEE NOTE 13)<br />

FLUSH THE SIDEWALK<br />

EDGE TO MATCH<br />

EXISTING<br />

1. CONTRACTOR SHALL BE SOLELY RESPONSIBLE FOR MEANS, METHODS, TECHNIQUES, SEQUENCES AND<br />

PROCEDURES OF CONSTRUCTION WHILE MAINTAINING SAFE WORK CONDITIONS. CONTRACTOR SHALL OBSERVE<br />

ALL OSHA AND ANY OTHER REGULATIONS PERTAINING TO SAFETY.<br />

2. CONTRACTOR SHALL VISIT THE SITE AND EXAMINE AND NOTE ALL CONDITIONS AS TO THE CHARACTER AND<br />

EXTENT OF THE WORK INVOLVED. THE CONTRACTOR SHALL ASSUME ALL THE RESPONSIBILITY FOR ALL LAYOUT<br />

WORK.<br />

3. THE CONTRACTOR, AT HIS OWN EXPENSE, MAY MAKE ADDITIONAL SURVEYS AND INVESTIGATIONS AS HE DEEMS<br />

NECESSARY TO DETERMINE EXISTING CONDITIONS.<br />

4. CONTRACTOR SHALL ENSURE THAT ALL VEHICLES USED ON THIS PROJECT FOR TRANSPORTATION OF<br />

MATERIALS ARE UNDER THE MAXIMUM ALLOWABLE LOADING FOR ROADS AND BRIDGES USED TO ACCESS THIS<br />

PROJECT.<br />

5. CONTRACTOR SHALL AT ALL TIMES CONDUCT ANY CONSTRUCTION WORK AS TO INSURE THE LEAST<br />

INCONVENIENCE TO THE PUBLIC AND ADJACENT PROPERTY OWNERS.<br />

6. ALL CONSTRUCTION MATERIAL AND PROCEDURE SHALL CONFORM TO THE LOUISIANA STANDARD<br />

SPECIFICATIONS FOR ROADS AND BRIDGES (DOTD) LATEST EDITION UNLESS OTHERWISE SPECIFIED.<br />

DEVIATIONS FROM THE SPECIFICATIONS SHALL HAVE TO BE APPROVED BY ENGINEER AND THE OWNER.<br />

7. THE CONTRACTOR SHALL BE RESPONSIBLE FOR LAYING OUT THE WORK AND VERIFYING ALL MEASUREMENTS<br />

AND GRADES PRIOR TO BEGINNING OF CONSTRUCTION. IT SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR<br />

TO ESTABLISH THE PROJECT LINE AND ADDITIONAL TEMPORARY BENCH MARKS FOR CONSTRUCTION PURPOSES<br />

BEFORE DESTROYING EXISTING MONUMENTS/ NAILS/ CROSS CUTS, ETC..<br />

8. IT SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR TO VERIFY LOCATION AND DEPTH OF ALL EXISTING<br />

UTILITIES BEFORE STARTING CONSTRUCTION.<br />

9. THE CONTRACTOR SHALL BE RESPONSIBLE FOR DAMAGE TO EXISTING UTILITIES WHICH OCCURS DURING<br />

CONSTRUCTION AND SHALL IMMEDIATELY REPORT ANY DAMAGE TO THE UTILITY ENTITIES & ENGINEER.<br />

DREXEL DR. PALMETTO ST.<br />

PLUG & ABANDON<br />

EXIST. PIPES<br />

APPLY ASPHALT<br />

SEALANT TO PARKING &<br />

DRIVING SURFACES<br />

REPAINT PARKING<br />

STRIPES<br />

REPAINT EXIST. WHEEL<br />

STOPS (YELLOW)<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

----<br />

DATE:<br />

PROJECT NO:<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

12.10.12<br />

01-08-1070-00<br />

6'<br />

6"<br />

6"<br />

1"<br />

6" 6"<br />

4"<br />

10. CONTRACTOR SHALL MAINTAIN ADEQUATE SURFACE DRAINAGE AWAY FROM THE BUILDING AT ALL TIMES.<br />

11. DIMENSIONS AND/OR ELEVATIONS MARKED N.T.S. ARE NOT SHOWN TO SCALE.<br />

12. ASPHALT SECTION SHALL BE CONSTRUCTED AT ALL PLACES SPECIFIED AS PER SHEET CA3.00 AND<br />

SPECIFICATIONS.<br />

13. CONTRACTOR SHALL REPAINT ALL EXISTING BOLLARDS TO MATCH EXISTING. CONTRACTOR SHALL LOCATE<br />

MISSING BOLLARDS WITHIN THE SITE AND PLACE THEM IN RESPECTIVE PLACES. REMOVABLE BOLLARDS AND<br />

SLEEVES ARE TO REMAIN & REPAINT WHITE TO MATCH EXISTING.<br />

REVISIONS:<br />

NO<br />

DATE<br />

DESCRIPTION<br />

# 4 REBAR<br />

SURFACE OF PAVEMENT<br />

1<br />

CA2.00<br />

WHEEL STOP<br />

N.T.S<br />

* No. 4 REBAR EMBEDDED 4" INTO PAVEMENT AND CUT 1" BELOW TOP<br />

OF WHEEL STOP. REBAR TO BE ATTACHED WITH EPOXY RESIN TO<br />

WHEEL STOP. WIPE EPOXY FLUSH WITH TOP OF WHEEL STOP. WHEEL<br />

STOP SHALL BE 6"X6"X6'.<br />

14. THE FIRST FLOOR LEVEL(LOWER) AS PER SURVEY IS 22.7' (WHICH IS SAME AS 100.00 AS PER ARCH. DWG.).<br />

15. ENTIRE ASPHALT PAVEMENT SHALL BE APPLIED WITH MAXX 1000 SEALER BY GARDNER GIBSON (OR APPROVED<br />

EQUAL).<br />

N<br />

DRAWN BY:<br />

CHECKED BY:<br />

SHEET TITLE<br />

CIVIL<br />

SITE PLAN<br />

SHEET NO<br />

CA2.00<br />

TFR<br />

DFB

EXIST. BUILDING<br />

NEW ASPHALT PAVEMENT<br />

(SEE ASPHALT REPAIR<br />

SECTION, THS. SHT.)<br />

NOTE:<br />

- FOR "NO PARKING" STRIPING<br />

SEE SHT. CA2.00<br />

- PROPOSED EL.<br />

- EXISTING EL.<br />

REQUIRED ASPHALT PAVING<br />

AFTER WIDENING OF THE GATE<br />

(FLOOR LEVEL: 22.7')<br />

LOADING DOCK ADDITION<br />

(FLOOR LEVEL: 26.7')<br />

SITE GRADING PLAN<br />

(SCALE: 1"=10'-0")<br />

MATCH EXIST. ELEVATION<br />

NEW<br />

DUMPSTER PAD<br />

REQUIRED ASPHALT<br />

PAVEMENT<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

EXIST. ASPHALT<br />

PAVEMENT<br />

8" MIN. OF<br />

CRUSHED STONE<br />

BASE COMPACTED<br />

TO 95% MAX.<br />

DENSITY OR<br />

APPROVED EQUAL<br />

COAT EDGES OF<br />

EXIST. PAVEMENT w/<br />

APPROVED TACK<br />

COAT<br />

ASPHALT REPAIR SECTION<br />

(SCALE: 1"=1'-0")<br />

CUT & REMOVE EXIST. ASPHALT<br />

PAVEMENT AND REPLACE WITH NEW<br />

HOT MIX ASPHALTIC CONCRETE. NEW<br />

ASPHALTIC CONCRETE SHALL BE THE<br />

GREATER OF 7" MIN.(2" WEARING, 5"<br />

BINDER) OR THICKNESS OF EXIST.<br />

PAVEMENT<br />

GEOGRID<br />

GEOTEXTILE<br />

FABRIC<br />

10" THICK<br />

SAND FILL<br />

EXIST.<br />

THICKNESS<br />

REQUIRED<br />

SAND FILL<br />

6"<br />

18"<br />

REQUIRED BASE<br />

THICKNESS AT THE EDGES<br />

ASPHALT REPAIR AT THE EDGES<br />

(for repair area greater than 100.0 S.F )<br />

(SCALE: 1"=1'-0")<br />

8"<br />

6"<br />

10"<br />

EXIST.<br />

PAVEMENT<br />

ASPHALT APPLICATION NOTES:<br />

1. SAW CUT AND REMOVE EXIST. PAVEMENT TO THE AREAS<br />

AND DEPTH AS REQUIRED.<br />

2. SURFACE PREPARATION: REMOVE LOOSE MATERIAL AND<br />

COMPACT SUB BASE. PROOF ROLL TO CHECK UNSTABLE<br />

AREAS.<br />

3. INSTALL GEOTEXTILE FABRIC AND GEOGRID AS PER<br />

MANUFACTURER.<br />

4. PLACE BASE MATERIAL AS PER SPECIFICATION AND<br />

COMPACT.<br />

5. APPLY TACK COAT OVER CONTACT SURFACES OF EXIST.<br />

PAVEMENT.<br />

6. APPLY PRIME COAT OVER COMPACTED BASE COURSE.<br />

7. PROVIDE AND PLACE BINDER COURSE AND WEARING<br />

COURSE AS PER SPECIFICATIONS.<br />

8. FOR ASPHALT REPAIR AREA GREATER THAN 100.0 S.F,<br />

THE CRUSHED STONE BASE THICKNESS AT EDGES SHALL<br />

BE INCREASED TO 18" AS SHOWN IN DETAIL BELOW.<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO<br />

