PVSR-R volume flow controller_round - Pichler

PVSR-R volume flow controller_round - Pichler

PVSR-R volume flow controller_round - Pichler

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

VOLUME FLOW CONTROLLER IN ROUND VERSION <strong>PVSR</strong>-R PAGE 12<br />

5 Installation<br />

for use as a product and must first<br />

be commissioned once it has been<br />

installed and connected in the technical<br />

ventilation system correctly and in line<br />

with the regulations.<br />

It can be installed in any position<br />

in the control system with the axes<br />

in a horizontal or vertical position.<br />

The installation must be carried out<br />

according to the <strong>flow</strong> direction given on<br />

the nameplate.<br />

For the correct functioning of the <strong>volume</strong><br />

<strong>flow</strong> <strong>controller</strong>, it is essential that the<br />

minimum distances to other installed<br />

components are observed during<br />

installation. A minimum <strong>flow</strong> path with<br />

the following length must be observed:<br />

L = approx. 2 x diameter.<br />

Minimum <strong>flow</strong> length<br />

Distance<br />

Offsets, arcs<br />

Other fittings such as diverters,<br />

T-pieces, reductions,<br />

Components such as fire dampers, sound<br />

absorbers<br />

1 x D<br />

2 x D<br />

2 x D<br />

D … Diameter of the <strong>volume</strong> <strong>flow</strong> <strong>controller</strong><br />

The combinations of multiple<br />

components, such as shaped parts with<br />

or without installed components, e.g.<br />

fire dampers, sound absorbers, etc.<br />

require greater minimum <strong>flow</strong> distances.<br />

Particular care must be taken in the<br />

case of deviations to the favourable<br />

technical <strong>flow</strong> of the measurement<br />

sensor (differential pressure sensor)<br />

during installation.<br />

The measurement sensor with the<br />

measurement lines (differential pressure<br />

sensor) must not be used on site for<br />

transport purposes.<br />

Measurement pipes must not be bent!<br />

Check for correct seating during<br />

installation!<br />

For correct functioning, carry out<br />

measures to exclude the risk of<br />

contamination of the control components<br />

(e.g. due to dust ingression). This can be<br />

carried out by installing suitable filter<br />

units in the air control system in front of<br />

the <strong>volume</strong> <strong>flow</strong> <strong>controller</strong>.<br />

During installation, check for<br />

clear access for inspection and<br />

cleaning purposes. The equipment<br />

is maintenance-free in terms of its<br />

mechanical components. According to<br />

the local conditions, it can be necessary<br />

to fit access openings in the air lines.<br />

If larger <strong>volume</strong> <strong>flow</strong> deviations have<br />

been determined, check the measuring<br />

equipment, the connecting nipple and<br />

the connection pipes and if necessary,<br />

carefully clean the equipment dry.<br />

When using the <strong>volume</strong> <strong>flow</strong> <strong>controller</strong>,<br />

condensate can occur in the <strong>volume</strong><br />

<strong>flow</strong> <strong>controller</strong> measurement pipes due<br />

to greater temperature differences. The<br />

condensate can impair sensor function<br />

or damage the sensor. Take precautions<br />

to prevent the formation of condensate<br />

using suitable measures on site, e.g. by<br />

insulating the measurement pipes.<br />

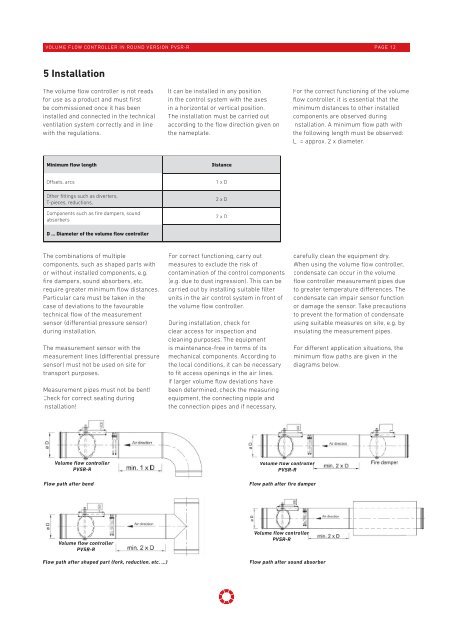

For different application situations, the<br />

minimum <strong>flow</strong> paths are given in the<br />

diagrams below.<br />

<strong>PVSR</strong>-R<br />

Flow path after bend<br />

roller<br />

Volume <strong>flow</strong> <strong>controller</strong><br />

<strong>PVSR</strong>-R<br />

Flow path after fire damper<br />

Volume <strong>flow</strong> <strong>controller</strong><br />

<strong>PVSR</strong>-R<br />

Flow path after shaped part (fork, reduction, etc. ...)<br />

Volume <strong>flow</strong> <strong>controller</strong><br />

<strong>PVSR</strong>-R<br />

Flow path after sound absorber