DATE<br />

DRAWN BY:<br />

CHECKED BY:<br />

SHEET TITLE<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

GRADING PLAN<br />

SHEET NO<br />

CA3.00<br />

TFR<br />

DFB

6<br />

1'-3"<br />

X<br />

CA4.02<br />

4'-6"<br />

15'-4"<br />

8" TH. CONCRETE WALL(SEE<br />

TYP. REINFORCEMENT DETAIL<br />

FOR STAIR, SHT. CA4.02)<br />

EXIST. BLDG.<br />

5'-6"<br />

6<br />

E<br />

CA4.00<br />

1<br />

1<br />

CA4.01<br />

A<br />

CA4.00<br />

2<br />

12" TIMBER PILE<br />

(TYP.- 6 No.s<br />

REQ'D)<br />

EXIST. BLDG.<br />

EDGE<br />

3<br />

CA4.01<br />

NEW LOADING DOCK ADDITION<br />

(SEE STRUCTURAL DWG.)<br />

6'-9"<br />

2'-9"<br />

2'-9"<br />

10"<br />

8" TH. SLAB<br />

ABOVE<br />

CONCRETE WALL<br />

1'-3"<br />

4'-6"<br />

CMU WALL<br />

(SEE SHT.<br />

CA4.02)<br />

DUMPSTER<br />

CAN<br />

FD<br />

Y<br />

CA4.02<br />

9"<br />

6'-9"<br />

13'-4"<br />

A<br />

B<br />

20'-1"<br />

4'-6" 2'<br />

12'-6"<br />

2<br />

CA4.01<br />

E<br />

CA4.00<br />

1'-6"<br />

A<br />

CA4.00<br />

B<br />

A<br />

A<br />

CA4.00<br />

D<br />

C<br />

B<br />

CA4.00<br />

E<br />

F<br />

A<br />

B<br />

LABEL<br />

SLAB REINFORCEMENT SCHEDULE<br />

BAR SIZE/ SPACING/<br />

LOCATION<br />

A #4 @ 8" O.C. BOT CONTINUOUS<br />

B #4 @ 8" O.C. BOT CONTINUOUS<br />

C #4 @ 8" O.C. TOP CONTINUOUS<br />

D #4 @ 8" O.C. TOP CONTINUOUS<br />

E #4 @ 8" O.C. CONTINUOUS<br />

F #4 @ 8" O.C. CONTINUOUS<br />

NOTES<br />

C<br />

C<br />

EXIST. COLUMN<br />

LINE<br />

CONCRETE FILLED<br />

BOLLARD<br />

(SEE SHT. CA4.02)<br />

NOTE:<br />

- FOR FLOOR DRAIN &<br />

HOT/ COLD WATER<br />

CONN., SEE MECH. DWG.<br />

2- #5 T & B<br />

(TYP.)<br />

3" CL<br />

℄<br />

1'-6"<br />

CMU WALL<br />

(SEE SHT.<br />

CA4.02)<br />

3" CL<br />

DUMPSTER SLAB PLAN<br />

(SCALE: 3 8"=1'-0")<br />

DOUBLE SWING GATE<br />

(SEE SHT. CA4.02)<br />

NOTE:<br />

SLAB REINFORCEMENT NOT<br />

SHOWN FOR CLARITY. SEE<br />

PLAN ON THIS SHT.<br />

#3 STIRRUP<br />

@ 1'-6" O.C.<br />

VAPOR<br />

BARRIER<br />

12" TIMBER PILE,<br />

60' LENGTH<br />

6"<br />

6"<br />

1'<br />

3" CL<br />

3" CL<br />

T.O. SLAB<br />

1'-6"<br />

8" TH. APROACH SLAB<br />

(SEE SHT. CA4.01)<br />

T.O. SLAB<br />

1'-9"<br />

6"<br />

1'-3"<br />

9"<br />

3" CL<br />

3" CL<br />

#3 STIRRUP<br />

@ 1'-6" O.C.<br />

VAPOR<br />

BARRIER<br />

12" TIMBER PILE,<br />

60' LENGTH<br />

EXIST. COLUMN<br />

LINE<br />

LOADING DOCK<br />

EDGE LINE<br />

3" CL<br />

℄<br />

2'<br />

1'-3"<br />

2" CL<br />

3" CL<br />

D<br />

CA4.00<br />

4'<br />

6"<br />

5- #5<br />

(TYP.)<br />

1<br />

8"<br />

1'-1"<br />

10'-10"<br />

C<br />

CA4.00<br />

14'-10" 6'<br />

DUMPSTER PAD<br />

REINFORCEMENT PLAN<br />

(SCALE: 3 8"=1'-0")<br />

2- #5 T & B<br />

(TYP.)<br />

2" CL<br />

℄<br />

1'-6"<br />

2<br />

3" CL<br />

#3 STIRRUP<br />

@ 1'-6" O.C.<br />

VAPOR<br />

BARRIER<br />

12" TIMBER PILE,<br />

60' LENGTH<br />

T.O. SLAB<br />

6"<br />

3" CL<br />

6"<br />

1'<br />

3" CL<br />

1'-6"<br />

2- #5 T & B<br />

(TYP.)<br />

2- #5 T & B<br />

(TYP.)<br />

2" CL<br />

2" CL<br />

℄<br />

1'-6"<br />

3" CL<br />

D<br />

CA4.00<br />

℄<br />

1'-6"<br />

3" CL<br />

SCALE:<br />

#3 STIRRUP<br />

@ 1'-6" O.C.<br />

SECTION D<br />

VAPOR<br />

BARRIER<br />

1 1/2" = 1'-0"<br />

#3 STIRRUP<br />

@ 1'-6" O.C.<br />

VAPOR<br />

BARRIER<br />

T.O. SLAB<br />

6"<br />

6"<br />

9"<br />

3" CL<br />

6"<br />

6"<br />

9"<br />

3" CL<br />

1'-3"<br />

T.O. SLAB<br />

1'-3"<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO<br />

DATE<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

DESCRIPTION<br />

100% CONSTRUCTION DOCUMENTS<br />

12.10.12<br />

01-08-1070-00<br />

A<br />

CA4.00<br />

SECTION A<br />

SCALE:<br />

1 1/2" = 1'-0"<br />

B<br />

CA4.00<br />

SECTION B<br />

SCALE:<br />

1 1/2" = 1'-0"<br />

C<br />

CA4.00<br />

SECTION C<br />

SCALE:<br />

1 1/2" = 1'-0"<br />

E<br />

CA4.00<br />

SECTION E<br />

SCALE:<br />

1 1/2" = 1'-0"<br />

DRAWN BY: RKR<br />

CHECKED BY:<br />

SHEET TITLE<br />

DFB<br />

DETAIL SHEET- I<br />

SHEET NO<br />

CA4.00

C<br />

#4 @ 8" O.C. BOTH DIRECTIONS<br />

3<br />

4<br />

" CLR.<br />

B<br />

#4 @ 8" O.C. BOTH DIRECTIONS<br />

A<br />

3/4" EXPANSION MATERIAL<br />

EXIST. BLDG.<br />

1 1 2 " CLR. 12'-6"<br />

18"x18" BEAM<br />

18"x18" BEAM<br />

18"x15" BEAM<br />

VAPOR BARRIER (TYP.)<br />

4'-6" 2'<br />

1<br />

CA4.01<br />

SECTION 1<br />

SCALE:<br />

1" = 1'-0"<br />

6"<br />

(TYP.)<br />

NEW LOADING DOCK<br />

3/4" EXPANSION MATERIAL<br />

SLAB EL. 22.58<br />

18"x15" BEAM<br />

LOADING<br />

DOCK<br />

FOOTING<br />

1<br />

#4 @ 8" O.C. BOTH DIRECTIONS<br />

#4 @ 8" O.C. BOTH DIRECTIONS<br />

3 TOP AND BOTTOM<br />

4<br />

" CLR.<br />

3/4" EXPANSION MATERIAL<br />

6"<br />

1<br />

2 1 " CLR.<br />

VAPOR BARRIER (TYP.)<br />

4'-0" 10'-10" 6'<br />

#4 @ 8" O.C. BOTH DIRECTIONS<br />

TOP AND BOTTOM<br />

3" CLR.<br />

2<br />

CA4.01<br />

18"x18" BEAM<br />

SECTION 2<br />

SCALE:<br />

1" = 1'-0"<br />

VAPOR BARRIER (TYP.)<br />

19'-9"<br />

2<br />

APROACH SLAB<br />

8"<br />

3"<br />

8"<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

3<br />

CA4.01<br />

SECTION 3<br />

SCALE:<br />

1" = 1'-0"<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO DATE<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

DRAWN BY: RKR<br />

CHECKED BY:<br />

SHEET TITLE<br />

DFB<br />

DETAIL SHEET- II<br />

SHEET NO<br />

CA4.01

METAL COPING<br />

TO MATCH BLDG.<br />

METAL COPING TO<br />

MATCH BLDG.<br />

SMOOTH STUCCO<br />

TO MATCH THE BLDG.<br />

(SEE ARCH. DWG.)<br />

GROUTED CONNECTION<br />

FILL WITH CONCRETE<br />

AND ROUND OFF TOP<br />

CMU BLOCK WALL<br />

GROUT ALL CORNERS<br />

6" SCH. 40 GALV.<br />

STEEL POST;<br />

PAINT YELLOW<br />

3'<br />

TOP OF THE<br />

FOOTING<br />

7'-8"<br />

#6 BARS & GROUT @ 16" O.C.<br />

#6 BARS & GROUT @ 16" O.C.<br />

2'<br />

NOTE:<br />

-THE DUMPSTER SLAB SHALL SLOPE<br />

TO DRAIN. HOWEVER, THE EDGES<br />

OF THE SLAB WHERE THE CMU<br />

WALLS STAND SHALL BE LEVEL TO<br />

THE WIDTH IF THE WALL.<br />

25" SPLICE<br />

(MIN.)<br />

CONCRETE FOOTING<br />

- CMU HEIGHT SHALL BE VERIFIED<br />

WITH ARCH DWG.<br />

1'<br />

6" CLR.<br />

1'-6"<br />

TYPICAL 6" BOLLARD DETAIL<br />

(SCALE: 3 4" =1'-0")<br />

9"<br />

TYPICAL DUMPSTER CMU<br />

WALL DETAIL<br />

(SCALE: 3 4" =1'-0")<br />

TYPICAL DUMPSTER CMU<br />

WALL SECTION<br />

(SCALE: 3 4" =1'-0")<br />

DUMPSTER<br />

SLAB LEVEL<br />

#5 @ 8" O.C.<br />

#4 @ 12" O.C.<br />

#4 @ 18" O.C.<br />

#3 @ 18" O.C.<br />

#4 @ 8" O.C.<br />

(TYP.)<br />

4'-10"<br />

#3 @ 9" O.C.<br />

#5 @ 8" O.C.<br />

#4 @ 12" O.C.<br />

#4 @ 18" O.C.<br />

1'-7"<br />

Y<br />

CA4.02<br />

#4 @ 6"O.C<br />

SCALE:<br />

3/4" = 1'-0"<br />

#5 @ 12"O.C<br />

#5 BAR<br />

TYP. STAIR DETAIL<br />

REFER ARCH. DWG.<br />

5"<br />

6"<br />

4"<br />

2" MAX. (TYP.)<br />

10'-0" GATE OPENING<br />

(2)- HEAVY DUTY<br />

DROP BOLTS<br />

PVC CAPS<br />

3/4"x1 1/4"<br />

PUNCHED RAILS<br />

1" SQ. WROUGHT IRON<br />

BARS AT 2" O.C.<br />

6" POST w/ PVC CAP<br />

PUNCHED RAIL<br />

HEAVY DUTY METAL<br />

HINGE<br />

GRADE<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

12.10.12<br />

01-08-1070-00<br />

2'-9"<br />

NO<br />

DATE<br />

DESCRIPTION<br />

X<br />

CA4.02<br />

TYP. REINFORCEMENT DETAIL FOR STAIRWELL<br />

SCALE:<br />

1" = 1'-0"<br />

3"<br />

1'-6"<br />

(2)- 4000 psi<br />

CONCRETE FOOTING<br />

GRADE BEAM<br />

METAL GATE DETAIL<br />

(SCALE: NTS)<br />

DRAWN BY: RKR<br />

CHECKED BY:<br />

SHEET TITLE<br />

DFB<br />

DETAIL SHEET- III<br />

SHEET NO<br />

CA4.02

GRAPHICAL KEY<br />

F<br />

F<br />

F<br />

18"<br />

ELECTRICAL OUTLET - 18" ABOVE FLOOR<br />

48"<br />

ELECTRICAL OUTLET - 48" ABOVE FLOOR<br />

P<br />

FIRE ALARM - MANUAL PULL BOX<br />

A<br />

FIRE ALARM - AUDIO<br />

V<br />

FIRE ALARM - VISUAL<br />

LIGHT SWITCH<br />

HVAC # IDENTIFIER<br />

####<br />

GENERAL NOTES<br />

1. THIS DRAWING IS A REPRESENTATION FOR REFERENTIAL<br />

PURPOSES; ACTUAL CONDITIONS MAY VARY, AND ARE TO BE VERIFIED<br />

IN FIELD BY CONTRACTOR.<br />

2. CONTRACTOR IS TO BE FAMILIAR WITH THE EXISTING SYSTEMS AND<br />

ELEMENTS IN THE BUILDING FOR COORDINATION<br />

3. CONTRACTOR TO CONFIRM POTENTIAL CONFLICTS, WHETHER<br />

EXPLICITLY SHOWN OR NOT.<br />

4. CONTRACTOR IS TO RELOCATE, AS NECESSARY, ANY EXISTING<br />

FIXTURES, OUTLETS, DEVICES, SWITCHES, ETC. THAT ARE TO REMAIN<br />

IN USE TO NEW FINISHED SURFACE WITHIN 3 FEET, IF EXISTING<br />

SURFACE IS COVERED OVER OR MADE INACCESSIBLE BY NEW<br />

CONSTRUCTION.<br />

#<br />

KEY NOTES:<br />

01 8 CONDUITS, 5" DIAMETER, ON 6" RAISED CONCRETE (FIBER OPTIC)<br />

02 CRAC UNIT ON DRAIN PAN<br />

03A VERTICAL CONDUITS: (4) 4" DIAMETER FREON LINES; (2) 3 4" DIAMETER WATER LINE; (1) ELECTRIC LINE<br />

03B<br />

04<br />

VERTICAL CONDUITS: (4) 4" DIAMETER FREON LINES; (2) 3 4" DIAMETER WATER LINE; (1) ELECTRIC LINE - CUT FOR FUTURE USE<br />

FLOOR ELECTRIC BOX FOR FUTURE USE<br />

05 ELECTRIC PANELBOARD<br />

06 OVERHEAD TRANSFORMER, 96" ABOVE GROUND<br />

07<br />

08<br />

CUT CONDUITS (2) 4" DIAMETER ELECTRIC, (2) 3 4" DIAMETER ELECTRIC<br />

OVERHEAD AIR DUCTS, NOT USED<br />

09 SWITCHBOARD<br />

10 WALL MOUNTED TRANSFER SWITCHES<br />

11 AUTOMATIC TRANSFER SWITCH<br />

12 GENERATOR<br />

13<br />

14<br />

(29) 3 4" CONDUITS<br />

STUBS: (1) ELECTRIC CONDUIT AND (1) WATER PIPE<br />

15 (16) 3" CONDUITS<br />

16 FIRE ALARM SYSTEM PANELS<br />

17 SPRINKLER SYSTEM PANELS<br />

18 EXISTING ELEVATOR: PARK IN SAFE CONDITION AND DISCONNECT.<br />

19 EXISTING MISC. ELECTRICAL EQUIP. AND PANELS ALONG WALL; SEE ELECTRICAL<br />

20 HALON SYSTEM SWITCH<br />

1<br />

2<br />

3<br />

4<br />

5<br />

+/- 225'-0"<br />

6<br />

7<br />

8<br />

9<br />

+/- 1'-2"<br />

+/- 12'-7"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 1'-2"<br />

+/- 1'-1"<br />

13<br />

D<br />

+/- 30'-0"<br />

F<br />

48"<br />

VIS<br />

48"<br />

04<br />

05<br />

ILSA<br />

05<br />

ILSA<br />

48" 48" 48"<br />

P<br />

08<br />

02<br />

HVAC 1<br />

04 08<br />

02<br />

04<br />

08<br />

HVAC 2<br />

06<br />

ILSB<br />

05<br />

TILSB<br />

06<br />

ILSD<br />

05<br />

TILSD<br />

F<br />

06<br />

TILCA<br />

05<br />

ILCA<br />

06<br />

TILCB<br />

05<br />

ILCB<br />

02 04<br />

08<br />

HVAC 3<br />

48"<br />

02 04<br />

08<br />

HVAC 4<br />

48"<br />

48"<br />

06<br />

TILPA<br />

05<br />

ILPA<br />

10<br />

06<br />

TIHLA<br />

11<br />

ATS1<br />

12<br />

GENSS1<br />

05<br />

1HLA<br />

05<br />

1HMA<br />

06<br />

TILSA<br />

05<br />

ILSC<br />

05<br />

IHRA<br />

05<br />

IHRA<br />

48"<br />

C<br />

B<br />

A<br />

+/- 92'-6"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

F<br />

VIS<br />

48"<br />

118A<br />

F<br />

AUD<br />

119<br />

STAIR #2<br />

121<br />

06<br />

TILSC<br />

07<br />

01<br />

05<br />

ILSE<br />

06<br />

TILSE<br />

07<br />

18"<br />

18"<br />

118B<br />

02<br />

HVAC 5<br />

20<br />

05<br />

ISLF<br />

06<br />

TISLF<br />

07<br />

08<br />

03A<br />

48" 48" 48" 48" 48"<br />

P<br />

48"<br />

18" 18"<br />

04<br />

03B<br />

02<br />

HVAC 6<br />

08<br />

03A<br />

48"<br />

18" 18"<br />

04 08<br />

04 04 08<br />

04<br />

03B 02<br />

03A<br />

03B 02<br />

03A<br />

08<br />

03B 02<br />

03A<br />

03B<br />

HVAC 7<br />

HVAC 8<br />

HVAC 9<br />

48"<br />

F<br />

48"<br />

05<br />

TILSG<br />

05<br />

ILSG<br />

05<br />

TILSH<br />

05<br />

ILSH<br />

05<br />

TILCE<br />

05<br />

ILCE<br />

48"<br />

48"<br />

48"<br />

02<br />

HVAC 10<br />

19<br />

01<br />

05<br />

ILCC<br />

06<br />

TILCC<br />

07<br />

05<br />

ILCC<br />

06<br />

TILCC<br />

07<br />

03<br />

18"<br />

48"<br />

AUD<br />

F<br />

18"<br />

18"<br />

EXISTING<br />

OFFICE<br />

106<br />

18<br />

104B<br />

101B<br />

106<br />

ENTRY HALL<br />

101<br />

EX.<br />

ELEVATOR<br />

105<br />

EXISTING BREAK<br />

ROOM<br />

107<br />

STAIR #1<br />

104<br />

16<br />

17<br />

F.R.R.<br />

108<br />

108<br />

102<br />

103<br />

EX. ELEVATOR<br />

ROOM<br />

103<br />

104A<br />

101A<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

12.10.12<br />

01-08-1070-00<br />

NO<br />

DATE<br />

DESCRIPTION<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

1<br />

EXISTING CONDITIONS - FIRST FLOOR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

SHEET TITLE<br />

EXISTING<br />

CONDITIONS -<br />

FIRST FLOOR<br />

SHEET NO<br />

D1.00

GRAPHICAL KEY<br />

F<br />

F<br />

F<br />

18"<br />

ELECTRICAL OUTLET - 18" ABOVE FLOOR<br />

48"<br />

ELECTRICAL OUTLET - 48" ABOVE FLOOR<br />

P<br />

FIRE ALARM - MANUAL PULL BOX<br />

A<br />

FIRE ALARM - AUDIO<br />

V<br />

FIRE ALARM - VISUAL<br />

LIGHT SWITCH<br />

HVAC # IDENTIFIER<br />

####<br />

GENERAL NOTES<br />

1. THIS DRAWING IS A REPRESENTATION FOR REFERENTIAL<br />

PURPOSES; ACTUAL CONDITIONS MAY VARY, AND ARE TO BE VERIFIED<br />

IN FIELD BY CONTRACTOR.<br />

2. CONTRACTOR IS TO BE FAMILIAR WITH THE EXISTING SYSTEMS AND<br />

ELEMENTS IN THE BUILDING FOR COORDINATION<br />

3. CONTRACTOR TO CONFIRM POTENTIAL CONFLICTS, WHETHER<br />

EXPLICITLY SHOWN OR NOT.<br />

4. CONTRACTOR IS TO RELOCATE, AS NECESSARY, ANY EXISTING<br />

FIXTURES, OUTLETS, DEVICES, SWITCHES, ETC. THAT ARE TO REMAIN<br />

IN USE TO NEW FINISHED SURFACE WITHIN 3 FEET, IF EXISTING<br />

SURFACE IS COVERED OVER OR MADE INACCESSIBLE BY NEW<br />

CONSTRUCTION.<br />

#<br />

KEY NOTES:<br />

01 8 CONDUITS, 5" DIAMETER, ON 6" RAISED CONCRETE<br />

02 CRAC UNIT ON DRAIN PAN<br />

03A VERTICAL CONDUITS: (4) 4" DIAMETER FREON LINES; (2) 3 4" DIAMETER WATER LINE; (1) ELECTRIC LINE<br />

03B<br />

04<br />

VERTICAL CONDUITS: (4) 4" DIAMETER FREON LINES; (2) 3 4" DIAMETER WATER LINE; (1) ELECTRIC LINE - CUT FOR FUTURE USE<br />

FLOOR ELECTRIC BOX FOR FUTURE USE<br />

05 ELECTRIC PANELBOARD<br />

06 OVERHEAD TRANSFORMER, 96" ABOVE GROUND<br />

07<br />

08<br />

CUT CONDUITS (2) 4" DIAMETER ELECTRIC, (2) 3 4" DIAMETER ELECTRIC<br />

OVERHEAD AIR DUCTS, NOT USED<br />

09 SWITCHBOARD<br />

10 WALL MOUNTED TRANSFER SWITCHES<br />

11 AUTOMATIC TRANSFER SWITCH<br />

12 GENERATOR<br />

13<br />

14<br />

(29) 3 4" CONDUITS<br />

STUBS: (1) ELECTRIC CONDUIT AND (1) WATER PIPE<br />

15 (16) 3" CONDUITS<br />

16 FIRE ALARM SYSTEM PANELS<br />

17<br />

18<br />

SPRINKLER SYSTEM PANELS<br />

EXISTING ELEVATOR: PARK IN SAFE CONDITION AND DISCONNECT.<br />

19 EXISTING MISC. ELECTRICAL EQUIP. AND PANELS ALONG WALL; SEE ELECTRICAL<br />

20 HALON SYSTEM SWITCH<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

D<br />

18"<br />

18"<br />

18" 18" 18" 18" 18"<br />

F<br />

P<br />

18" 18" 18" 18" 18"<br />

14 14<br />

14<br />

15<br />

14 14 02<br />

14<br />

CRAC 39<br />

15<br />

14<br />

05<br />

2LPA<br />

06<br />

T2LPA<br />

06<br />

T2HLA<br />

05<br />

2HLA<br />

?<br />

1HMB<br />

?<br />

2HMB<br />

18"<br />

18"<br />

F<br />

VIS<br />

18"<br />

F<br />

AUD<br />

C<br />

18"<br />

B<br />

A<br />

F<br />

18"<br />

VIS<br />

STAIR #2<br />

209<br />

205C<br />

F<br />

F<br />

18"<br />

VIS<br />

P<br />

205B<br />

14 15<br />

14<br />

14<br />

14<br />

02<br />

15<br />

14 14 14 14<br />

CRAC 24<br />

18" 18" 18" 18" P<br />

18" 18" 18"<br />

18"<br />

18"<br />

18"<br />

F<br />

18"<br />

18"<br />

18"<br />

203<br />

18"<br />

AUD<br />

P<br />

17<br />

F<br />

F<br />

15<br />

EX.<br />

ELEVATOR<br />

213<br />

STAIR #1<br />

203<br />

18"<br />

201<br />

EX. RESTROOM<br />

201<br />

202<br />

EX. CLOSET<br />

202<br />

18"<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

DATE:<br />

PROJECT NO:<br />

12.10.12<br />

01-08-1070-00<br />

REVISIONS:<br />

NO<br />

DATE<br />

DESCRIPTION<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

1<br />

EXISTING CONDITIONS - SECOND FLOOR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

SHEET TITLE<br />

EXISTING<br />

CONDITIONS -<br />

SECOND FLOOR<br />

SHEET NO<br />

D1.01

GRAPHICAL KEY<br />

F<br />

F<br />

F<br />

18"<br />

ELECTRICAL OUTLET - 18" ABOVE FLOOR<br />

48"<br />

ELECTRICAL OUTLET - 48" ABOVE FLOOR<br />

P<br />

FIRE ALARM - MANUAL PULL BOX<br />

A<br />

FIRE ALARM - AUDIO<br />

V<br />

FIRE ALARM - VISUAL<br />

LIGHT SWITCH<br />

DEMOLISH<br />

RELOCATE<br />

GENERAL NOTES<br />

1. PROPERLY CUT, CAP AND SEAL REMAINING CONDUITS AND PIPES.<br />

2. AFTER REMOVAL OF AN ELEMENT, THE REMAINING FINISHES ARE TO MATCH EXISTING<br />

3. PROPERLY DISPOSE OF ALL DEMOLITION DEBRIS<br />

4. RELOCATED ELEMENTS ARE TO BE CLEANED AND REPAIRED TO "LIKE NEW" CONDITION.<br />

5. ALL INSTALLATIONS ARE TO BE MADE WITH MINIMAL DISTURBANCE TO ADJACENT SURFACES<br />

6. MOST OF OVERHEAD EQUIPMENT, CONDUIT, AND JUNCTION BOXES ARE TO REMAIN - COORDINATE WITH<br />

MECHANICAL AND ELECTRICAL<br />

7. REFER TO MECHANICAL AND ELECTRICAL PLANS FOR SPECIFICS REGARDING REMOVAL AND/OR<br />

RESTORATION OF EXISTING EQUIPMENT SUCH AS OUTLETS, FIXTURES, ETC.<br />

8. PROVIDE PROPER BRACING AND SHORING DURING DEMOLITION AND CONSTRUCTION ACTIVITIES.<br />

9. UTILIZE SAFE WORK PRACTICES AT ALL TIMES ON JOB SITE.<br />

10. MAKE STRAIGHT CLEAN CUTS AT EDGES OF DEMOLITION AREAS.<br />

11. EXISTING BUILDING FLOODPROOFING IS TO BE CONFIRMED AND CERTIFIED AT CONCLUSION OF<br />

CONSTRUCTION.<br />

12. REPAIR OR REPLACE MISCELLANEOUS EXISTING DAMAGED FINISHES WITH FINISHES TO MATCH<br />

EXISTING ADJACENT.<br />

13. ALL EXTERIOR MECHANICAL PENETRATIONS OVER 8" X 8" ARE TO HAVE SECURITY BARS INSTALLED.<br />

14. REPLACE SEALANT JOINT BETWEEN PRECAST CONCRETE PANEL AND SLAB (TYP)<br />

15. REMOVE LOOSE AND DAMAGED VCT, PREP FLOOR FOR NEW VCT TO MATCH EXISTING<br />

16. ALL EXISTING CRAC UNITS TO BE TESTED PRIOR TO REMOVAL IN ORDER TO ENSURE THAT THEY ARE IN<br />

A SUFFICIENT WORKING CONDITION. REPORT TO CLIENT STATUS OF THESE UNITS BEFORE REMOVAL.<br />

THE NUMBER OF EACH RELOCATED CRAC UNIT CAN BE CHANGED IF SPECIFIED UNIT IS NOT WORKING.<br />

#<br />

KEY NOTES:<br />

01<br />

02<br />

03<br />

REMOVE LIFT, STAIR, LANDING, AND DOCK; REGRADE AND PAVE TO MATCH.<br />

PROTECT, SERVICE AND REPAIR REMOVABLE FLOOD GATES AND FRAMES, CERTIFY AT CONCLUSION OF CONSTRUCTION.<br />

EXCAVATE AT DEPRESSION, REPAIR ANY DAMAGED UTILITY, FILL, REGRADE AND PAVE TO MATCH<br />

ADJACENT SURFACE, REF: CIVIL.<br />

04 DEMO FURR OUT AROUND COLUMN<br />

05<br />

06<br />

DEMO FLOOR AND SLAB FOR ELEVATOR INSTALLATION, REFER TO STRUCTURAL 3/A4.01<br />

REMOVE ELECTRIC EQUIPMENT, AND ALL ASSOCIATED CONDUIT; SEE ELECTRICAL<br />

07A REMOVE CRAC UNIT AND ALL ASSOCIATED DUCTWORK; OWNER TO RELOCATE AT NEW LOCATION OFFSITE<br />

07B REMOVE CRAC UNIT AND ALL ASSOCIATED DUCTWORK; TO BE RELOCATED TO NEW LOCATION WITHIN BUILDING.<br />

08 RESTORE CRAC UNIT AND ALL ASSOCIATED DUCTWORK; SEE MECHANICAL<br />

09 SAW CUT FOR NEW OPENING IN PRECAST PANELS; COORD WITH STRUCTURAL, SEE DET. 3/AA4.01<br />

10 SAW CUT FOR NEW DOOR OPENING IN PRECAST PANELS, FLOOD WALL TO REMAIN; COORD WITH STRUCTURAL<br />

11 SAW CUT FOR NEW TRANSACTION WINDOW OPENING IN PRECAST PANELS, FLOOD WALL TO REMAIN; COORD WITH STRUCTURAL<br />

12 EXISTING NON-FUNCTIONING ELEVATOR - NOT IN CONTRACT, NO WORK<br />

13 DEMO EXISTING DUCT<br />

14 DEMO FLOOD WALL, REFER TO STRUCTURAL<br />

1<br />

2<br />

3<br />

4<br />

5<br />

+/- 225'-0"<br />

6<br />

7<br />

8<br />

9<br />

+/- 1'-2"<br />

+/- 12'-7"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

+/- 1'-2"<br />

+/- 1'-1"<br />

D<br />

13<br />

07A<br />

CRAC 1<br />

06<br />

13<br />

06<br />

13 07A<br />

13 07B<br />

13 07B<br />

13<br />

CRAC 2<br />

CRAC 3<br />

CRAC 3<br />

06<br />

06<br />

06<br />

+/- 30'-0"<br />

C<br />

B<br />

+/- 92'-6"<br />

02<br />

+/- 30'-0"<br />

+/- 30'-0"<br />

118A<br />

16<br />

STAIR #2<br />

121<br />

06<br />

06<br />

UP<br />

119<br />

118B<br />

13<br />

04<br />

15<br />

08<br />

CRAC 5<br />

04 04 04<br />

13<br />

07B<br />

CRAC 6<br />

18<br />

13<br />

07A<br />

CRAC 7<br />

06<br />

13<br />

05<br />

07A<br />

CRAC 8<br />

06<br />

06 06 06<br />

13<br />

07B<br />

CRAC 9<br />

13<br />

08<br />

CRAC 10<br />

06<br />

12<br />

06<br />

06<br />

13<br />

EXISTING<br />

OFFICE<br />

106<br />

104B<br />

101B<br />

106<br />

ENTRY HALL<br />

101<br />

EX.<br />

ELEVATOR<br />

105<br />

EXISTING BREAK<br />

ROOM<br />

107<br />

107<br />

STAIR #1<br />

104<br />

02<br />

15<br />

F.R.R.<br />

108<br />

108<br />

102<br />

103<br />

EX. ELEVATOR<br />

ROOM<br />

103<br />

02<br />

UP<br />

104A<br />

101A<br />

03<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO DATE<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

100% CONSTRUCTION DOCUMENTS<br />

A<br />

12'-10"<br />

11<br />

FEMA 'B'<br />

2'-0 3 4 " 10'-6" 3'-4" 3'-9" 25'-0" 2'-6"<br />

10<br />

FEMA 'B'<br />

14<br />

FEMA 'A'<br />

09<br />

FEMA 'B'<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

SHEET TITLE<br />

01<br />

FIRST FLOOR DEMO<br />

& REPAIR PLAN<br />

SHEET NO<br />

1<br />

FIRST FLOOR DEMO & REPAIR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

D1.02

GRAPHICAL KEY<br />

F<br />

F<br />

F<br />

18"<br />

ELECTRICAL OUTLET - 18" ABOVE FLOOR<br />

48"<br />

ELECTRICAL OUTLET - 48" ABOVE FLOOR<br />

P<br />

FIRE ALARM - MANUAL PULL BOX<br />

A<br />

FIRE ALARM - AUDIO<br />

V<br />

FIRE ALARM - VISUAL<br />

LIGHT SWITCH<br />

DEMOLISH<br />

RELOCATE<br />

GENERAL NOTES<br />

1. PROPERLY CUT, CAP AND SEAL REMAINING CONDUITS AND PIPES.<br />

2. AFTER REMOVAL OF AN ELEMENT, THE REMAINING FINISHES ARE TO MATCH EXISTING<br />

3. PROPERLY DISPOSE OF ALL DEMOLITION DEBRIS<br />

4. RELOCATED ELEMENTS ARE TO BE CLEANED AND REPAIRED TO "LIKE NEW" CONDITION.<br />

5. ALL INSTALLATIONS ARE TO BE MADE WITH MINIMAL DISTURBANCE TO ADJACENT SURFACES<br />

6. MOST OF OVERHEAD EQUIPMENT, CONDUIT, AND JUNCTION BOXES ARE TO REMAIN - COORDINATE WITH<br />

MECHANICAL AND ELECTRICAL<br />

7. REFER TO MECHANICAL AND ELECTRICAL PLANS FOR SPECIFICS REGARDING REMOVAL AND/OR<br />

RESTORATION OF EXISTING EQUIPMENT SUCH AS OUTLETS, FIXTURES, ETC.<br />

8. PROVIDE PROPER BRACING AND SHORING DURING DEMOLITION AND CONSTRUCTION ACTIVITIES.<br />

9. UTILIZE SAFE WORK PRACTICES AT ALL TIMES ON JOB SITE.<br />

10. MAKE STRAIGHT CLEAN CUTS AT EDGES OF DEMOLITION AREAS.<br />

11. EXISTING BUILDING FLOODPROOFING IS TO BE CONFIRMED AND CERTIFIED AT CONCLUSION OF<br />

CONSTRUCTION.<br />

12. REPAIR OR REPLACE MISCELLANEOUS EXISTING DAMAGED FINISHES WITH FINISHES TO MATCH<br />

EXISTING ADJACENT.<br />

13. ALL EXTERIOR MECHANICAL PENETRATIONS OVER 8" X 8" ARE TO HAVE SECURITY BARS INSTALLED.<br />

14. REPLACE SEALANT JOINT BETWEEN PRECAST CONCRETE PANEL AND SLAB (TYP)<br />

15. REMOVE LOOSE AND DAMAGED VCT, PREP FLOOR FOR NEW VCT TO MATCH EXISTING<br />

16. ALL EXISTING CRAC UNITS TO BE TESTED PRIOR TO REMOVAL IN ORDER TO ENSURE THAT THEY ARE IN<br />

A SUFFICIENT WORKING CONDITION. REPORT TO CLIENT STATUS OF THESE UNITS BEFORE REMOVAL.<br />

THE NUMBER OF EACH RELOCATED CRAC UNIT CAN BE CHANGED IF SPECIFIED UNIT IS NOT WORKING.<br />

#<br />

KEY NOTES:<br />

01 REMOVE LIFT, STAIR, LANDING, AND DOCK; REGRADE AND PAVE TO MATCH.<br />

02<br />

03<br />

PROTECT, SERVICE AND REPAIR REMOVABLE FLOOD GATES AND FRAMES, CERTIFY AT CONCLUSION OF CONSTRUCTION.<br />

EXCAVATE AT DEPRESSION, REPAIR ANY DAMAGED UTILITY, FILL, REGRADE AND PAVE TO MATCH<br />

ADJACENT SURFACE, REF: CIVIL.<br />

04<br />

05<br />

DEMO FURR OUT AROUND COLUMN<br />

DEMO FLOOR AND SLAB FOR ELEVATOR INSTALLATION, REFER TO STRUCTURAL 3/A4.01<br />

06 REMOVE ELECTRIC EQUIPMENT, AND ALL ASSOCIATED CONDUIT; SEE ELECTRICAL<br />

07A REMOVE CRAC UNIT AND ALL ASSOCIATED DUCTWORK; OWNER TO RELOCATE AT NEW LOCATION OFFSITE<br />

07B REMOVE CRAC UNIT AND ALL ASSOCIATED DUCTWORK; TO BE RELOCATED TO NEW LOCATION WITHIN BUILDING.<br />

08 RESTORE CRAC UNIT AND ALL ASSOCIATED DUCTWORK; SEE MECHANICAL<br />

09 SAW CUT FOR NEW OPENING IN PRECAST PANELS; COORD WITH STRUCTURAL, SEE DET. 3/AA4.01<br />

10<br />

11<br />

SAW CUT FOR NEW DOOR OPENING IN PRECAST PANELS, FLOOD WALL TO REMAIN; COORD WITH STRUCTURAL<br />

SAW CUT FOR NEW TRANSACTION WINDOW OPENING IN PRECAST PANELS, FLOOD WALL TO REMAIN; COORD WITH STRUCTURAL<br />

12<br />

13<br />

EXISTING NON-FUNCTIONING ELEVATOR - NOT IN CONTRACT, NO WORK<br />

DEMO EXISTING DUCT<br />

14 DEMO FLOOD WALL, REFER TO STRUCTURAL<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

D<br />

08<br />

CRAC 39<br />

C<br />

B<br />

205C<br />

05<br />

12<br />

203<br />

201<br />

EX. RESTROOM<br />

201<br />

202<br />

EX. CLOSET<br />

202<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

A<br />

DN<br />

STAIR #2<br />

209<br />

205B<br />

07B<br />

CRAC 24<br />

UP<br />

STAIR #1<br />

203<br />

DN<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO<br />

DATE<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

1<br />

SECOND FLOOR DEMO & REPAIR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

SHEET TITLE<br />

SECOND FLOOR<br />

DEMO & REPAIR<br />

PLAN<br />

SHEET NO<br />

D1.03

GRAPHICAL KEY<br />

E-ACC<br />

#<br />

KEYNOTES<br />

01 DEMO AREA FOR ELEVATOR; REFER TO STRUCTURAL<br />

DEMOLISH AREA<br />

02A REMOVE AND RELOCATE EXISTING ROOFTOP UNIT ; COORDINATE WITH OWNER FOR NEW STORAGE LOCATION.<br />

02B REMOVE EXISTING ROOFTOP UNIT, AND SAFELY STORE IN TEMPORARY LOCATION WHILE NEW ROOF IS BEING INSTALLED.<br />

UNIT IS TO BE RE-INSTALLED UPON INSTALLATION OF NEW ROOF. REFER TO SHEET AA1.03 FOR NEW LOCATION.<br />

DEMOLISH 03 REMOVE ALL EXISTING PIPING AT ROOF LEVEL.<br />

04 EXISTING PIPE CHASE, TO REMAIN.<br />

EXISTING AIR CONDITIONING CONDENSER<br />

05 EXISTING ROOFTOP UNIT, TO BE REMOVED AND THEN RELOCATED AT SAME LOCATION UPON COMPLETION OF REROOFING.<br />

06 EXISTING EXHAUST FAN, TO BE REMOVED AND THE RELOCATED AT SAME LOCATION UPON COMPLETION OF REROOING.<br />

GENERAL NOTES<br />

01. REMOVE EXISTING ROOFING SYSTEM IN ITS ENTIRETY, DOWN TO THE STRUCTURAL DECK. THIS INCLUDES ALL ROOFING<br />

MEMBRANE, INSULATION, COPING, AND FLASHING.<br />

02. REMOVE ALL EXISTING MECHANICAL CURBS.<br />

03. REMOVE EXISTING LIGHTNING PROTECTION SYSTEM. TO BE REINSTALLED AT LATER TIME, PER MANUFACTURER'S<br />

RECOMMENDATIONS.<br />

04. REMOVE ALL EXTERIOR LIGHTING AND CONDUIT THAT IMPEDES WITH ROOF DEMOLITION / RE-ROOFING PROCESS, TO BE<br />

REINSTALLED AFTER RE-RROING. TEST FIXTURES BEFORE REMOVAL, NOTIFY ARCHITECT IF FIXTURE IS NOT OPERABLE.<br />

04 04<br />

03 03<br />

02B<br />

E-ACC 5<br />

02A<br />

E-ACC 1<br />

02B<br />

E-ACC 6<br />

02A<br />

E-ACC 2<br />

02A<br />

E-ACC 7<br />

01<br />

03 03 03<br />

02B<br />

E-ACC 39<br />

02B<br />

E-ACC 3<br />

02A<br />

E-ACC 8<br />

02B<br />

E-ACC 24<br />

02B<br />

E-ACC 4<br />

02B<br />

E-ACC 9<br />

02B<br />

E-ACC 10<br />

05<br />

05<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

DATE:<br />

PROJECT NO:<br />

12.10.12<br />

01-08-1070-00<br />

REVISIONS:<br />

04 04 04<br />

NO<br />

DATE<br />

DESCRIPTION<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

SHEET TITLE<br />

1 ROOF DEMO & REPAIR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

ROOF DEMO &<br />

REPAIR PLAN<br />

SHEET NO<br />

D1.04

FEMA ELIGIBLE ITEMS<br />

A. PROVIDE 144 SF. CONCRETE WALL DEMOLITIONS. WALL CUT-OUT FOR ROLL-UP DOOR INSTALLATION.<br />

B. PROVIDE 576 LF. CONCRETE CUTTING. WALL CUT-OUT FOR ROLL-UP DOOR INSTALLATION.<br />

C. PROVIDE AND INSTALL 1 EA. ROLL-UP DOOR (SEE ATTACHED VENDOR QUOTE)<br />

D. PROVIDE AND INSTALL 2 EA. ROLLING SECURITY GATES<br />

E. PROVIDE AND INSTALL 2 EA. ELECTRIC GATES OPENERS<br />

F. PROVIDE AND INSTALL 3 EA. ACCESS CONTROL CARD READERS<br />

GENERAL SITE NOTES<br />

1. ALL EXISTING EXTERIOR SIGNAGE AND ANCHORAGES TO BE REMOVED, PATCH AS NECESSARY<br />

2. ADDITIONAL NEW EXTERIOR LIGHTING SHALL BE MOUNTED TO BUILDING RE: ELECTRICAL<br />

3. NEW EXTERIOR SECURITY CAMERAS TO BE PROVIDED. LOCATIONS AND QUANTITIES TO BE COORDINATED WITH OWNER.<br />

4. PATCH AREAS OF WORN OR DETERIORATED ASPHALT, PREP FOR ASPHALT SEALANT<br />

5. APPLY ASPHALT SEALANT TO ALL EXISTING ASPHALT PARKING AND DRIVING SURFACES<br />

6. REMOVE EXISTING RAZOR WIRE ON FENCES, REPLACE WITH NEW RAZOR WIRE SUPPORTED BY BARBED WIRE<br />

7. REMOVE ALL VEGETATION FROM CHAINLINK MESH.<br />

8. REPLACE BENT AND BROKEN FENCE POSTS AND RUSTED FENCING MESH, AS NECESSARY.<br />

#<br />

SITE KEY NOTES<br />

01 NEW ROLLING SECURITY GATES; MODIFY TRUCK ENTRY TO AT LEAST 30' WIDTH, COORD. W/ STRUCTURAL<br />

02 EXISTING CONCRETE UTILITY SERVICE PAD TO REMAIN, TYP.<br />

03 INSTALL NEW CRUSHED STONE ON TOP OF FABRIC BASE LAYER<br />

04 EXISTING SINKHOLE, REPAIR PER CIVIL<br />

06 NEW DUMPSTER ENCLOSURE<br />

07 NEW CONCRETE STOOP WITH HANDRAILS, SEE CIVIL<br />

08 EXISTING CONCRETE STOOP<br />

09 POWER ALONG PROPERTY LINE TO BE RELOCATED PER CODE, TO PROVIDE ADEQUATE CLEARANCES TO<br />

NEW ADDITION, COORDINATE WITH ENTERGY<br />

11 DEMO EXISTING LIGHT POLE AND ASSOCIATED FIXTURES. REMOVE EXISTING OVERHEAD LINE,<br />

TERMINATE SERVICE AT ADJACENT POWER POLE; PATCH ASPHALT PAVING<br />

12 DEMOLISH EXISTING LOADING DOCK, STAIRS, DOCK LEVELLER, AND BOLLARDS.FILL, REGRADE AND<br />

RESURFACE TO MATCH EXISTING PAVEMENT<br />

13 EXISTING CRUSHED STONE TO REMAIN<br />

14A EXISTING CONCRETE BOLLARD, TO REMAIN, REPAINT YELLOW.<br />

14B NEW CONCRETE BOLLARD, PAINT YELLOW TO MATCH EXISTING<br />

14C EXISTING REMOVABLE BOLLARD AND SLEEVES TO REMAIN, REPAINT WHITE TO MATCH EXISTING<br />

15 NEW CARD ACCESS CONTROL AT GATE WITH REMOTE CONTROL FROM WITHIN BUILDING<br />

16 NEW ELECTRIC GATE OPENER, FEMA ELIGIBLE<br />

17 WHEEL STOPS TO REMAIN, REPAINT SAFETY YELLOW, TYP.<br />

18 STRIPE PARKING AND MARSHALLING AREAS, PER CIVIL<br />

19 NEW DIESEL FUEL TANK ON EXISTING CONCRETE PADS<br />

20 EXISTING FIBER OPTIC SERVICE CONNECTION TO REMAIN<br />

21 EXISTING HIGH VOLTAGE SWITCH, TO REMAIN<br />

22 NEW GENERATOR ON EXISTING CONCRETE PAD<br />

23 EXISTING TRANSFORMER ON CONCRETE PAD, TO REMAIN<br />

24 REPAIR EXISTING CHAIN LINK FENCE WHERE DAMAGED.<br />

25 WATER METER LOCATION; SEE CIVIL<br />

SALCEDO ST.<br />

25<br />

03<br />

24<br />

03<br />

HOWARD AVE.<br />

WV<br />

20<br />

18<br />

18<br />

11<br />

16<br />

FEMA 'E'<br />

03<br />

08<br />

NO PARKING<br />

15<br />

14B<br />

01<br />

FEMA 'D'<br />

11<br />

14B<br />

NEW LOADING<br />

DOCK ADDITION<br />

EXISTING 2 STORY BUILDING ON<br />

CONC. SLAB<br />

<strong>950</strong> S. RENDON ST.<br />

FIRST FLOOR ELEV. 22.7'<br />

SECOND FLOOR ELEV. 39.7'<br />

RENDON ST.<br />

14B<br />

06<br />

14B<br />

11<br />

22<br />

19<br />

02<br />

14A<br />

04<br />

14C<br />

18<br />

14A<br />

12<br />

16<br />

FEMA 'E'<br />

15<br />

01<br />

FEMA 'D'<br />

09<br />

23<br />

02<br />

14A<br />

17<br />

03<br />

21<br />

20<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

DATE:<br />

PROJECT NO:<br />

12.10.12<br />

01-08-1070-00<br />

DIXON ST.<br />

PALMETTO ST.<br />

REVISIONS:<br />

NO DATE<br />

DRAWN BY:<br />

CHECKED BY:<br />

SHEET TITLE<br />

DESCRIPTION<br />

PJ<br />

CP<br />

1<br />

SITE PLAN<br />

SCALE: 1:20<br />

OVERALL SITE PLAN<br />

SHEET NO<br />

G1.00

FEMA ELIGIBLE ITEMS<br />

A. PROVIDE 144 SF. CONCRETE WALL DEMOLITIONS. WALL CUT-OUT FOR ROLL-UP DOOR INSTALLATION.<br />

B. PROVIDE 576 LF. CONCRETE CUTTING. WALL CUT-OUT FOR ROLL-UP DOOR INSTALLATION.<br />

C. PROVIDE AND INSTALL 1 EA. ROLL-UP DOOR (SEE ATTACHED VENDOR QUOTE)<br />

D. PROVIDE AND INSTALL 2 EA. ROLLING SECURITY GATES<br />

E. PROVIDE AND INSTALL 2 EA. ELECTRIC GATES OPENERS<br />

F. PROVIDE AND INSTALL 3 EA. ACCESS CONTROL CARD READERS<br />

GRAPHICAL KEY<br />

CR SECURITY CARD READER<br />

FE FIRE EXTINGUISHER<br />

EXISTING WALL<br />

NEW WALL<br />

FLOOR DRAIN<br />

GENERAL NOTES<br />

1. CONTRACTOR IS RESPONSIBLE FOR MOVING ANY SWITCHES, DEVICES, OUTLETS,<br />

CONTROLS, SENSORS, ETC. FROM ANY COVERED CONDITION TO FACE OF NEW<br />

CONSTRUCTION WITH LIKE NEW INSTALLATION.<br />

2. COORDINATE INTERIOR SHELVING WITH FURNITURE DRAWINGS, 1/AA7.00<br />

3. ALL WALLS TO BE PAINTED W-1 WITH BASE B-1, TYP. ALL EXPOSED CEILING TO BE<br />

PAINTED C-1, TYP. REFER TO FINISH SCHEDULE 6/AA7.02<br />

4. ALL EXISTING CRAC UNITS TO BE TESTED PRIOR TO REMOVAL IN ORDER TO ENSURE<br />

THAT THEY ARE IN A SUFFICIENT WORKING CONDITION. REPORT TO CLIENT STATUS OF<br />

THESE UNITS BEFORE REMOVAL. THE NUMBER OF EACH RELOCATED CRAC UNIT CAN BE<br />

CHANGED IF SPECIFIED UNIT IS NOT WORKING.<br />

#<br />

KEYNOTES:<br />

02 PAINTED BOLLARD, TYP.<br />

04 NEW CONCRETE RAMP AND STAIR; SEE DET 9/AA6.01<br />

05 EXISTING CONCRETE PADS, TO REMAIN<br />

06 NEW PRE-FABRICATED METAL STAIR, LANDING, AND RAILING ASSEMBLY<br />

07 PROVIDE FLOOD VENTS IN LOADING DOCK AREA AS REQUIRED BY CODE.<br />

08 POURED IN PLACE CONCRETE STAIR<br />

09<br />

10<br />

11<br />

EXISTING CRAC UNIT<br />

EXISTING CRAC UNIT, RELOCATED TO THIS LOCATION<br />

ELEVATOR CONTROLS AND CARD READER<br />

12 NEW FREIGHT ELEVATOR<br />

15 AREA FLOOR DRAIN; SEE PLUMBING<br />

16 MOTORIZED DOCK LEVELER, COORD WITH ELECTRICAL AND STRUCTURAL<br />

17<br />

18<br />

FLOOD FRAME AND DOOR TO MATCH EXISTING REFER TO 2&3/AA8.00<br />

CMU DUMPSTER ENCLOSURE , SEE CIVIL<br />

19<br />

20<br />

SERVICE/REPLACE DAMAGED FLOOD FRAMES AND DOORS PER MANUFACTURER RECOMENDATION<br />

NEW FLOOR AT ELEVATOR INSTALL, TO MATCH EXISTING/SURROUNDING<br />

21 METAL CORNER GUARD, UP TO 4'-0" HIGH<br />

22 EXISTING STOOP<br />

23 ADD IMPACT RESISTANT GYP BOARD TO PERIMETER OF COLUMN<br />

1<br />

2<br />

3<br />

2<br />

AA4.01<br />

4<br />

1<br />

AA4.02<br />

02<br />

AA3.01<br />

5<br />

6<br />

7<br />

8<br />

9<br />

225'-0"<br />

12'-6"<br />

30'-0" 30'-0" 30'-0" 30'-0" 30'-0" 30'-0" 30'-0" 1'-3"<br />

1<br />

D<br />

92'-6"<br />

B<br />

01<br />

AA3.00<br />

A<br />

3'-4"<br />

2'-4"<br />

C<br />

02<br />

22<br />

118A<br />

1'-3"<br />

1'-3"<br />

4'-0" 3'-4" 3'-5"<br />

119<br />

STORAGE<br />

119<br />

9'-9"<br />

STAIR #2<br />

118<br />

FIRST FLOOR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

17<br />

9'-2"<br />

UP<br />

CR<br />

17<br />

FE<br />

CR<br />

118B<br />

24'-5"<br />

3'-4"<br />

1'-2"<br />

21<br />

09<br />

CRAC 5<br />

42'-2"<br />

AA<br />

AB<br />

10<br />

CRAC 6<br />

6'-2"<br />

13'-6"<br />

1'-6"<br />

1<br />

AA4.01<br />

02<br />

02<br />

5 SIM.<br />

116B<br />

20'-5"<br />

3<br />

116A<br />

1<br />

58'-4" 3'-4" 3'-1"<br />

8"<br />

3'-0"<br />

2'-2"<br />

2'-7" 12'-0"<br />

FEMA 'C'<br />

1'-7"<br />

CR<br />

08<br />

SALLY PORT<br />

116<br />

HB<br />

C H<br />

02<br />

FE<br />

02<br />

FD<br />

06<br />

116C<br />

114<br />

VEST.<br />

114<br />

115A<br />

115C<br />

111A<br />

11 12<br />

15<br />

FE<br />

CR<br />

CR<br />

11<br />

21<br />

CR<br />

CR<br />

1'-7" 12'-0"<br />

02<br />

AA3.00<br />

CR<br />

63'-2"<br />

CR<br />

CR, FEMA 'F'<br />

CR<br />

21<br />

OPEN AREA<br />

117<br />

26'-4"<br />

FREIGHT<br />

ELEVATOR<br />

113<br />

LOADING<br />

SERVICE AREA<br />

115<br />

16<br />

03<br />

111B<br />

CR<br />

111C<br />

3'-8 1 2 " 18'-11" 3'-8 1 2 "<br />

2<br />

15<br />

27'-7"<br />

6" 3'-4" 23'-9"<br />

2<br />

31'-8 1 2"<br />

11<br />

1'-11 1 2"<br />

20'-0"<br />

3'-6"<br />

3'-4"<br />

2'-11"<br />

6<br />

21<br />

5<br />

CR<br />

FE<br />

115D<br />

1'-4"<br />

CR, FEMA 'F'<br />

FE<br />

4'-9"<br />

13<br />

112<br />

1'-7"<br />

21<br />

12<br />

CR<br />

115B<br />

C<br />

H HB<br />

1'-10"<br />

8<br />

4<br />

16'-6"<br />

ELEVATOR<br />

MACHINE<br />

ROOM<br />

112<br />

DN<br />

FD<br />

14'-10"<br />

111D<br />

20'-0"<br />

15<br />

02<br />

02<br />

7<br />

1'-8" 10'-4" 1'-4"<br />

CR<br />

CR<br />

1<br />

C3.00<br />

85'-4"<br />

AMON STORAGE<br />

111<br />

119'-8"<br />

28'-3"<br />

1'-9"<br />

3'-4"<br />

CR 111E<br />

60'-7" 5'-0" 6'-3"<br />

10<br />

CRAC 9<br />

CR, FEMA 'F'<br />

09<br />

CRAC 10<br />

5'-8"<br />

110A<br />

2'-2 1 2 "<br />

101B<br />

CR104B<br />

106<br />

05<br />

EXISTING<br />

ELECTRIC<br />

109<br />

ELECTRICAL CLOSET<br />

110<br />

EXIST. OFFICE<br />

106 EXIST. BRK RM<br />

107<br />

12'-9"<br />

6'-4"<br />

FE<br />

CR<br />

CR<br />

CR<br />

05<br />

05<br />

107<br />

ENTRY HALL<br />

101<br />

EXIST. ELEV.<br />

105<br />

STAIR #1<br />

104<br />

17<br />

F.R.R.<br />

108<br />

108<br />

102<br />

103<br />

EXIST. ELEV.<br />

RM<br />

103<br />

UP<br />

104A<br />

CR<br />

3<br />

101A<br />

17<br />

1'-3" 30'-0"<br />

30'-0"<br />

30'-0"<br />

1'-3"<br />

01<br />

AA3.01<br />

92'-6"<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

DATE:<br />

PROJECT NO:<br />

REVISIONS:<br />

NO<br />

DATE<br />

DRAWN BY:<br />

CHECKED BY:<br />

SHEET TITLE<br />

12.10.12<br />

01-08-1070-00<br />

DESCRIPTION<br />

PJ<br />

CP<br />

FIRST FLOOR PLAN<br />

SHEET NO<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

AA1.01<br />

100% CONSTRUCTION DOCUMENTS

GRAPHICAL KEY<br />

CR SECURITY CARD READER<br />

FE FIRE EXTINGUISHER<br />

EXISTING WALL<br />

NEW WALL<br />

FLOOR DRAIN<br />

GENERAL NOTES<br />

1. CONTRACTOR IS RESPONSIBLE FOR MOVING ANY SWITCHES, DEVICES, OUTLETS,<br />

CONTROLS, SENSORS, ETC. FROM ANY COVERED CONDITION TO FACE OF NEW<br />

CONSTRUCTION WITH LIKE NEW INSTALLATION.<br />

2. COORDINATE INTERIOR SHELVING WITH FURNITURE DRAWINGS, 1/AA7.00<br />

3. ALL WALLS TO BE PAINTED W-1 WITH BASE B-1, TYP. ALL EXPOSED CEILING TO BE<br />

PAINTED C-1, TYP. REFER TO FINISH SCHEDULE 6/AA7.02<br />

4. ALL EXISTING CRAC UNITS TO BE TESTED PRIOR TO REMOVAL IN ORDER TO ENSURE<br />

THAT THEY ARE IN A SUFFICIENT WORKING CONDITION. REPORT TO CLIENT STATUS OF<br />

THESE UNITS BEFORE REMOVAL. THE NUMBER OF EACH RELOCATED CRAC UNIT CAN BE<br />

CHANGED IF SPECIFIED UNIT IS NOT WORKING.<br />

#<br />

KEYNOTES:<br />

02 PAINTED BOLLARD, TYP.<br />

04 NEW CONCRETE RAMP AND STAIR; SEE DET 9/AA6.01<br />

05 EXISTING CONCRETE PADS, TO REMAIN<br />

06 NEW PRE-FABRICATED METAL STAIR, LANDING, AND RAILING ASSEMBLY<br />

07 PROVIDE FLOOD VENTS IN LOADING DOCK AREA AS REQUIRED BY CODE.<br />

08 POURED IN PLACE CONCRETE STAIR<br />

09<br />

10<br />

11<br />

EXISTING CRAC UNIT<br />

EXISTING CRAC UNIT, RELOCATED TO THIS LOCATION<br />

ELEVATOR CONTROLS AND CARD READER<br />

12 NEW FREIGHT ELEVATOR<br />

15 AREA FLOOR DRAIN; SEE PLUMBING<br />

16 MOTORIZED DOCK LEVELER, COORD WITH ELECTRICAL AND STRUCTURAL<br />

17<br />

18<br />

FLOOD FRAME AND DOOR TO MATCH EXISTING REFER TO 2&3/AA8.00<br />

CMU DUMPSTER ENCLOSURE , SEE CIVIL<br />

19<br />

20<br />

SERVICE/REPLACE DAMAGED FLOOD FRAMES AND DOORS PER MANUFACTURER RECOMENDATION<br />

NEW FLOOR AT ELEVATOR INSTALL, TO MATCH EXISTING/SURROUNDING<br />

21 METAL CORNER GUARD, UP TO 4'-0" HIGH<br />

22 EXISTING STOOP<br />

23 ADD IMPACT RESISTANT GYP BOARD TO PERIMETER OF COLUMN<br />

1<br />

2<br />

3<br />

4<br />

5<br />

2<br />

1<br />

AA4.01<br />

AA4.02<br />

1'-3" 12'-6" 30'-0" 30'-0" 30'-0" 30'-0" 30'-0" 30'-0" 30'-0"<br />

6<br />

7<br />

8<br />

9<br />

1'-3"<br />

30'-01 8 " 30'-1 13<br />

16 "<br />

1'-1"<br />

D<br />

C<br />

B<br />

A<br />

DN<br />

23<br />

205C<br />

STAIR #2<br />

209<br />

23 23<br />

23<br />

CR<br />

FE<br />

CR<br />

205B<br />

23 23 23 23 23 23 23 23<br />

23<br />

64'-1"<br />

23<br />

23<br />

10<br />

CRAC 24<br />

23 23<br />

23 20<br />

23<br />

21<br />

21<br />

CR<br />

11<br />

10<br />

CRAC 3<br />

26'-4"<br />

FREIGHT<br />

ELEVATOR<br />

206<br />

10<br />

CRAC 4<br />

21<br />

20'-0"<br />

21<br />

OPEN SERVICE AREA<br />

205<br />

12<br />

23 23<br />

23<br />

23<br />

23<br />

23<br />

09<br />

CRAC 39<br />

23 23<br />

23<br />

23<br />

23<br />

23<br />

31'-10"<br />

2'-4"<br />

6'-4"<br />

23'-2"<br />

FE<br />

CR<br />

203<br />

CR<br />

205A<br />

UP<br />

25'-7"<br />

HALLWAY<br />

204<br />

EX.<br />

ELEVATOR<br />

213<br />

STAIR #1<br />

203<br />

23<br />

201<br />

EX. RESTROOM<br />

201<br />

202<br />

EX. CLOSET<br />

202<br />

DN<br />

1'-3"<br />

30'-3"<br />

30'-0"<br />

30'-0"<br />

1'-3"<br />

92'-6"<br />

RENDON ST. WAREHOUSE PHASE I AND PHASE II<br />

<strong>950</strong> SOUTH RENDON STREET<br />

NEW ORLEANS, LOUISIANA<br />

100% CONSTRUCTION DOCUMENTS<br />

DATE:<br />

PROJECT NO:<br />

12.10.12<br />

01-08-1070-00<br />

1<br />

AA4.01<br />

REVISIONS:<br />

NO<br />

DATE<br />

DESCRIPTION<br />

DRAWN BY:<br />

CHECKED BY:<br />

PJ<br />

CP<br />

SHEET TITLE<br />

1<br />

SECOND FLOOR PLAN<br />

SCALE: 1/8" = 1'-0"<br />

SECOND FLOOR PLAN<br />

SHEET NO<br />

AA1.02

GENERAL NOTES<br />

1. NEW SBS ROOFING SYSTEM TO BE INSTALLED FOR ENTIRETY OF ROOF<br />

2. ALL WORK ON EXISTING ROOF IS TO BE PERFORMED IN ACCORDANCE WITH MANUFACTURERS<br />

REQUIREMENTS TO MAINTAIN EXISTING AND NEW WARRANTIES.<br />

3. ALL ROOF PENETRATIONS OVER 8"X8" TO HAVE SECURITY BARS INSTALLED PER 8/AA1.04<br />

4. ALL EXISTING ROOF TOP UNITS TO BE RECONDITIONED FOR USE. REFER TO<br />

MECHANICAL PLANS FOR SCOPE OF ROOF TOP EQUIPMENT SERVICE AND MODIFICATIONS<br />

5. INSTALL NEW REFRIGERANT LINES FOR EACH RELOCATED ROOF TOP UNIT<br />

6. ALL CURBS ARE TO BE REMOVED PRIOR TO INSTALLING NEW ROOF. RELOCATED ROOF TOP<br />

UNITS ARE TO BE INSTALLED WITH NEW CURBS AT LOCATIONS WHERE CURBS PREVIOUSLY<br />

EXISTED. VERIFY IN FIELD LOCATION OF EXISTING CURBS, AND NOTIFY ARCHITECT IN<br />

PRE-CONSTRUCTION MEETING<br />

7. REMOVE, SERVICE, AND REINSTALL EXISTING LIGHTNING PROTECTION SYSTEM, PER<br />

MANUFACTURER'S RECOMMENDATIONS.<br />

8. REINSTALL ROOFTOP LIGHTING AND LIGHT FIXTURES THAT WERE REMOVED DURING<br />

RE-ROOING PROCESS. REPLACE ANY FIXTURES THAT WERE DEEMED INOPERABLE DURING<br />

TESTING.<br />

#<br />

KEYNOTES<br />

01 REMOVE EXISTING ROOFING SYSTEM TO EXIST. DECK, AND INSTALL NEW SBS ROOFING SYSTEM FOR ENTIRETY OF ROOF.<br />

02 REMOVE AND REPLACE CAP FLASH, SEE DET. 6/AA1.04; SECURE EXISTING ROOF PENETRATIONS WITH METAL BARS, SPRAY<br />

FOAM, AND MOTION SENSORS, SEE DET. 8/AA1.04.<br />

03 MODIFY EXISTING DOWNSPOUT TO DRAIN OVER NEW LOADING DOCK ROOF<br />

04 PREVIOUSLY REMOVED HVAC UNIT, TO BE REINSTALLED; SEE MECHANICAL.<br />

05 NEW HVAC UNIT<br />

06 LOCATION OF NEW HVAC UNIT, TO BE INSTALLED IN PHASE II. CONSTRUCT CURB HERE IN PHASE I. REFER TO DETAIL A/AA1.05.<br />

07<br />

08<br />

AREA OF ROOF TO BE DEMOLISHED IN ORDER TO INSTALL NEW ELEVATOR.<br />

NEW ROOF PADS<br />

09 EXISTING ROOFTOP UNITS; CLEAN & SERVICE, SEE MECHANICAL<br />

10 NEW EXHAUST VENT FOR FREIGHT ELEVATOR; SECURE AS REQUIRED, REFER TO 9-A1.04<br />

11 NEW SCUPPERS, CONDUCTOR HEADS AND DOWNSPOUTS, TO MATCH EXISTING FINISH<br />

12<br />

13<br />

NEW LOW SLOPE ROOF OVER FREIGHT ELEVATOR; SBS ROOFING SYSTEM<br />

EXPANSION JOINT AT CONNECTION OF NEW TO EXISTING.<br />

1<br />

2<br />

3<br />

2<br />

AA4.01<br />

4<br />

1<br />

AA4.02<br />

5<br />

2<br />